Method for preparing blue copperas and co-producing calcium hydroxide by using phosphogypsum

A technology of copper sulfate pentahydrate and calcium hydroxide, which is applied in the field of comprehensive treatment and utilization of phosphogypsum, can solve problems such as waste of resources, and achieve the effects of environmental protection, small investment, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

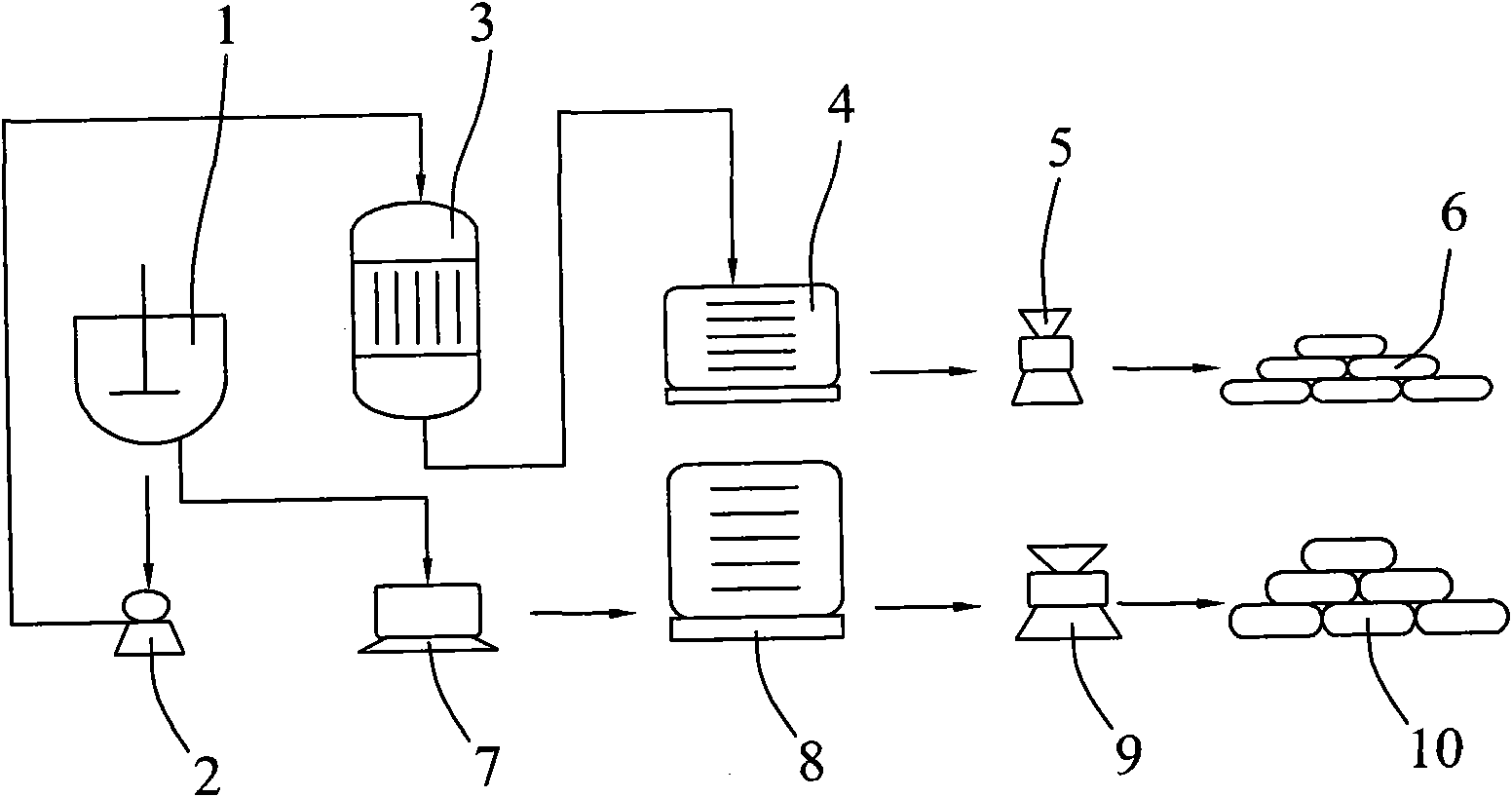

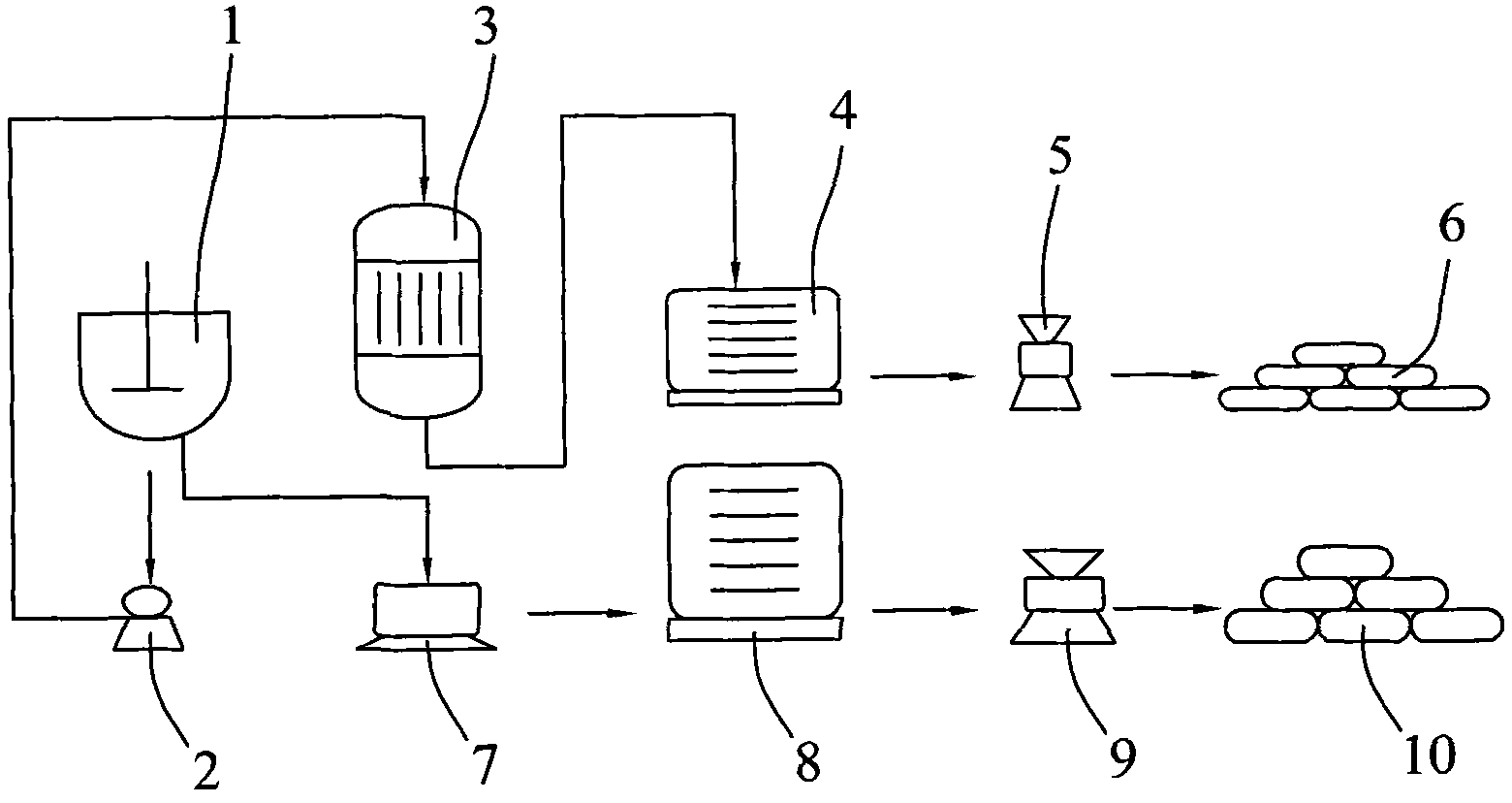

[0023] A method for preparing copper sulfate pentahydrate and co-producing calcium hydroxide with phosphogypsum, first convert the amount of pure substance calcium sulfate contained in industrial phosphogypsum products, and mix 300kg of calcium sulfate-containing phosphogypsum with diluted copper hydroxide The solution is put into the reactor (1) of 1: 0.52 according to the mass ratio of calcium sulfate and copper hydroxide pure substance, and the chemical reaction is carried out under slow stirring; then the reaction product is suction filtered in the suction filter (2), Obtain clarified copper sulfate pentahydrate solution and calcium hydroxide filter cake; Use a little calcium sulfate and copper hydroxide to remove the residual impurity in the copper sulfate pentahydrate solution of gained respectively, filter, and this moment has removed fluoride, phosphorus compounds, sulfides and other pollutants; the copper sulfate pentahydrate solution is sent to the distiller (3) for s...

Embodiment 2

[0025] A method for preparing copper sulfate pentahydrate and co-producing calcium hydroxide with phosphogypsum, first convert the amount of pure substance calcium sulfate contained in industrial phosphogypsum products, and mix 300kg of calcium sulfate-containing phosphogypsum with diluted copper hydroxide The solution is put into the reactor (1) of 1: 0.72 according to the mass ratio of calcium sulfate and copper hydroxide pure substance, and the chemical reaction is carried out under slow stirring; then the reaction product is suction filtered in the suction filter (2), Obtain clarified copper sulfate pentahydrate solution and calcium hydroxide filter cake; Use a little calcium sulfate and copper hydroxide to remove the residual impurity in the copper sulfate pentahydrate solution of gained respectively, filter, and this moment has removed fluoride, phosphorus compounds, sulfides and other pollutants; the copper sulfate pentahydrate solution is sent to the distiller (3) for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com