High-efficiency cotton picker head

A technology for picking cotton and machine head, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of reduced yield, low harvesting rate, high trash content, etc., and achieve the effect of low trash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

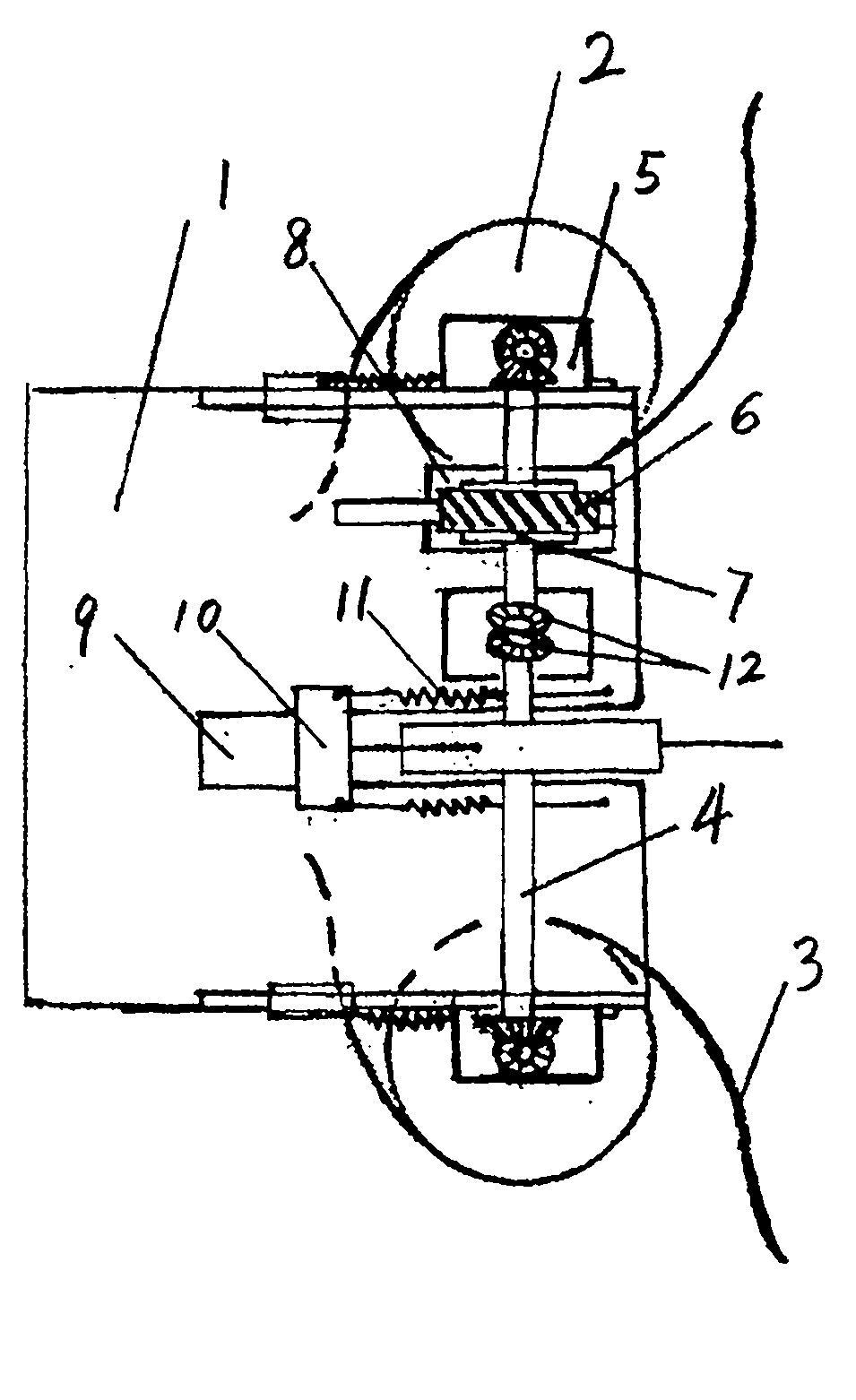

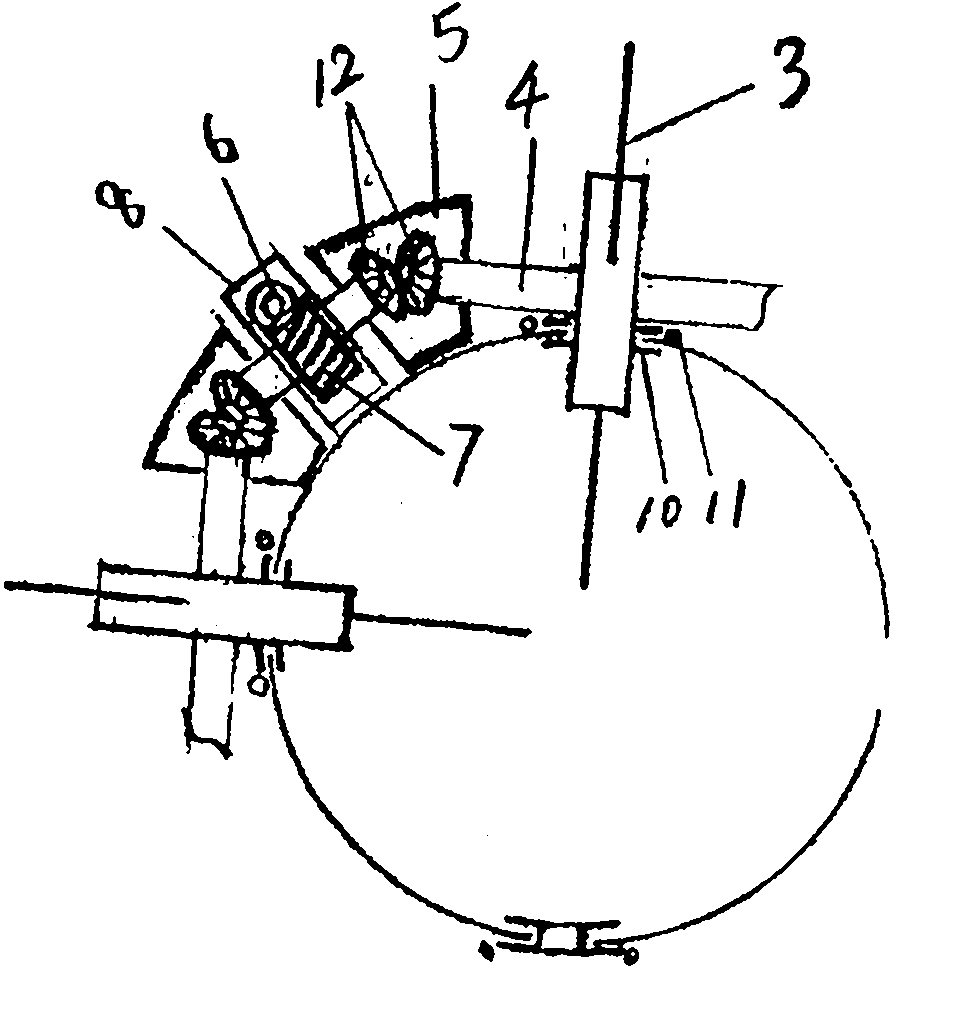

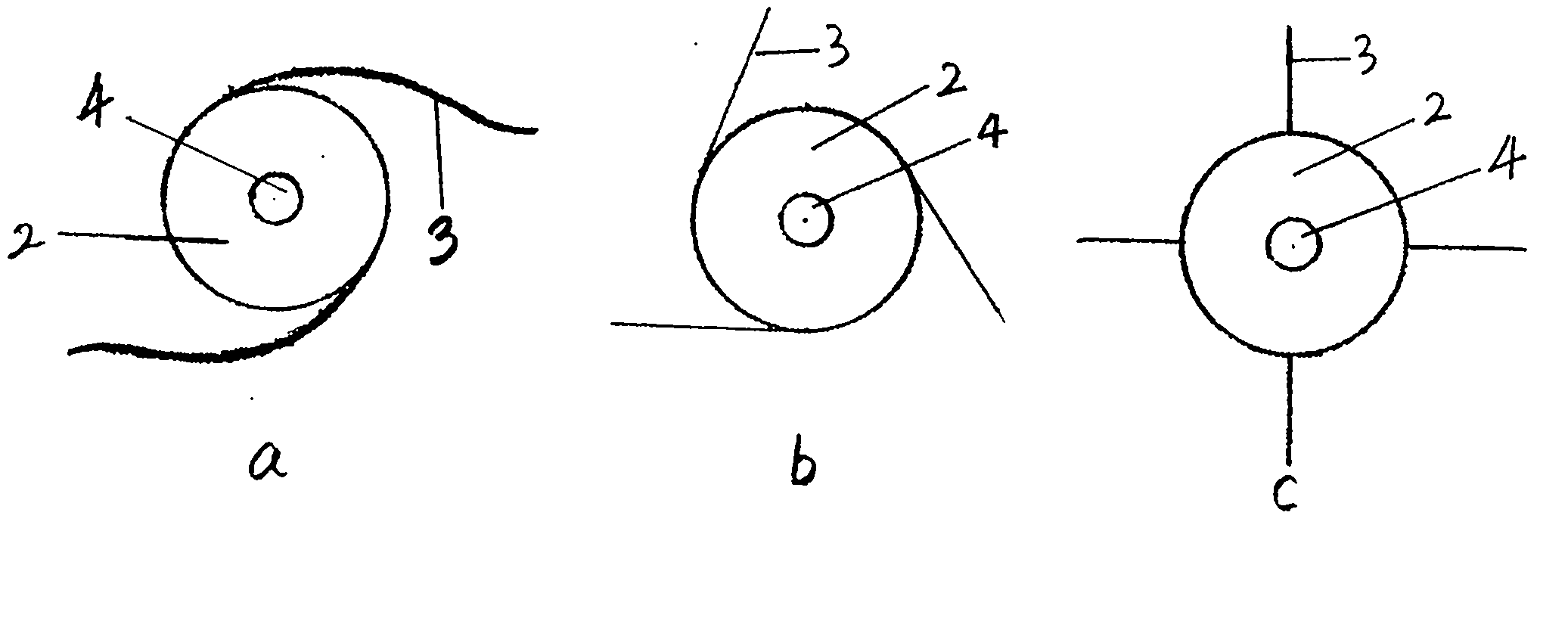

[0011] Around one end of the hard tube material (1) are fixedly provided with several supporting frames (5). The cotton picking claw assembly is housed in the supporting frame. The cotton picking claw assembly is composed of a base circle (2), a cotton picking claw (3), and Cotton claw shaft (4) is formed, and its shape feature is: be provided with cotton picking claw (3) on the outer circle of the basic circle body that is fixed with cotton picking claw shaft (4) in the center, each cotton picking claw shaft is connected by connecting piece (12) Connect and interlock with each other, open a chute (9) corresponding to the mouth of the hard tube material at each cotton picking claw, place a slider (10) in each chute, and the slider is connected to the The mouth of the hard tube material constitutes a doffing device. When the cotton picking claw is turned to the slider, the combination of the spring and the slider generates and maintains a certain pressure on the cotton picking c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com