A magnetic gravity screening process for mixed iron ore

An iron ore and process technology, which is applied in the field of magnetic gravity screening of mixed iron ore, can solve the problems of difficult separation, large magnetic difference between magnetite and iron oxide ore, and high processing cost, so as to reduce the cost of ore dressing, The effect of low SiO2 content and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

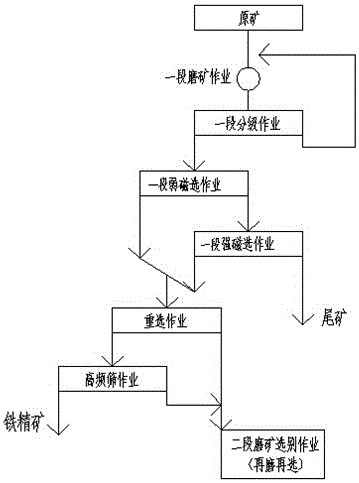

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the specific embodiment of Anhui Jinrisheng Mining Co., Ltd. Zhouyoufang Concentrator, the present invention will be further elaborated, but not limited to the following embodiments:

[0027] 1) After the mixed iron ore produced by Zhouyoufang Iron Mine and specularite is crushed, it is first fed into a ball mill for grinding operation, and after the grinding and grading closed-circuit cycle operation process, the grading overflow fineness is controlled At -200 mesh 45-55%, the monomer dissociation degree of useful mineral magnetite and iron oxide ore can reach 70-80%, realizing the effective dissociation of 2 / 3 to 4 / 5 useful minerals and gangue minerals , the graded product is ore pulp, and the concentration of the ore pulp is 35-45% which is suitable for the separation operation requirements;

[0028] 2) The grinding and grading operation in step 1) is a closed-circuit cycle operation process, that is, the ore pulp after grinding by the mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com