Preparation technique of cobalt decanoate by hybrid reaction of cobaltous carbonate and organic acid

A preparation process, technology of cobalt neodecanoate, applied in the field of preparation of cobalt decanoate, can solve the problems of low cobalt content, unstable adhesion, and low melting point of cobalt neodecanoate, achieve enhanced adhesion level, prevent metal Corrosion, pH balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

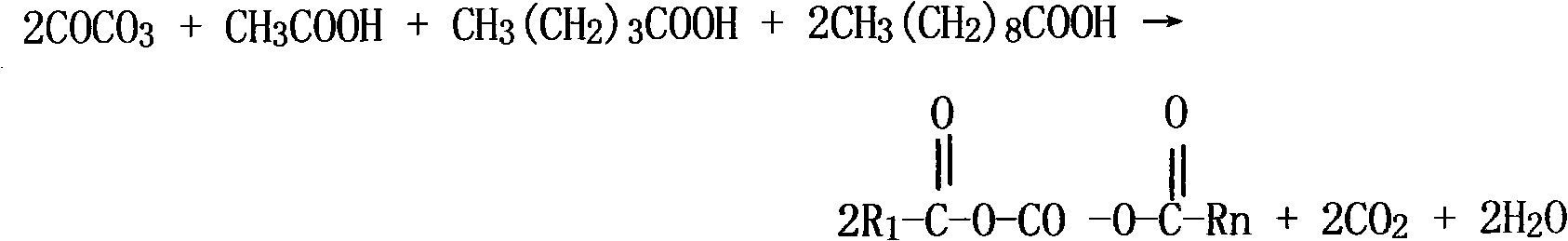

Method used

Image

Examples

Embodiment 1

[0032] Add 28g of glacial acetic acid, 100g of neodecanoic acid, 12g of pivalic acid, and 92g of cobalt carbonate to a 1000ml four-neck flask with a reflux condenser, a temperature-regulating electric heating mantle, and a vacuum pump in sequence, and control the reaction temperature at 95°C for 3 hours. Heating and drainage, vacuum decompression and drainage, get rid of the water generated by the reaction, add 16g of abietic acid at a temperature of 165°C, react for 1 hour, add 10g of active calcium carbonate at 165°C, and discharge after uniform stirring for 1 hour to obtain Cobalt neodecanoate product, the cobalt content is 20.3%, the appearance is blue-purple.

Embodiment 2

[0034] Add 30g of glacial acetic acid, 102g of neodecanoic acid, 16g of pivalic acid, and 96g of cobalt carbonate to a 1000ml four-necked flask with a reflux condenser, a temperature-regulating electric heating mantle, and a vacuum pump in sequence, and control the reaction temperature at 90°C. The reaction time is 3.5 hours. Heating and draining, vacuum decompressing and draining, removing the water generated by the reaction, adding 12g of abietic acid at a temperature of 160°C, and reacting for 2 hours, adding 8g of active calcium carbonate at a temperature of 160°C, stirring evenly for 1 hour The cobalt neodecanoate product was obtained, with a cobalt content of 20.8% and a blue-purple appearance.

Embodiment 3

[0036] Add 32g of glacial acetic acid, 104g of neodecanoic acid, 15g of pivalic acid, and 93g of cobalt carbonate into a 1000ml four-neck flask with a reflux condenser, a temperature-regulating electric heating mantle, and a vacuum pump in sequence, and control the reaction temperature at 100°C. The reaction time is 3.5 hours. Heating and drainage, vacuum decompression and drainage, get rid of the water generated by the reaction, add 14g of abietic acid at a temperature of 168°C, and react for 2 hours, add 12g of active calcium carbonate at a temperature of 168°C, stir evenly for 1 hour, and put The cobalt neodecanoate product was obtained, with a cobalt content of 20.5% and a blue-purple appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com