Regenerated resin sand for sand mold and preparation process thereof

A technology for regenerating resin and sand molds, applied in casting molding equipment, molds, cores, etc., can solve the problems of increasing environmental protection costs and pressures, a large amount of acid-base waste water, etc., to improve the penetration resistance of molten metal and improve the compactness. , the effect of good plastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

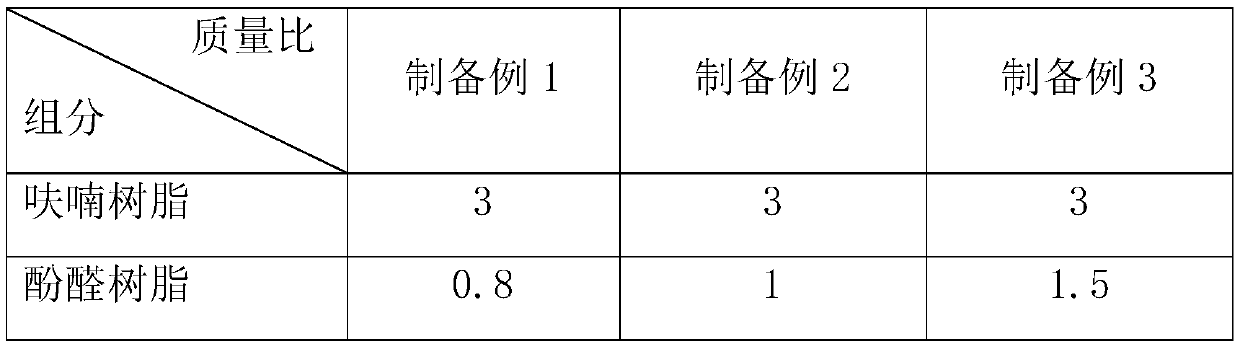

Examples

Embodiment 1

[0046] Embodiment 1: a kind of preparation technology of regenerated resin sand for sand mold, comprises the following steps:

[0047] S301. Old sand crushing: add the used waste sand to the jaw crusher for coarse crushing, and the coarsely crushed old sand is crushed by the roller machine;

[0048] S302, magnetic separation treatment: add the secondary pulverized old sand obtained in step S301 into a magnetic separator with a magnetic field strength of 0.8T, and separate the metal residues in the old sand after magnetic separation;

[0049]S303. Roasting and purification: put the old sand in step S302 into a roasting furnace for roasting, first set the furnace temperature to 250°C, and roast for 2 hours, then set the furnace temperature to 700°C, and continue roasting for 1 hour;

[0050] S304, crushing and sieving: cooling the roasted sand to below 60°C, and then crushing and sieving to obtain a regenerated sand preparation;

[0051] S305. Washing and drying: rinse the recl...

Embodiment 2

[0055] Embodiment 2: a kind of preparation technology of regenerated resin sand for sand mold, comprises the following steps:

[0056] S301. Old sand crushing: add the used waste sand to the jaw crusher for coarse crushing, and the coarsely crushed old sand is crushed by the roller machine;

[0057] S302, magnetic separation treatment: add the secondary pulverized old sand obtained in step S301 into a magnetic separator with a magnetic field strength of 0.8T, and separate the metal residues in the old sand after magnetic separation treatment;

[0058] S303. Roasting and purification: put the old sand in step S302 into a roasting furnace for roasting, first set the furnace temperature to 300°C, roast for 2.5 hours, then set the furnace temperature to 750°C, and continue roasting for 1.5 hours;

[0059] S304, crushing and sieving: cooling the roasted sand to below 60°C, and then crushing and sieving to obtain a regenerated sand preparation;

[0060] S305. Washing and drying: ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com