Preparation method of semi-micrometer cobalt powder

A technology of cobalt powder and cobalt carbonate, which is applied in the field of preparation of half-micron cobalt powder, can solve the problems of difficult filtration and washing, high energy consumption and high cost, and achieve the effect of improving anti-oxidation performance and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

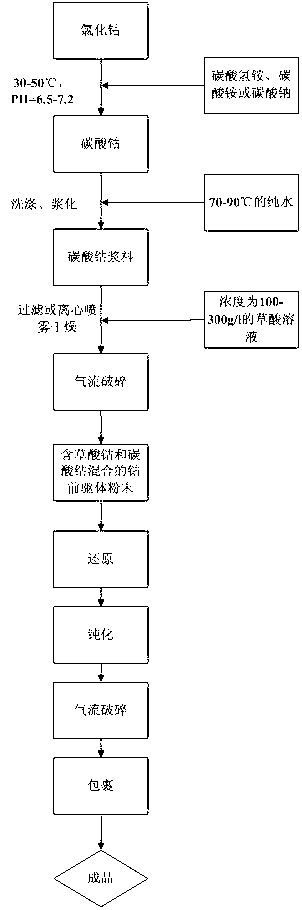

Method used

Image

Examples

Embodiment 1

[0029] Take cobalt chloride and ammonium bicarbonate reaction as example, illustrate, and described method comprises the following steps:

[0030] 1. React cobalt chloride with a concentration of 80 g / L and ammonium bicarbonate with a concentration of 150 g / L at a temperature of 45 °C and a pH value of 6.5;

[0031] 2. Filter the solution obtained after the reaction to obtain a precipitate of cobalt carbonate, which is then washed and slurried with pure water at 70 °C;

[0032] 3. Industrial grade oxalic acid is dissolved with pure water, and the oxalic acid solution that obtains concentration is 100 g / L, adds in the above-mentioned cobalt carbonate slurry by the flow rate of 20 L / min and reacts, and the mol ratio of described cobalt carbonate and oxalic acid is 1:0.5, stirring speed 400 r / min, reaction temperature 20 ℃, after adding the oxalic acid solution, react for 1 hour, and filter after the pH value reaches 6-7;

[0033] 4. After the above materials are dried, they are...

Embodiment 2

[0036] Take cobalt chloride and ammonium carbonate reaction as example, illustrate, and described method comprises the following steps:

[0037] 1. React cobalt chloride with a concentration of 120 g / L and 250 g / L ammonium carbonate at a reaction temperature of 50 °C and a pH value of 7.2;

[0038] 2. Filter the solution obtained after the reaction to obtain cobalt carbonate precipitate, and then wash and slurry with pure water at 90 °C;

[0039] 3. Dissolve food-grade oxalic acid in pure water into an oxalic acid solution with a concentration of 300 g / L, the molar ratio of cobalt carbonate to oxalic acid is 1:0.99, and add it into the above-mentioned cobalt carbonate slurry at a flow rate of 100 L / min. Reaction, the stirring speed is 800 r / min, the reaction temperature is 40 ℃, after adding the oxalic acid solution, react for 5 hours, and after the pH value reaches 6-7, carry out centrifugal spray drying;

[0040] 4. After the above materials are dried, they are crushed by a...

Embodiment 3

[0044] Take cobalt chloride and sodium carbonate reaction as example, illustrate, and described method comprises the following steps:

[0045] 1. React cobalt chloride with a concentration of 100 g / L and sodium carbonate with a concentration of 200 g / L, the reaction temperature is 40 °C, and the pH value is 6.8;

[0046] 2. Filter the solution obtained after the reaction to obtain cobalt carbonate precipitate, and then wash and slurry with 80 °C pure water;

[0047]3. Dissolve industrial-grade oxalic acid in pure water into an oxalic acid solution with a concentration of 200 g / L. The molar ratio of cobalt carbonate to oxalic acid is 1:0.7, and add it into the above-mentioned cobalt carbonate slurry at a flow rate of 60 L / min. Reaction, the stirring speed is 700 r / min, the reaction temperature is 15 ℃, after adding the oxalic acid solution, react for 3 hours, and filter after the pH value reaches 6-7;

[0048] 4. After the above materials are dried, they are crushed by air flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com