High-nicotine tobacco extract and application thereof

A technology of tobacco extract and high nicotine, which is applied in the directions of tobacco, application, and treatment of tobacco, can solve the problems of loss of aroma components, weak product aroma, and difficulty in dissolving, so as to maintain the original aroma of tobacco, the strong aroma of tobacco, The effect of reducing the tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

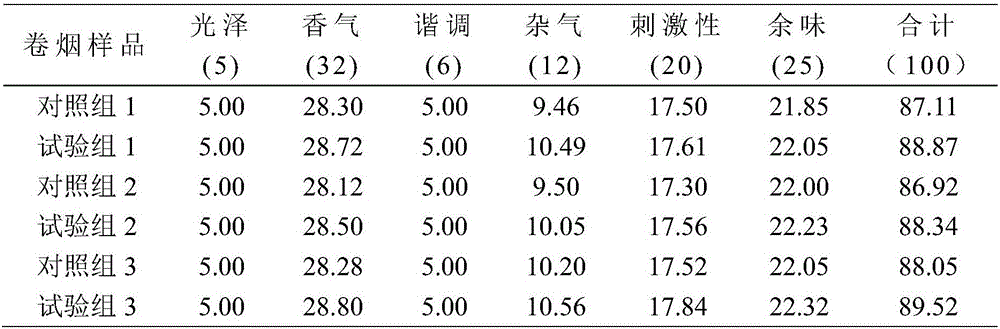

Examples

Embodiment 1

[0031] In this embodiment, the high nicotine tobacco extract is prepared by the following steps:

[0032] 1) Pretreatment: Weigh 1 kg of flue-cured tobacco raw material, place the raw material in a SY-III-A experimental tobacco processor, spray commercially available ammonia water with 2% of the raw material mass, and place it in a sealed place for 12 hours to fully absorb the tobacco leaves, then heat Bake at 60°C for 4 hours;

[0033]2) Pulverize the baked material to 10 meshes, and roll it through a rolling-type wall breaking machine for 3 times to obtain powder;

[0034] Subcritical extraction: add butane (mass ratio 1:8) to the powder, extract at a temperature of 25°C and saturated vapor pressure for 2 hours to obtain an extract;

[0035] The extract is placed in a separation tank, and the solvent is separated by the principle of vacuum evaporation to obtain a crude extract;

[0036] Add 5 times the mass of 95% ethanol to the crude extract while stirring, heat to 50°C a...

Embodiment 2

[0041] In this embodiment, the high nicotine tobacco extract is prepared by the following steps:

[0042] 1) Pretreatment: Weigh 1 kg of flue-cured tobacco raw material, place the raw material in a SY-III-A type experimental tobacco processor, spray a saturated aqueous solution of histidine with a mass of 25% of the raw material, and seal it for 6 hours to make the tobacco leaves fully absorbed. Then heat to 70°C and bake for 5h;

[0043] 2) Pulverize the baked material to 100 mesh, and roll it through a rolling-type wall breaking machine for 3 times to obtain powder;

[0044] Subcritical extraction: add dimethyl ether (mass ratio 1:12) to the powder, extract at a temperature of 45°C and saturated vapor pressure for 0.5h to obtain an extract;

[0045] The extract is placed in a separation tank, and the solvent is separated by the principle of vacuum evaporation to obtain a crude extract;

[0046] Add 10 times the mass of 95% ethanol to the crude extract while stirring, heat ...

Embodiment 3

[0051] In this embodiment, the high nicotine tobacco extract is prepared by the following steps:

[0052] 1) Pretreatment: Weigh 1 kg of flue-cured tobacco raw material, place the raw material in a SY-III-A type experimental tobacco processor, spray 2% lysine saturated aqueous solution of the raw material quality, seal and place for 10 hours, so that the tobacco leaves can be fully absorbed, Then heat to 50°C and bake for 2h;

[0053] 2) Pulverize the baked material to 50 mesh, and roll it through a roller-type wall breaking machine for 3 times to obtain powder;

[0054] Subcritical extraction: add butane (mass ratio 1:10) to the powder, extract at a temperature of 45°C and saturated vapor pressure for 1.5 hours to obtain an extract;

[0055] The extract is placed in a separation tank, and the solvent is separated by the principle of vacuum evaporation to obtain a crude extract;

[0056] Add 8 times the mass of 95% ethanol to the crude extract while stirring, heat to 40°C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com