Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Hydraulic mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic mining is a form of mining that uses high-pressure jets of water to dislodge rock material or move sediment. In the placer mining of gold or tin, the resulting water-sediment slurry is directed through sluice boxes to remove the gold. It is also used in mining kaolin and coal.

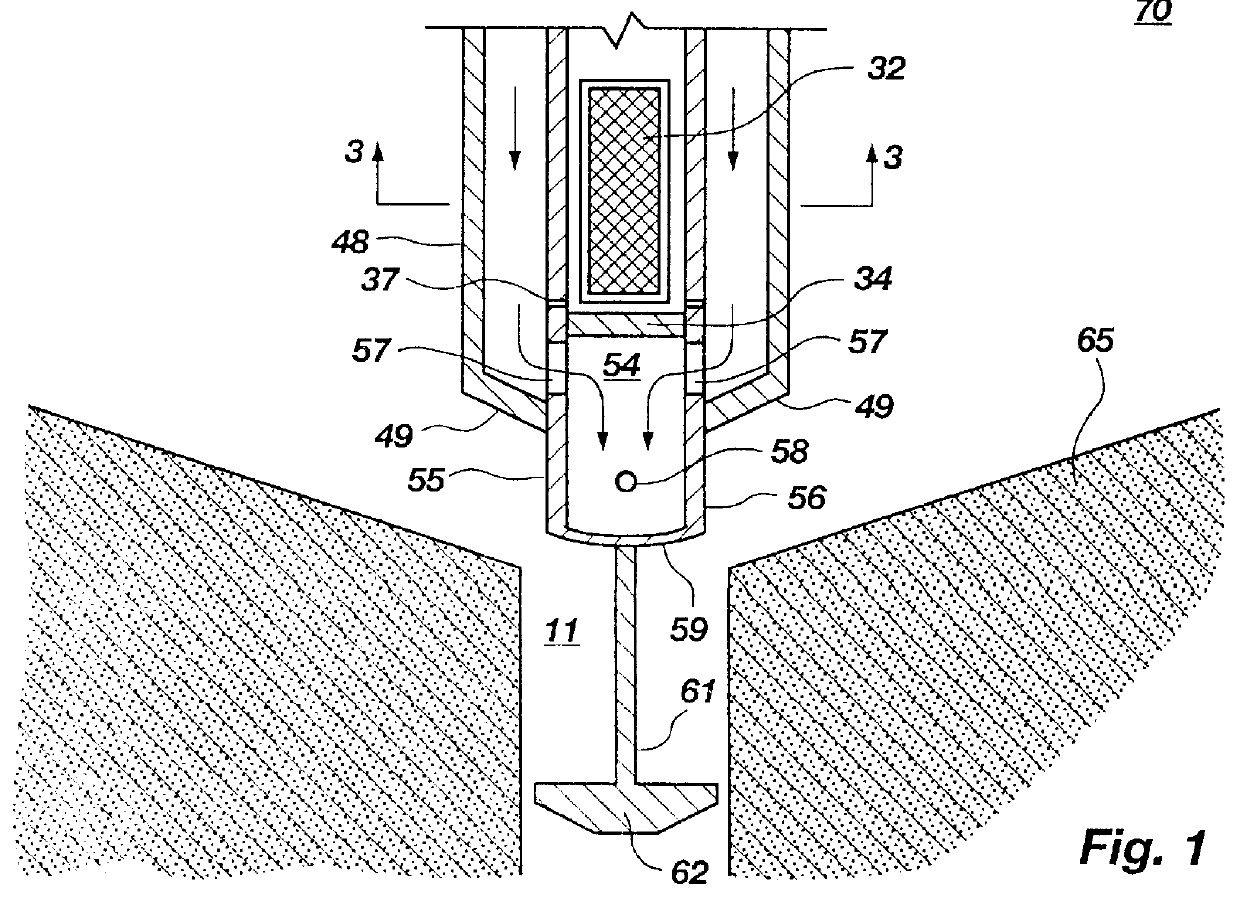

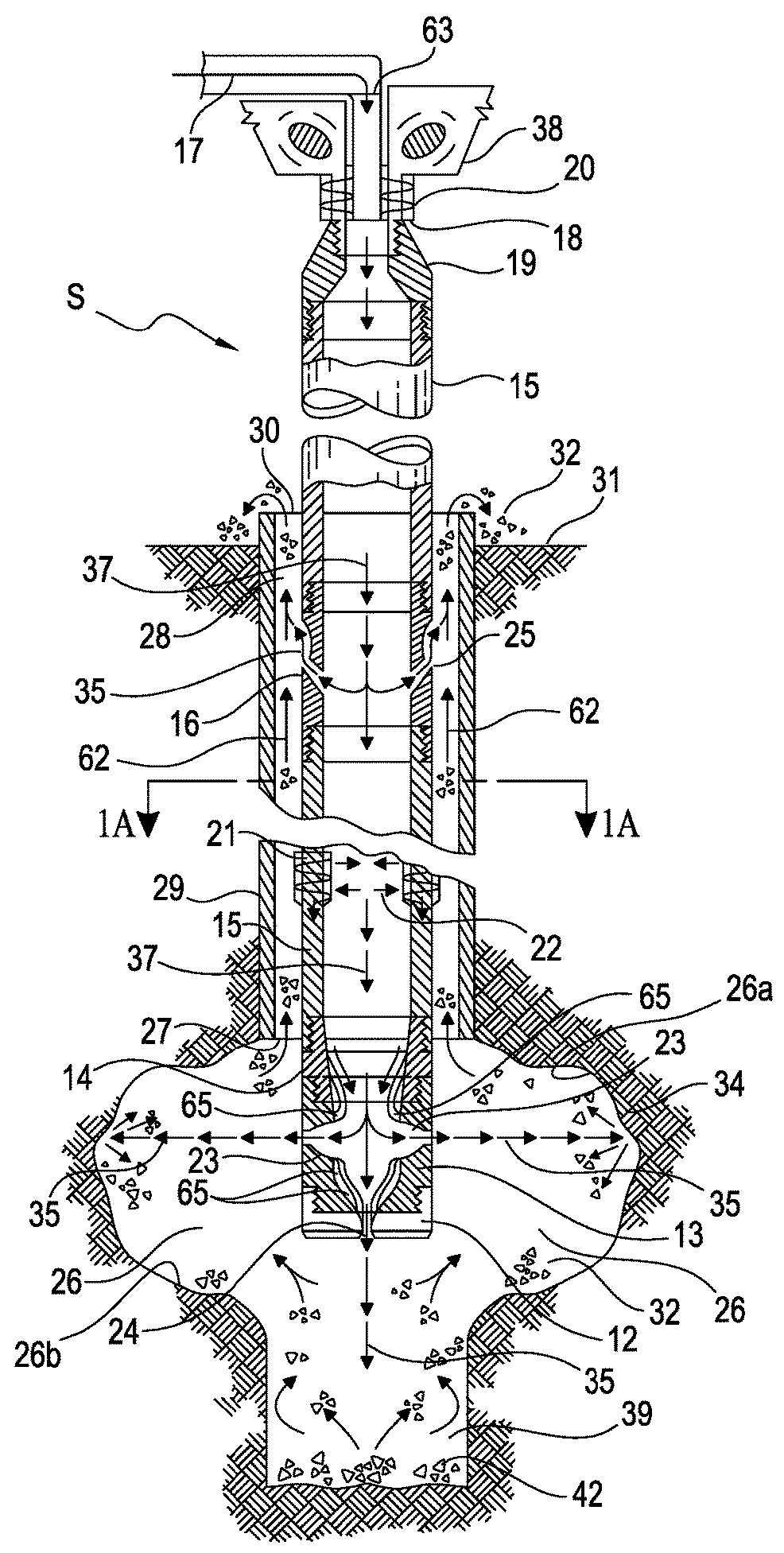

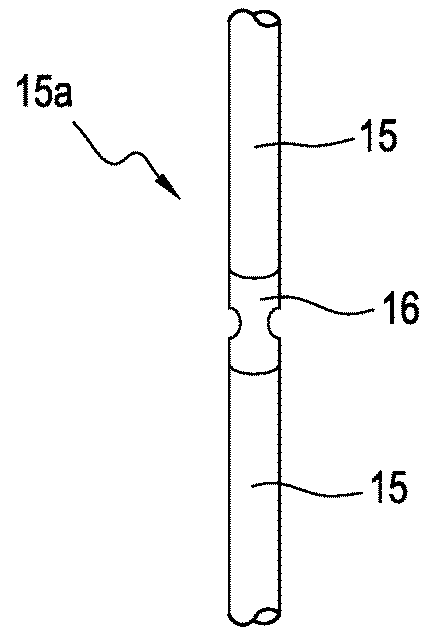

Hydraulic mining of tar sand bitumen with aggregate material

A method and apparatus for the hydraulic removal of bitumen from a tar sand deposit comprises forming a borehole into the tar sand deposit and securing a casing into the borehole. Into the casing is inserted a mining tool having a water / diluent channel and a slurry exit channel. Through the casing the borehole is charged with crushed aggregate. At the lower end of the tool are nozzles through which high pressure hot water / diluent is injected as a jet from the water / diluent channel into the tar sand deposit causing a cavity to form in the tar sand deposit. The heat of the water / diluent jets and dissolving action of the diluent softens the tar sand contacted and the impact of the jets and the scouring action of the aggregate, as impinged upon by the jets, removes the tar sand from the surface of the developing cavity into a water phase. A bitumen / diluent phase rises to the surface of the water phase and is removed from the cavity through the casing. A water sand slurry at the bottom of the developing cavity is removed from the slurry exit channel where sand is subsequently removed and the water is recovered and reintroduced back into the process along with makeup water and diluent. Water temperature and pressures are controlled to optimize the hydraulic mining process.

Owner:RAAM

Fluidized coal and gas simultaneous mining system and synchronous mining method of system

ActiveCN110656937AInhibition releaseImprove reliabilityUnderground miningFluid removalWell drillingGas release

The invention discloses a fluidized coal and gas simultaneous mining system and a synchronous mining method of the system. The fluidized coal and gas simultaneous mining system comprises a hydraulic mining part, a shaft bottom coal and rock treatment part and a coal and rock transport part. Gas released in a hydraulic mining process can be extracted by a gas extraction pump through a gas extraction inclined hole formed in the top of a coal mining driller, a hydraulic mined coal and rock mixture can be subjected to coal and rock separation by the shaft bottom coal and rock treatment part and the coal and rock transport part and then transported upwards and out of a well in a classified manner, the hydraulic mining part and the shaft bottom coal and rock treatment part work respectively without influence to each other, and reliability and mining efficiency of the hydraulic mining process can be greatly improved; automatic work of manless mining can be realized, and mining safety of a coal and gas outburst coal seam is greatly improved; and the system is suitable for mining coal seam resources such as boundary coal and wandering coal seams with low coal content and complex geologicalconditions and is particularly applicable to coal mining of a soft and weak coal seam where coal and gas are prone to outburst.

Owner:CHINA UNIV OF MINING & TECH

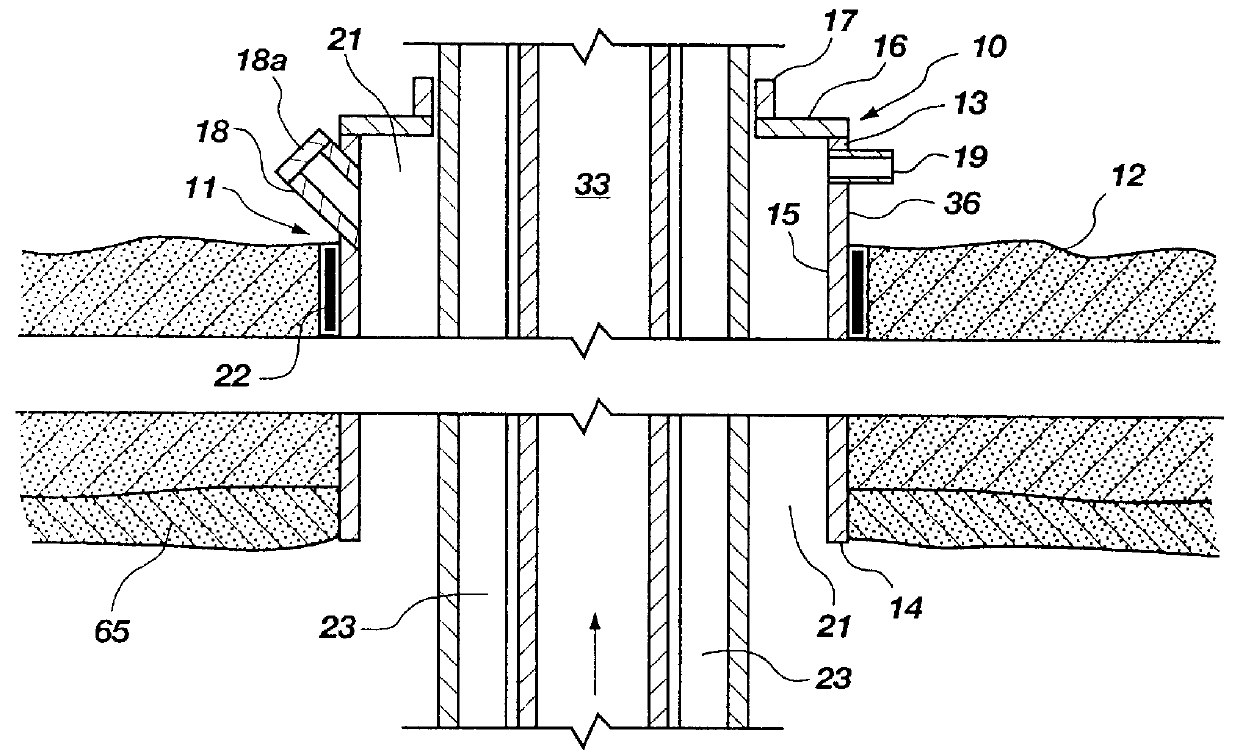

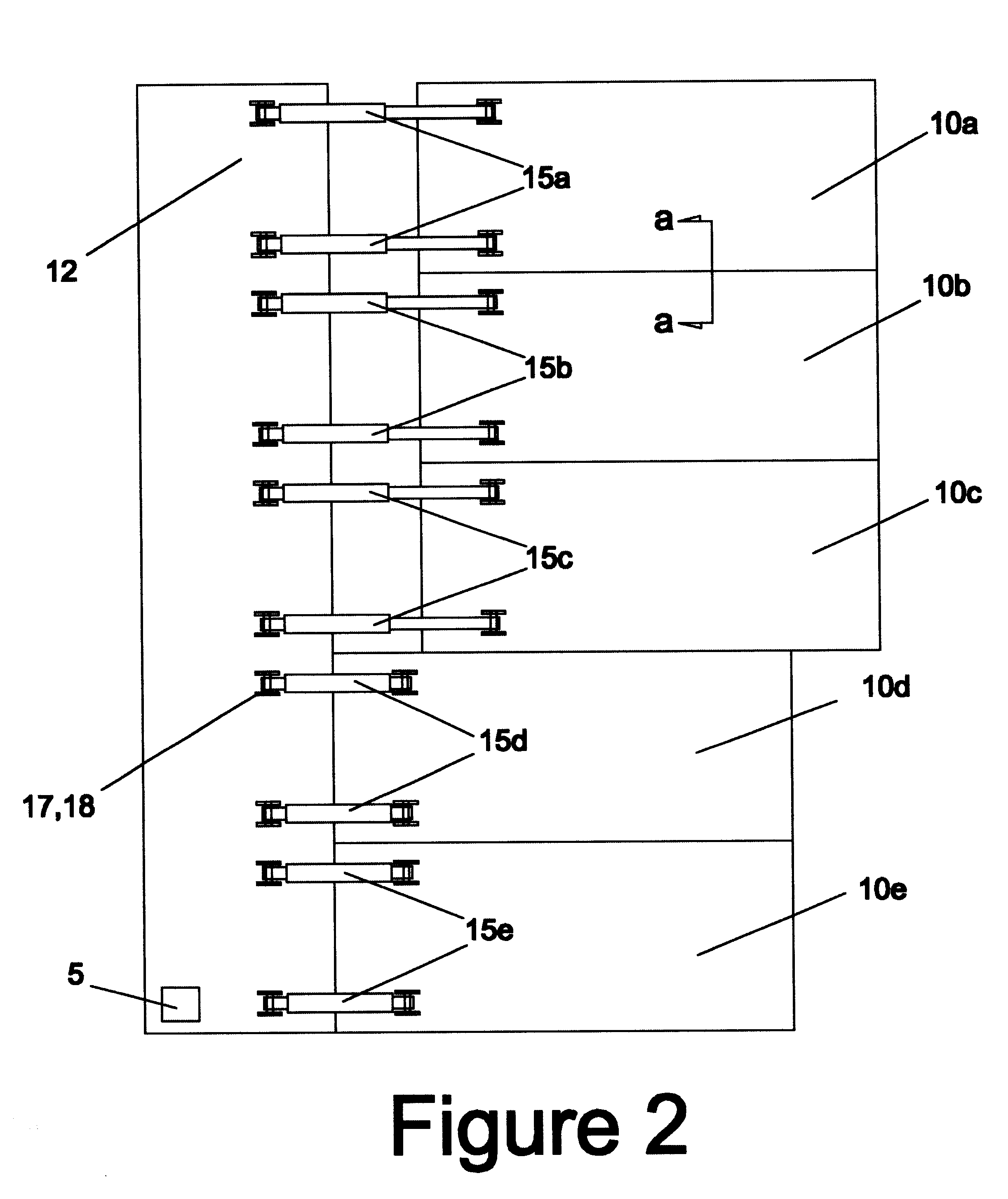

Self advancing mining sled

InactiveUS6267191B1Economical and reliableMachines/dredgers working methodsRider propulsionHydraulic miningAerospace engineering

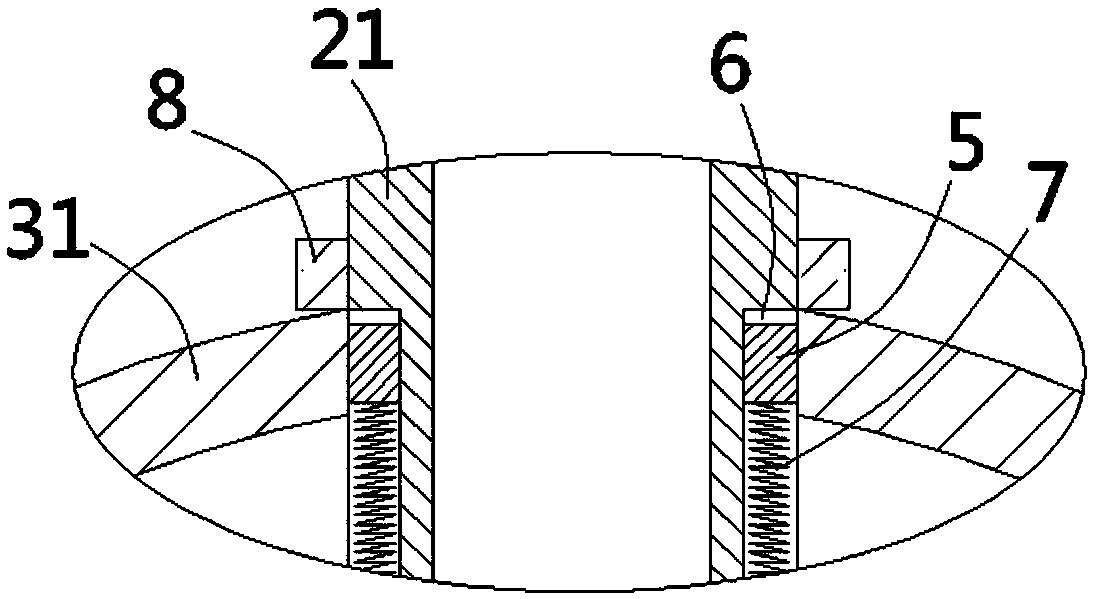

Disclosed is a self propelled device and method for transporting and positioning bulk solids handling equipment across working surfaces of limited bearing strength. Multiple advancing sleds (10) and equipment base sleds (12) are connected by interlocking angles (21) and thrust cylinders (15). Alternate extension and retraction of thrust cylinders (15) cause alternate sleds to push forward while other sleds serve as anchors. Methods to use the self advancing mining sled in hydraulic mining and dry mining applications are disclosed.

Owner:ROTHSCHILD KEITH R

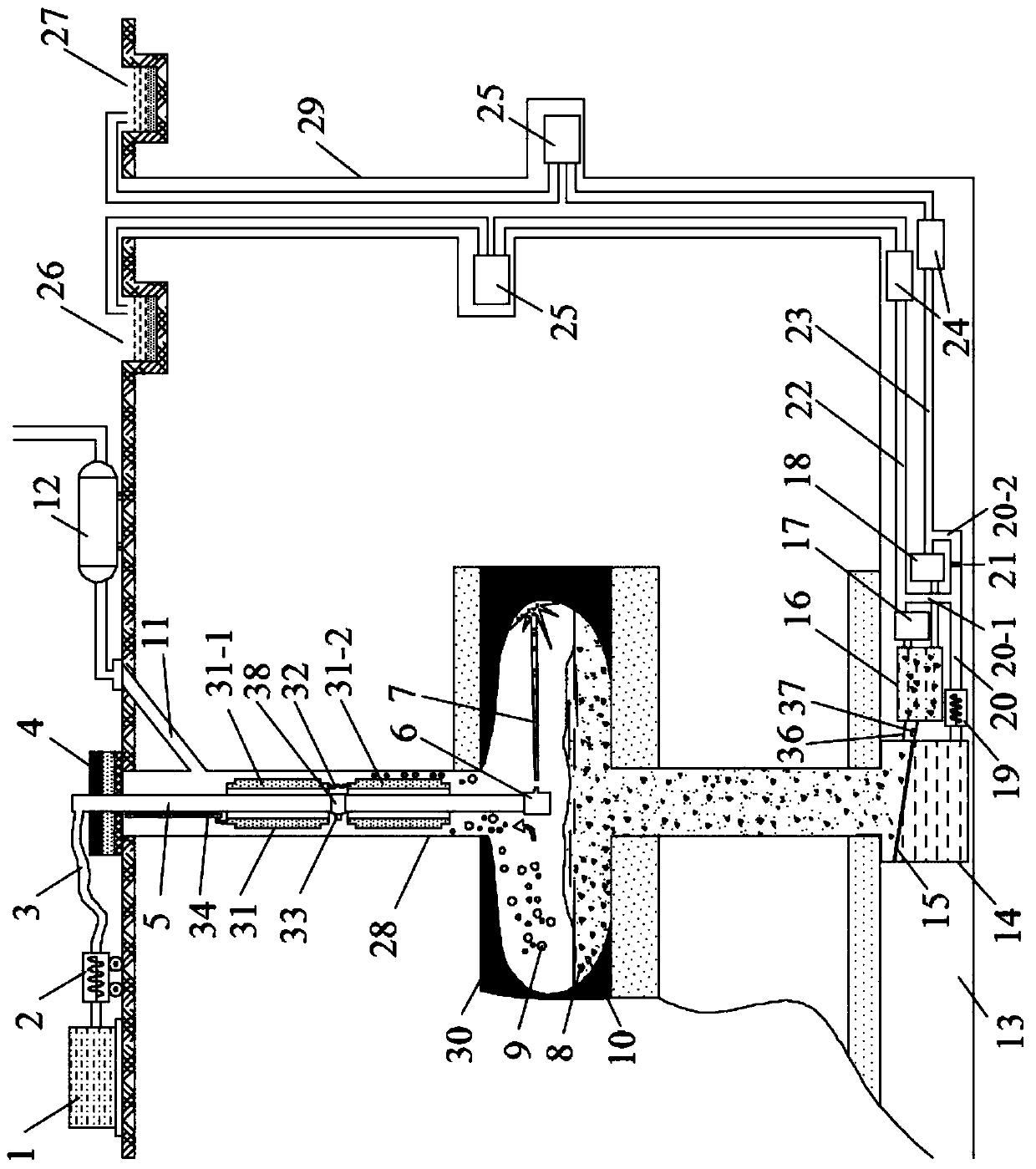

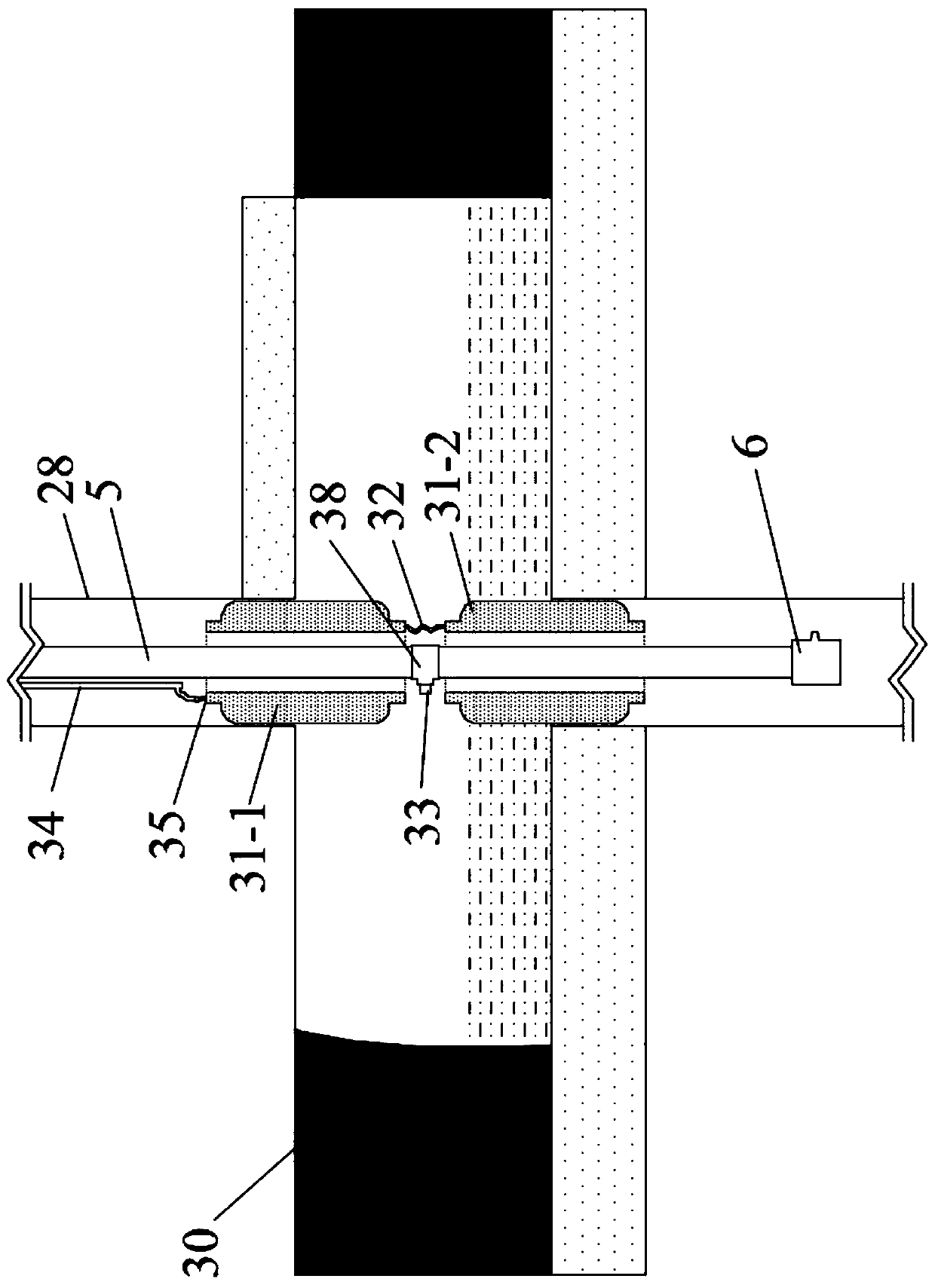

Coal and gas co-mining three-dimensional physical simulation comprehensive experiment system

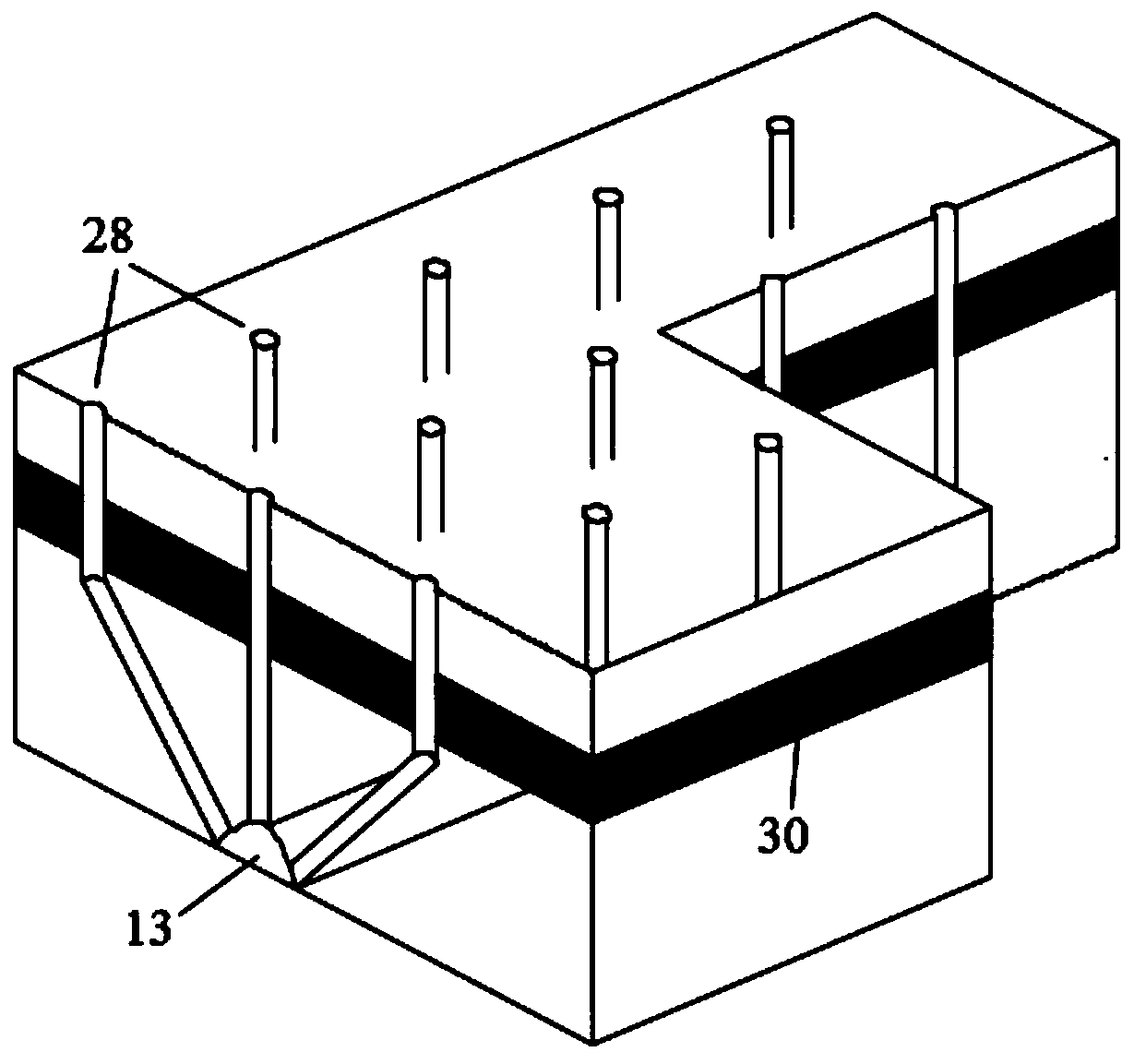

The invention discloses a coal and gas co-mining three-dimensional physical simulation comprehensive experiment system, and belongs to the technical field of coal and gas safe co-mining. The system comprises a box, a hydraulic mining unit, a hydraulic loading unit, a ventilation roadway unit, a gas injection control unit, and a test unit. The first surface and third surface, which is opposite to the first surface, of the box are both provided with a gas testing hole. The second surface of the box is provided with an air inlet hole and an air return hole. The fourth surface of the box is provided with a wire outlet hole. The hydraulic mining unit comprises parallelly arranged hydraulic cylinders and support steel bars, and two hydraulic cylinders and the bottom of the box connect and support one steel bar. The hydraulic loading unit comprises a loading frame, which is arranged on the guide rails of the box. The guide rails are arranged on two sides of the box. The ventilation roadway comprises a roadway and a ventilating machine. A high pressure steel bottle in the gas injection control unit is communicated with a multi-way air distribution cabinet through an air distribution pipe, the air distribution pipe is communicated with a sub-pipeline; and the test unit comprises a gas testing unit, a stress testing unit, and a slight shock testing unit.

Owner:XIAN UNIV OF SCI & TECH

Pressure sensor for measuring hydraulic pressure

InactiveCN1508525AEasy to removeFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesTransducerEngineering

Owner:CATERPILLAR INC

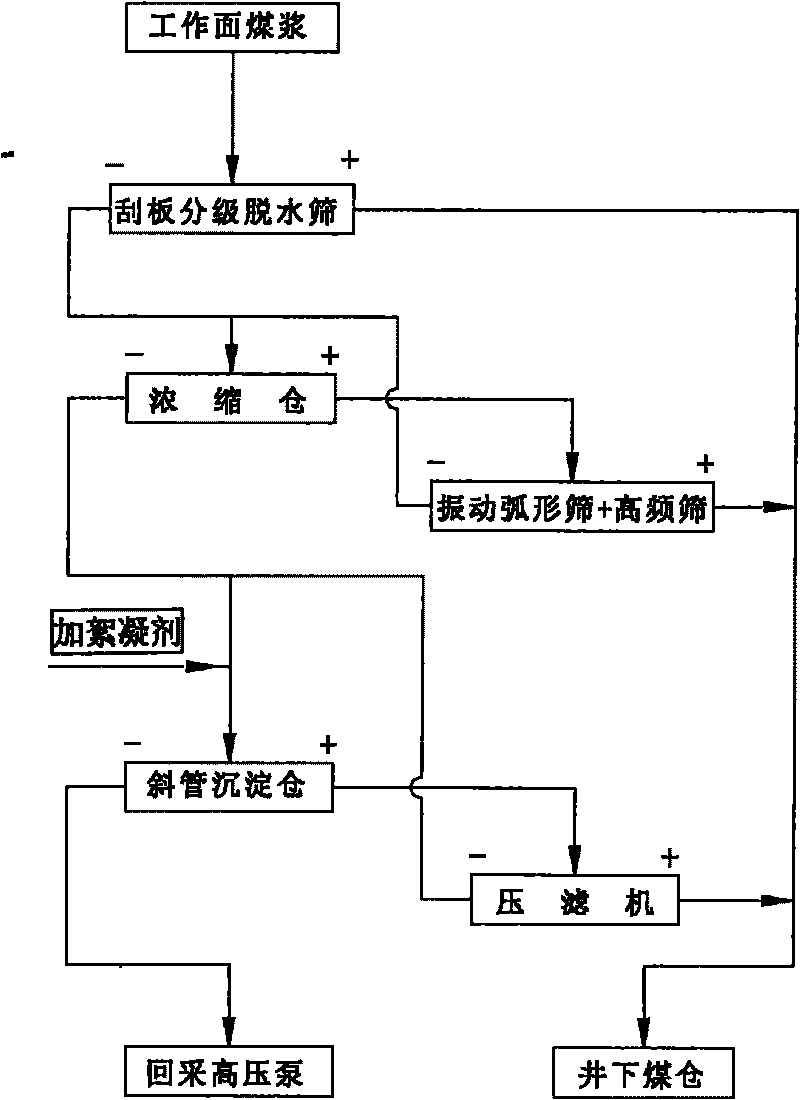

Process for fully dehydrating coal under hydraulic coal mining well

InactiveCN101711929ARealize dry transport and dry liftLow investment costHydraulic miningFiltration circuitsCoal waterThree stage

The invention discloses a process for fully dehydrating coal under a hydraulic coal mining well, belongs to the technical field of hydraulic coal mining production methods, and is used for realizing full dehydration and dry conveying and dry hoisting under the hydraulic coal mining well. The technical scheme is that: coal slurry from a hydraulic mining face enters a scraper and pit sizing-desliming screen firstly, block coal (more than 0.5-1.0mm) on the screen is dehydrated by a scraper conveyer provided with a sieve plate and then enters a coal bunker, and products under the screen overflow to a concentration bin; base flow in the concentration bin is pumped to a vibration curve screen and a high-frequency screen for dehydration, coarse slime (0.2 to 1.0mm) on the screens enters the coal bunker, and water under the screens flows back to the concentration bin; and the overflow in the concentration bin is mixed with a flocculating agent and then enters an inclined pipe settling bin, and the base flow fine slime (less than 0.2mm) in the inclined pipe settling bin is pumped to a pressure filter for dehydration and recovery. The invention adopts a three-stage dehydration process, full dehydration and dry conveying and dry hoisting under the hydraulic coal mining well are completely realized, a coal and water hoisting system and a ground dehydrating system are eliminated, and the process has the advantages of low investment cost and low total power of running equipment.

Owner:煤炭科学研究总院唐山研究院

Large-tonnage hydraulic mining vehicle braking system and method

ActiveCN106314405ASimple structureEasy to manufactureBraking action transmissionBrake coolingControl systemCooling effect

The invention discloses a large-tonnage hydraulic mining vehicle braking system which comprises a hydraulic braking unit, a hydraulic cooling unit and a cooling control system. The hydraulic braking unit comprises a hydraulic oil tank, a double-way prefill valve, a double-way braking valve, a parking brake handle valve, a first hydraulic pump, a first filter, a first overflow valve, a front axle braking energy accumulator, a rear axle braking energy accumulator, a front axle brake, a rear axle brake and a parking brake. The hydraulic cooling unit comprises a cooling fluid tank, a second hydraulic pump, a second filter and a second overflow valve, and the cooling control system comprises a controller, a first temperature sensor, a second temperature sensor, a third temperature sensor, a fourth temperature sensor and a relay. The invention further discloses a large-tonnage hydraulic mining vehicle braking method. The large-tonnage hydraulic mining vehicle braking system is novel and reasonable in design, convenient to achieve and safe and reliable in braking, ensures the vehicle safety, is good in practicability, good in usage effect and suitable for popularization and usage, and the brake is good in cooling effect.

Owner:XIAN UNIV OF SCI & TECH

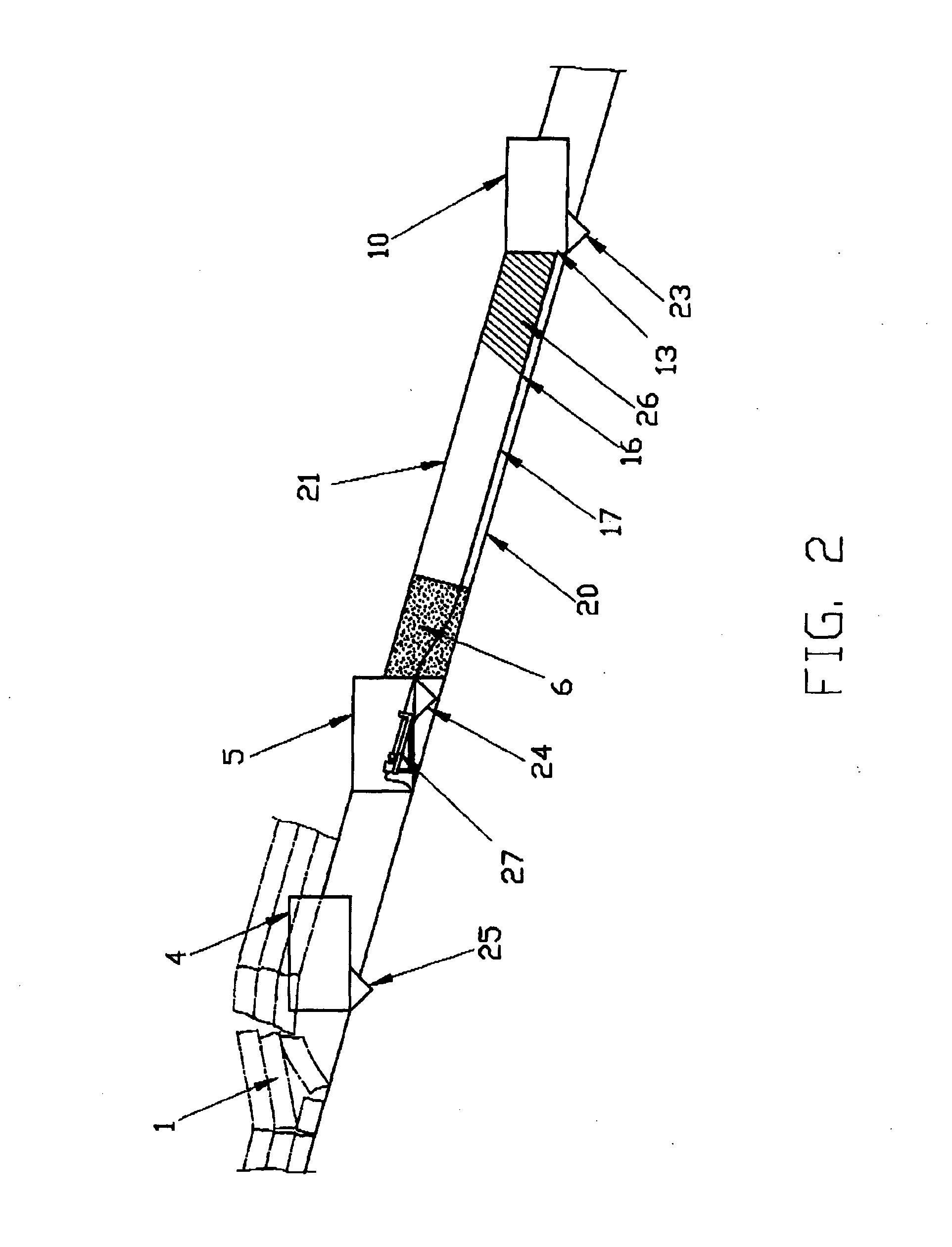

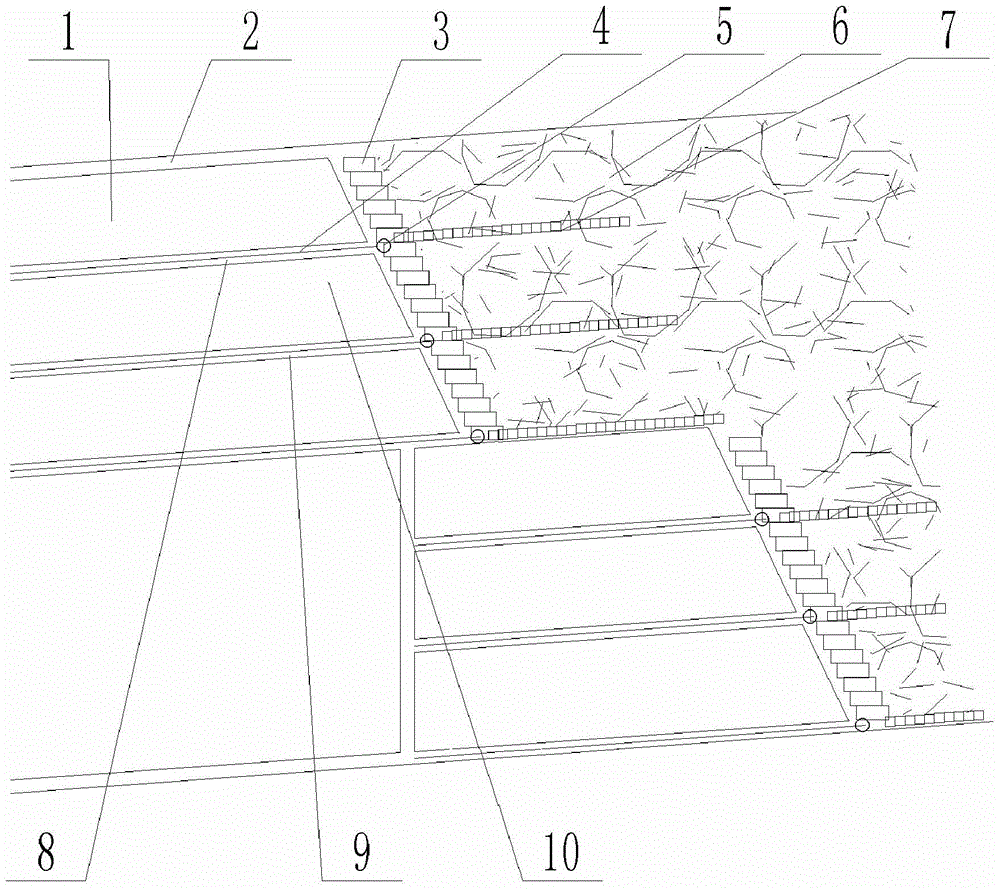

Hydraulic Mining System for Tabular Orebodies Utilising Directional Drilling

InactiveUS20130127231A1Easy to moveEasy retrievalDisloding machinesUnderground miningSlurryDirectional drilling

A mining system for extracting ore using directional chilling techniques to obtain access to the orebody. Spaced-apart roadways are formed in the ore formation, with a downhill roadway being lower in elevation than the other roadway, and the downhill roadway having a ditch therein draining downhill. A borehole is formed between roadways in the ore formation using the directional drill bit, and then the end of the drill string is equipped with a jetting nozzle. The jetting nozzle is moved within the borehole to erode the formation and mine the ore. In one embodiment, a slurry of mined ore and jetting fluid flows as a slurry down the intersection of the mined face and the floor towards a ditch formed in the downhill roadway. In another embodiment, a slurry of the mined ore and the jetting fluid flows down the borehole, and then down the ditch formed in the downhill roadway. In each case, the ore flows down the downhill roadway to a sump. From the sump, the ore is carried to the surface for transportation and eventual refining or use.

Owner:GRAY IAN

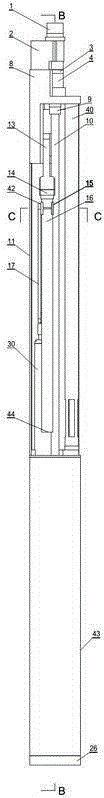

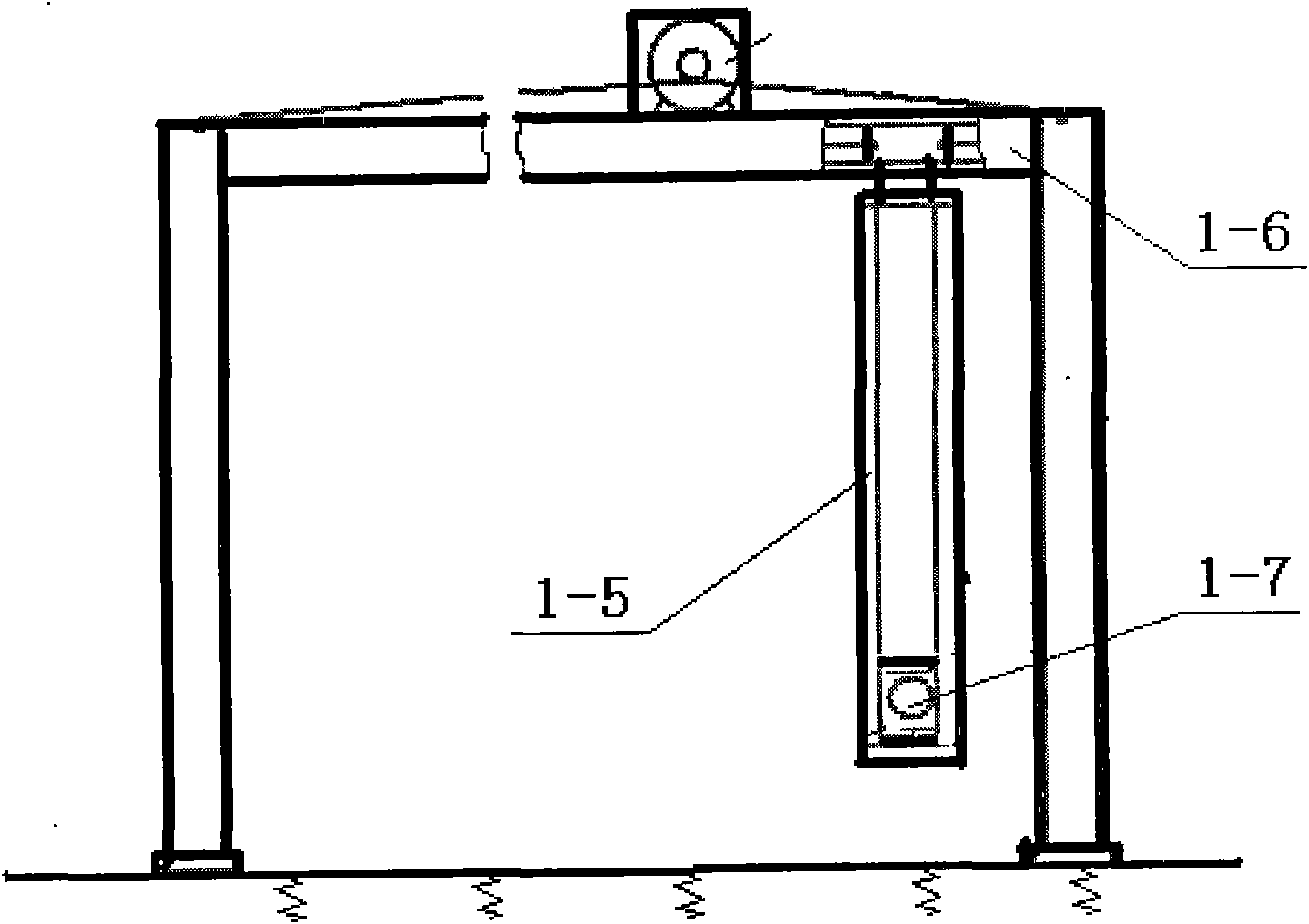

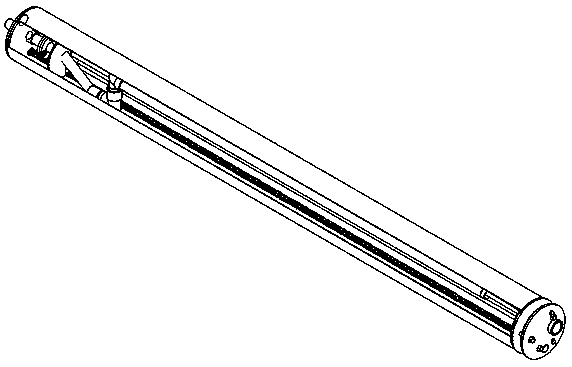

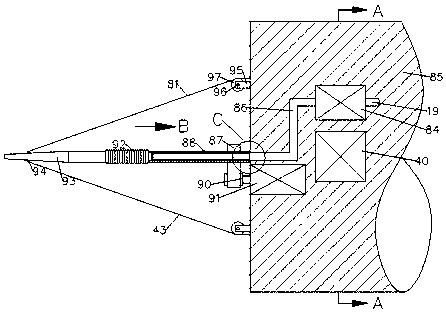

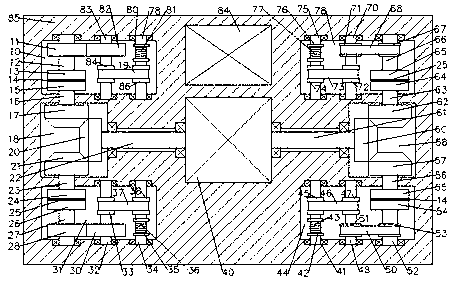

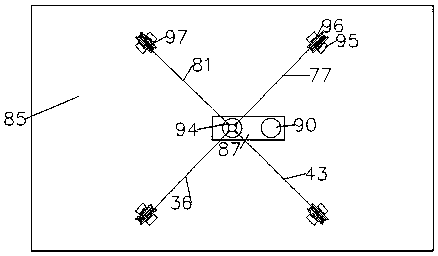

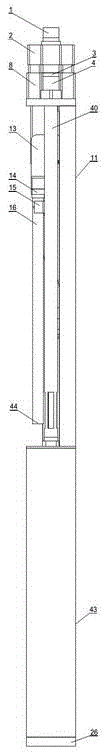

Electronic control telescopic drilling tool for borehole hydraulic mining

InactiveCN104005767AExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningBall screwDrivetrain

The invention discloses an electronic control telescopic drilling tool for borehole hydraulic mining. The electronic control telescopic drilling tool for the borehole hydraulic mining is composed of a high pressure water conveying system, a power transmission system, a hydraulic giant telescopic system and a deslagging channel. A hydraulic giant of the electronic control telescopic drilling tool can stretch out for a designed distance in the radial direction, the range of the borehole hydraulic mining is enlarged greatly, and production efficiency is improved. The electronic control telescopic drilling tool for the borehole hydraulic mining has the advantages that the rotating angle and speed of a stepping motor can be controlled accurately through a computer, the opening angle of the hydraulic giant can be controlled precisely, and the stretching and retracting actions of the hydraulic giant are stable through the transmission mode of a ball screw.

Owner:JILIN UNIV

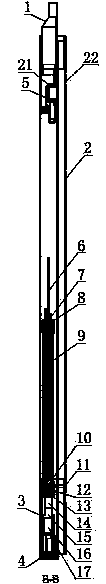

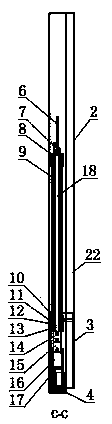

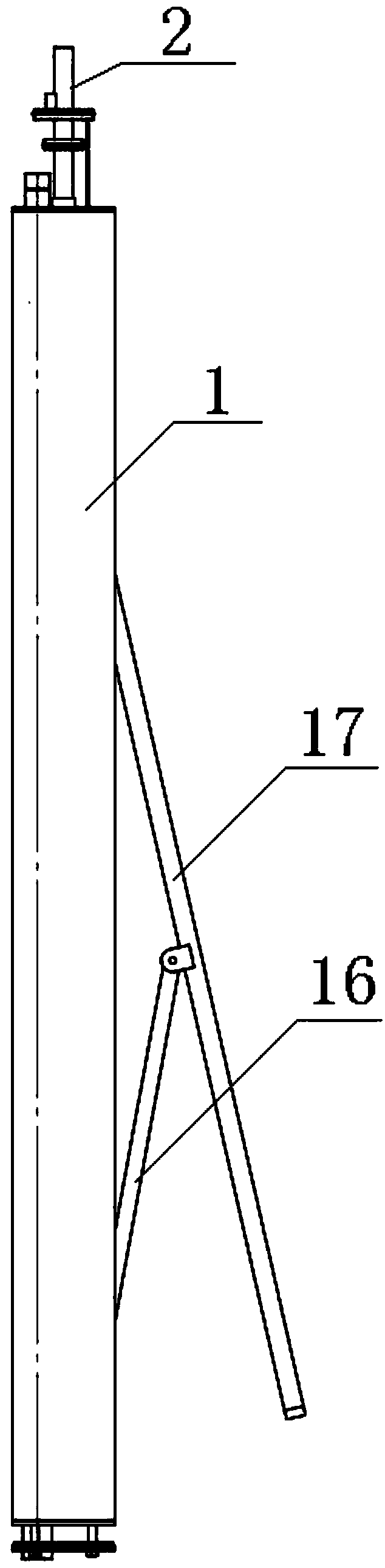

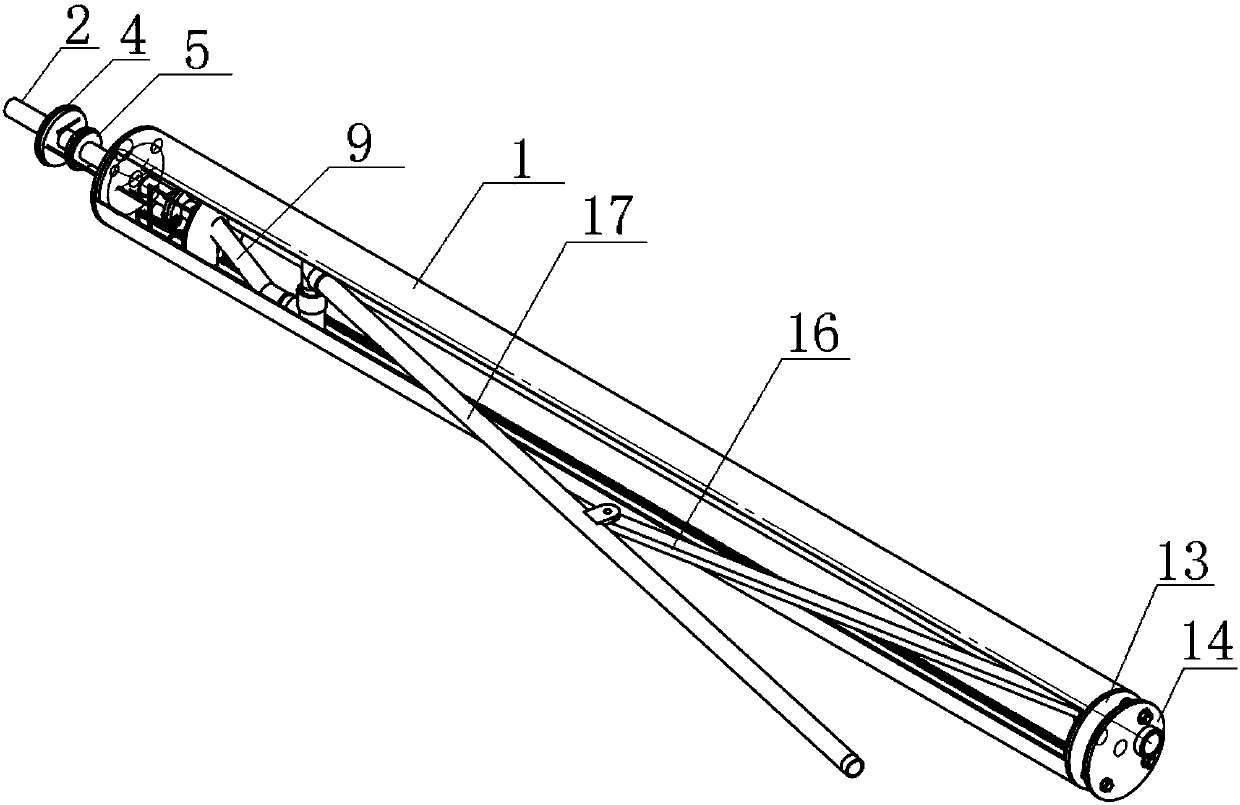

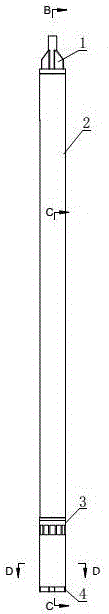

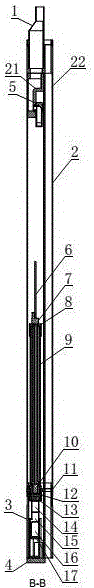

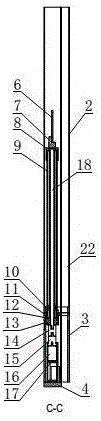

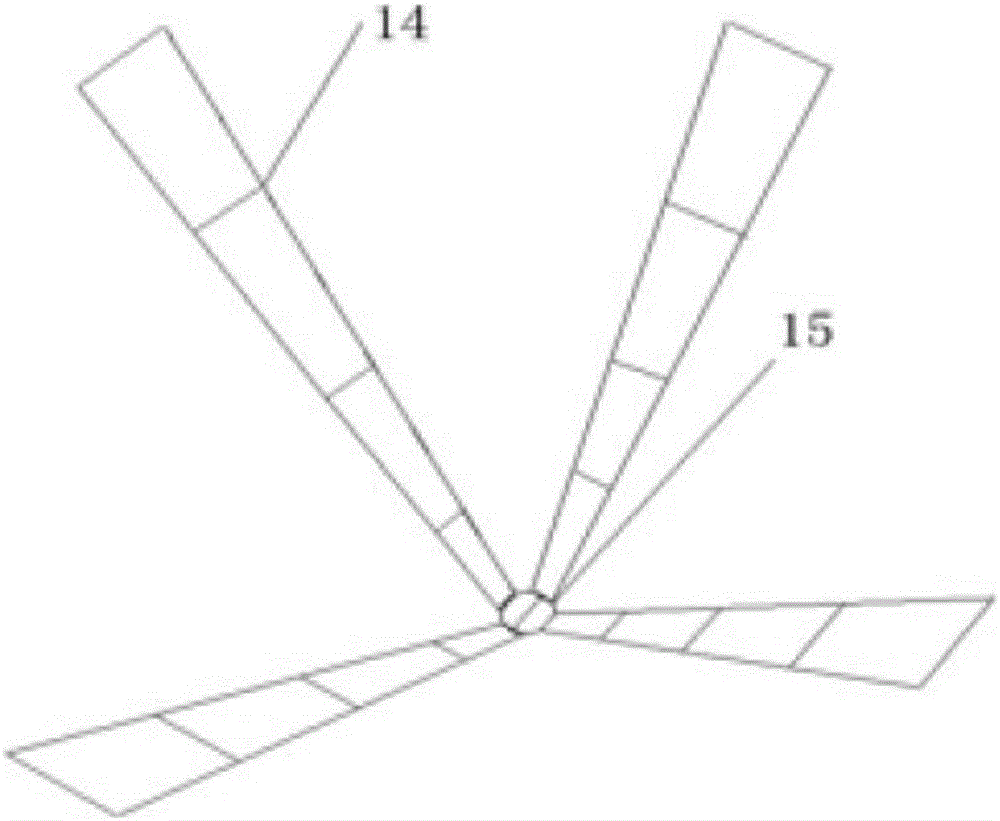

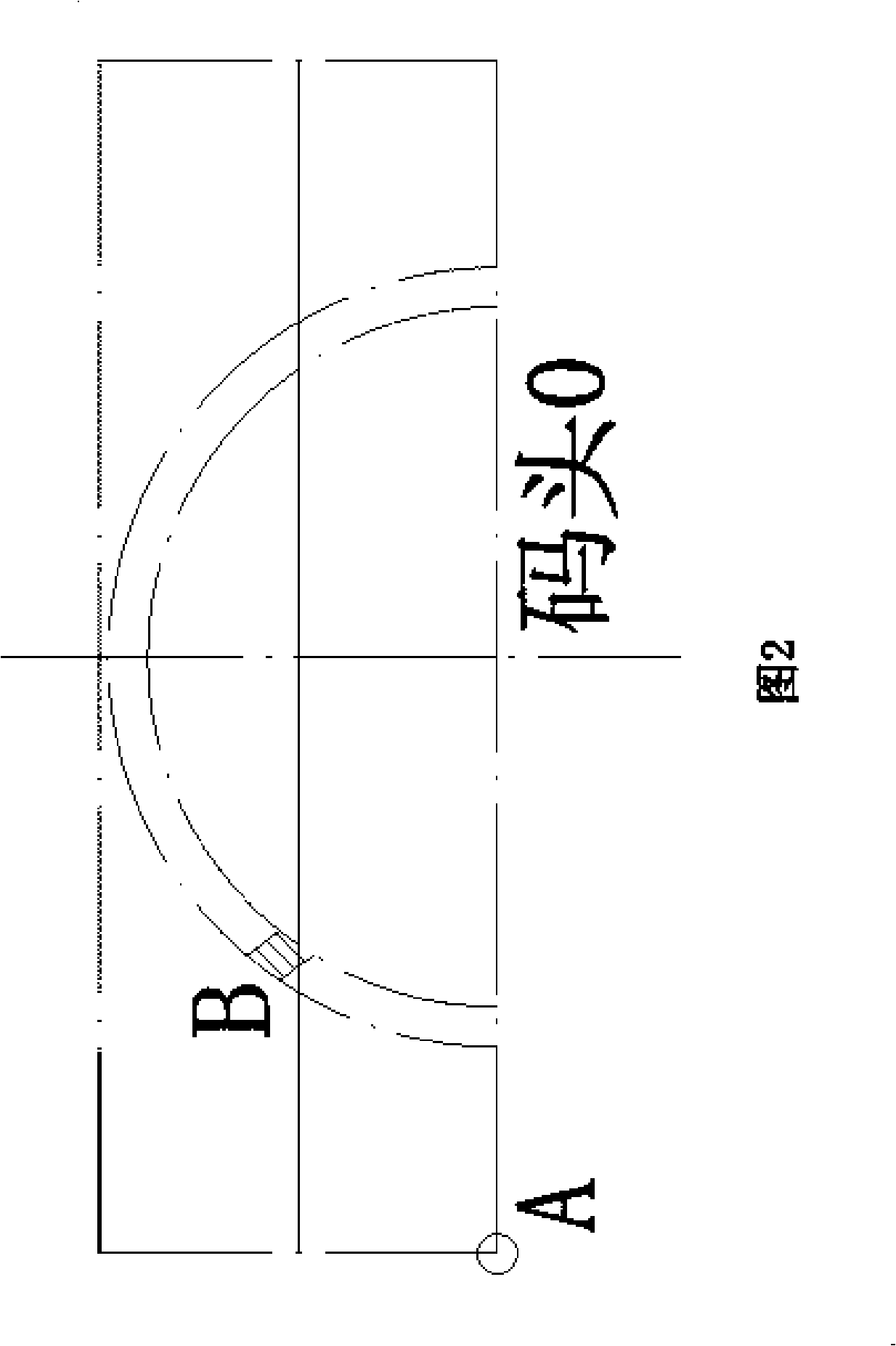

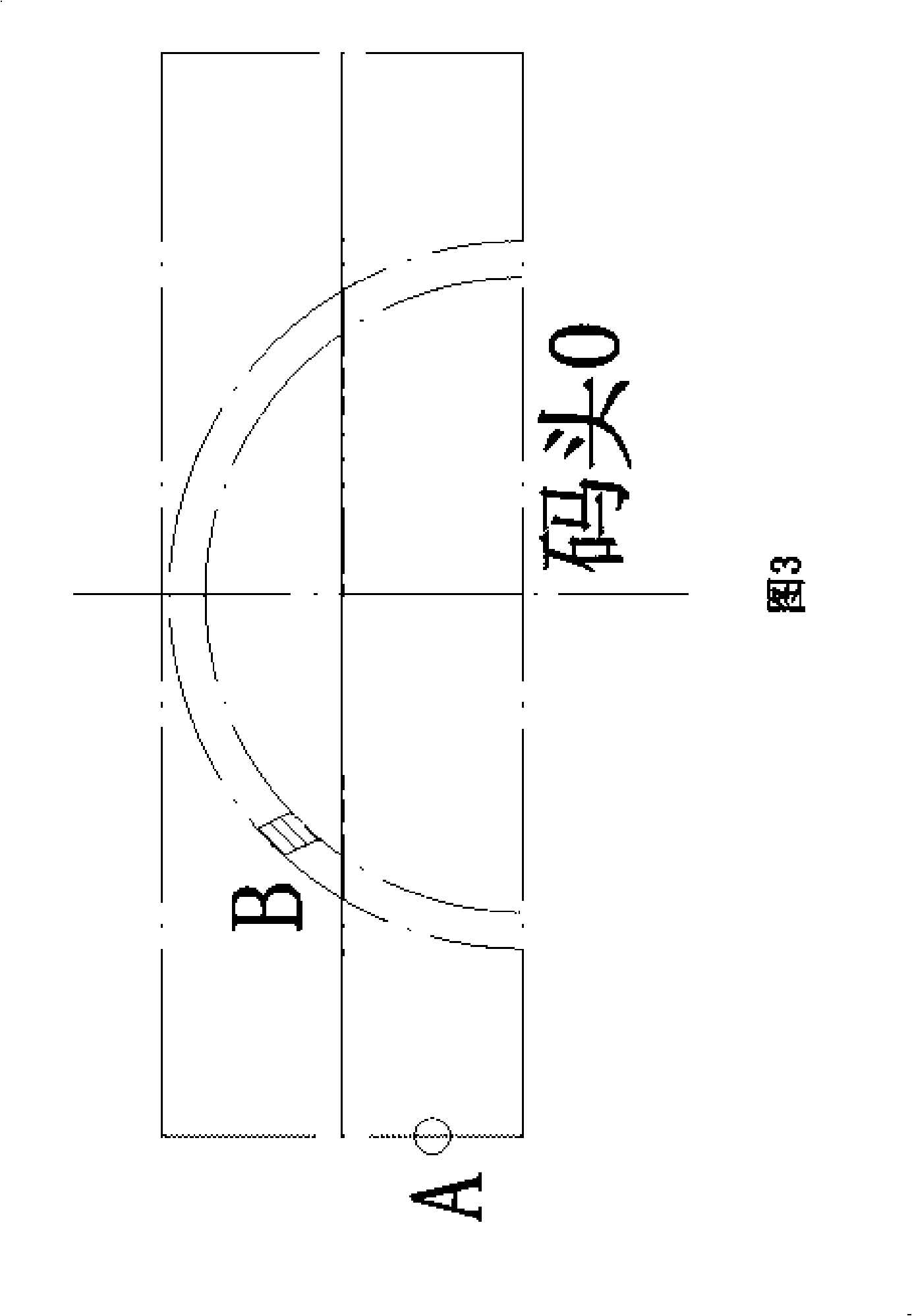

Mechanical type telescopic water gun based on gear and rack transmission

ActiveCN107939404AEasy to take backAvoid the problem of sharp weakening of high-pressure water energyHydraulic miningGear wheelEngineering

The invention discloses a mechanical type telescopic water gun based on gear and rack transmission. The mechanical type telescopic water gun mainly comprises a high pressure water pipe, an upper hydraulic pipe, a hydraulic pipe high-pressure rotary connector, a high-pressure water pipe rotary connector, racks, an eccentric adapter locking bolt, an eccentric adapter, a right-angle connector, an ejection rod, the water gun, a water gun high-pressure rotary connector, a sliding plate, gears, brake plate protective plates, a lower hydraulic pipe, a hydraulic cylinder and a brake plate, wherein ina hydraulic mining process, the high pressure water pipe is lowered according to a required stretching angle of the water gun; when the water gun reaches the set stretching angle, a brake system control valve is turned on to enable the brake plate to brake the gears, so that the stretching angle of the water gun can be fixed, and rocks are crushed. According to the mechanical type telescopic watergun disclosed by the invention, the stretching angle of the water gun is freely adjusted, and the water gun is conveniently stretched and retracted; a distance between a spray nozzle of the water gunand a mining layer is controlled according to the design, and the problem that high pressure water energy is severely weakened because of submerged jetting is solved, so that an aim of increasing anenergy utilization ratio of high-pressure water jetting is fulfilled, and finally, the mining efficiency is improved.

Owner:JILIN UNIV

Shortwall hydraulic mining method along strike

ActiveCN104632224AAdaptableReasonable process designHydraulic miningSpontaneous combustionEngineering

The invention provides a shortwall hydraulic mining method along strike and belongs to the technical field of coal mining. The mining method is used for solving the problems of difficult face ventilation, serious gas harm, imperfect ventilation system, poor operation safety, unavailability for coal seams with high gas and serious spontaneous combustion tendency, relatively narrow application range, low recovery ratio and the like of the traditional hydraulic mining methods. According to the shortwall hydraulic mining method along strike, stope ventilation is focused and the arrangement of a hydraulic mining tunnel and the support pattern of the working face are improved, and therefore, a mining method conforming to ventilation and gas control requirements is established. The shortwall hydraulic mining method along strike is reasonable in process design, safe and reliable, and capable of well meeting the requirements of the underground hydraulic mining operations; as a result, the effective support for an exposed roof on the hydraulic mining face and the reasonable ventilation of the working face are realized, and the coal mining efficiency and the operational safety are remarkably improved.

Owner:沈阳天安特种机器人有限公司

Comprehensive recovery method for copper and iron in copper tailings

ActiveCN105709920ASolve idle wasteSolve environmental problemsWet separationMechanical material recoveryRecovery methodResource utilization

The invention provides a comprehensive recovery method for copper and iron in copper tailings. The comprehensive recovery method includes the following steps that raw tailings are subject to hydraulic mining to prepare tailing slurry, then the tailing slurry is conveyed to a spiral chute for reselection and separation, reselected tailing slurry is thickened through a first pasty fluid thickener, and the thickened tailing slurry is used for tailing filling; reselected concentrate slurry is subject to water-ore separation through a thickener, separated water is recycled and reused, and separated ore sand is levigated through a mill; reground ore slurry is subject to the floatation processes of flotation roughing, primary selection, secondary selection and scavenging, and copper concentrates are recovered; scavenging tailings are subject to magnetic separation recovering to obtain iron ore concentrates; and magnetic separation tailings are thickened through a second pasty fluid thickener, and the thickened magnetic separation tailings are used for tailing filling. By means of the comprehensive recovery method, the copper and the valuable element iron in the copper tailings can be comprehensively recovered, the resource using rate can be improved, idle waste of the copper tailings is avoided, and environmental pollution is reduced.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Hydraulic mining device

The invention discloses a hydraulic mining device. The hydraulic mining device comprises a device box body, and the device box body is internally provided with a hydraulic giant base rotary cavity; and the hydraulic giant base rotary cavity is internally provided with a group of hydraulic giant mechanical arms and a driving device in a rotating fit mode, wherein the hydraulic giant mechanical armsare in longitudinal symmetry, can rotate and can automatically adjust the directions, and the driving device drives hydraulic giant mechanical arm bases to rotate. The hydraulic mining device has theadvantages that the structure is simple, the operation is convenient, after a machine is placed in front of a mining heap, the machine can automatically swing a hydraulic giant forearm by rotating ahydraulic giant base and starting a hydraulic giant forearm driving air cylinder and enable a hydraulic giant to enter a working position by starting hydraulic giant rear arm rotating air cylinders torotate hydraulic giant rear arms, then the hydraulic giant is started to start jetting, and then mining mechanical arms can automatically start to get back minerals and put the minerals into a dehydration cavity.

Owner:兰溪太纲电子科技有限公司

An electronically controlled single-action retractable drilling tool for hydraulic mining of boreholes

InactiveCN104018838BExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningBall screwDrivetrain

The invention discloses an electrically controlled single-action telescopic drilling tool for borehole hydraulic mining. The telescopic drilling tool consists of a high-pressure water delivery system, a power transmission system, an electrically controlled single-action system, a water gun arm extending-retracting system and a slag discharging pipeline. The designed water gun can stretch out for the design distance along the radial direction, so that the range of borehole hydraulic mining is greatly widened, and the production efficiency is improved. According to the power transmission system, the rotating angle and speed of a stepping motor can be accurately controlled by a computer, so the opening angle of the water gun can be accurately controlled, and the water gun can stably extend and retract by utilizing a transmission mode of a ball screw. Moreover, the drilling tool is provided with the electrically controlled single-action system, the rotation torque of the drilling tool is provided by the stepping motor of the electrically controlled single-action system instead of a drill stem, and a phenomenon that a power transmission cable is damaged in the process of rotating the drill stem is avoided.

Owner:JILIN UNIV

An electronically controlled telescopic drilling tool for hydraulic mining of boreholes

InactiveCN104005767BExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningBall screwDrivetrain

The invention discloses an electronic control telescopic drilling tool for borehole hydraulic mining. The electronic control telescopic drilling tool for the borehole hydraulic mining is composed of a high pressure water conveying system, a power transmission system, a hydraulic giant telescopic system and a deslagging channel. A hydraulic giant of the electronic control telescopic drilling tool can stretch out for a designed distance in the radial direction, the range of the borehole hydraulic mining is enlarged greatly, and production efficiency is improved. The electronic control telescopic drilling tool for the borehole hydraulic mining has the advantages that the rotating angle and speed of a stepping motor can be controlled accurately through a computer, the opening angle of the hydraulic giant can be controlled precisely, and the stretching and retracting actions of the hydraulic giant are stable through the transmission mode of a ball screw.

Owner:JILIN UNIV

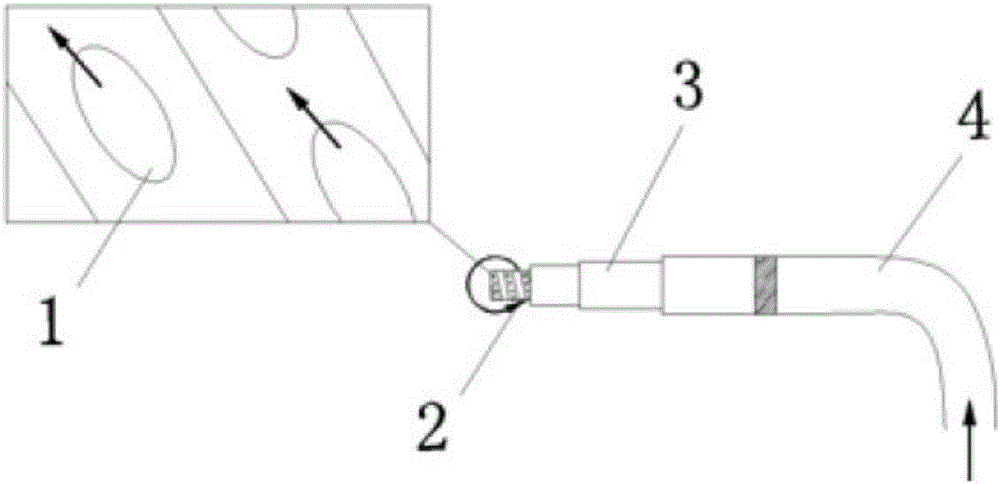

Low-frequency pulsing sonic and hydraulic mining method

ActiveUS9995127B1Improve economyHigh slurry recovery rateDisloding machinesLiquid/gas jet drillingCouplingBorehole mining

Enhanced method for borehole mining comprising: drilling a borehole using a low-frequency pulsing sonic, hydraulic mining system including a pulsed jet assembly; inserting casing into the borehole above target deposit depth; inserting and rotating assembly into the casing with a sub-coupling and a shoe rock bit positioned below the casing; pumping fluid into the borehole; evaluating slurry at surface; fracturing and disaggregating materials at target deposit with pulsing jets from the sub-coupling and rock bit causing light slurry to flow upwardly to the annulus between the borehole casing and the downhole assembly, then upwardly through the annulus to the surface of the borehole thereby causing heavy slurry to concentrate in a sump, located below the pulse jet rock bit; continuing to form cavity at target location; removing pulsed jet assembly from borehole; running core barrel to extract heavy slurry from sump; analyzing slurry to determine whether to continue with operation.

Owner:GEODRILLING TECH INC

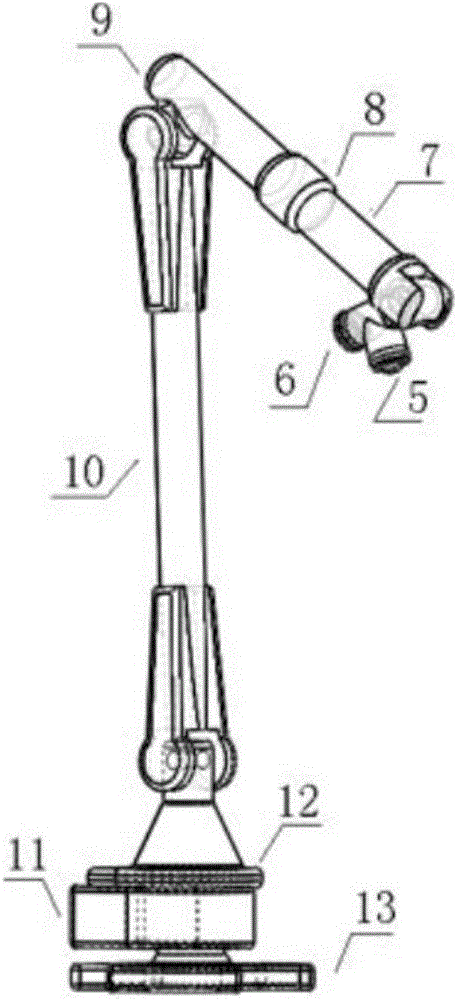

Drilling hydraulic mining downhole excavating robot

InactiveCN106593438ASmooth flowbackEasy to operateDisloding machinesSlitting machinesMovable typeHigh pressure

The invention discloses a drilling hydraulic mining downhole excavating robot comprising at least a hydraulic giant part, a mechanical force arm, a mechanical arm protective cover, a movable type carrying platform, a robot power transmission device and a robot self-balancing device. A water supply hose joint of the hydraulic giant part is welded to a hollow drill column of the mechanical force arm. A protective cover joint is arranged on the hollow drill column. The mechanical arm protective cover is jointed with the protective cover joint through an inner hexagon screw. A mechanical force arm seat at the bottom of the mechanical force arm is fixed on the movable carrying platform through a bolt, the movable carrying platform is erected on the robot power transmission device, and the robot self-balancing device is erected in the robot power transmission device. The excavating robot can be used for achieve 360-degree all-dimensional intelligentized exploitation in spread space of underground ore bodies, and is suitable for the severe environment such as high temperature and high pressure of a deep hole. Drilling efficiency and drilling quality in the exploration drilling process can be improved obviously, the exploration drilling cost is reduced and production security is increased.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

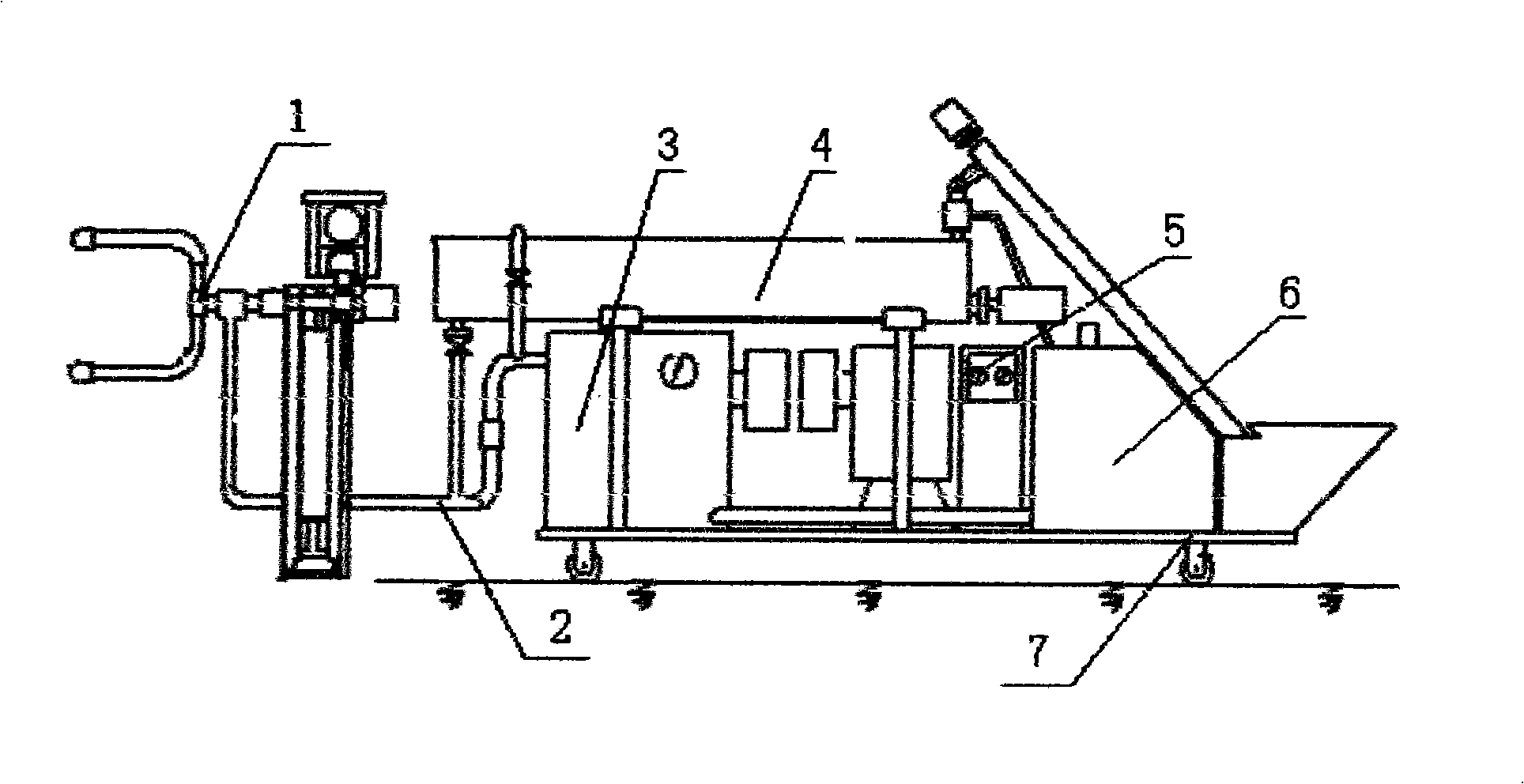

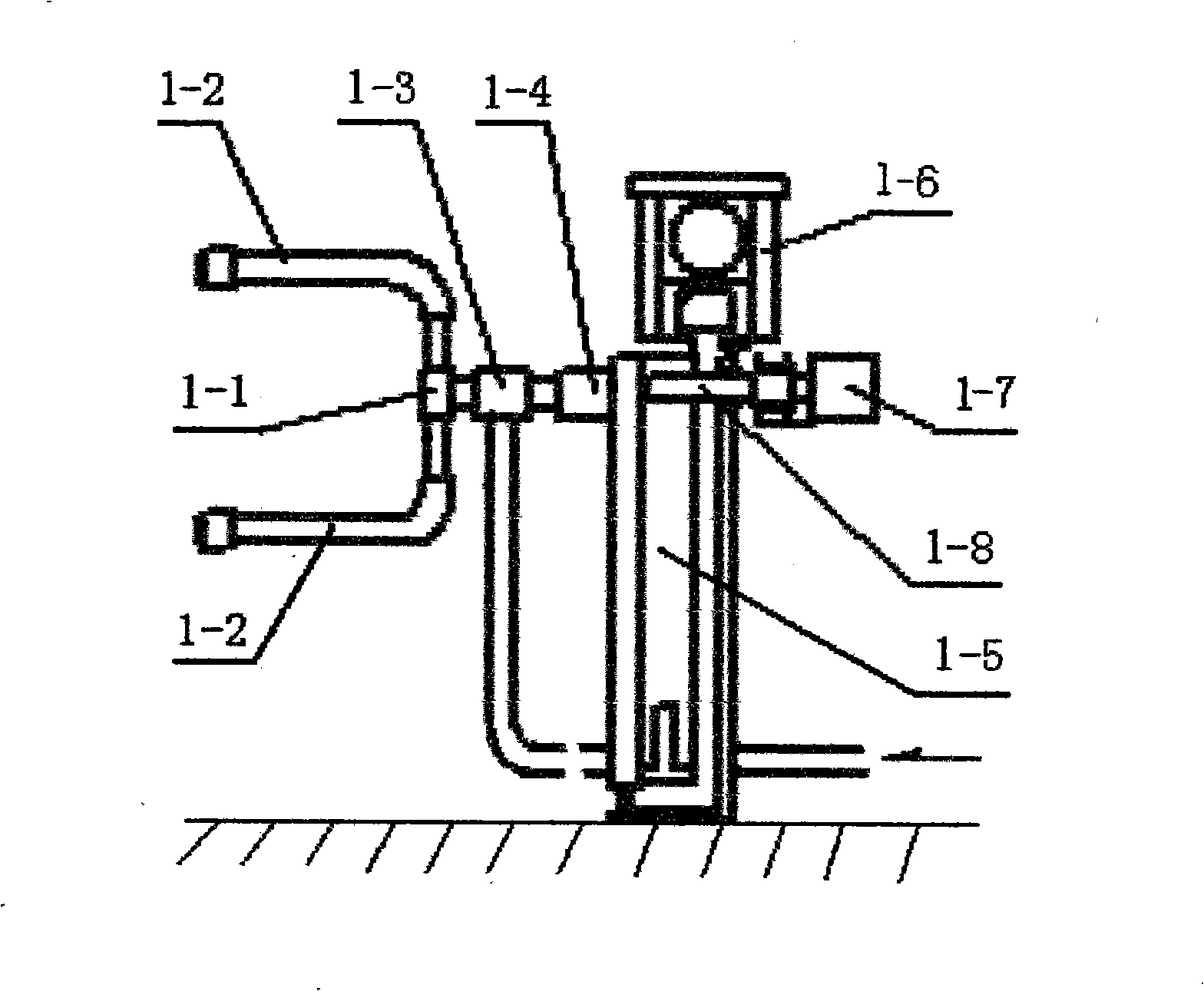

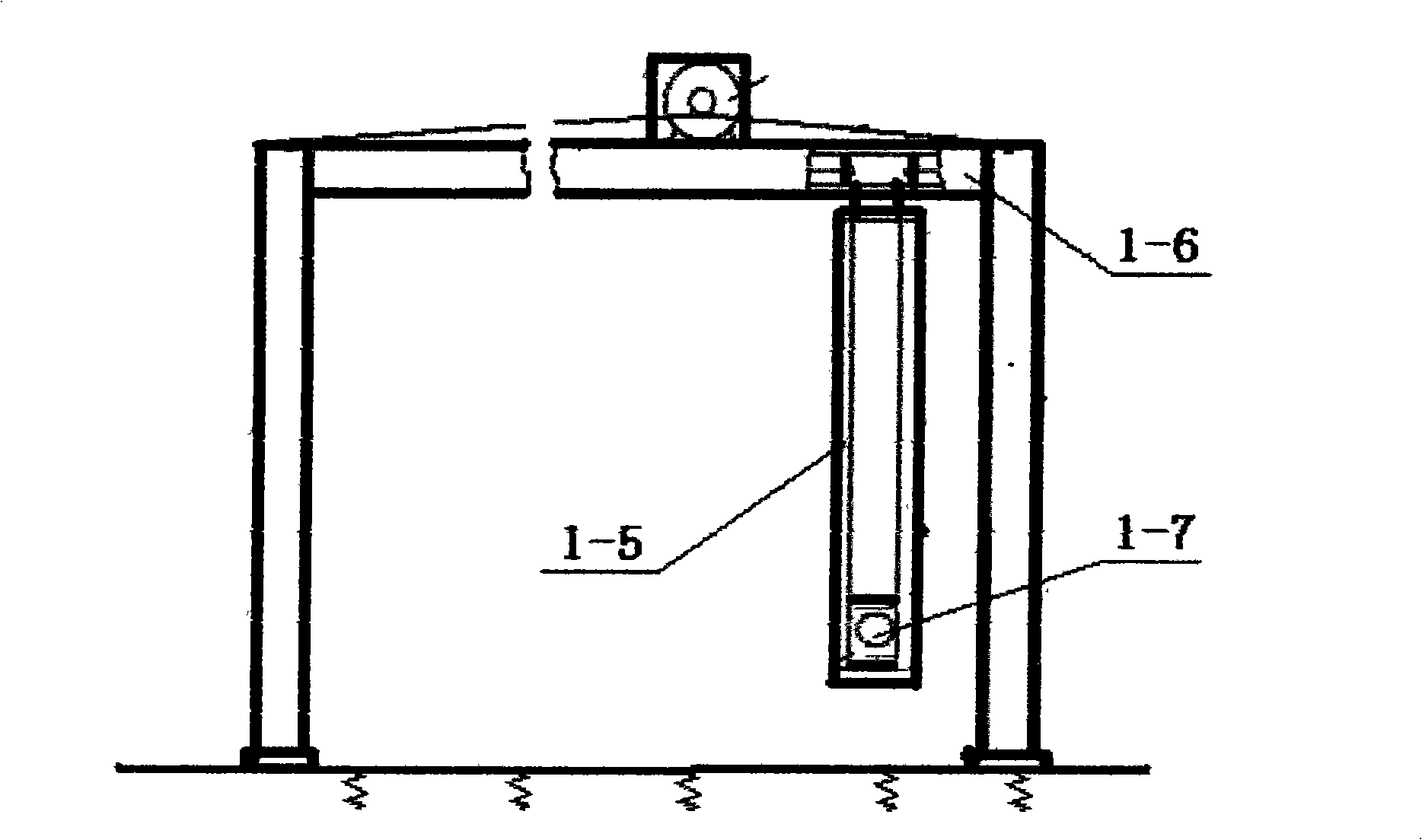

Easy hydraulic extraction machine

The invention relates to the manufacturing field of a mining machine, in particular to a simple hydraulic mining machine. The simple hydraulic mining machine is characterized in that a high-pressure hydraulic pump unit (3), a front mixing type abradant continuous mixing device (4), a control operating platform (5) and a wastewater recovery processing system (6) are fixed on a self-propelled flat car (7) to form the body of the machine; and a hydraulic cutter moving mechanism (1) is connected with the body through a water sand mixing transport pipe manifold (2). The simple hydraulic mining machine which has the advantages of environmental protection, energy conservation, small size, light weight, low cost, high efficiency, safety and reliability can meet the requirements of extracting lump ores, and improve the labor intensity and working environment of operators.

Owner:XIAN DONGXIN GASOLINEEUM EQUIP PLANT

Simple and convenient hydraulic mining method and equipment

The invention relates to the manufacturing field of mining machinery, in particular to simple and convenient hydraulic mining method and equipment, characterized in that high-pressure hydraulic cutting equipment is adopted to cut ores on extracting surfaces into a plurality of relatively regular autonomous blocks in geometry regions, and then the ores in the form of the relatively regular autonomous blocks in the geometry regions are broken by a simple ore breaking tool to fall off the ground. The simple and convenient hydraulic mining equipment is characterized by comprising the high-pressure hydraulic cutting equipment and the simple ore breaking tool which are separate mutually and are separately used. The simple and convenient hydraulic mining method and equipment have the advantages of environment protection, energy saving, small size, light weight, low cost, high efficacy, safety and reliability, and can meet the requirement of exploiting large ores and also improve the work intensity and the working conditions of operators.

Owner:XIAN DONGXIN GASOLINEEUM EQUIP PLANT

Mechanical telescopic water gun based on turbo-worm transmission

PendingCN108266128AAvoid sharply weakening problemsImprove energy utilizationConstructionsLiquid/gas jet drillingSlagSpray nozzle

The invention discloses a mechanical telescopic water gun based on turbo-worm transmission. The mechanical telescopic water gun comprises a worm, a guide rod, a worm gear protecting plate, a sliding plate, a worm gear, an ejector rob, a water gun, a right-angle joint, a water gun high-pressure rotary joint, an eccentric connecting pipe, a top end cover, a slag discharge pipe and a high-pressure water pipe. In the process of hydraulic mining, the worm can be rotated according to the extension angle of the required water gun, and when the water gun reaches the set extension angle, the rotation of the worm can be controlled to fix the extension angle of the water gun and to crush the rock. The extension angle of the water gun is freely adjusted, and is convenient to extend and retract; and the distance between a nozzle of the water gun and ore bed can be controlled according to the design, the problem that the energy of high-pressure water is sharply reduced due to the submerged jet is avoided, so that the purpose of improving the energy utilization rate of high-pressure water jet is achieved, and finally the mining efficiency is improved.

Owner:JILIN UNIV

Lubricated cartridge for hydraulic mining shovel track

A cartridge assembly for a track chain includes a bushing and a track pin. The bushing has an outer surface and an inner surface, the inner surface defining a passage in the form of a cylindrical bore. The bushing forms a lubrication reservoir adjacent the inner surface and extending towards the outer surface of the bushing. The track pin is disposed within the cylindrical bore, and the bushing isrotatable with respect to the track pin. An outer surface of the track pin is in fluid communication with the lubrication reservoir. The outer surface of the bushing corresponds with an outer diameter of the cartridge assembly. The outer diameter of the cartridge assembly is less than a diameter of supporting bores such that the cartridge assembly is rotatable with respect to inside surfaces of the supporting bores.

Owner:CATERPILLAR INC

Salt-field collection operation method

InactiveCN101264903AAvoid bendingAvoid breaking accidentsAlkali metal chloridesEngineeringHydraulic mining

The invention discloses an operation method for harvesting salt field, which is characterized in that according to the positions of hydraulic mining ship and wharf, under the control of GPS system, fold and snap accident of the floating pipeline in harvesting process by the movement of anchor ship position is avoided completely, greatly increasing stability of coal mining and reducing maintenace expenditure of equipment.

Owner:安徽煌盛环境科技有限公司

Jetting device for oil-shale drill hydraulic mining

ActiveCN111535812AImprove adaptabilityImprove mining efficiencyLiquid/gas jet drillingHydraulic miningThermodynamicsWater flow

Owner:东港智科产业园有限公司

Hydraulic mining control method

The invention discloses a hydraulic mining control method. According to the hydraulic mining control method, a hydraulic mining head direction control device is used and comprises a control head; a power unit is arranged in the control head and comprises a driving motor, a first driving cavity and a second driving cavity, wherein the first driving cavity and the second driving cavity are arrangedon the left side and the right side; the transmission is transmitted into the first driving cavity and the second driving cavity through the driving of the driving motor; and an upper left control part is arranged above the first driving cavity. The hydraulic mining control method has the advantages that the structure is simple, the operation is convenient, the water spraying direction can be flexibly controlled by controlling starting of a lower left control part, an upper right control part, the upper left control part and a lower right control part, the positions before and after mining canbe changed under the action of an air cylinder, flexible mining can be carried out with the cooperation of the flexible change of the water spraying direction, and ores which are difficult to mine under general technical conditions can be mined.

Owner:台州椒江起临农业机械科技有限公司

Electrically controlled single-action telescopic drilling tool for borehole hydraulic mining

InactiveCN104018838AExpansion of mining areaIncrease productivityLiquid/gas jet drillingHydraulic miningDrivetrainBall screw

The invention discloses an electrically controlled single-action telescopic drilling tool for borehole hydraulic mining. The telescopic drilling tool consists of a high-pressure water delivery system, a power transmission system, an electrically controlled single-action system, a water gun arm extending-retracting system and a slag discharging pipeline. The designed water gun can stretch out for the design distance along the radial direction, so that the range of borehole hydraulic mining is greatly widened, and the production efficiency is improved. According to the power transmission system, the rotating angle and speed of a stepping motor can be accurately controlled by a computer, so the opening angle of the water gun can be accurately controlled, and the water gun can stably extend and retract by utilizing a transmission mode of a ball screw. Moreover, the drilling tool is provided with the electrically controlled single-action system, the rotation torque of the drilling tool is provided by the stepping motor of the electrically controlled single-action system instead of a drill stem, and a phenomenon that a power transmission cable is damaged in the process of rotating the drill stem is avoided.

Owner:JILIN UNIV

Goal Shortwall Hydraulic Mining Method

ActiveCN104632224BAdaptableReasonable process designHydraulic miningSpontaneous combustionEngineering

Owner:沈阳天安特种机器人有限公司

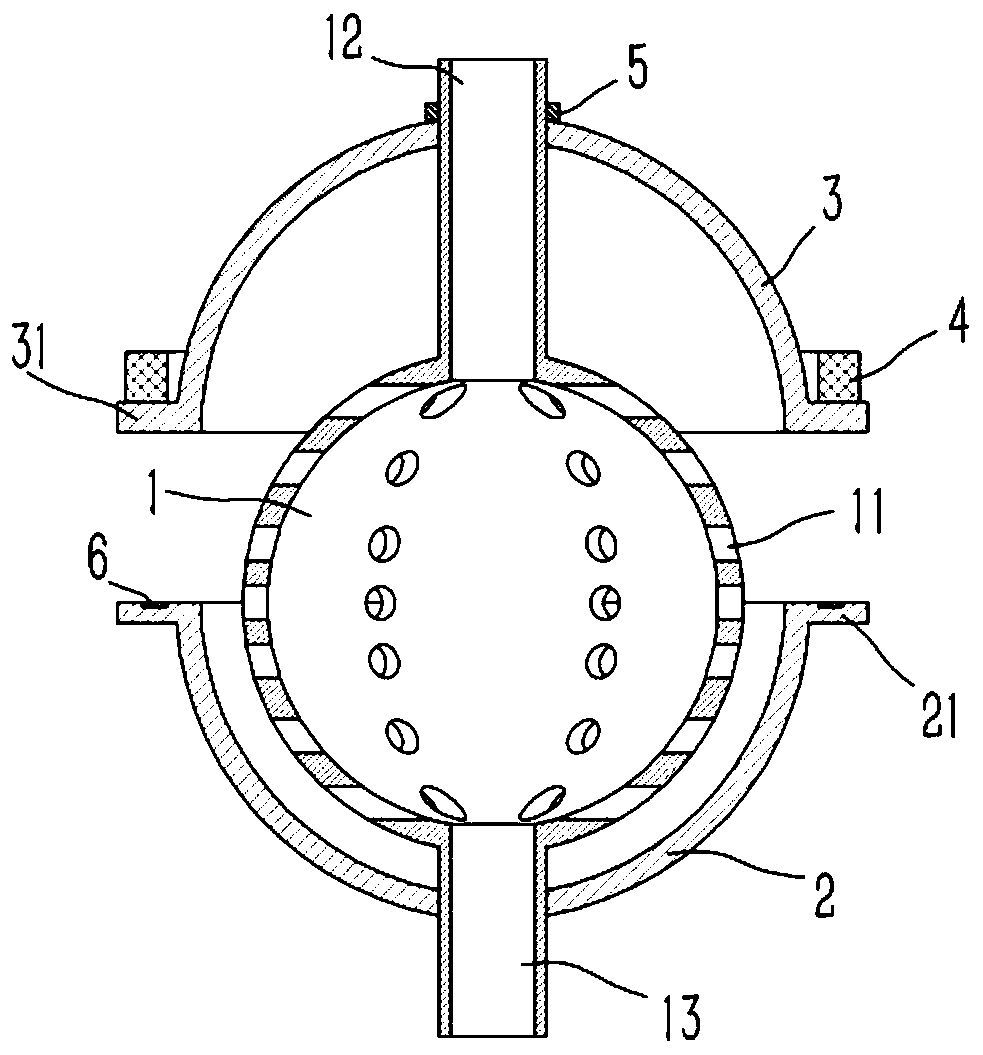

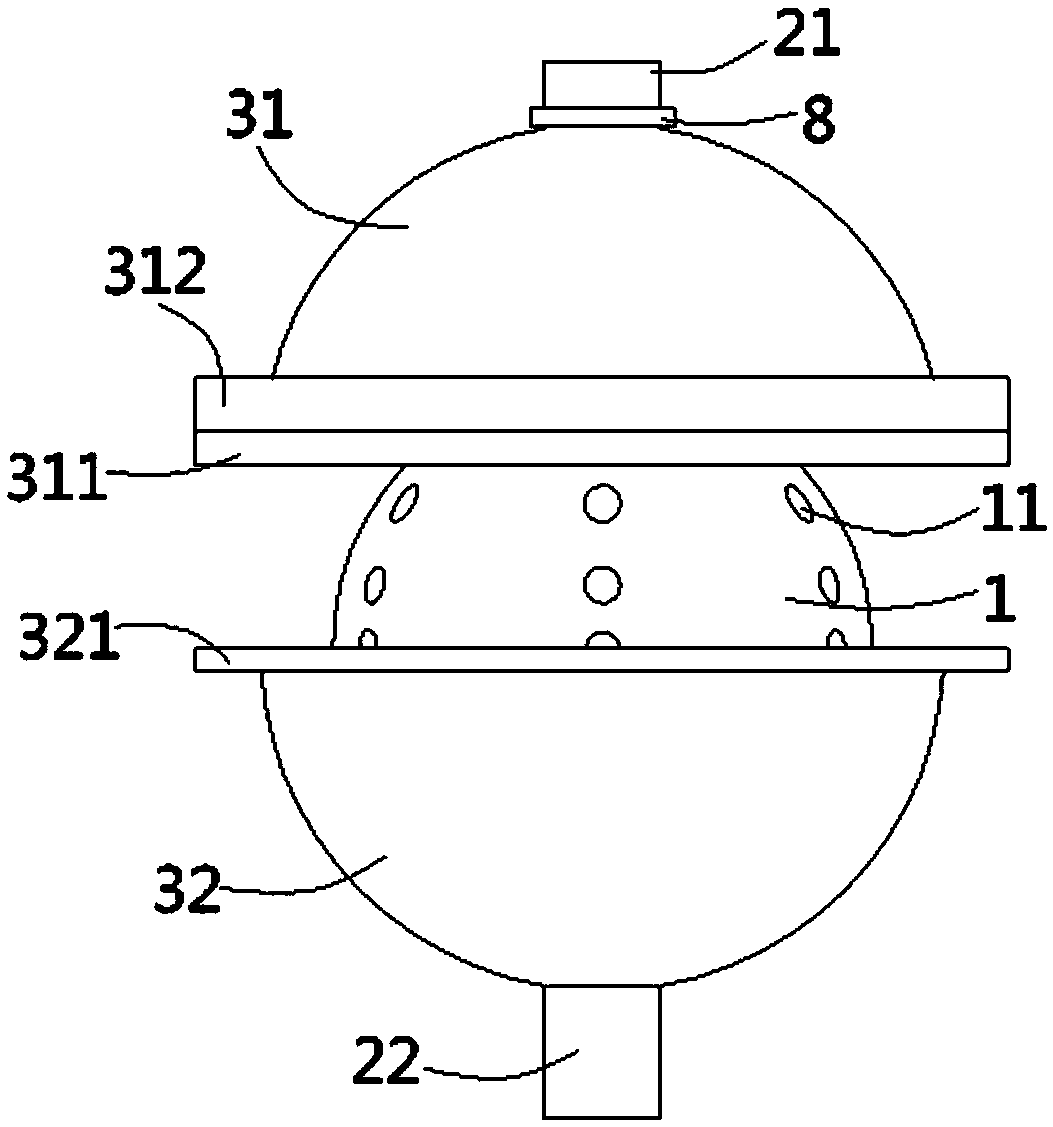

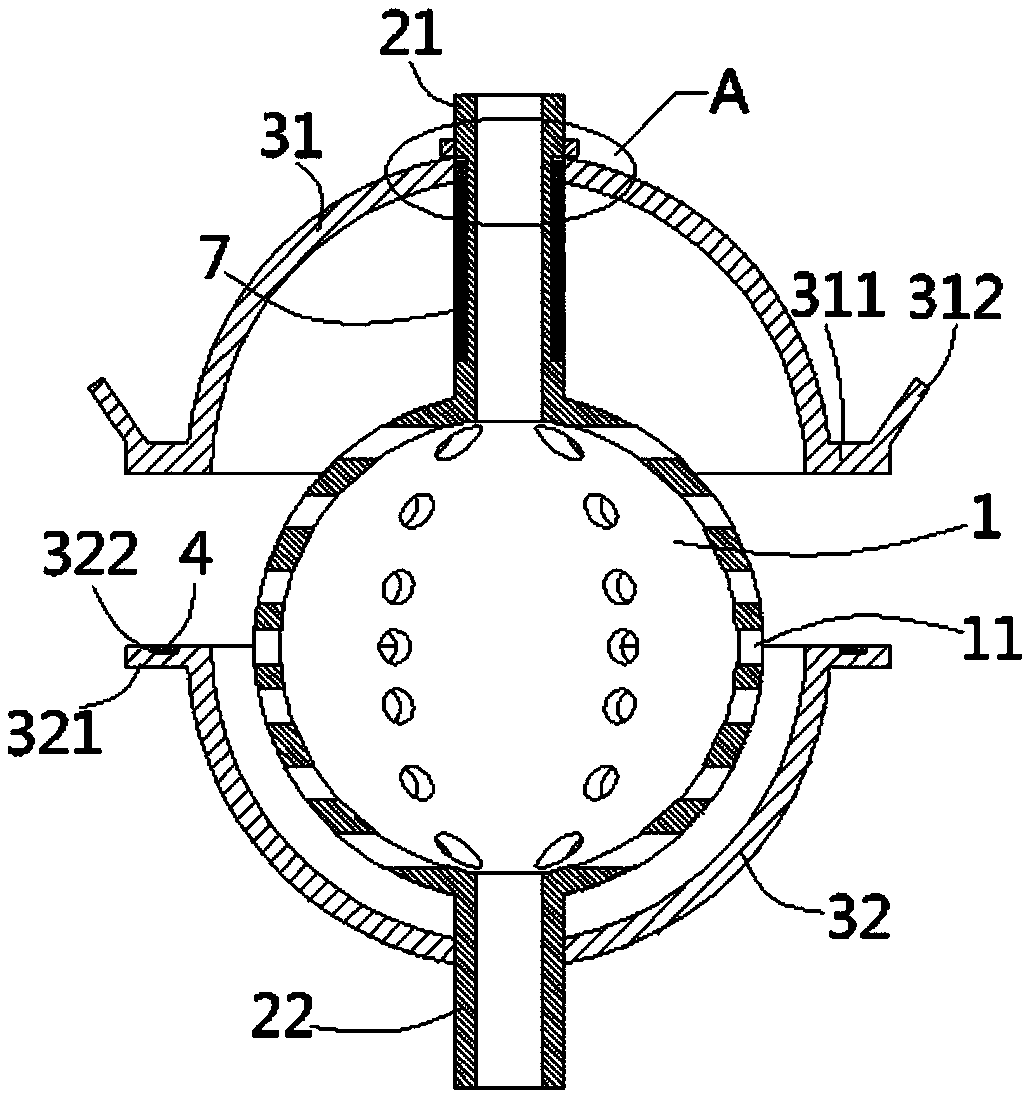

A spherical drain water collector for hydraulic mining

The invention discloses a spherical drain water collector for hydraulic mining. The spherical drain water collector includes a spherical water collector body, a plurality of drainage holes are formedin the water collector body, an upper connecting pipe is formed at the top end of the water collector body, and a lower connecting pipe is formed at the bottom end of the water collector body. A semispherical lower shell is fixed to the lower connecting pipe in an inserting-sleeving mode, the outer side of the water collector body is sleeved with the lower shell in an inserting mode, and a horizontal and annular lower retaining side is formed on the upper side edge of the lower shell. The upper connecting pipe is sleeved with a semispherical upper shell in an inserting mode, an opening of theupper shell faces down, a horizontal and annular upper retaining side is formed on the lower side edge of the upper shell, an annular floating ring is fixed to the upper end face of the upper retaining side, and a limiting ferrule is fixed to the upper connecting pipe and located on the upper side of the upper shell in an inserting-sleeving mode. The spherical drain water collector for hydraulic mining is simple in structure and conducive to the drainage in a mine tunnel, and at the same time, the blockage condition can be reduced.

Owner:罗茜

A multifunctional coal mining hydraulic protection arm raking support device

The present invention relates to a raking support device for a multi-functional coal mining hydraulic protective arm. The device includes: an overturning cover beam, an overturning cover beam jack, a top beam, a hydraulic column, a cover beam, a front connecting rod, a rear connecting rod, a base, Scraper conveyor, protective arm support jack, energy-absorbing protective plate, protective arm, rake coal hopper jack, telescopic arm jack, telescopic arm, rake coal hopper, the flip cover beam is connected with the flip cover beam jack, the flip The cover beam, the overturn cover beam jack, the hydraulic column, and the cover beam are respectively connected with the top beam, the cover beam is connected with the front link and the rear link, and the hydraulic column, scraper conveyor, front link, rear link and The base is connected, the telescopic arm jack is connected with the telescopic arm, the protective arm support jack is connected with the protective arm, the protective arm is connected with the energy-absorbing protective plate, and the protective arm is arranged on the multifunctional coal mining hydraulic protective arm. Rake mount bracket unit front.

Owner:BEIJING CHENGTIAN HENGYE COAL MINE EQUIP CO LTD

Spherical draining and water-collecting device for hydraulic mining

The invention discloses a spherical draining and water-collecting device for hydraulic mining. The spherical draining and water-collecting device comprises a spherical water collector. Draining holesare formed in the water collector. An upper connecting pipe is formed at the top end of the water collector, and a lower connecting pipe is formed at the bottom end of the water collector. A hemispherical lower shell is fixed to the lower connecting pipe in an inserted-sleeving mode. The upper connecting pipe is sleeved with a hemispherical upper shell in an inserted mode. An annular upper retaining side is formed at the side edge of the lower end of the upper shell. An annular lower retaining side is formed at the side edge of the upper end of the lower shell. An inclined annular flanging isformed at the outer side edge of the upper retaining side. A spherical sealed body can be formed by the upper shell and the lower shell. A plurality of inserted-connecting blocks are formed on the inner wall of the upper end of the upper shell. A plurality of vertical guiding grooves are formed in the outer wall of the upper connecting pipe. The inserted-connecting blocks are connected into the guiding grooves in an inserted mode. Pressure springs are arranged in the guiding grooves. The two ends of the pressure springs abut against the inserted-connecting blocks and the inner walls of the bottoms of the guiding grooves correspondingly. According to the spherical draining and water-collecting device, draining in a mine can be facilitated, and meanwhile, the blockage condition can be reduced.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Experimental system and method for simulating geological deformation caused by hydrate thermal exploitation

InactiveCN112665986BImprove mining efficiencyAvoid geological disastersMaterial strength using tensile/compressive forcesUsing optical meansTemperature controlDeformation monitoring

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com