Preparation method and equipment for nano-grade superfine cobalt powder

An ultra-fine cobalt powder, nano-scale technology, applied in the field of preparation of ultra-fine cobalt powder, can solve the problems of expensive precipitant, difficult process implementation, lengthy ion process, etc., to achieve short process, easy process implementation, and control of process conditions easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

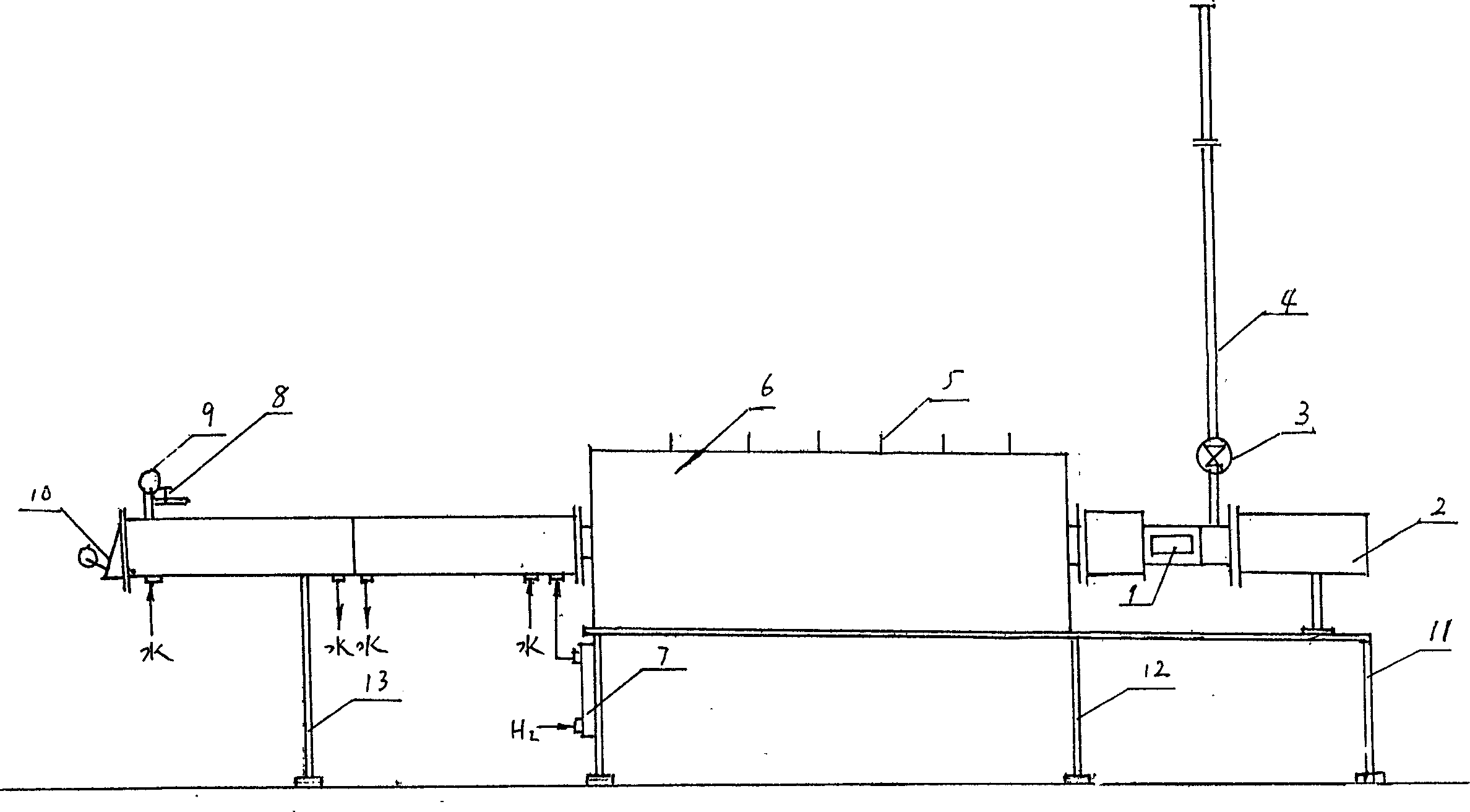

Image

Examples

Embodiment 1

[0016] (1) The precursor of nano-scale cobalt powder - the raw material solution used for the preparation of ultra-fine cobalt carbonate powder is: CoCl 2 The solution contains Co 2+ 82g / l, NH 4 ·HCO 3 The concentration is 25wt%, the reaction synthesis temperature is 30°C, PH=7.4, the speed of adding to the reactor: CoCl 2 Solution 30L / min, NH 4 ·HCO 3 The solution is 100L / min; the stirring speed is 600r / min, and the aging time is 1.0 hour; the preparation device adopts the special device disclosed by CN1686828A, and the prepared CoCO 3 Powder, its main chemical composition: Ee, Cu, Mn, Ni, Pb, Zn, Ca, Mg, Cl - The impurity contents are all ≤0.01%, Co≤50%, H 2 O≤0.2%, average particle size≤0.1 μm; (2) thermal reduction The superfine cobalt carbonate powder prepared in step (1) is placed in the superfine cobalt carbonate powder thermal reduction electric furnace of the present invention described above for thermal reduction , the specific operation process is as follows:...

Embodiment 2

[0018] CoCl 2 The solution concentration contains Co 2+ 150g / l, reaction synthesis temperature 45°C, PH=7.2, adding reactor speed: CoCl 2 Solution 90L / min, NH 4 ·HCO 3 The saturated solution is 300L / min; the stirring speed is 8000r / min, and the aging time is 1.5 hours; the thermal reduction temperature of the ultrafine cobalt carbonate powder is 400°C, and the others are the same as in Example 1. Can continuously prepare specific surface area ≥ 40m 2 / g spherical or quasi-spherical nano-scale high-energy cobalt powder with an average particle size of 30-50nm and an oxygen content of ≤0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com