Nitrogen-doped porous carbon polyhedron@nanometer cobalt phosphide composite catalyst capable of efficiently activating persulfate and preparation method of composite catalyst

A nitrogen-doped porous carbon and composite catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of good electron transport performance, secondary pollution of catalysts, and difficulty in recycling. Achieve significant environmental and economic significance and overcome the effect of large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

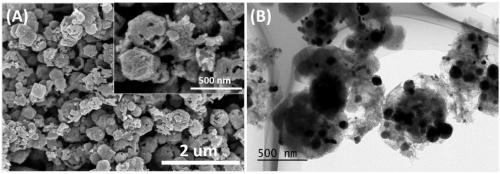

[0034] A nitrogen-doped porous carbon polyhedron@nano cobalt phosphide composite catalyst capable of efficiently activating persulfate, the steps of which are:

[0035] a. Basic cobalt carbonate (Co(CO 3 ) 0.5 (OH)·0.11H 2 O) nanowire preparation: 0.56g CoSO 4 ·7H 2 O was dissolved in 40 mL of a mixture consisting of 7 mL of glycerin and 33 mL of distilled water and stirred evenly. After adding 0.1 g of urea to dissolve, the resulting solution was transferred to a 50 mL hydrothermal reactor and heated at 170 °C for 24 h. After the reaction, the reactor was naturally cooled to room temperature, and the precipitate was collected by centrifugation, washed alternately with water and alcohol for several times, and then dried to obtain Co(CO 3 ) 0.5 (OH)·0.11H 2 O nanowires.

[0036] b. Preparation of cobalt phosphide (CoP) nanowires: Co(CO) obtained in step a 3 ) 0.5 (OH)·0.11H 2 O nanowires and NaH 2 PO 2 respectively piled up in different positions of the same magneti...

Embodiment 2

[0043] With embodiment 1, difference is:

[0044] CoSO in step a 4 ·7H 2 The mass of O is 1.2g, which is dissolved in a mixed solution consisting of 10mL glycerin and 30mL distilled water, the mass of urea is 0.14g, the hydrothermal reaction temperature is 180°C, and the reaction time is 30h;

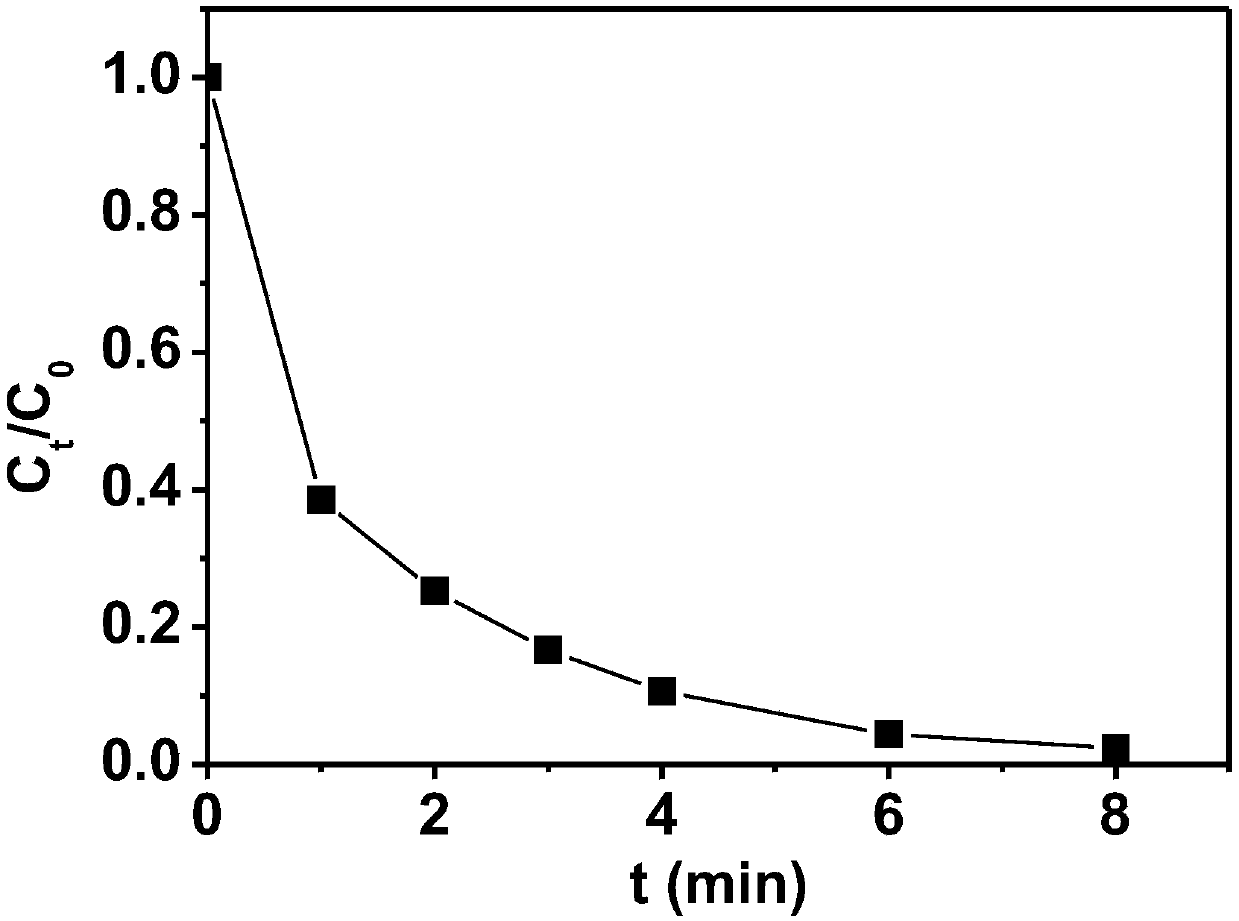

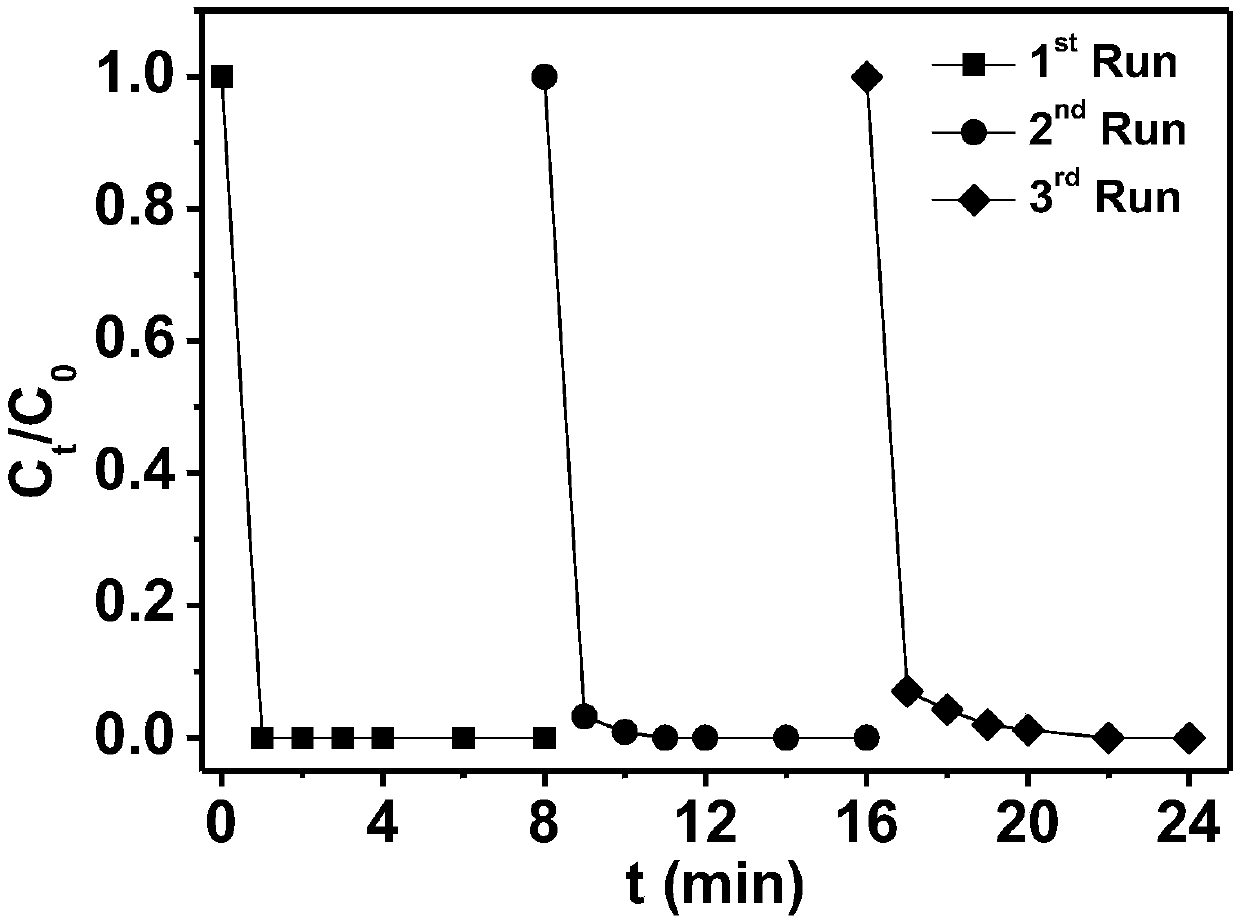

[0045] Under the same experimental conditions as in Example 1, the obtained catalyst had a degradation rate of 99% to bisphenol A within 8 minutes.

Embodiment 3

[0047] With embodiment 1, difference is:

[0048] In step a, the cobalt salt was changed to cobalt chloride, the mass of which was 0.4g, dissolved in a mixed solution consisting of 5mL of glycerin and 35mL of distilled water, the mass of urea was 0.06g, the hydrothermal reaction temperature was 160°C, and the reaction time was 18h;

[0049] Under the same experimental conditions as in Example 1, the obtained catalyst had a degradation rate of 89% to bisphenol A within 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com