Electric copper plating liquid and electric copper plating process thereof

A technology of electroplating copper and plating solution, which is applied in the direction of jewelry, etc., and can solve the problems of accelerating copper deposition on the board surface and decreasing TP value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

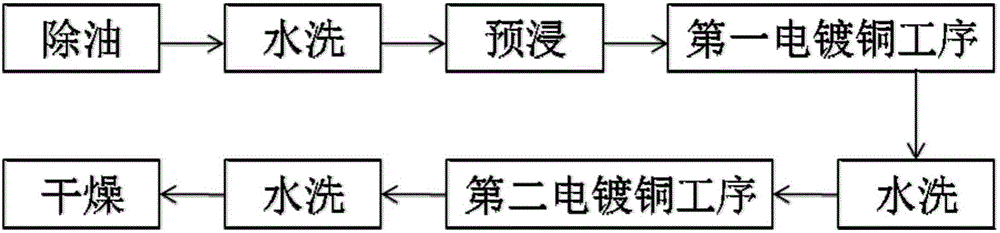

Method used

Image

Examples

Embodiment 1

[0050] What present embodiment adopts is that Rohm and Haas Company produces COPPER GLEAM TM ST-920 electroplating solution additive (typical three-component formula), according to the instruction manual, prepare the electroplating solution according to the following formula.

[0051] Copper sulfate pentahydrate: 70g / L

[0052] Sulfuric acid: 220g / L

[0054] The components of ST920 electroplating solution additives are added according to the concentration of the instructions:

[0055] ST920 Brightener: 2.75mL / L

[0056] ST920 inhibitor: 17.5mL / L

[0057] ST920 leveling agent: 3.25mL / L

[0058] ST920 stabilizer: 5mL / L

[0059] Deionized water: balance.

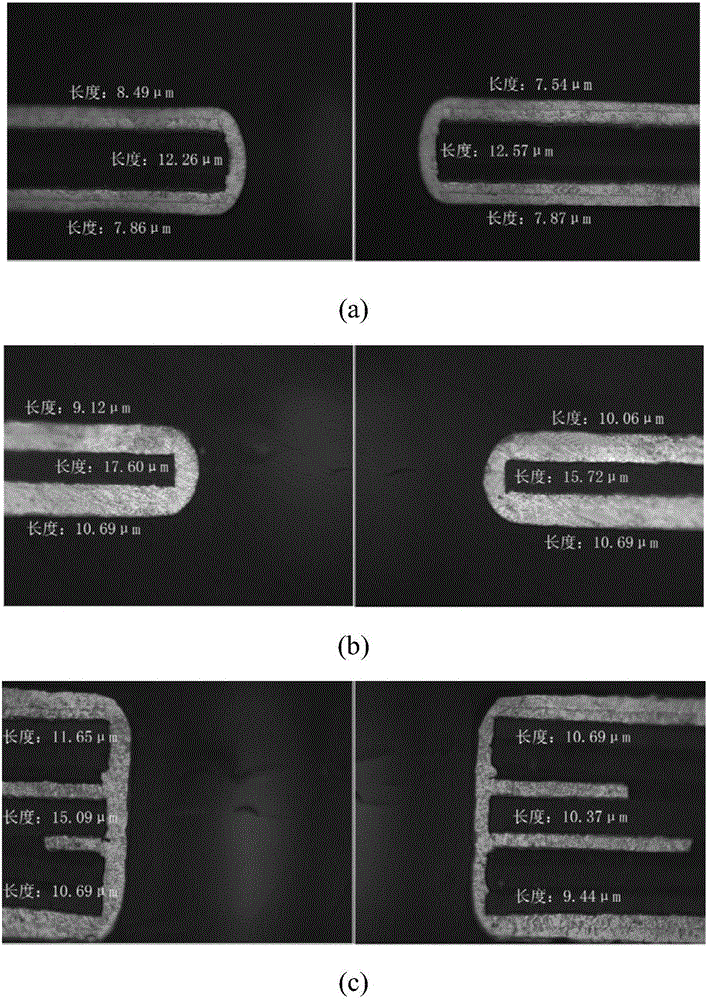

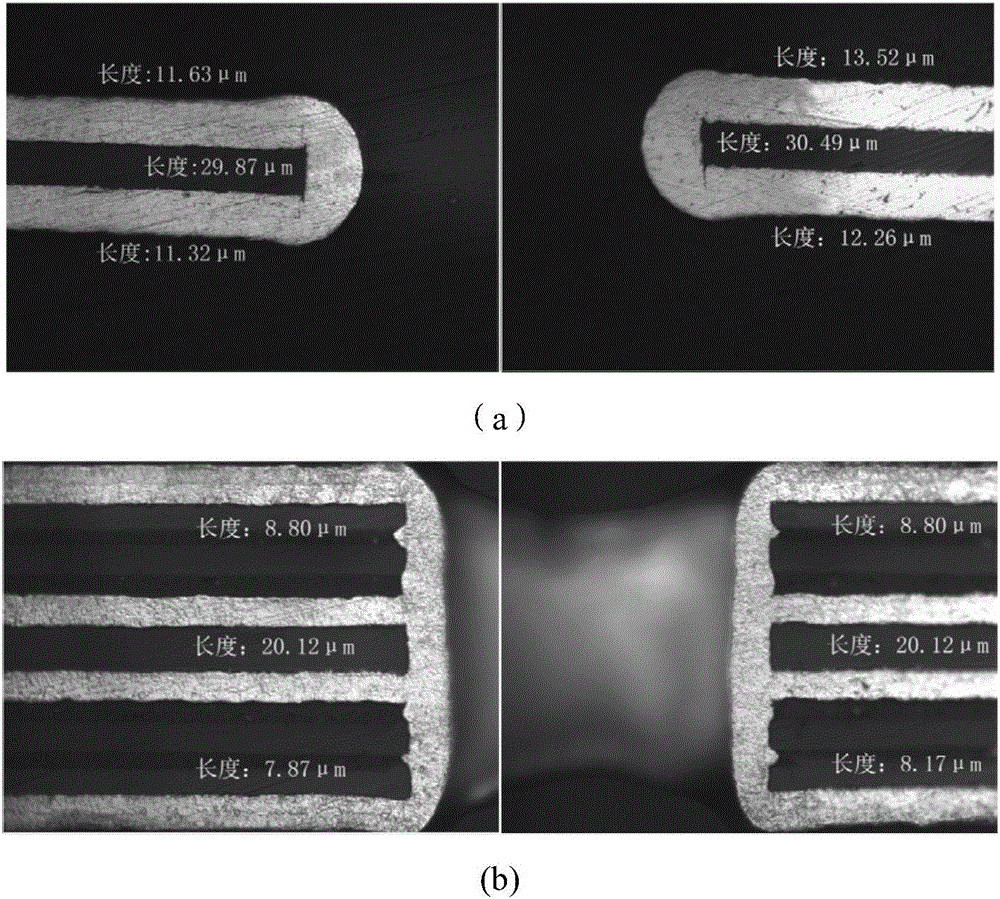

[0060] After a series of pre-treatments are performed on the flexible board of a specific specification, that is, degreasing, water washing, and pre-soaking, electroplating is performed in the above-mentioned copper plating solution. In this embodiment, the black-holed flexible plate to be...

Embodiment 2

[0062] What this embodiment adopts is the additive of electroplating bath of MACUSPEC VP100 produced by Mai Demei Company (this formula does not contain leveling agent, but the brightening agent it uses is different from the present invention). Prepare the electroplating solution according to the following recipe according to the instruction manual.

[0063] Copper sulfate pentahydrate: 120g / L

[0064] Sulfuric acid: 200g / L

[0066] The components of VP100 electroplating solution additives are added according to the concentration in the instructions:

[0067] VP100 Brightener: 1mL / L

[0068] VP100 inhibitor: 10mL / L

[0069] Deionized water: balance.

[0070] After a series of pre-treatments are performed on the flexible board of a specific specification, that is, degreasing, water washing, and pre-soaking, electroplating is performed in the above-mentioned copper plating solution. In this embodiment, the black-holed flexible plate to be plat...

Embodiment 3

[0072] What this embodiment adopts is the additive of electroplating plating solution of MACUSPEC VP100 produced by Mai Demei Company. Prepare the electroplating solution according to the following recipe according to the instruction manual.

[0073] Copper sulfate pentahydrate: 120g / L

[0074] Sulfuric acid: 200g / L

[0075] Chloride ion: 70mg / L

[0076] The components of VP100 electroplating solution additives are added according to the concentration in the instructions:

[0077] VP100 Brightener: 1mL / L

[0078] VP100 inhibitor: 10mL / L

[0079] Deionized water: balance.

[0080] After a series of pre-treatments are performed on the flexible board of a specific specification, that is, degreasing, water washing, and pre-soaking, electroplating is performed in the above-mentioned copper plating solution. In this embodiment, the black-holed flexible board to be plated is used as the negative electrode, and the soluble phosphorus-containing copper is used as the anode. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com