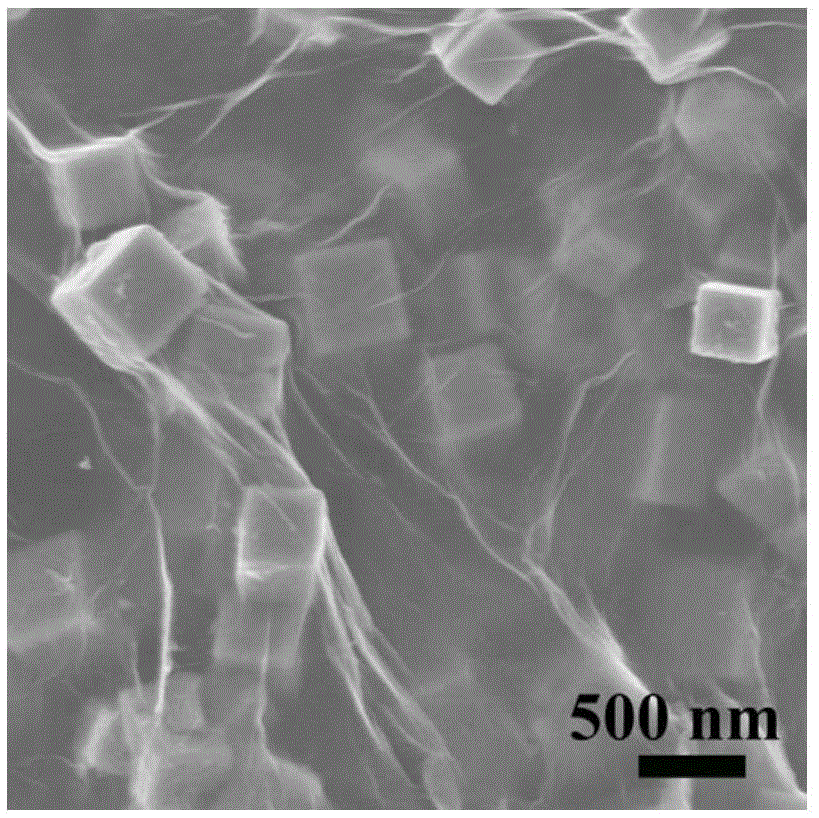

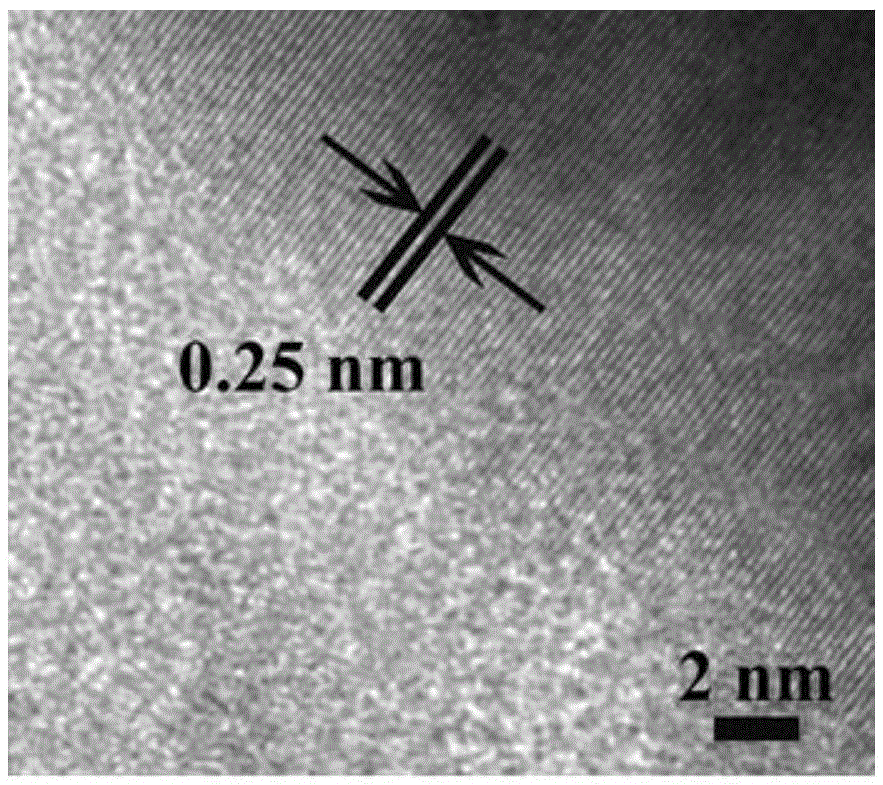

Preparation method of cubic cuprous oxide/graphene nanocomposite

A technology of nanocomposite materials and cuprous oxide, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve the problem of low photocatalytic performance improvement, poor morphology of composite products, and complicated preparation methods cumbersome and other problems, to achieve the effect of facilitating mass industrial production, excellent appearance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, 0.4g of copper sulfate pentahydrate and 50mg of graphene oxide are uniformly dispersed in 80mL of ultrapure water in a 600W ultrasonic machine for 8 minutes;

[0031] Step 2, the above solution was mechanically stirred in a water bath at 60°C for 30 minutes.

[0032] Step 3, 10mL of 1mol / L sodium hydroxide solution was added dropwise to the reaction solution, and one minute after the dropwise addition, quickly poured into 10mL of 0.3mol / L glucose solution, and continued to mechanically stir at 60°C for two and a half hours .

[0033] Step 4: Centrifuge the obtained suspension at 6000 rpm, alternately wash and centrifuge it with ultrapure water and ethanol for 4 times, and dry it in a vacuum oven at 40°C to obtain a cuprous oxide / graphene nanocomposite powder.

[0034] The cuprous oxide / graphene composite nanomaterial prepared in Example 1 was used for visible light catalysis research on methyl orange. 20 g of the nanocomposite powder prepared in Example 1 was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com