Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Contain less impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

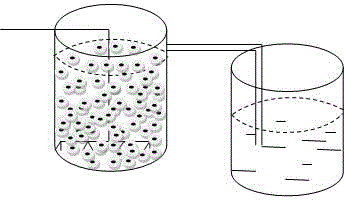

Separation method for 1,5-pentanediamine

ActiveCN108276292AHigh purityContain less impurityAmino compound purification/separationChemistryPolyamide

The invention discloses a separation method for 1,5-pentanediamine. The separation method comprises the following steps: (1) contacting a 1,5-pentanediamine solution with cationic resin and carrying out adsorption; and (2) eluting 1,5-pentanediamine adsorbed onto the resin. Compared with the prior art, the separation and recovery method for 1,5-pentanediamine in the invention increases the yield of 1,5-pentanediamine; a treated solution obtained after adsorption by resin is basically free of 1,5-pentanediamine residues and the resin does not adsorb tetrahydropyridine, thalli, proteins and other impurities, so separated 1,5-pentanediamine is high in purity and low in impurity content; and the treated solution obtained after resin adsorption does not contain any polar organic solvent, so thesolution is free of harm to environment and easy to treat, and environmental pollution and separation cost are reduced. Meanwhile, a 1,5-pentanediamine diacid solution obtained after elution with diacid can be directly used as a raw material for synthesis of high-performance polyamide.

Owner:CATHAY R&D CENT CO LTD

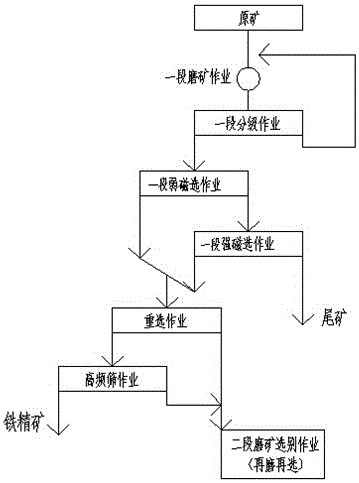

Magnetic ore rescreening process for mixed iron ore

ActiveCN104190522AReasonable workmanshipReliable technologyGrain treatmentsWet separationMonomerMaterials science

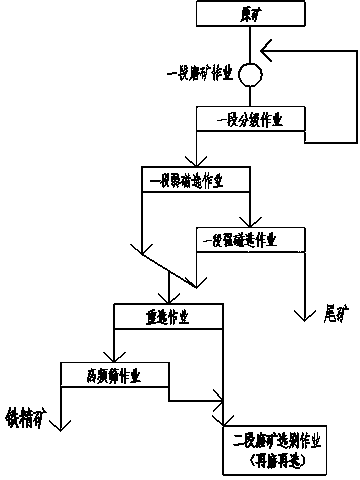

The invention discloses a magnetic ore rescreening process for mixed iron ore. The process comprises the following process steps: performing primary ore grinding, performing primary grading, performing primary low intensity magnetic separation, performing primary strong magnetic separation, rescreening, performing high frequency screening and performing secondary ore grinding and selecting. According to the invention, partial qualified iron ore concentrate and partial tailings are thrown out preferentially under the condition that the dissociation degree of useful mineral monomers is insufficient after the primary ore grinding operation, the amount of materials subjected to secondary regrinding and reselecting is reduced, and the aim of reducing the ore dressing cost is achieved.

Owner:ANHUI JINRISHENG MINING

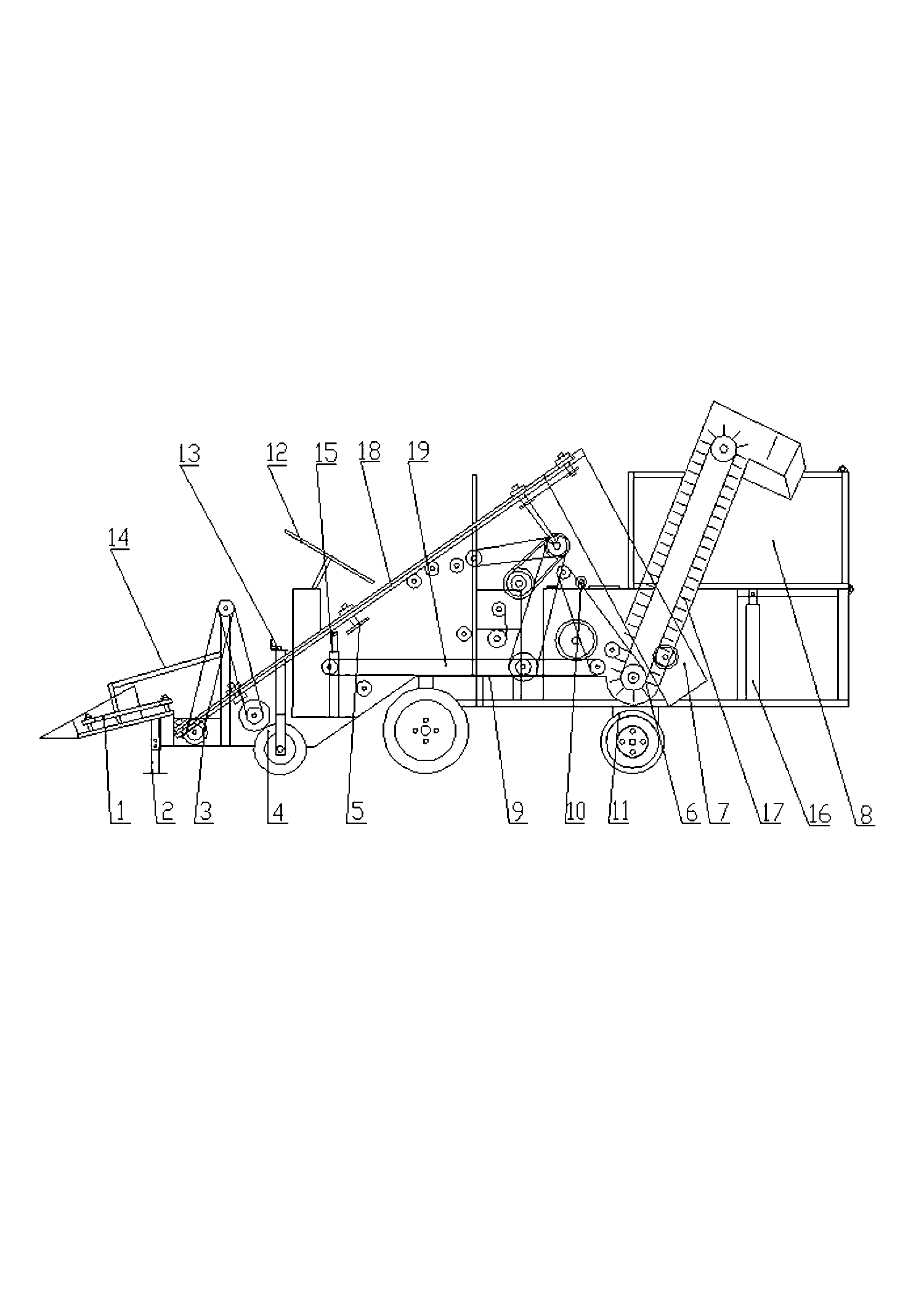

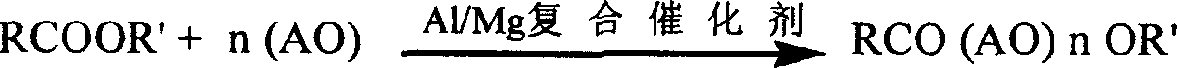

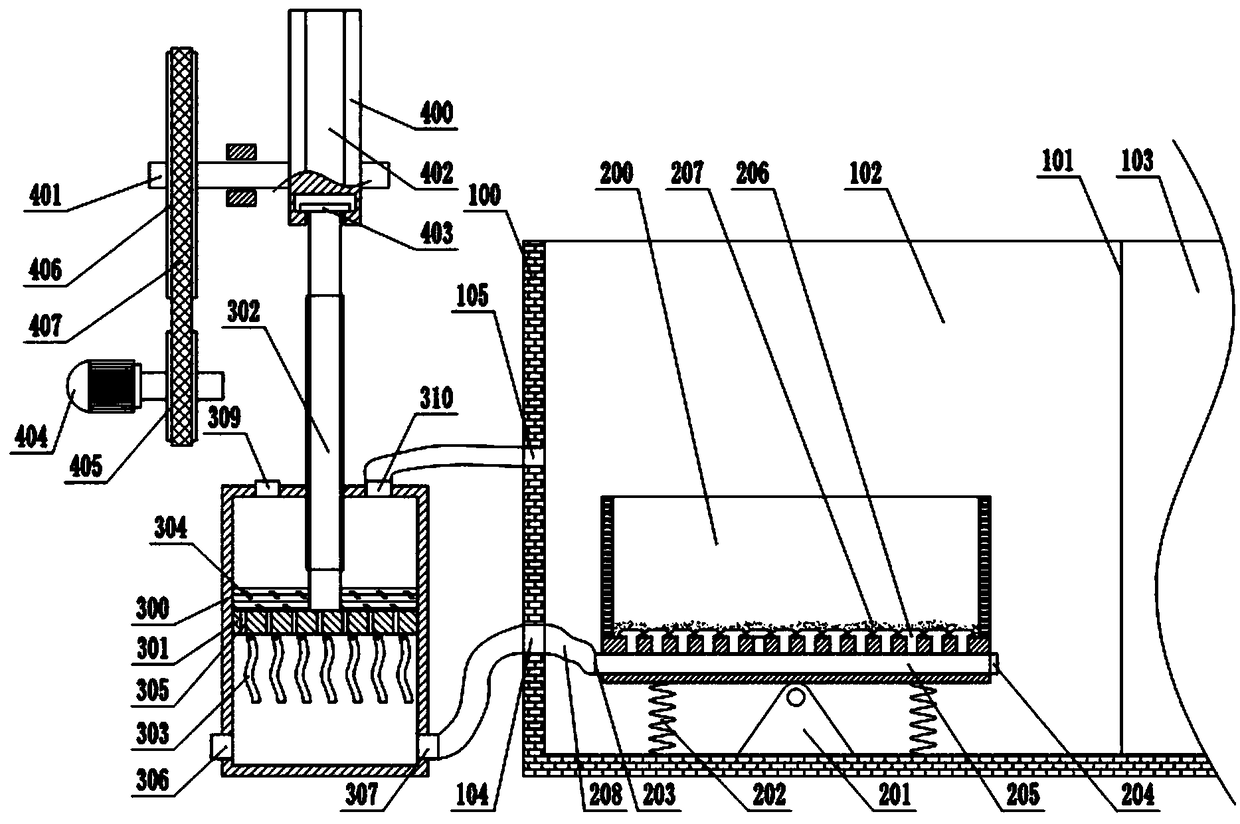

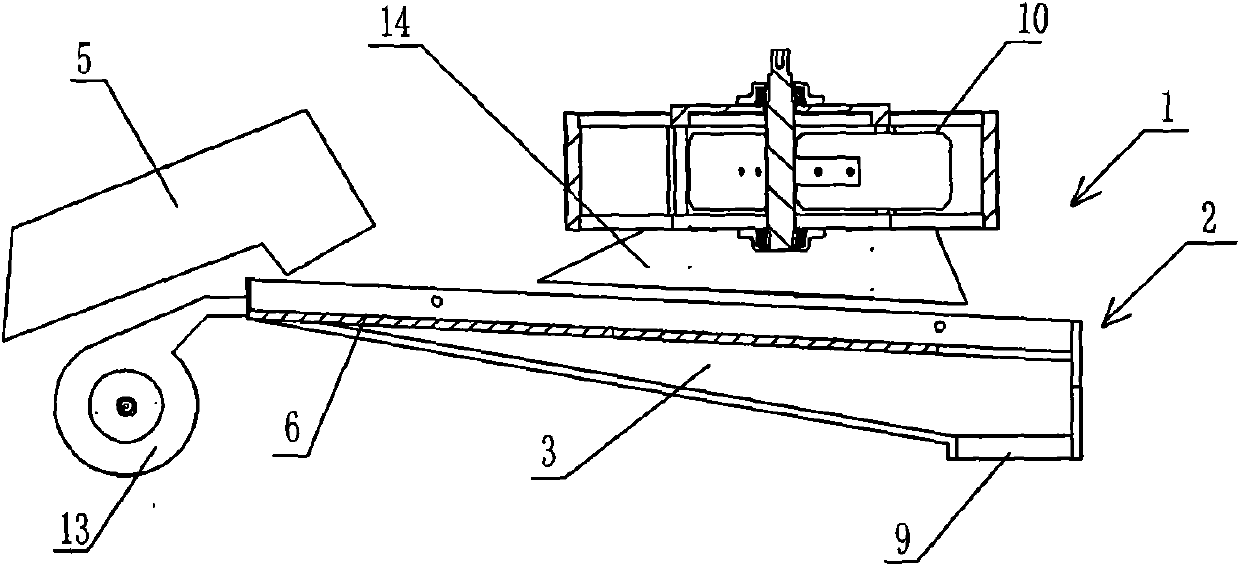

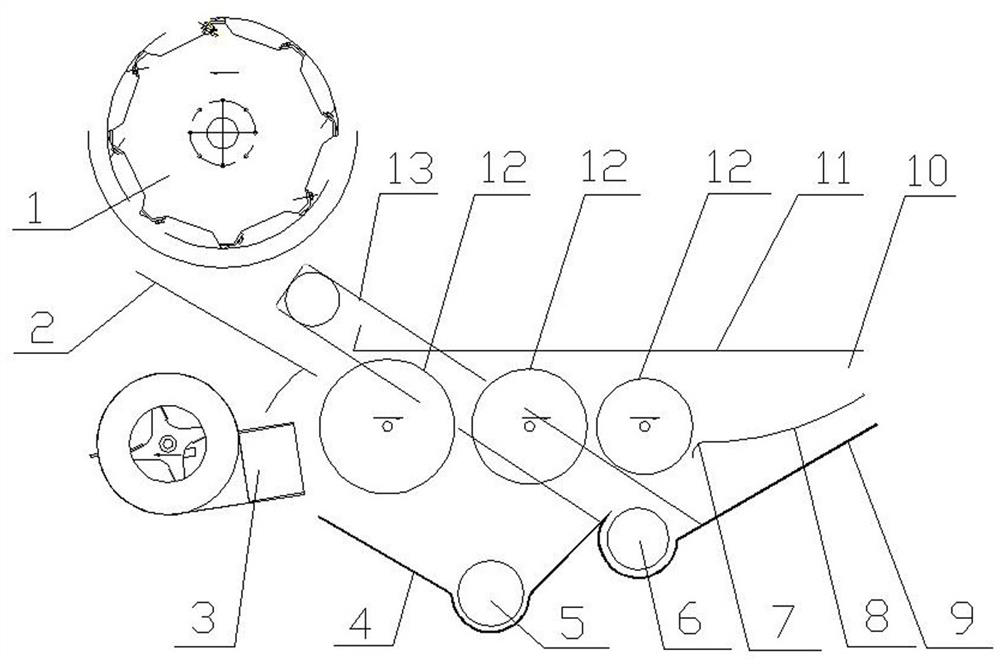

Combine-harvester for garlic and carrot

InactiveCN103222368ACompact structureReduce volumeLiftersTopping machinesControl systemProcess engineering

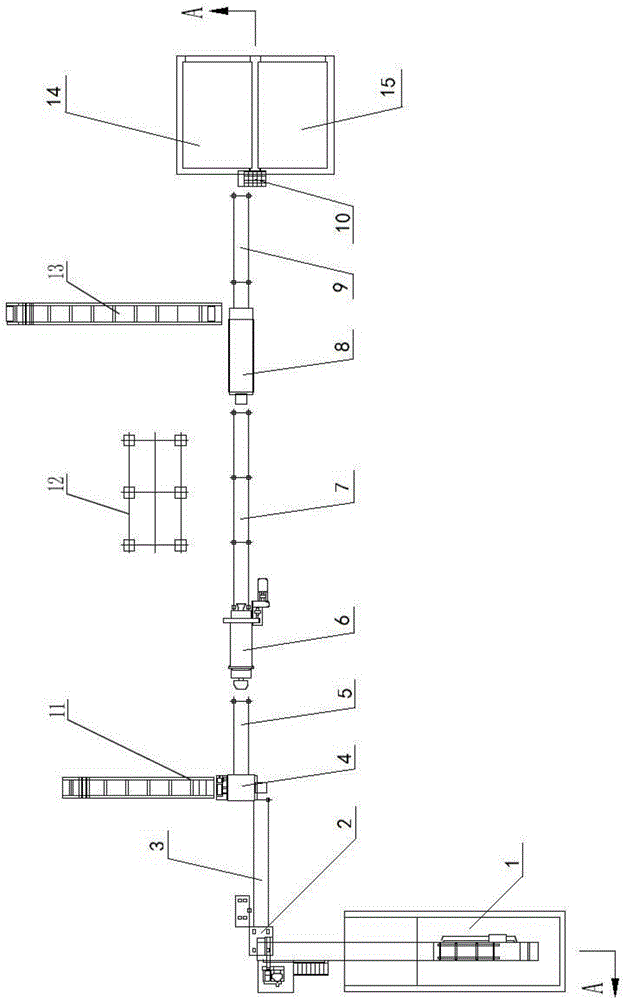

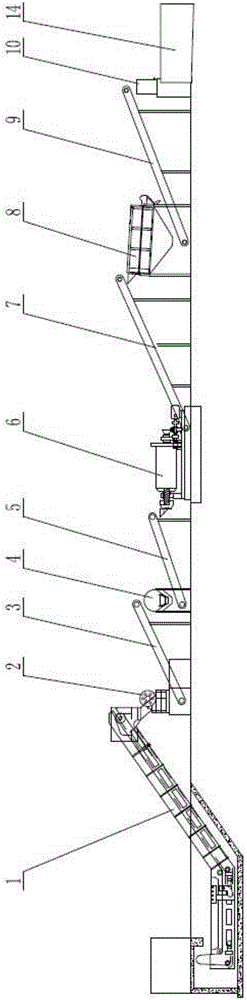

The invention relates to a combine-harvester for garlic and carrot. The combine-harvester for garlic and carrot comprises a working part, a walking part, a driving part and a control system, wherein the working part adopts a machine frame as a mounting supporter; a clamping device, a digging shovel, and an adjusting and limiting wheel are arranged at the front end of the machine frame; a vibration mud cleaning, conveying and cutting device is arranged in the middle of the machine frame; and a lifting mechanism, an output device and a container are arranged at the rear end of the machine frame. The combine-harvester for the garlic and the carrot combines the functions such as digging, harvesting, cutting and containing into a single machine, has the advantages of simple and compact structure, small size, light weight, strong adaptation, high operating efficiency, convenience in use, assembly and disassembly, easiness in maintenance, low power consumption, cleanliness in separation, less impurity, wide application range and remarkable benefits, and can meet various field operation requirements.

Owner:GUANGDONG DANXIA AGRI MACHINERY

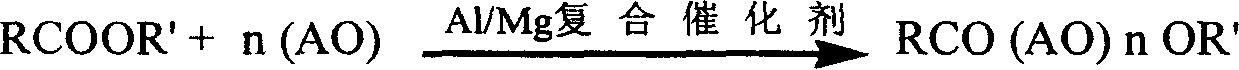

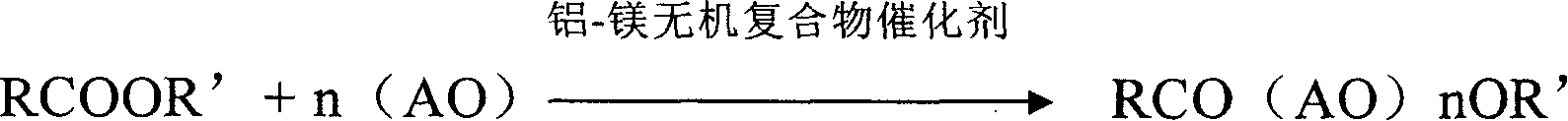

Al-Mg catalyst and catalytic synthesis process of alkoxyl carboxylate ether

InactiveCN1706546AEasy to prepareLow manufacturing costPhysical/chemical process catalystsCarboxylateEther

The present invention belongs to the field of catalyst preparing and organic compound synthesizing technology. The present invention provides one kind one Al-Mg catalyst for the embedded alkoxylation reaction between materials alkyl carboxylate and alkylene oxide, and the catalyst catalyzed one-step process of synthesizing diblocked alkoxyl carboxylate ether. The catalyst is inorganic metal compound and has simple preparing process and low cost. The catalyzing mechanism is double active point catalysis, and through double point embedding, all ester radical C-O bonds of the alkyl carboxylate are embedded into polyalkoxyl radical to obtain polyalkoxyl ester ether blocked with acyl and alkyl simultaneously and final product with high end blocking rate and high purity.

Owner:JIANGNAN UNIV

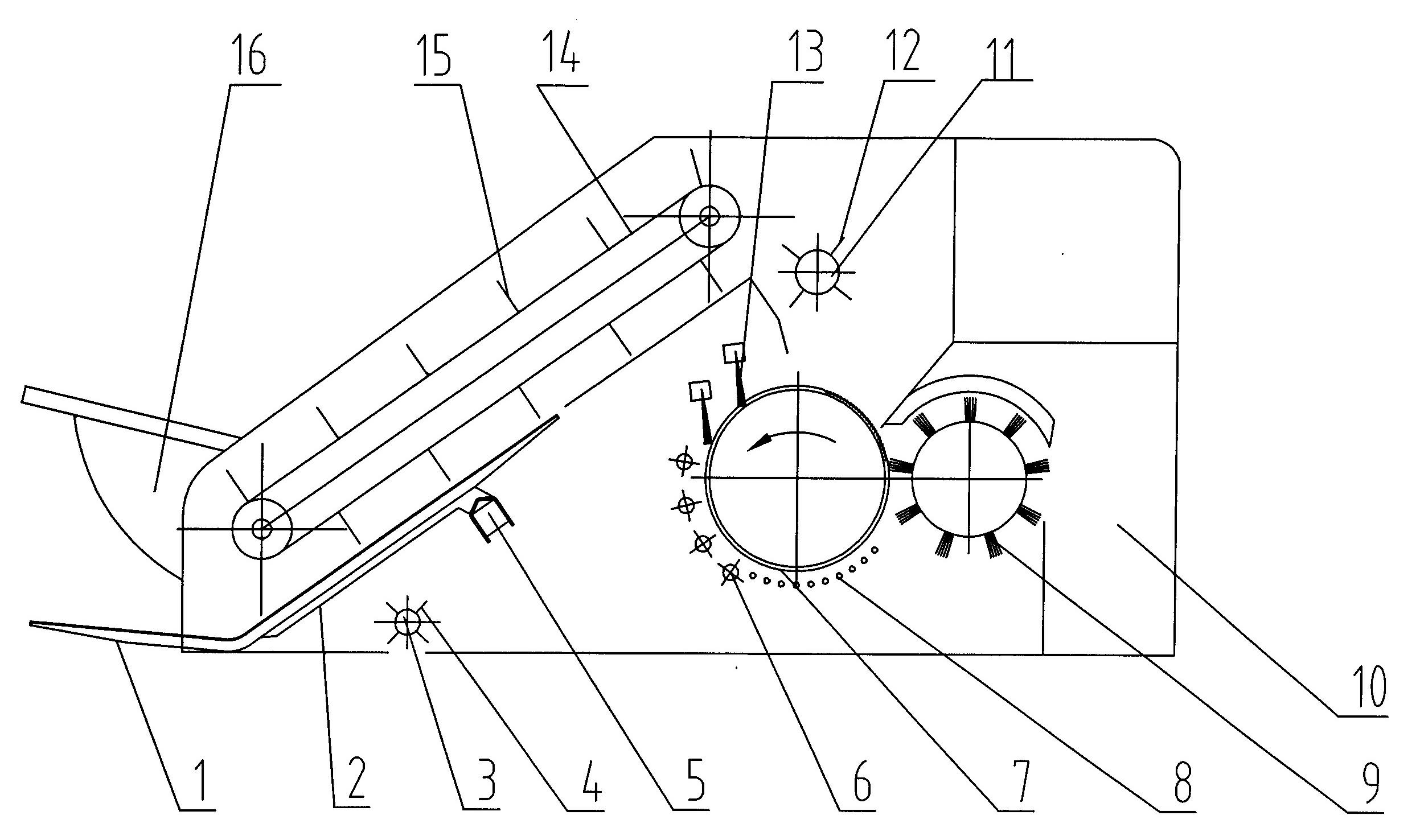

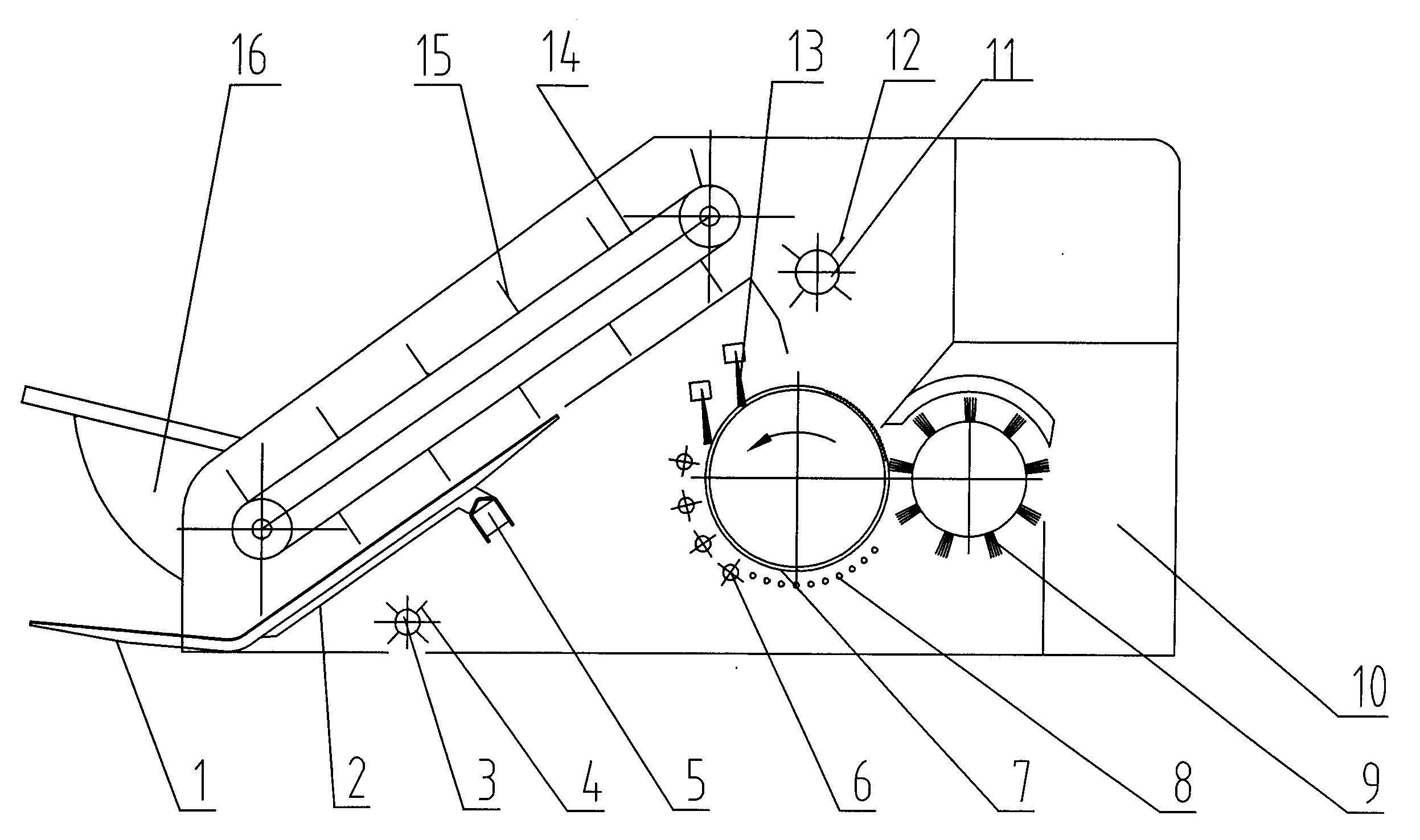

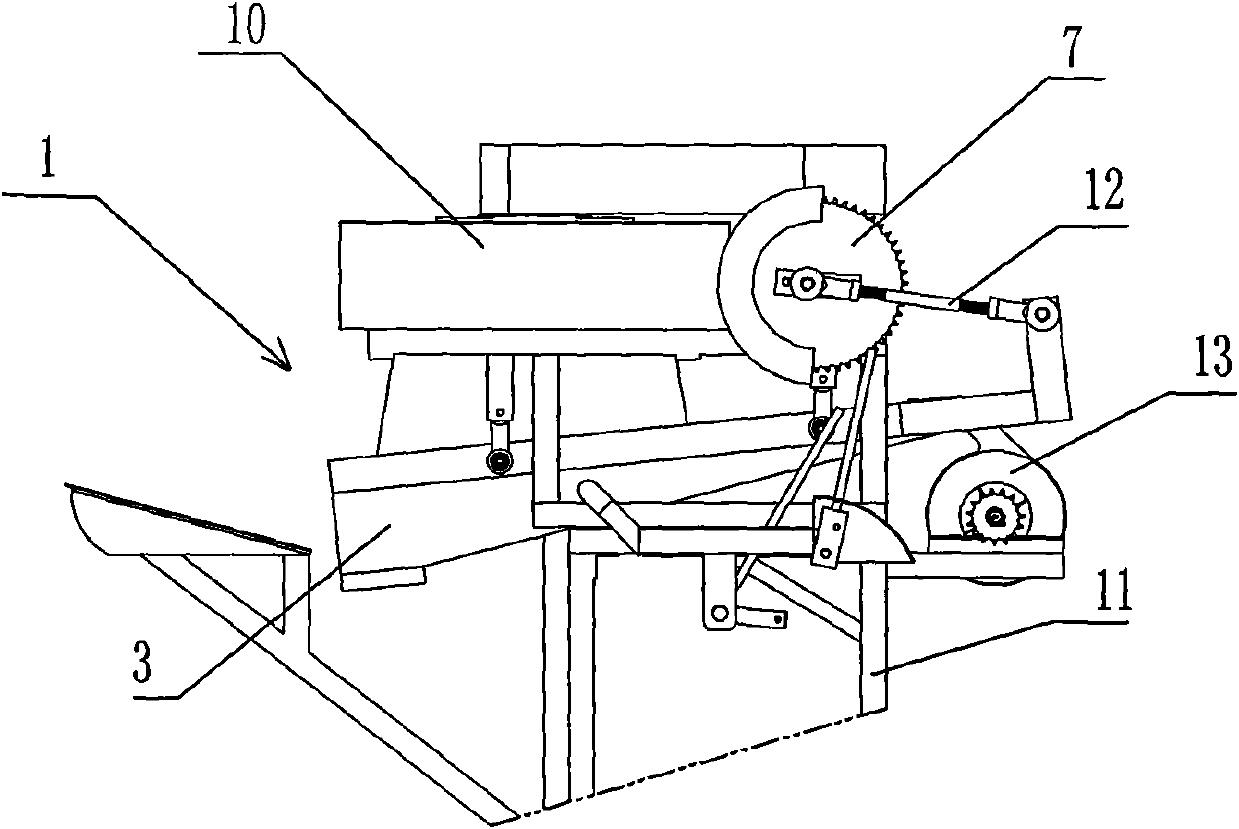

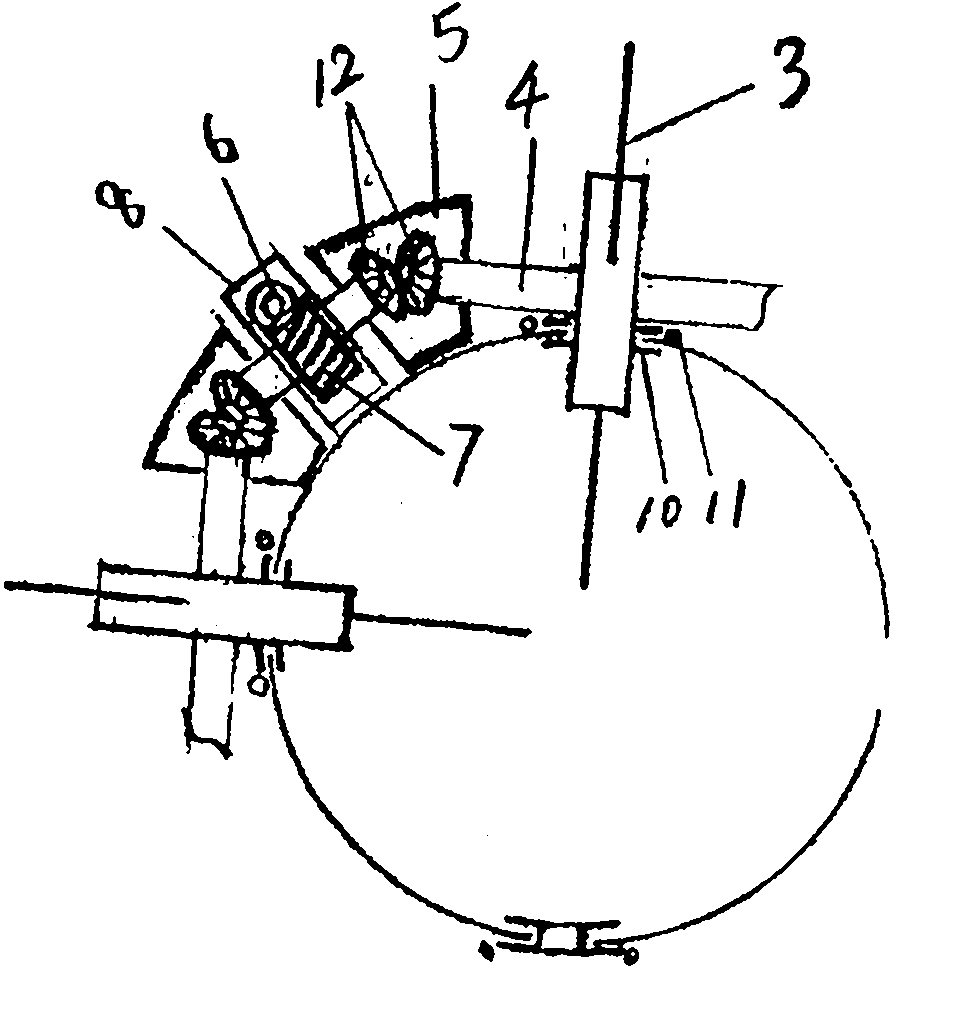

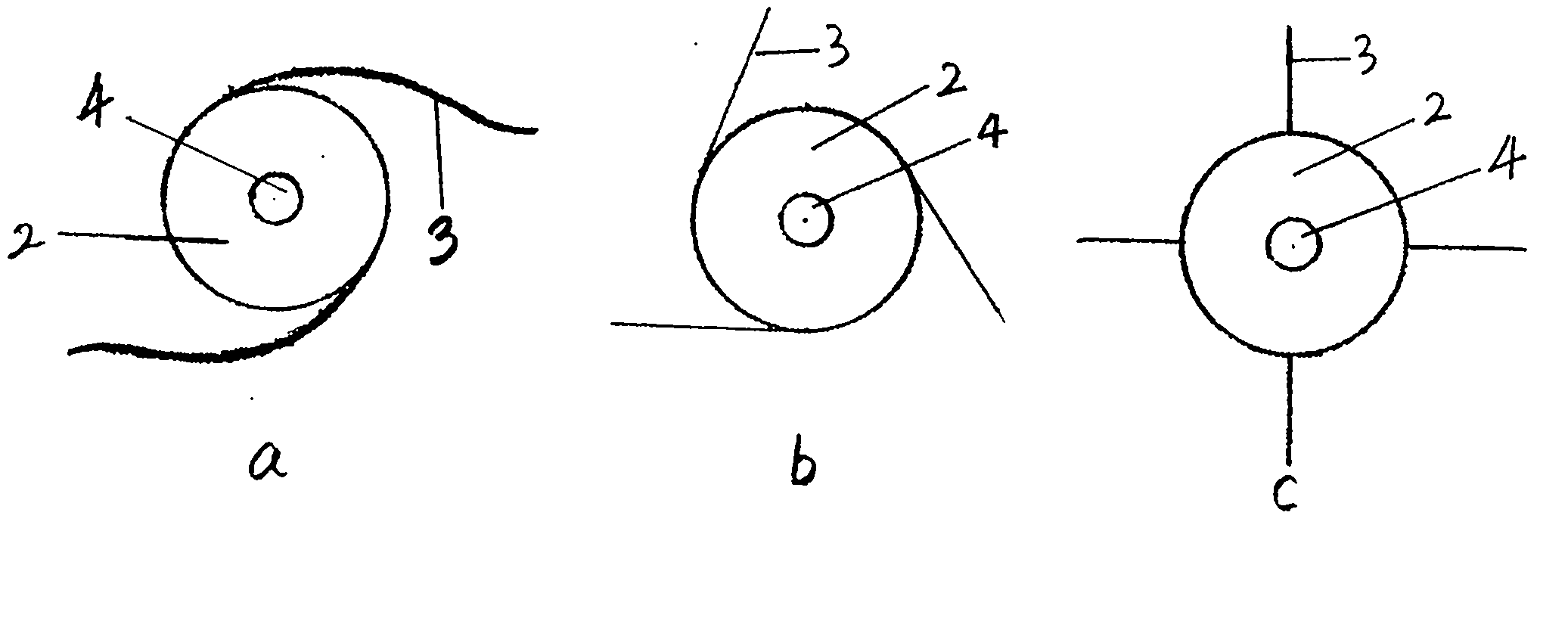

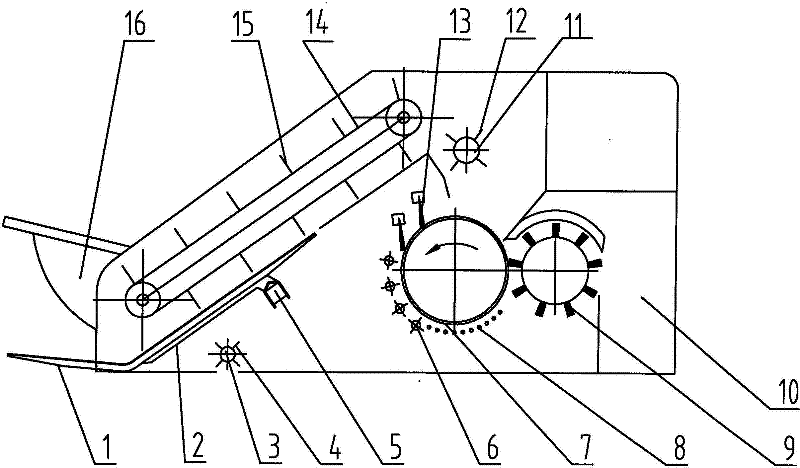

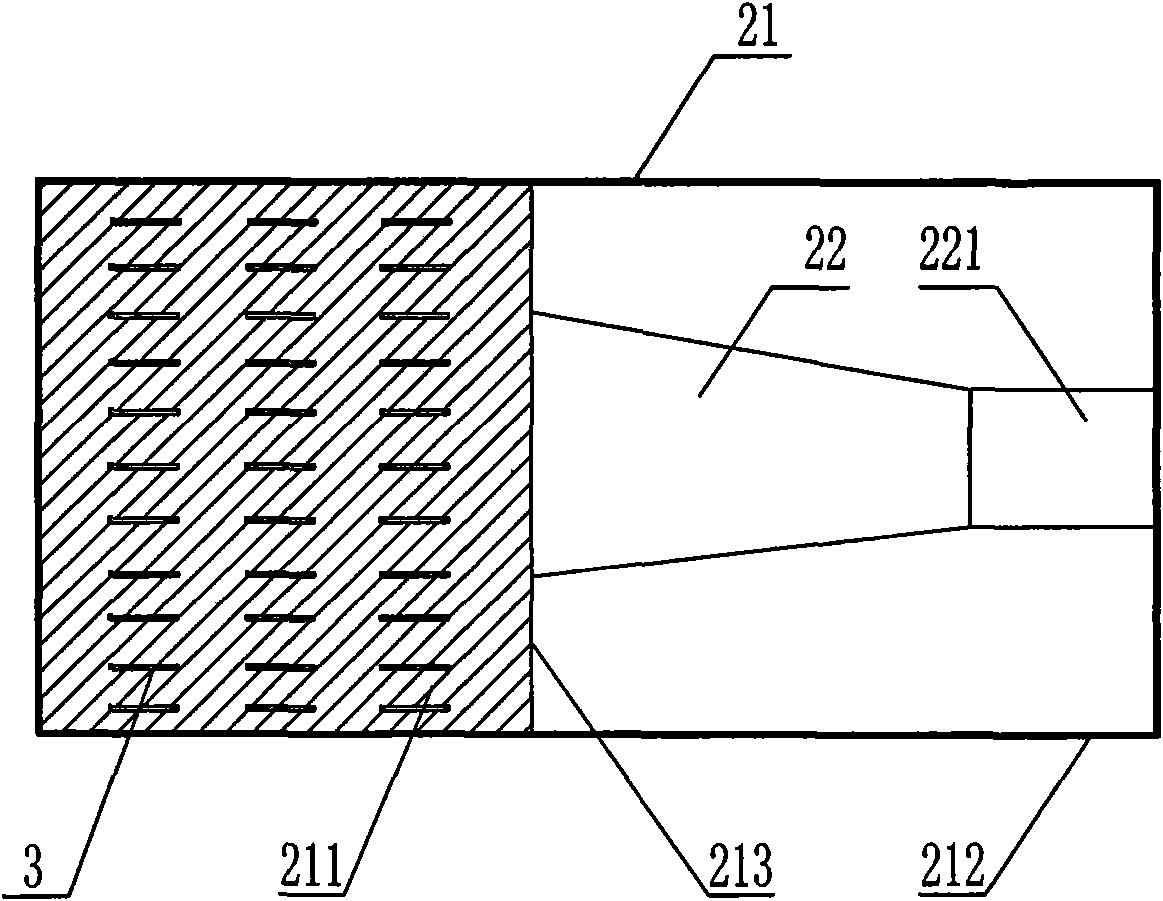

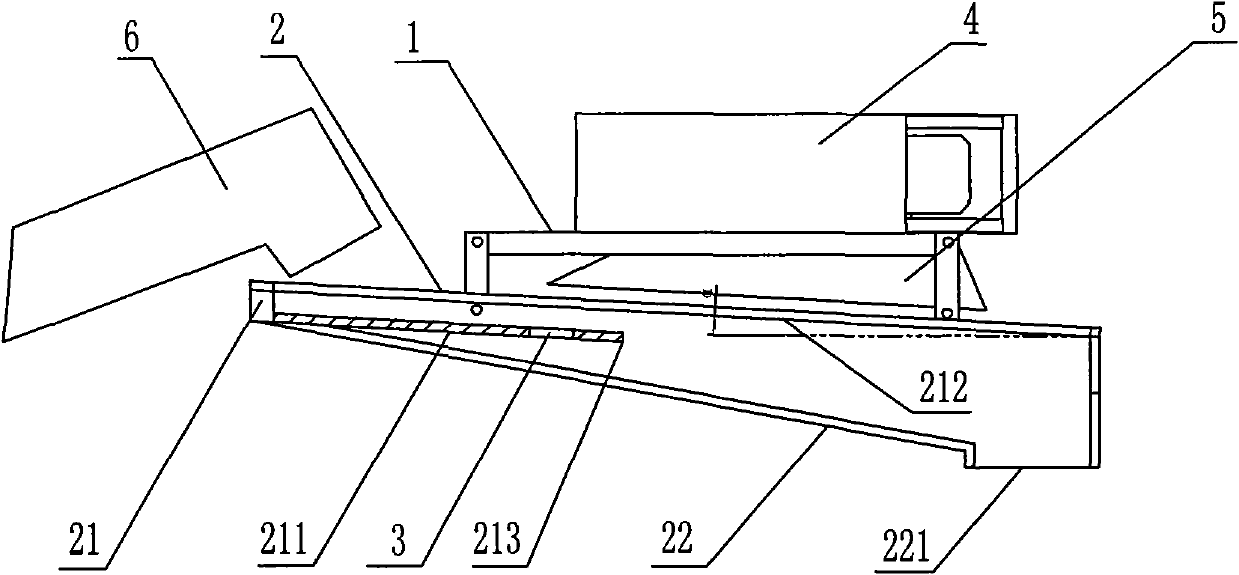

Combined comb-tooth-type cotton picker with self-cleaning function

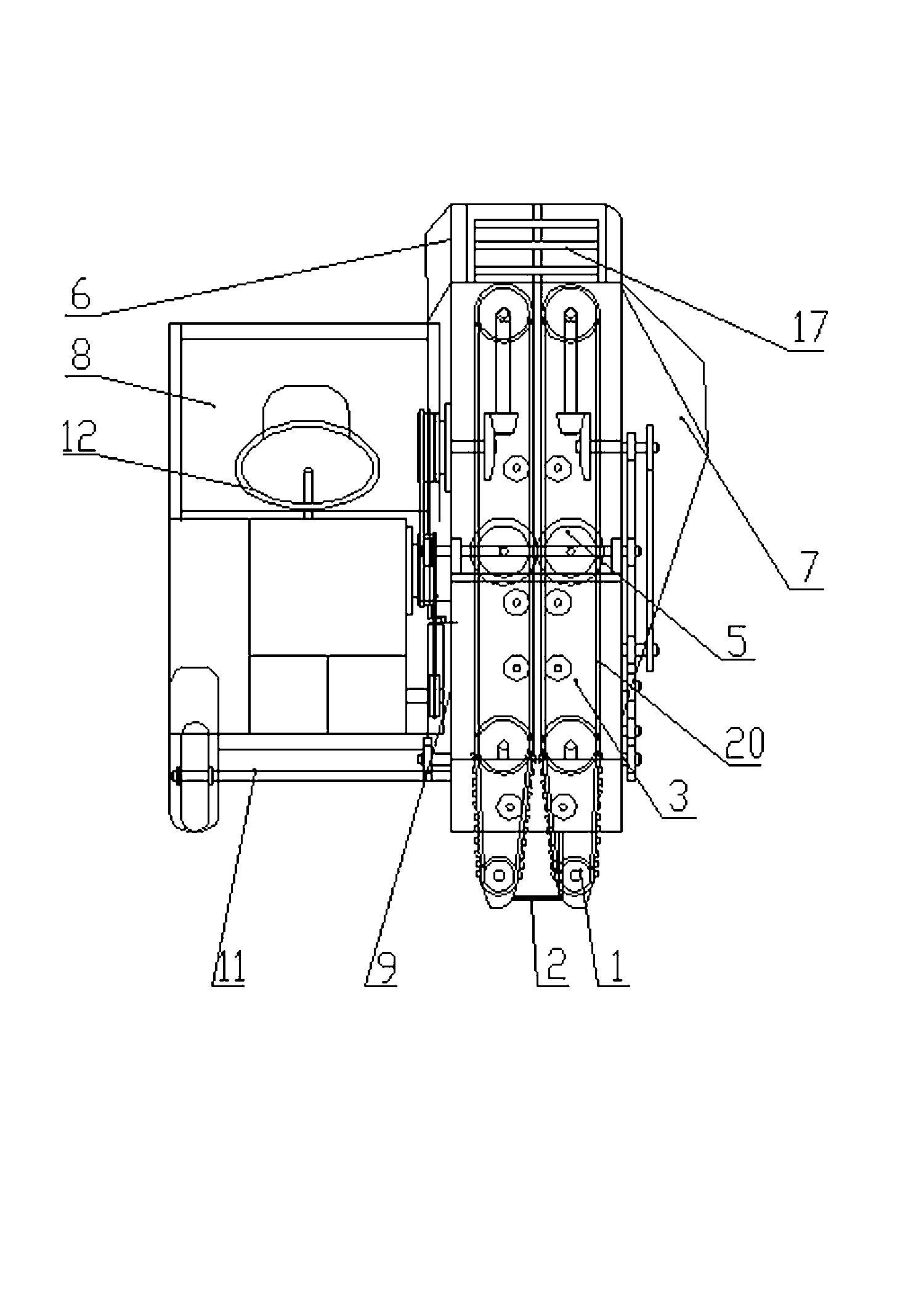

The invention discloses a combined comb-tooth-type cotton picker with a self-cleaning function, comprising a power-driven chain-harrow-type transmission device arranged on the upper frontal end of a rack and a cotton cleaning machine formed by a U-shaped sawtooth roller and a steel brush cotton roller; a cotton stalk pressing guide device is arranged on the rack at the front part of a picking platform; comb teeth which are mutually parallel are fixedly connected on a crossbeam evenly; the front ends of the comb teeth incline upwards; a power-driven pulling preventing roller is arranged at the rear lower part of the comb teeth; the chain-harrow-type transmission device which is matched with the comb teeth is arranged above the comb teeth; a cotton feeding roller is arranged on a discharge hole of the chain-harrow-type transmission device; the cotton cleaning device formed by the U-shaped sawtooth roller and the steel brush cotton roller is arranged below the cotton feeding roller; and a cotton collecting chamber is arranged at the rear part of the cleaning device. The cotton picker provided by the invention has no special requirements on the cotton planting mode in row space, and can be suitable for the planting mode of any row space; in the combined cotton picker, 'zero distance' transmission is implemented, thus the cotton picker has the advantages of novel and compact structure, simple and direct operational procedures, convenience in maintenance, low manufacture cost, long service life, low operational failure rate and low-impurity seed cotton and the like.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

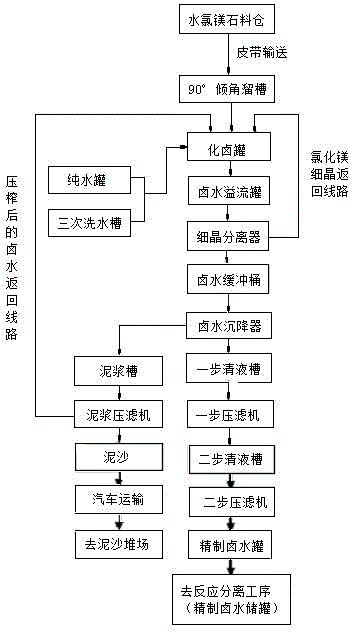

Method of continuous dissolution of salt lake bischofite to prepare high-concentration magnesium chloride solution

ActiveCN104030327AFast dissolutionIncrease the speed of saltMagnesium chloridesHigh concentrationSalt lake

The invention relates to the technical field of salt chemistry, particularly relates to a method of continuous dissolution of salt lake bischofite to prepare a high-concentration magnesium chloride solution, to a production device for achieving a process of large-scale bischofite dissolution to prepare refined brine, and provides a industrial demonstration effect route for developing magnesium series oxides in the Qinghai salt lake in the future. The method includes steps of: unloading bischofite, conveying and loading the material by conveying belts, feeding, dissolving into brine, allowing crude brine to overflow, performing magnesium chloride fine grain separation, buffering the brine, thickening and depositing the brine, obtaining a first-step clear liquid, subjecting the first-step clear liquid to first-step filter pressing, obtaining a second-step clear liquid, subjecting the second-step clear liquid to second-step filter pressing, squeezing and filtering the bottom material of a thickening machine, conveying mud cake, subjecting the brine to accident handling, and conveying and storing the refined brine so as to obtain the brine with technical indexes meeting requirements of ammonia gas combined reactions. The concentration of Mg<2+> in the refined brine is 115+ / -3 g / L. The refined brine is clear, transparent and free of solid suspension impurities.

Owner:青海西部镁业有限公司

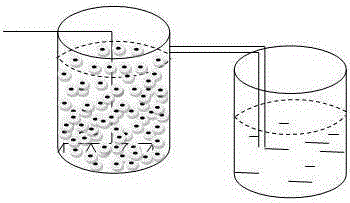

Giant salamander breeding pond

The invention relates to the technical field of breeding devices and particularly discloses a giant salamander breeding pond. The giant salamander breeding pond comprises a breeding pond body, whereina separation net is arranged in the middle of the breeding pond and divides the breeding pond into a hatching zone and a growth zone, a hatching bucket is arranged in the hatching zone, the bottom ofthe hatching bucket is hinged to a mounting base, a water draining pipe horizontally penetrates through the bottom wall of the hatching bucket, and air bags are uniformly distributed in the hatchingbucket. The giant salamander breeding pond also comprises a stirring bucket, wherein a piston is slidingly connected in the stirring bucket, a through hole is vertically formed in the piston, a pistonrod is connected to the top of the piston, the piston rod is in threaded connection with the top of the stirring bucket, and the end, extending out of the stirring bucket, of the piston rod is connected with a transmission mechanism. The bottom of the piston is connected with a flexible stirring belt. An air inlet one-way valve and a water outlet one-way valve are arranged on the side wall of thestirring bucket, an air outlet one-way valve and a water intlet one-way valve are arranged at the top of the stirring bucket, the water outlet one-way valve is communicated with the water draining pipe, and the water inlet one-way valve is communicated with the breeding pond. By adopting the giant salamander breeding pond, no direct impact is produced on fertilized ovum of giant salamanders, andthe oxygen content demand in water can be met.

Owner:正安县鲵食养殖有限公司

Fluorite beneficiation process

The invention relates to a fluorite beneficiation process. The beneficiation process is characterized by comprising the following steps of 1) calcium removal beneficiation of fluorite; 2) preparation of a fluorite floatation agent, wherein an intermediate produce crude fatty acid or mixed fatty acid produced by oleic acid is employed as a raw material, concentrated sulfuric acid in an amount which is 50 to 20 percent based on the weight of the fatty acid is added into the fatty acid to sulfate the fatty acid, and a beneficiation foaming agent in an amount which is 0.4 to 3 percent based on the weight of the fatty acid is added into a reaction product to obtain a product; 3) preparation of a composition of a fluorite floatation regulator, wherein any one of sulfuric acid, hydrochloric acid, nitric acid and acetic acid and corresponding salt are compounded with sodium silicate salt according to a proportion of the acid, the salt corresponding to the acid and the sodium silicate salt of (1-2.5):(1-5):(0.5-3); 4) fluorite floatation, a mixture consisting of acid, alkali and a synergist is employed as a regulator, oleic acid or rubber sodium oleate is employed as a collecting agent, and a process flow is a compound loop for fluorite floatation.

Owner:赣县金磊鑫矿业有限公司

A magnetic gravity screening process for mixed iron ore

ActiveCN104190522BReasonable workmanshipReliable technologyGrain treatmentsWet separationMaceralMaterials science

The invention discloses a magnetic ore rescreening process for mixed iron ore. The process comprises the following process steps: performing primary ore grinding, performing primary grading, performing primary low intensity magnetic separation, performing primary strong magnetic separation, rescreening, performing high frequency screening and performing secondary ore grinding and selecting. According to the invention, partial qualified iron ore concentrate and partial tailings are thrown out preferentially under the condition that the dissociation degree of useful mineral monomers is insufficient after the primary ore grinding operation, the amount of materials subjected to secondary regrinding and reselecting is reduced, and the aim of reducing the ore dressing cost is achieved.

Owner:ANHUI JINRISHENG MINING

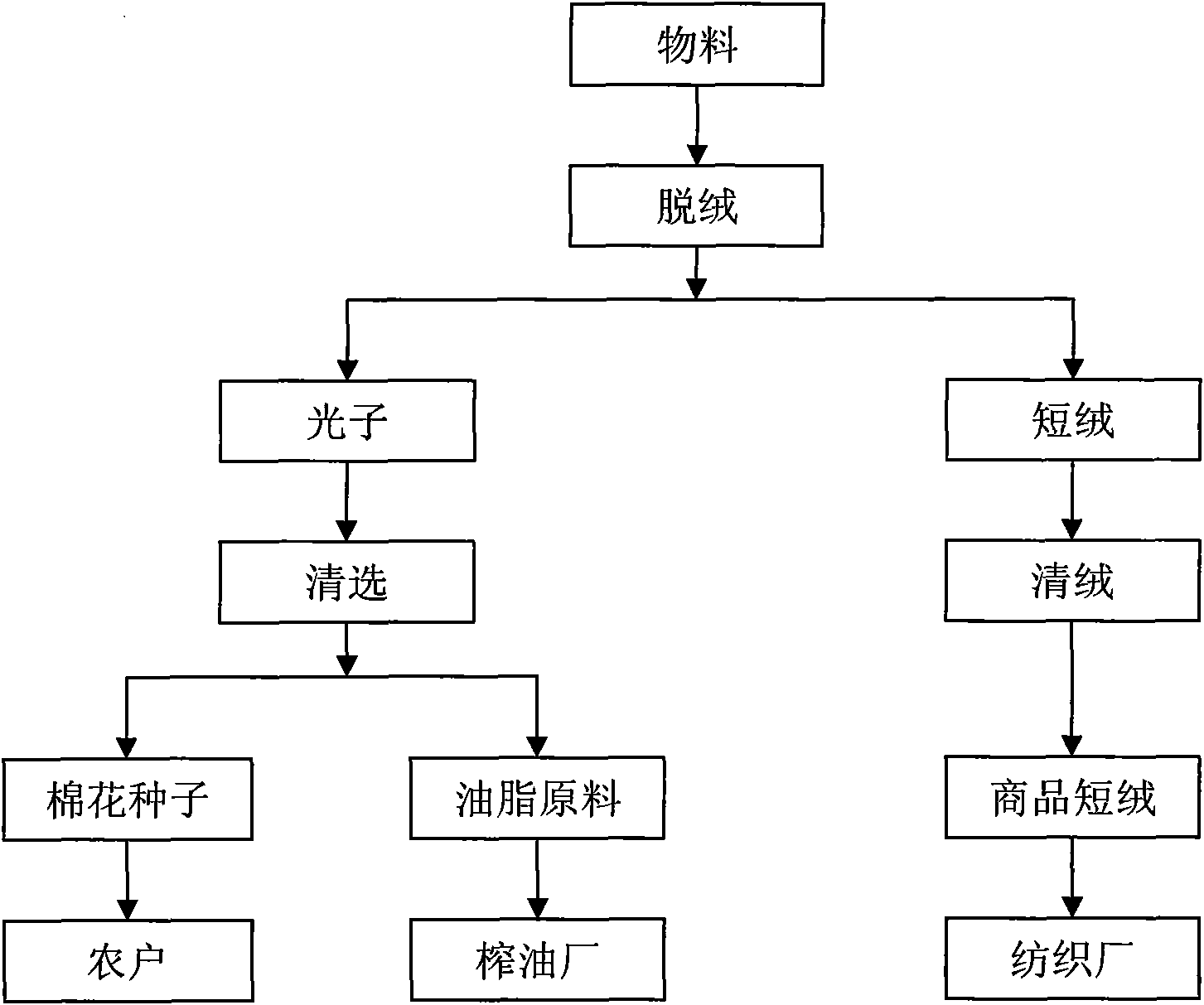

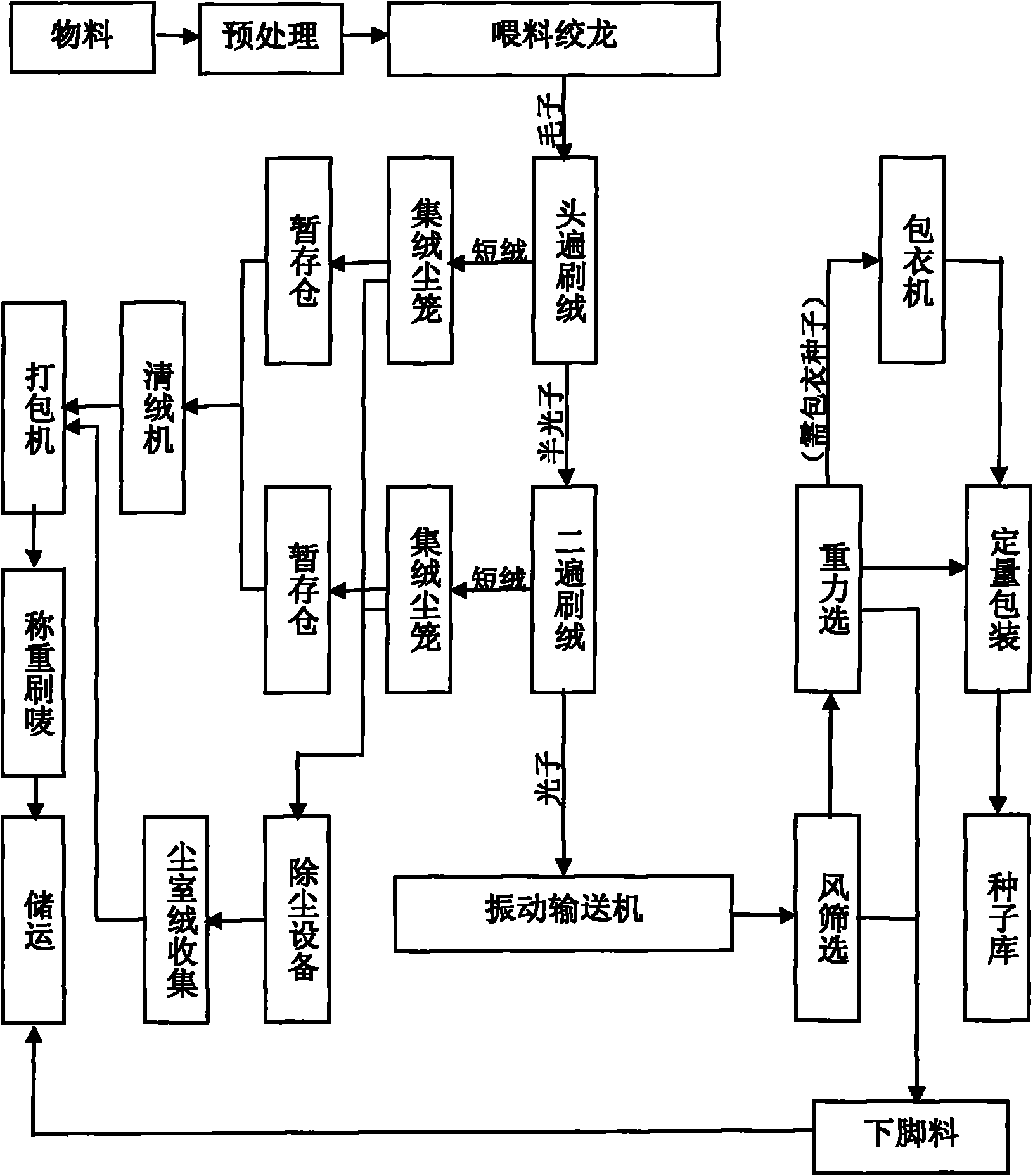

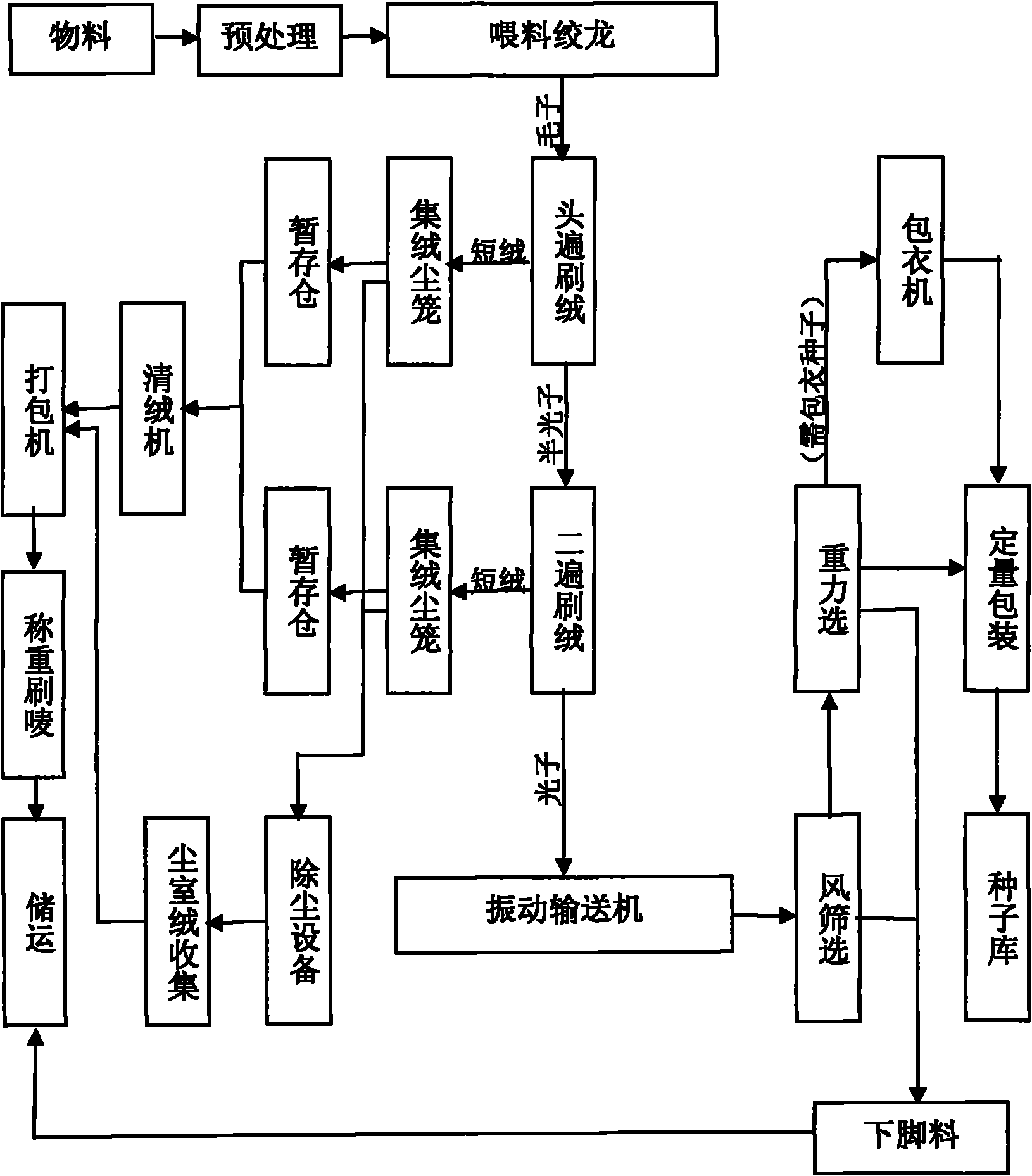

Cotton seed, commodity linter and grease raw material co-production process based on delinting technology of cylindrical brushing machine

InactiveCN101974787ASimple processShort processing routeVegetable fibre separation from seedsSeed and root treatmentEngineeringCottonseed

The invention relates to the cotton processing technical field, in particular to a cotton seed, commodity linter and grease raw material co-production process based on the delinting technology of a cylindrical brushing machine. The co-production process is characterized by producing cotton seeds, commodity linters and grease raw materials at the same time by primary processing of materials (fluff). Compared with the prior art, the co-production process has the advantages of simple process flow, short processing route, high production efficiency, low cottonseed crushing ratio, guaranteed seed quality, fewer linter impurities, easy linter cleaning, high commodity linter level, complete waste (photon) skin, convenient hulling, thorough separation between cotton hulls and cotton kernels and high oil yield. In the process, the linter obtained by double brushing is collected, cleaned and packaged respectively, thus ensuring grade quality of the commodity linter.

Owner:SHANGHAI KUDUN ELECTROMECHANICAL TECH

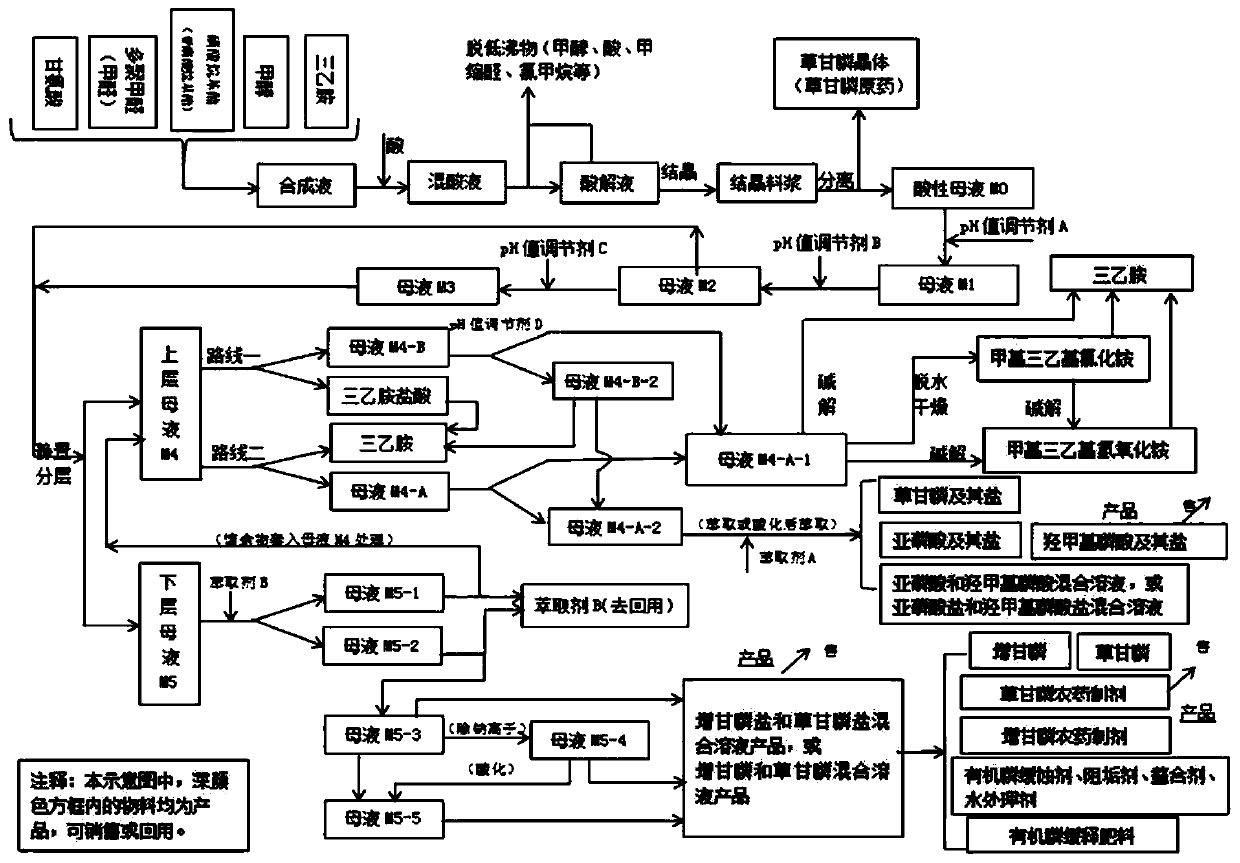

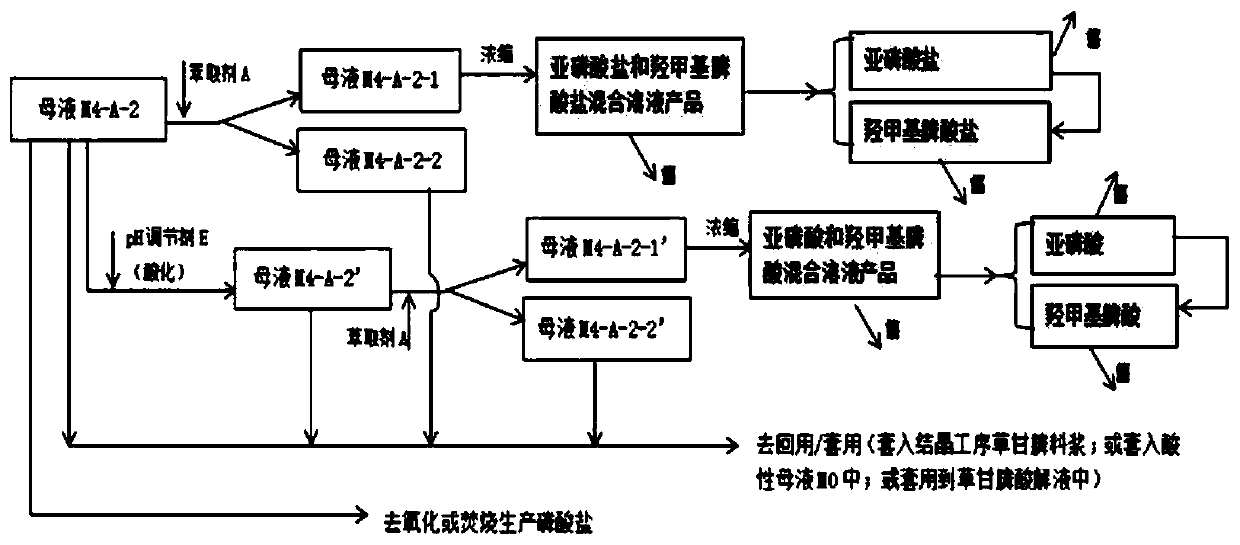

Glyphosate mother liquor comprehensive treatment and resource recycling method

PendingCN111333519AReduce volume and handling costsLess impuritiesAmino compound purification/separationGroup 5/15 element organic compoundsPhosphorous acidPulp and paper industry

The invention discloses a glyphosate mother liquor comprehensive treatment and resource recycling method which comprises the following steps: adding a pH value regulator into acidic mother liquor M0,standing for layering, and separating the solution to obtain mother liquor M4 at the upper layer and mother liquor M5 at the lower layer; the mother liquor M4 and the mother liquor M5 are treated andapplied, triethylamine hydrochloride, triethylamine, chloride salt, methyltriethylammonium chloride, phosphorous acid or salt thereof, hydroxymethylphosphonic acid or salt thereof, glyphosate or saltthereof, glyphosate or salt thereof and glyphosate or salt thereof are recovered from the mother liquor M4 and the mother liquor M5, and are respectively and correspondingly converted into products with higher additional values for utilization. The glyphosate mother liquor comprehensive treatment and resource recycling method has the advantages that the emission is reduced from the source; the method reduces the total amount and treatment load of the glyphosate mother liquor, reduces environmental pollution, realizes reasonable recycling and appreciation of resources, improves economic benefits, is environment-friendly, outstanding in economic benefits and good in technical implementation effect, and is suitable for large-scale industrial application.

Owner:陈兴华

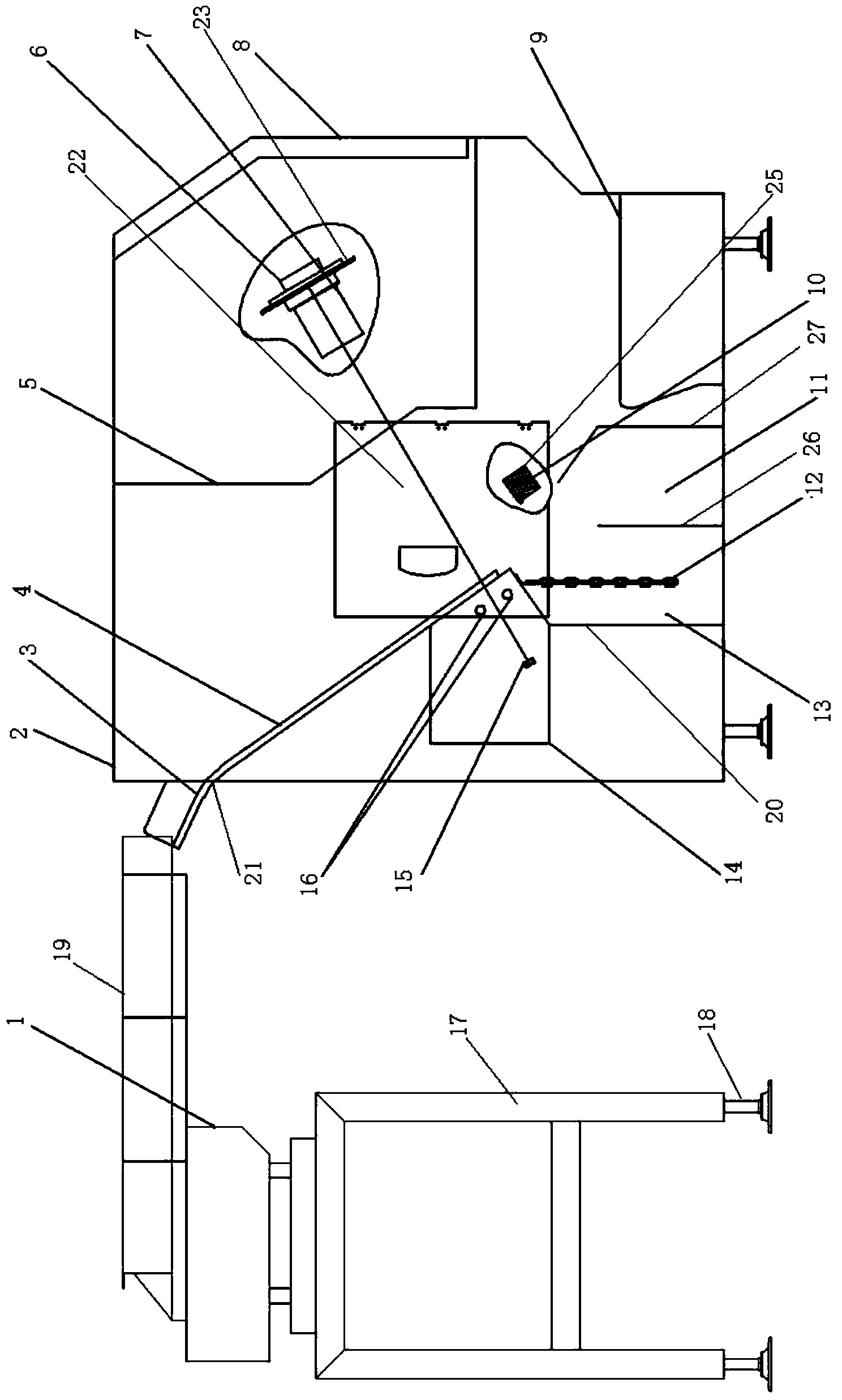

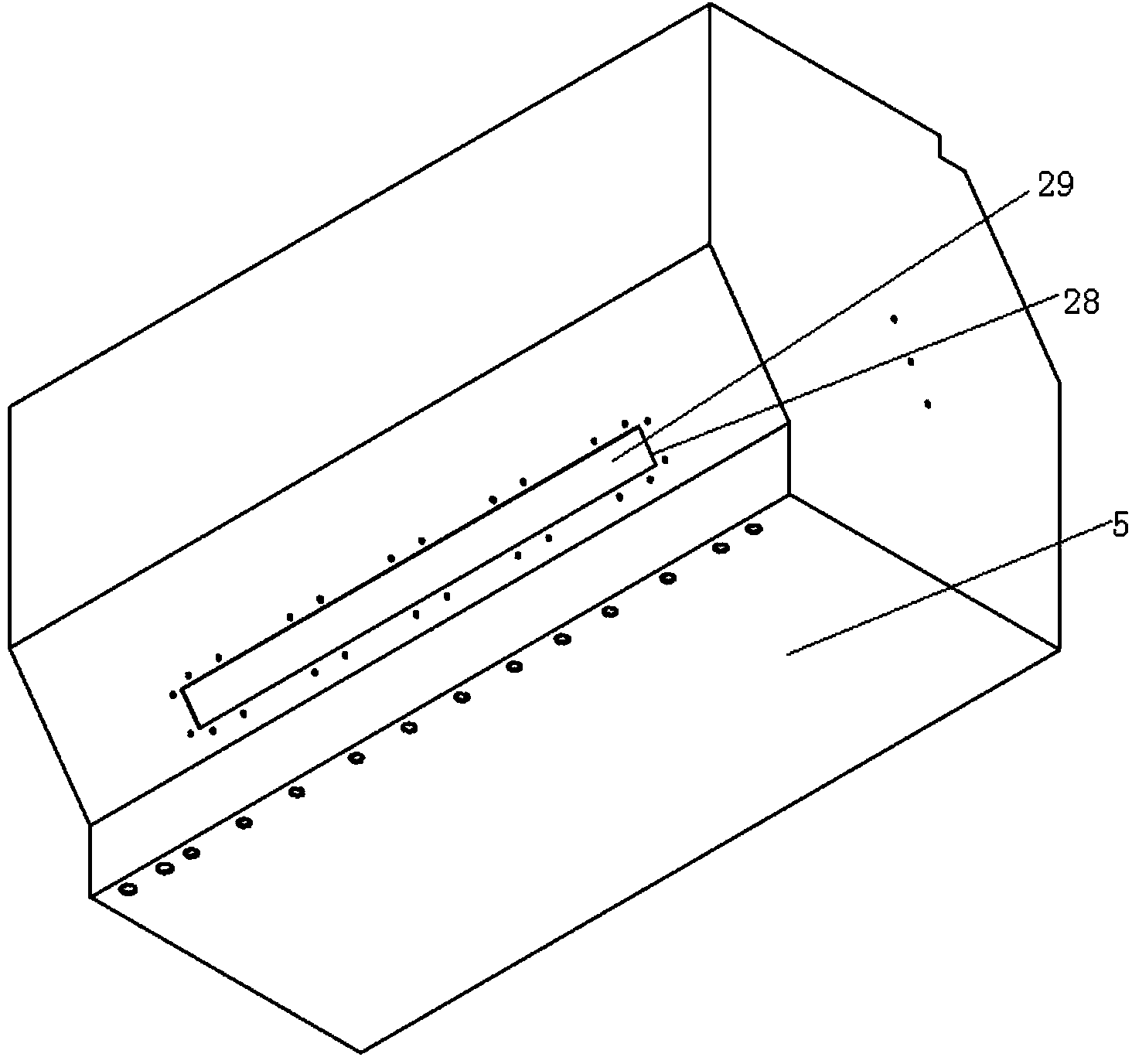

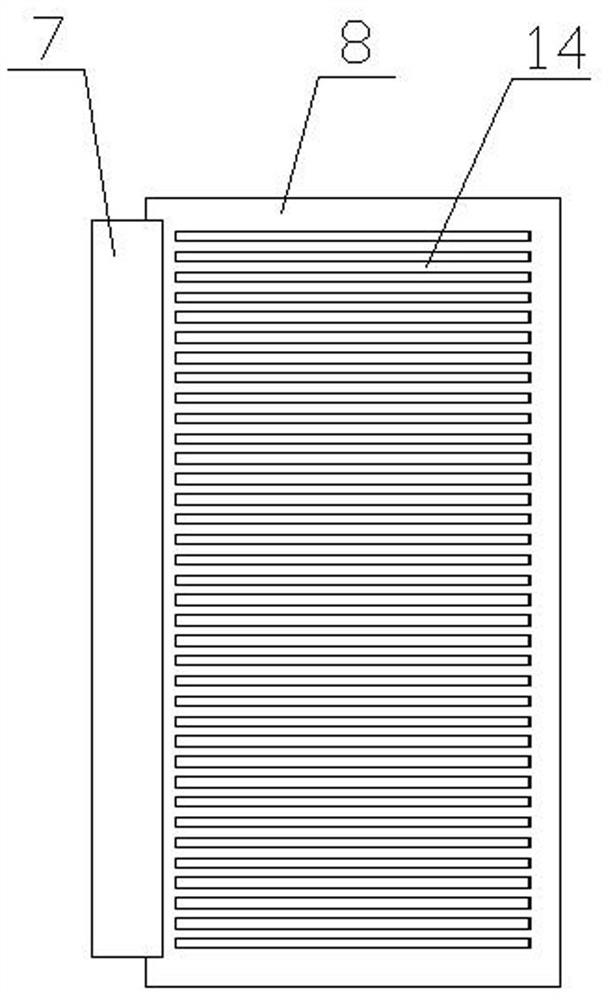

Air suction and air blow-combined separation type grain cleaning device for reaping machine

The invention relates to an air suction and air blow-combined separation type grain cleaning device for a reaping machine. The device comprises a sieve which is arranged on a machine frame and is driven by a driving mechanism to swing back and forth, wherein the sieve consists of a single-layered sieve body and a grain warehouse attached to the sieve; the single-layered sieve body comprises a sieve bottom board and a square frame baffle; the front section of the square frame baffle is provided with the sieve bottom board, and the rear section of the square frame baffle is provided with a warehouse inlet; a draft fan and an air collection hood are arranged above the sieve; and one end of the sieve is provided with an air blower. The device can separate grains and weeds efficiently, the separated grains contain a small number of impurities, and the device has the advantages of simple structure, small volume, low power consumption and the like.

Owner:湖南省双峰县湘源皇视电子有限公司

Preparation method of high-purity calcium hydrogen phosphate

InactiveCN108046228AHigh purityContain less impurityPhosphorus compoundsPhosphoric acidMonobasic calcium phosphate

The invention relates to the technical field of calcium hydrogen phosphate preparation, and discloses a preparation method of high-purity calcium hydrogen phosphate. An acid-alkali neutralization method is adopted, a phosphoric acid solution with a mass part of 30%-40% is used, calcium oxide powder is placed in an ultrasound vibrator for ultrasonic agitation after a certain amount of water is added, time is 5-15 minutes, frequencies are 30-50 kHz, and a calcium hydroxide suspension is made. The phosphoric acid solution and the calcium hydroxide suspension are put into a reaction still for reactions at temperatures of 65-75 DEG C, ph is controlled at about 5.5-6, reaction time is 30-50 minutes, and continuous stirring is conducted to generate a calcium hydrogen phosphate solution, and the calcium hydrogen phosphate is obtained after drying and evaporation; the calcium hydrogen phosphate has the advantages of capable of saving resources, being recyclable, and containing less impurities.

Owner:SICHUAN MIANZHU SANJIA FEED CO LTD

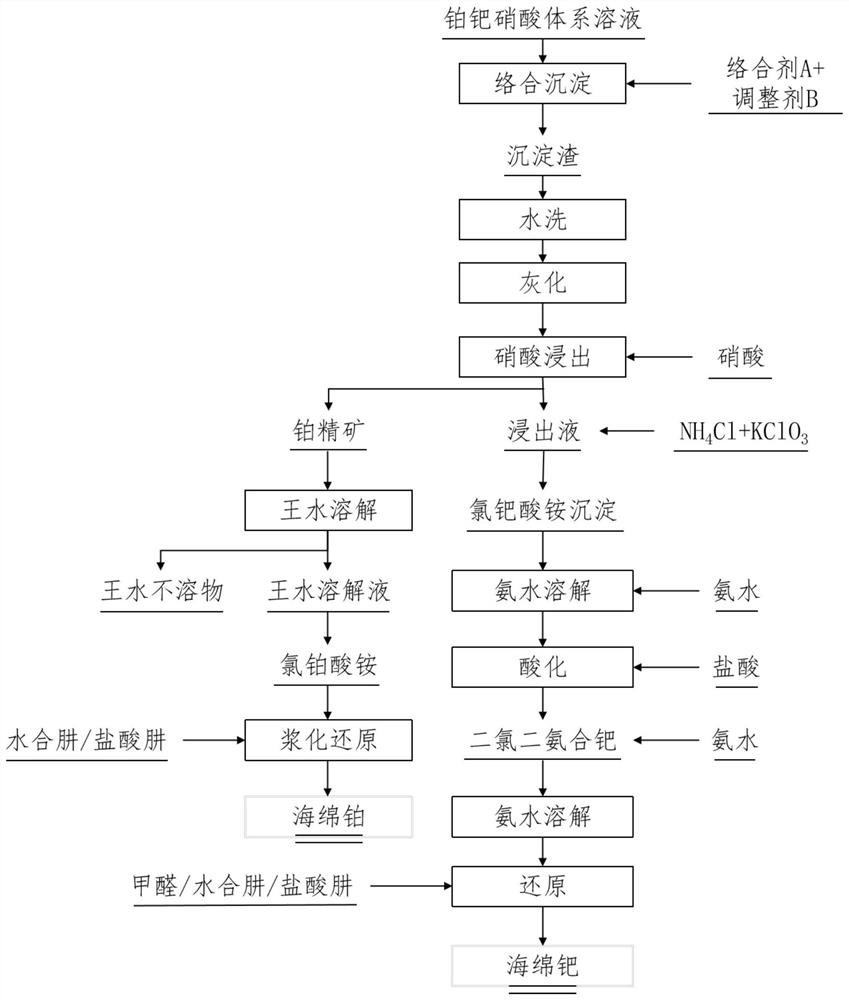

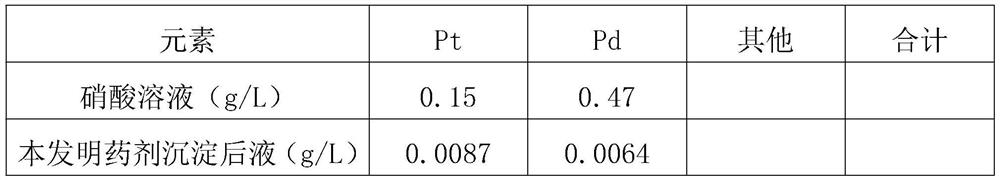

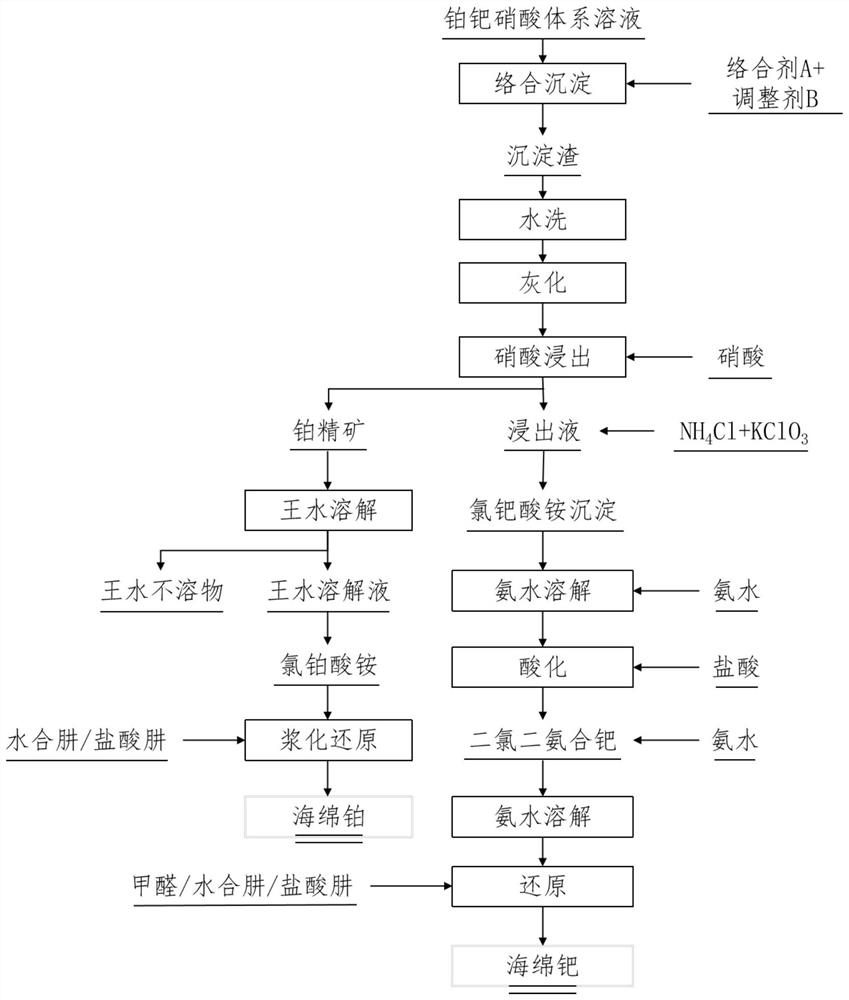

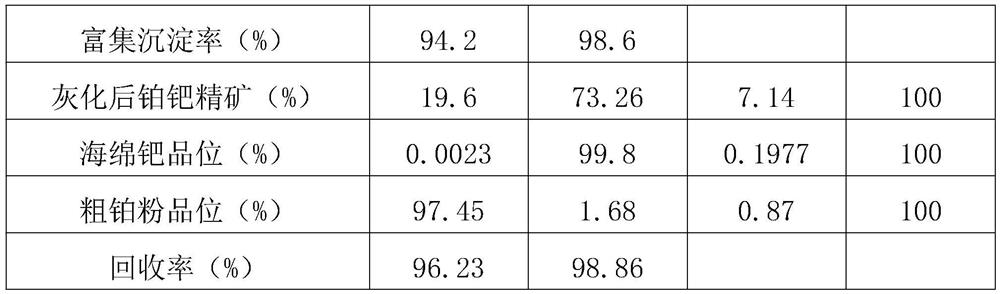

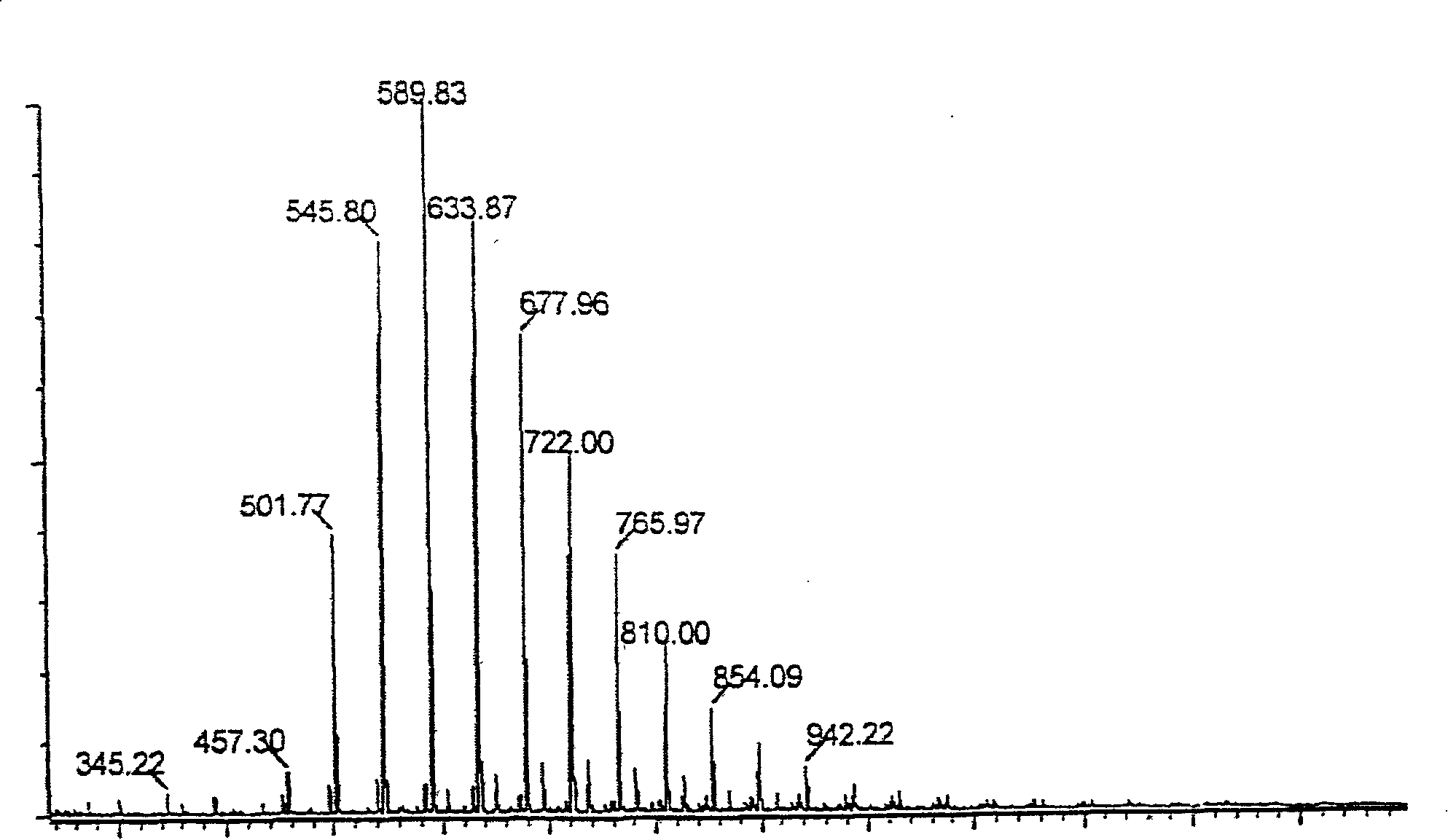

Method for efficiently enriching platinum and palladium from low-concentration platinum-palladium nitric acid system solution

The invention discloses a method for efficiently enriching platinum and palladium from a low-concentration platinum-palladium nitric acid system solution. The method comprises the steps of adjusting the pH value of the nitric acid system solution, adding a complexing agent A, carrying out two-stage temperature control reaction, then adding an adjusting agent B, obtaining a platinum-palladium complex precipitate after the reaction is finished, calcining the precipitate to remove organic matters to obtain platinum-palladium concentrate, separating platinum and palladium by adopting nitric acid leaching, nitrate removal and filtering, adding NH4Cl and KClO3 into a filtrate to obtain a red precipitate, adding ammonia water into the red precipitate, carrying out dissolving and filtering, addingHCl to obtain a yellow precipitate, dissolving the yellow precipitate with ammonia water, adding a reducing agent to obtain sponge palladium, dissolving platinum concentrate with aqua regia, adding NH4Cl into the filtered solution to obtain a precipitate, and slurrying and reducing the precipitate to obtain crude platinum powder. The method solves the problems of incomplete recovery, high impurity content, difficulty in enrichment of platinum and palladium, small obtained precipitate particles, slow filtration and the like existing when the platinum and palladium concentration is low, and hasthe advantages of high-efficiency enrichment of platinum and palladium, high product purity, high recovery efficiency and the like.

Owner:WESTERN MINING CO LTD +2

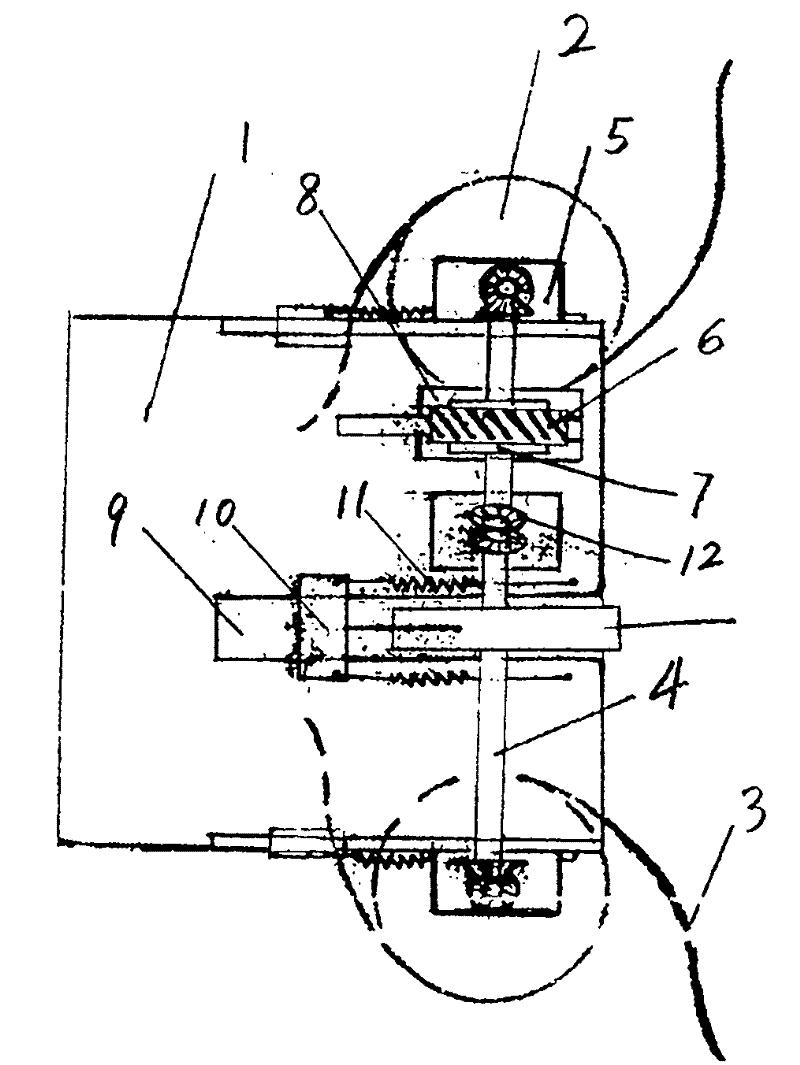

Treatment system for separating manganese-iron alloy slag iron and separating method

InactiveCN106622640AEasy to separateImprove finished product qualitySolid separationGrain treatmentsSlagManganese

The invention provides a treatment system for separating manganese-iron alloy slag iron. The treatment system comprises a slag fishing machine, a crusher, a first drum sieve, a ball mill, a second drum sieve and a washbox which are sequentially arranged. A first belt conveyer is arranged between the crusher and the first drum sieve. A second belt conveyer is arranged between one discharge port of the first drum sieve and the ball mill, and a fifth belt conveyer is arranged on the other discharge port. A third belt conveyer is arranged between the ball mill and the second drum sieve, a fourth belt conveyer is arranged between one discharge port of the second drum sieve and one side of the washbox, and a sixth belt conveyer is arranged on the other discharge port. A fine powder pond and a tailing pond are arranged on the other side of the washbox. First separation of the slag iron is achieved through the crusher and the first drum sieve, second separation of the slag iron is achieved through the ball mill and the second drum sieve, third separation of the slag iron is achieved through the washbox, the slag iron mixture is subjected to three times of separation in sequence, it is guaranteed that the slag iron is fully separated, and the finished product quality is high.

Owner:陕西盛华冶化有限公司

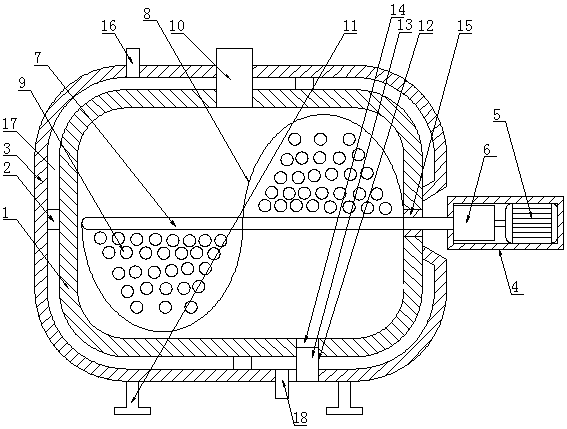

Preparation method of low-viscosity caramel pigment and production device thereof

InactiveCN108065175ALow viscosityWidely applicableChemical/physical/physico-chemical stationary reactorsFeed devicesWaste productCaramel Flavor

The invention discloses a preparation method of caramel pigment. By optimizing the preparation process of the caramel pigment, the content of 4-methylimidazole can be effectively reduced; in addition,in the coking reaction process, by adding saccharose ester, viscosity during sugar discharging is effectively reduced, color rate is not influenced, and the application range of products is improved;meanwhile, the invention further discloses a production device for preparing the caramel pigment, the production device comprises a kettle body, a spiral stirring piece, a material discharge valve, amobile layer, a fixed layer and the like, by adopting the production device, reaction materials can be uniformly heated, less foam is produced during coking, and product quality is uniform; double-layer design is adopted for the material discharge valve in the production device, the fixed layer and the mobile layer are provided with one-to-one corresponding through holes, the mobile layer can berotated to enable the one-to-one corresponding through holes to be staggered, the closure of the material discharge valve is realized, the one-to-one corresponding through holes are communicated by rotating the mobile layer, the opening of the material discharge valve is realized, the coked large-particle defective products can be effectively filtered, the quality of products is guaranteed, meanwhile, waste products are convenient to recycle, waste is reduced, and the production cost is saved.

Owner:杨烨天

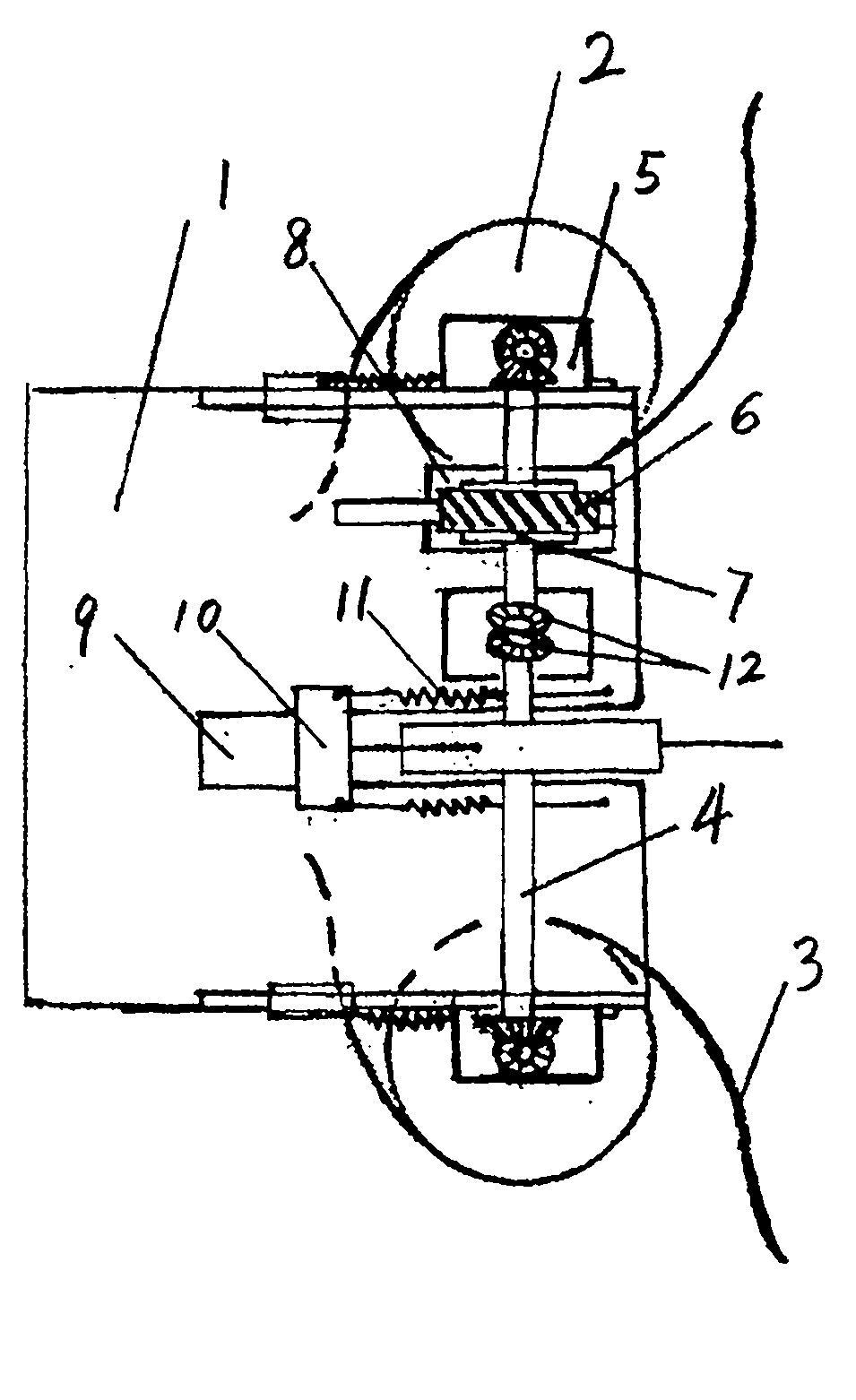

High-efficiency cotton picker head

The invention relates to a high-efficiency cotton picker head, a plurality of supporting frames are arranged around one end of a hard pipe material, a cotton picking claw assembly is arranged on each supporting frame, a sliding slot is arranged at the axial position of each cotton picking claw corresponding to the hard pipe material, a slide block is placed in each sliding slot, the slide blocks are connected to the mouth of a hard pipe through springs, external power is transmitted to the mutually linked cotton picking claw assemblies through a gear box, the cotton picking claw assemblies simultaneously and relatively rotate at the mouth of the hard pipe material to pick cotton approaching the cotton picking claw assemblies, and the picked cotton is output from the other end of the hard pipe material.

Owner:孙骏

Cultivation method of new cotton variety

InactiveCN107646599AContain less impurityDrip irrigation head water time delayCotton cultivationFertilising methodsDynamic fieldDisease

The invention discloses a cultivation method of a new cotton variety. The cultivation method comprises the following steps that firstly, sowing is conducted , wherein the sowing step comprises the sub-steps of land preparation, sowing in good time and control over the sowing quantity, the sowing depth and the sowing quality requirements; secondly, field management is conducted, wherein the step offield management comprises the sub-steps of drip irrigation for seedling emergence, hardening breaking, reseeding, timely intertillage, fertilizer conditioning, water and fertilizer management and topping; thirdly, disease and pest control is conducted. The cultivation method has the advantages that the cultivation method of the new cotton variety is high in yield and quality, the early, dense, dwarf, mulching and uniform high-yield cotton cultivation technology is carried out, key technologies, such as film mulching for increasing temperature, reasonable dense planting, drip irrigation for seedling emergence, current fertilizer conditioning, timely defoliation, are applied in the key periods, such as sowing, seedling emergence, topping and defoliation, the four key production links of preparation before sowing, sowing to guarantee full seedlings, field management and harvesting are well managed, the dynamic field indicators that cotton seedlings emerge in April, cotton buds emerge inMay, cotton flowers emerge in June, cotton bolls emerge in July and cotton batting emerges in August are achieved, and the high-yield, high-quality and efficient aims are achieved.

Owner:石河子农业科学研究院

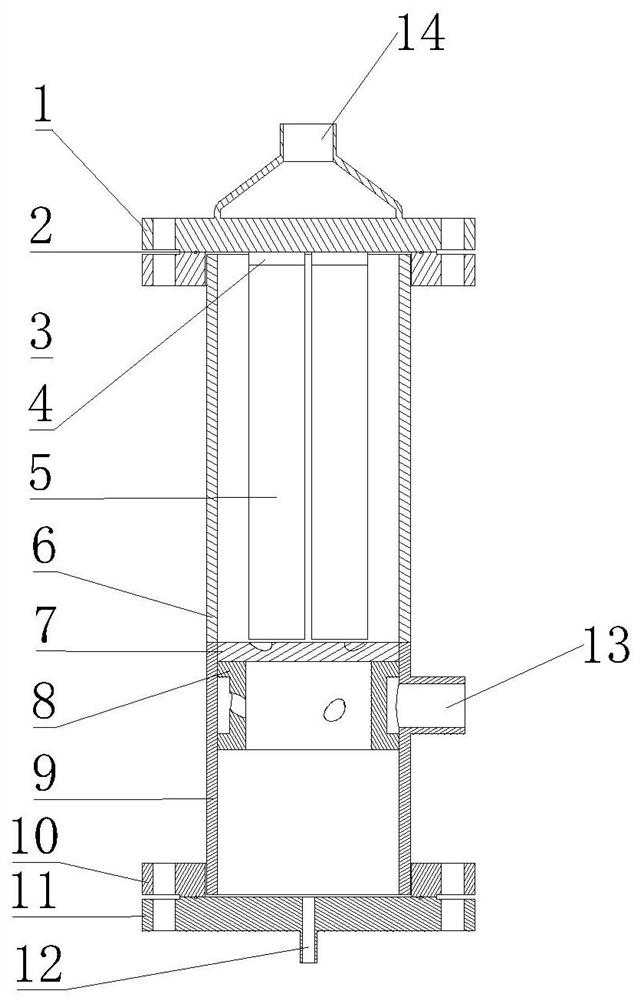

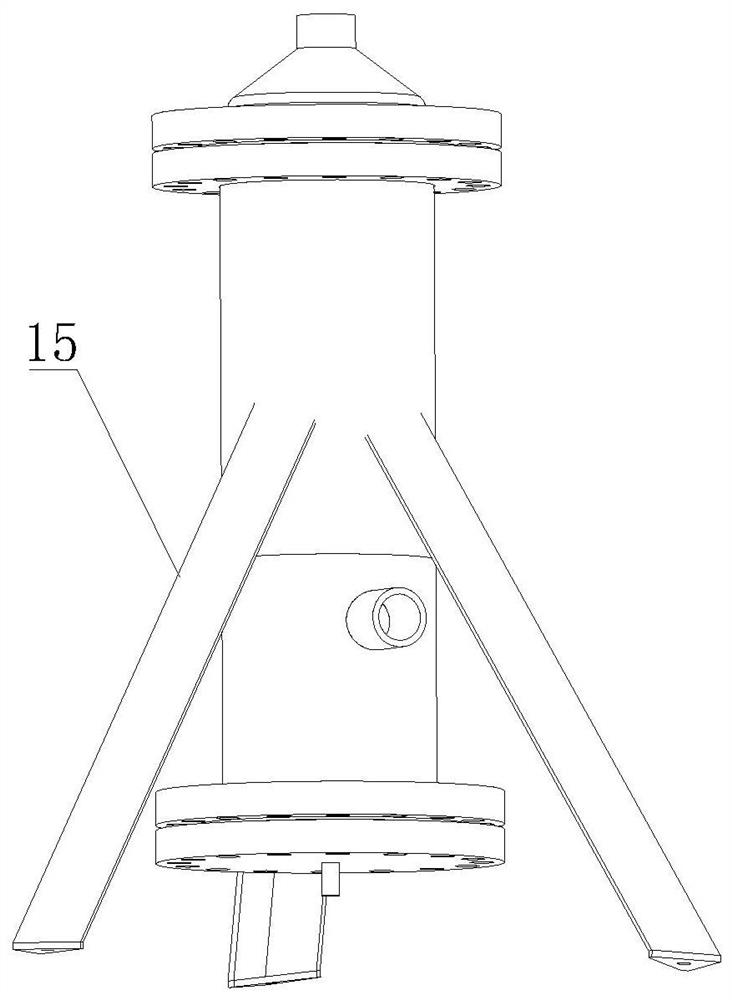

Two-stage cyclone filtering device

ActiveCN112473303AGood sand removal effectGood sealingCombination devicesEngineeringEnvironmental geology

The invention discloses a two-stage cyclone filtering device which adopts a two-stage cyclone design of a cyclone and a cyclone plate, natural gas mixed with coarse and fine sand grains with differentsizes is subjected to cyclone filtering through a first cyclone hole in the cyclone and a second cyclone hole in the cyclone plate respectively, and coarse sand is subjected to cyclone centrifugal filtering through the lower part of a cylinder body; fine sand is subjected to cyclone centrifugal filtration at the upper part of the cylinder body, sand grains in natural gas are subjected to optimized centrifugal filtration by designing the arrangement mode of the first cyclone hole and the second cyclone hole, then the sand grains are filtered by the aid of a filter cylinder, and finally, the natural gas discharged from a gas outlet is low in impurity content; overall, the functions of good sand discharging effect, good sealing performance, convenient disassembly and assembly, online sand discharging and the like can be achieved.

Owner:重庆市正华钻采设备有限公司

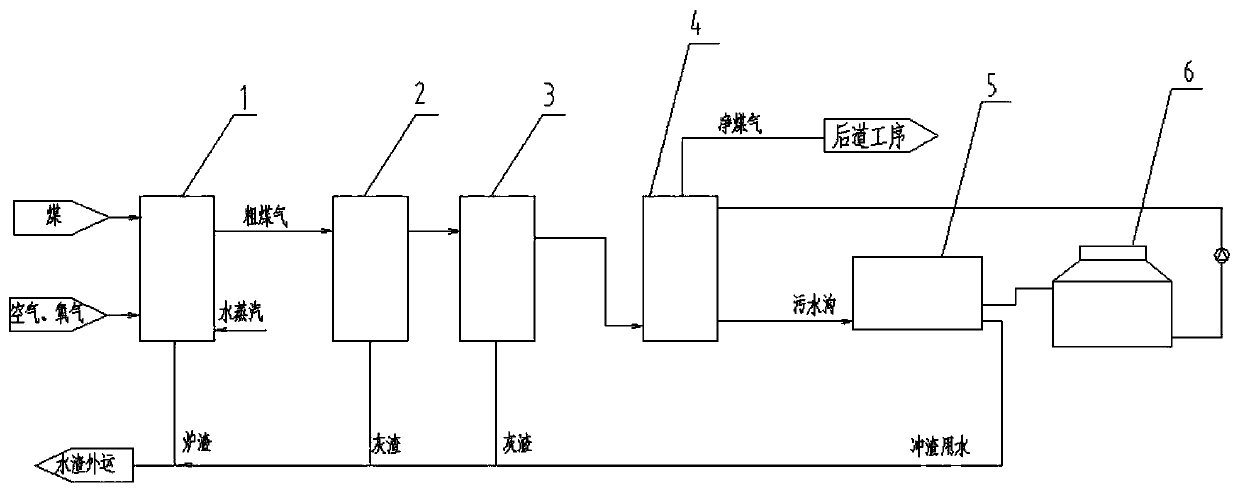

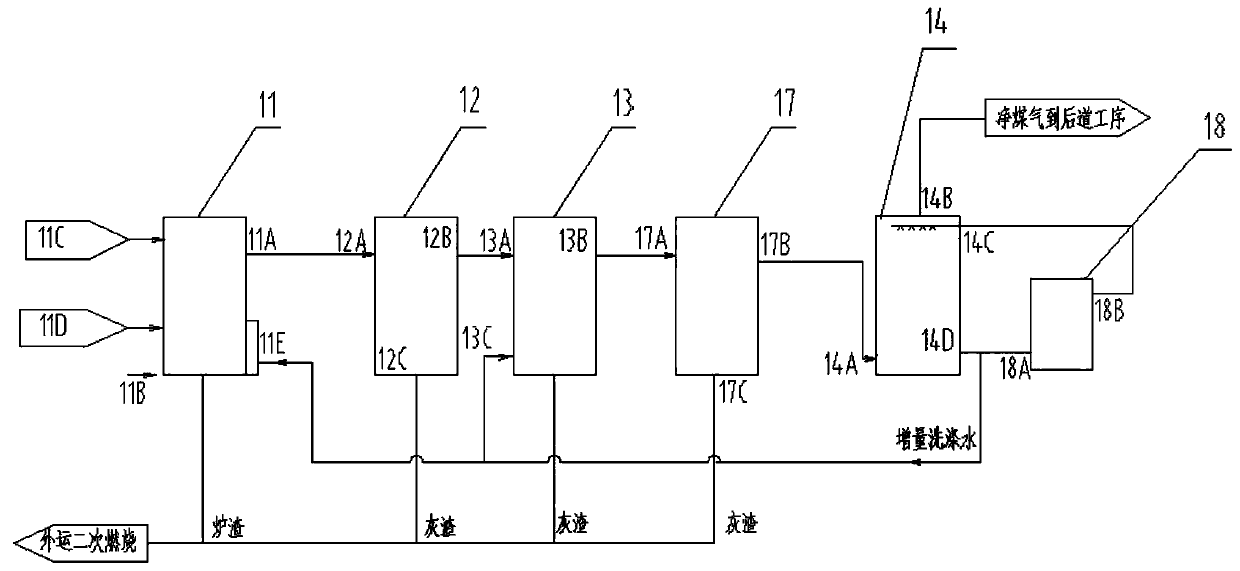

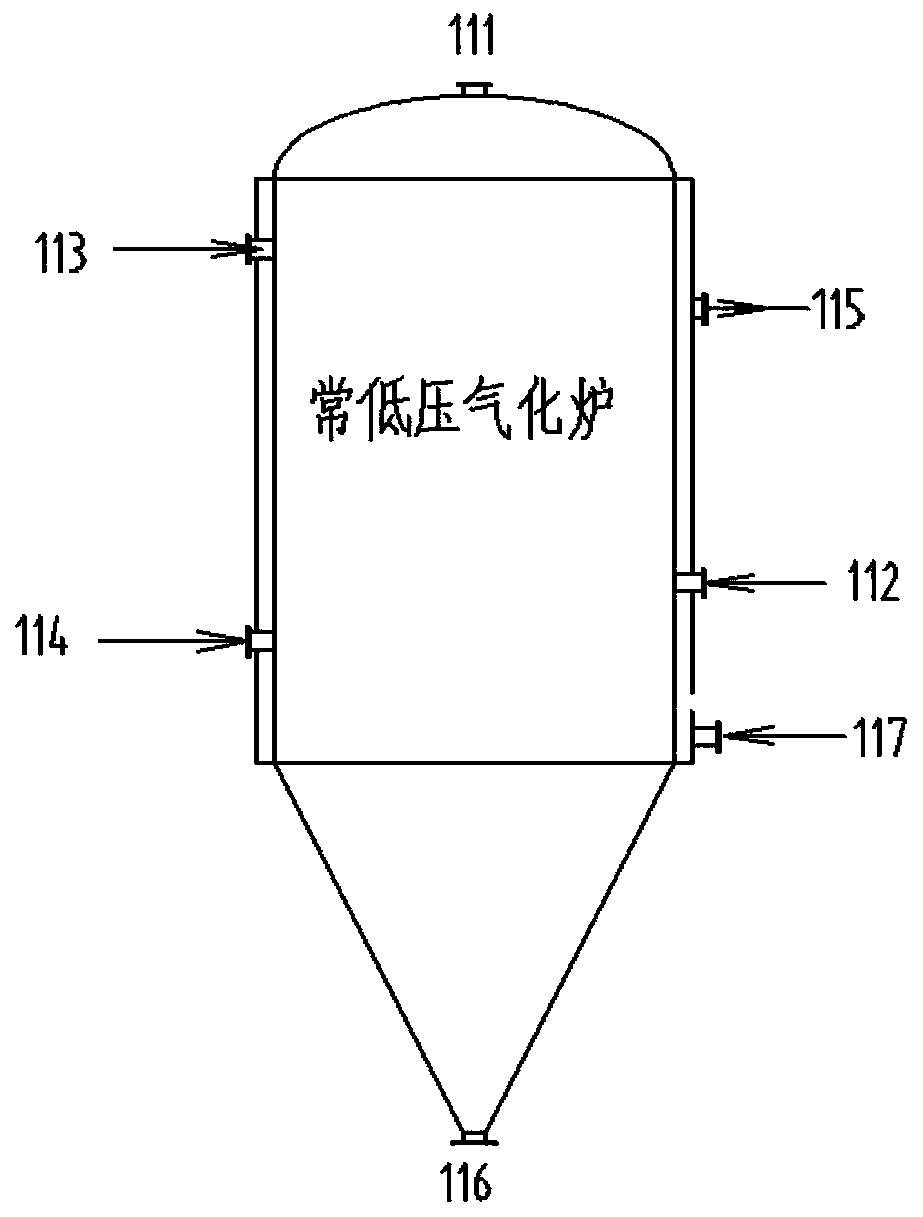

Coal-to-gas multi-pollution-source integrated treatment system and method

ActiveCN110129096AReduce COD valueContain less impurityEnergy inputCombustible gas purificationEngineeringTower

The invention discloses coal-to-gas multi-pollution-source integrated treatment system and method. The system comprises a normal-low pressure gasification device (11), a primary gas-solid separation device (12), a heat exchanger (13), a scrubber tower (14), a self-cleaning filter (17) and a water heat exchanger (18), wherein the normal-low pressure gasification device (11), the primary gas-solid separation device (12), the heat exchanger (13), the self-cleaning filter (17), the scrubber tower (14) and the water heat exchanger (18) are sequentially connected. The primary gas-solid separation device (12) is the following treatment device of the normal-low pressure gasification device (11), the heat exchanger (13) is the following treatment device of the primary gas-solid separation device (12), the self-cleaning filter (17) is the following treatment device of the heat exchanger (13), the scrubber tower (14) is the following treatment device of the self-cleaning filter (17), and the water heat exchanger (18) is the following treatment device of the scrubber tower (14). The system and the method solve the problems of poor environmental protection effect, serious pollution to the surrounding environment and the like in the existing process.

Owner:上海境业环保能源科技股份有限公司

A kind of separation method of 1,5-pentanediamine

ActiveCN108276292BReduce pollutionReduce separation costsAmino compound purification/separationOrganic solventPolyamide

The invention discloses a separation method for 1,5-pentanediamine. The separation method comprises the following steps: (1) contacting a 1,5-pentanediamine solution with cationic resin and carrying out adsorption; and (2) eluting 1,5-pentanediamine adsorbed onto the resin. Compared with the prior art, the separation and recovery method for 1,5-pentanediamine in the invention increases the yield of 1,5-pentanediamine; a treated solution obtained after adsorption by resin is basically free of 1,5-pentanediamine residues and the resin does not adsorb tetrahydropyridine, thalli, proteins and other impurities, so separated 1,5-pentanediamine is high in purity and low in impurity content; and the treated solution obtained after resin adsorption does not contain any polar organic solvent, so thesolution is free of harm to environment and easy to treat, and environmental pollution and separation cost are reduced. Meanwhile, a 1,5-pentanediamine diacid solution obtained after elution with diacid can be directly used as a raw material for synthesis of high-performance polyamide.

Owner:CATHAY R&D CENT CO LTD

Combined comb-tooth-type cotton picker with self-cleaning function

The invention discloses a combined comb-tooth-type cotton picker with a self-cleaning function, comprising a power-driven chain-harrow-type transmission device arranged on the upper frontal end of a rack and a cotton cleaning machine formed by a U-shaped sawtooth roller and a steel brush cotton roller; a cotton stalk pressing guide device is arranged on the rack at the front part of a picking platform; comb teeth which are mutually parallel are fixedly connected on a crossbeam evenly; the front ends of the comb teeth incline upwards; a power-driven pulling preventing roller is arranged at the rear lower part of the comb teeth; the chain-harrow-type transmission device which is matched with the comb teeth is arranged above the comb teeth; a cotton feeding roller is arranged on a discharge hole of the chain-harrow-type transmission device; the cotton cleaning device formed by the U-shaped sawtooth roller and the steel brush cotton roller is arranged below the cotton feeding roller; and a cotton collecting chamber is arranged at the rear part of the cleaning device. The cotton picker provided by the invention has no special requirements on the cotton planting mode in row space, and can be suitable for the planting mode of any row space; in the combined cotton picker, 'zero distance' transmission is implemented, thus the cotton picker has the advantages of novel and compact structure, simple and direct operational procedures, convenience in maintenance, low manufacture cost, long service life, low operational failure rate and low-impurity seed cotton and the like.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

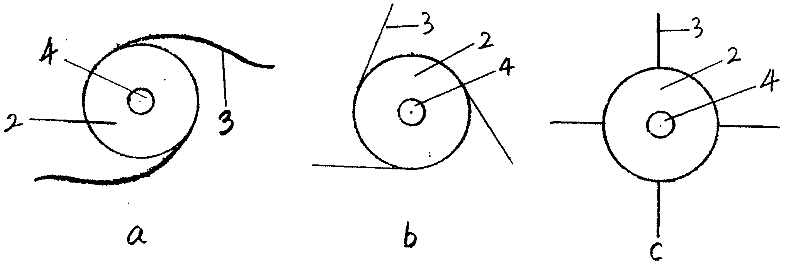

High-efficiency cotton picker head

The invention relates to a high-efficiency cotton picker head, a plurality of supporting frames are arranged around one end of a hard pipe material, a cotton picking claw assembly is arranged on each supporting frame, a sliding slot is arranged at the axial position of each cotton picking claw corresponding to the hard pipe material, a slide block is placed in each sliding slot, the slide blocks are connected to the mouth of a hard pipe through springs, external power is transmitted to the mutually linked cotton picking claw assemblies through a gear box, the cotton picking claw assemblies simultaneously and relatively rotate at the mouth of the hard pipe material to pick cotton approaching the cotton picking claw assemblies, and the picked cotton is output from the other end of the hard pipe material.

Owner:孙骏

Exhausting separating cleaning apparatus for combine harvester

The invention discloses an exhausting separating cleaning apparatus for combine harvesters. The invention comprises a reciprocating wobbling sieve driven by a driving mechanism installed on the frame. The sieve comprises a sieve body and a grain-gathering bin whose bottom is equipped with a grain exit. The sieve body comprises a sieve base plate and a square baffle plate. The front part of the sieve nest is equipped with a sieve base plate; the back part is equipped with a grain entrance and the upside is equipped with a drawing fan and a wind-gathering cover. The invention has a good cleaning effect that grains and weeds can be efficiently separated and the separated grains contain little foreign matters; the invention is of simple structure and low power consumption and occupies small space, thus is in favor of raising whole machine performance of harvesters.

Owner:湖南省双峰县湘源皇视电子有限公司

Sorting machine for sorting hard materials and sorting method thereof

The invention discloses a sorting machine for sorting hard materials and a sorting method thereof. The sorting machine comprises a rack, a feeding mechanism, a charging mechanism, a sorting mechanism and a material receiving mechanism, wherein feeding mechanism vibrates, so that materials can rapidly fall off to the sorting mechanism in a controllable mode; mixed materials display the properties of light transmitting and light tightness or light reflection and no light reflection through light sources; a sensor and a lens can recognize materials which are not required to be sorted and materials required to be sorted, and then a valve terminal spray nozzle is used for separating the materials which are not required to be sorted and the materials required to be sorted; the separated materials are classified and gathered by the material receiving mechanism. According to the invention, efficient, rapid and high-yield effects can be achieved, so that the impurity content of the hard materials can be reduced greatly, and the benefits and processing efficiency are improved; under the condition that the hard material requirement is increased day by day, high-quality hard materials can be provided efficiently and rapidly.

Owner:ANHUI VISION OPTOELECTRONICS TECH

A method for efficiently enriching platinum and palladium from low concentration platinum palladium nitric acid system solution

The invention discloses a method for efficiently enriching platinum and palladium from a low-concentration platinum-palladium nitric acid system solution. By adjusting the pH of the nitric acid system solution, adding complexing agent A and then adding regulator B after two stages of temperature control reaction, the reaction ends Finally, a platinum-palladium complex precipitate is obtained, and then the precipitate is calcined to remove organic matter to obtain a platinum-palladium concentrate. Separation of platinum and palladium is achieved by nitric acid leaching, nitric acid removal, and filtration. Add NH to the filtrate 4 Cl and KClO 3 Obtain a red precipitate, add ammonia water to the red precipitate to dissolve and filter, then add HCl to obtain a yellow precipitate, then dissolve the yellow precipitate with ammonia water, and then add a reducing agent to obtain palladium sponge. Dissolve the platinum concentrate with aqua regia, and add NH to the solution after filtration 4 Cl, a precipitate is obtained, and the precipitate is slurried and reduced to obtain a coarse platinum powder. It solves the problems of incomplete recovery when the concentration of platinum and palladium is low, high impurity content, difficulty in enriching platinum and palladium, small precipitate particles, slow filtration, etc., and has the advantages of efficient enrichment of platinum and palladium, high product purity, and high recovery efficiency.

Owner:WESTERN MINING CO LTD +2

Al-Mg catalyst and catalytic synthesis process of alkoxyl carboxylate ether

InactiveCN100398196CGreat operating flexibilityContain less impurityPhysical/chemical process catalystsOrganic compound preparationEtherActive point

The present invention belongs to the field of catalyst preparing and organic compound synthesizing technology. The present invention provides one kind one Al-Mg catalyst for the embedded alkoxylation reaction between materials alkyl carboxylate and alkylene oxide, and the catalyst catalyzed one-step process of synthesizing diblocked alkoxyl carboxylate ether. The catalyst is inorganic metal compound and has simple preparing process and low cost. The catalyzing mechanism is double active point catalysis, and through double point embedding, all ester radical C-O bonds of the alkyl carboxylate are embedded into polyalkoxyl radical to obtain polyalkoxyl ester ether blocked with acyl and alkyl simultaneously and final product with high end blocking rate and high purity.

Owner:JIANGNAN UNIV

A kind of method for preparing high-concentration magnesium chloride solution by continuous dissolving of bischofite in salt lake

ActiveCN104030327BFast dissolutionImprove halogenation efficiencyMagnesium chloridesHigh concentrationSalt lake

Owner:青海西部镁业有限公司

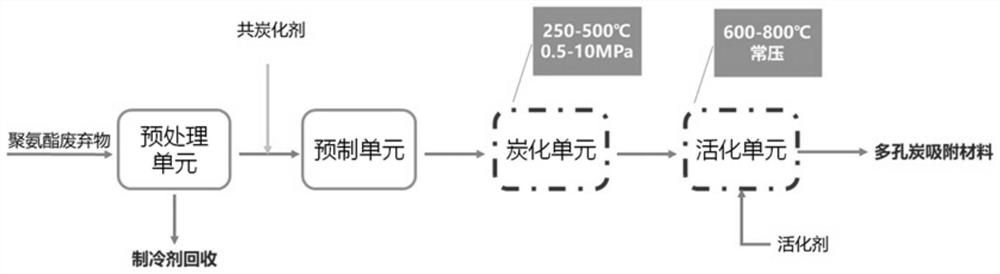

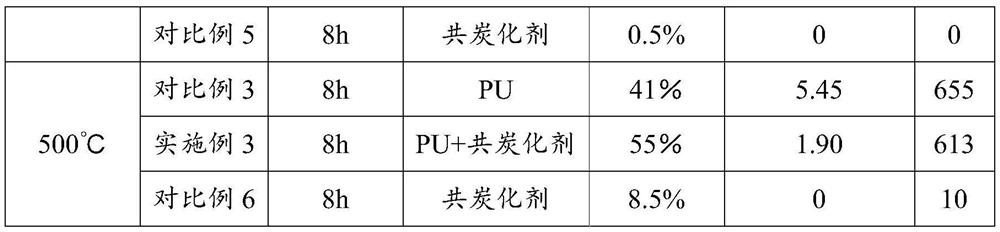

A high-temperature co-carbonization agent and its application in the carbonization process of plastic waste to increase carbon and fix impurities

The invention relates to a high-temperature co-carbonization agent and application thereof to recarburizing and impurity fixing in the carbonization process of plastic waste. The application of the high-temperature co-carbonization agent to recarburizing and impurity fixing in the carbonization process of the plastic waste comprises the steps that polyurethane waste is pretreated; the pretreated polyurethane powder is mixed with the co-carbonization agent, and carbonization is carried out under the protection of inert gas to form a carbonization material; and the carbonization material is mixed with an activating agent, high-temperature activation is carried out under the protection of the inert gas, the activating agent is removed, and drying is carried out to obtain an activated carbon product. According to the high-temperature co-carbonization agent and the application thereof tp recarburizing and impurity fixing in the carbonization process of the plastic waste, a synergistic effect existing between waste polyurethane plastics and the co-carbonization agent is used for improving the carbonization process yield, the activated carbon is prepared through high yield, the gas yieldand impurity-contained micromolecules in the preparation process are reduced, waste is turned into wealth, and good industrial application potentiality can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A curved grid plate re-cleaning type three-cylinder sieve oat cleaning device

ActiveCN109601142BReduce loadImprove efficiencyThreshersAgricultural engineeringStructural engineering

The invention relates to the field of agricultural machinery, in particular to an arc-shaped grid plate re-cleaning type three-cylinder sieve oat cleaning device. It includes a casing, a three-drum sieve cleaning mechanism, a grained rod drum type threshing mechanism, a reselection mechanism and a collection mechanism; the three-drum sieve cleaning mechanism includes a fan installed at one end of the casing, and a fan installed at the other end of the casing. The position of the miscellaneous discharge port and the rotation of the three cylindrical screens arranged in the casing and between the fan and the miscellaneous discharge port; The arc-shaped grid plate is distributed in the casing between the cylinder screen with the smallest diameter and the miscellaneous discharge port, and the first conveying auger is distributed at the position below the cylinder screen with the smallest diameter and the arc-shaped grid plate, The second conveying auger is used to convey the sieve collected in the first conveying auger to the largest diameter drum screen. The invention can effectively reduce the impurity rate and loss rate of oat grain cleaning in the prior art.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com