Sorting machine for sorting hard materials and sorting method thereof

A sorting machine and material technology, applied in the field of sorting machines for sorting hard materials, can solve the problems of unrecognizable, high energy consumption, low quality, etc., and achieve the effects of high processing efficiency, reduced impurities, and fast sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

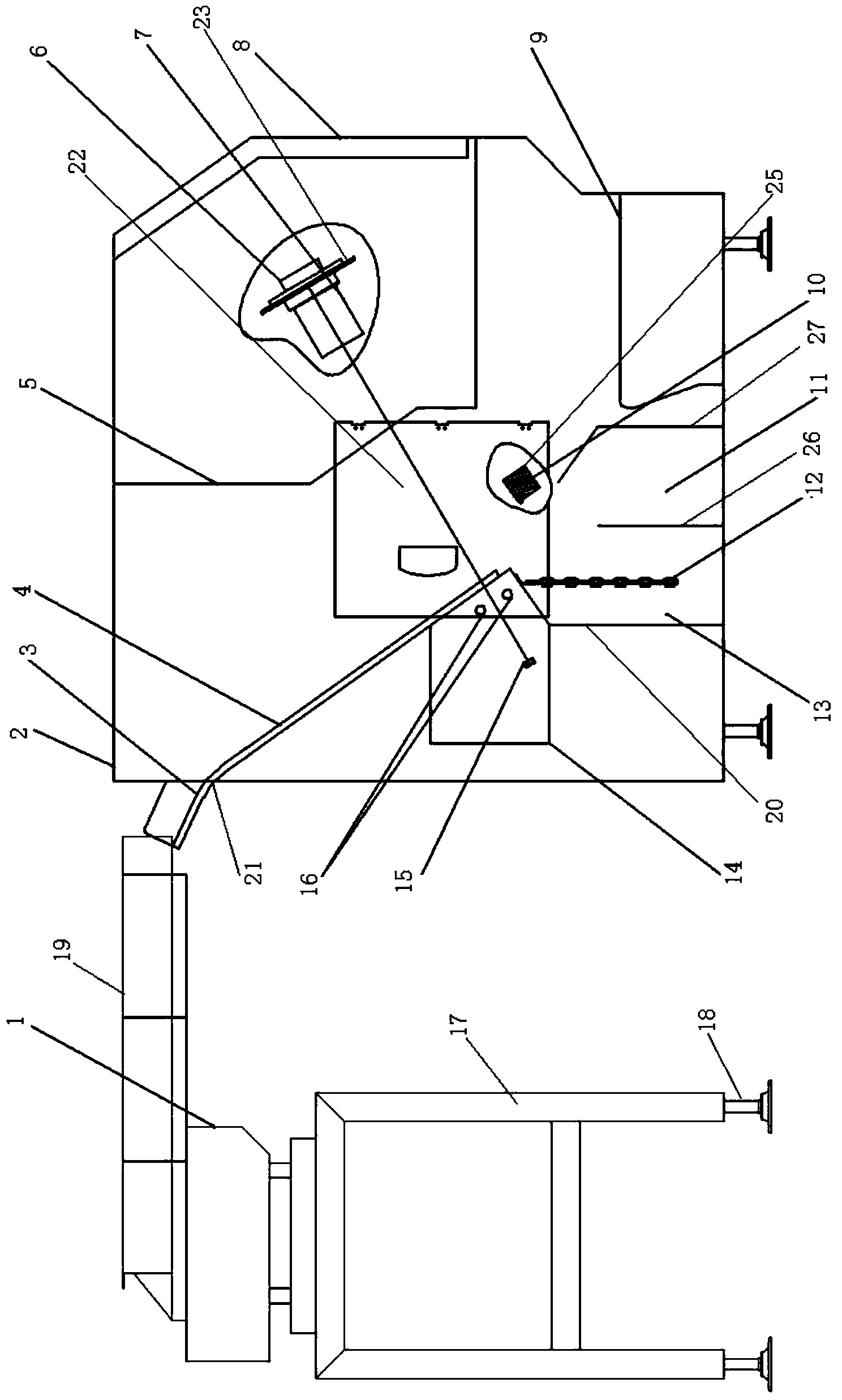

[0028] like figure 1 As shown, a sorting machine for sorting hard materials includes a frame 2, a feeding mechanism, a feeding mechanism, a sorting mechanism, and a material receiving mechanism.

[0029] Frame 2 is oppositely arranged with feeding mechanism, and feeding mechanism is made of feeder 1 fixed on support frame 17 (feeder 1 used in this embodiment is available on the market), and feeder 1 There is a feeding port 19, the bottom of the support frame 17 and the frame 2 are all arranged on the universal hoof 18, and the universal hoof 18 is used to adjust the level and height. One side of the frame 2 is provided with a feed inlet 21, and the adjacent side is provided with a side door 22, and a front door 8 is provided on the upper part of the side opposite to the feed inlet 21, and the front door 8 is fixed on the frame 2 using a hinge.

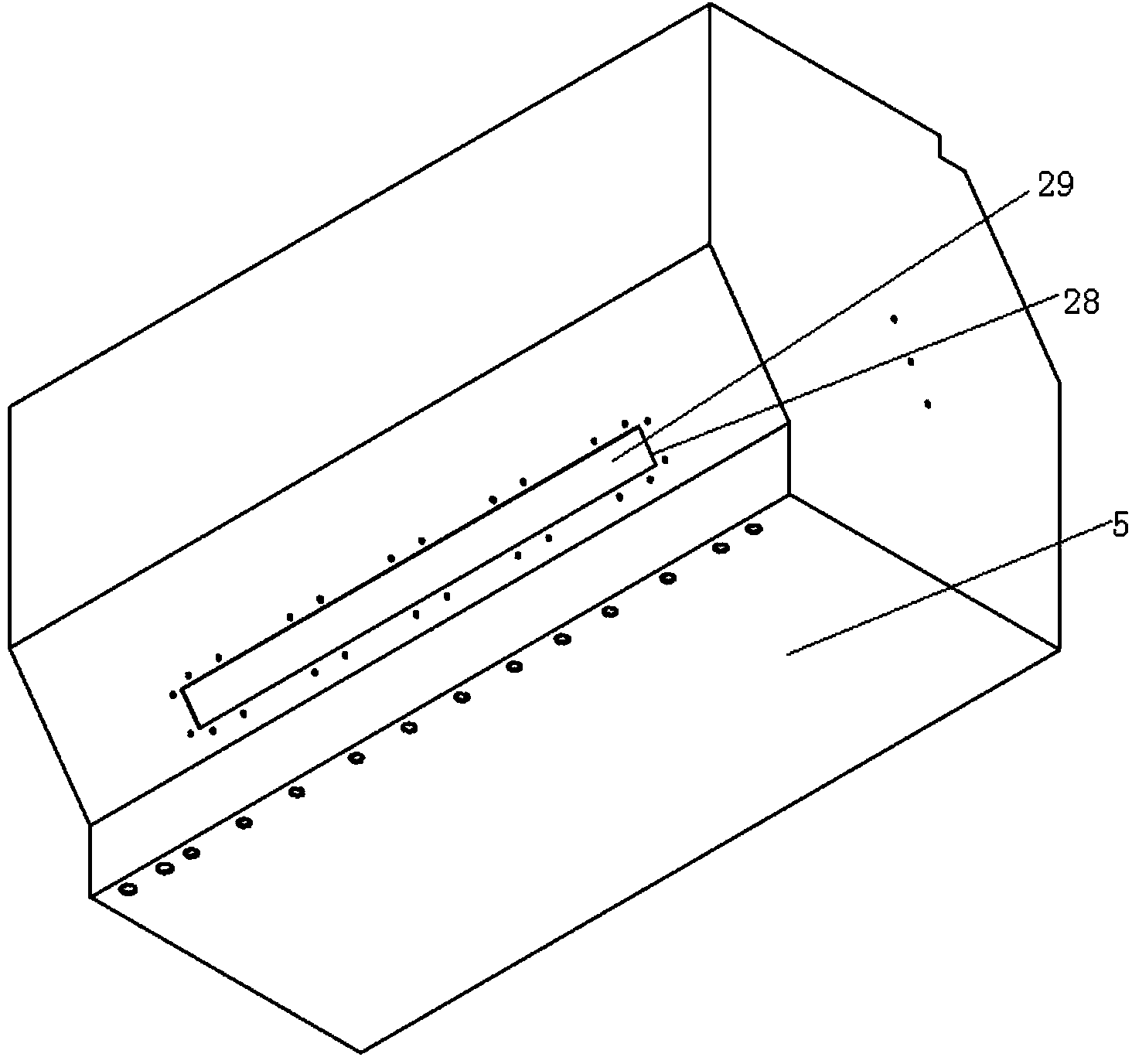

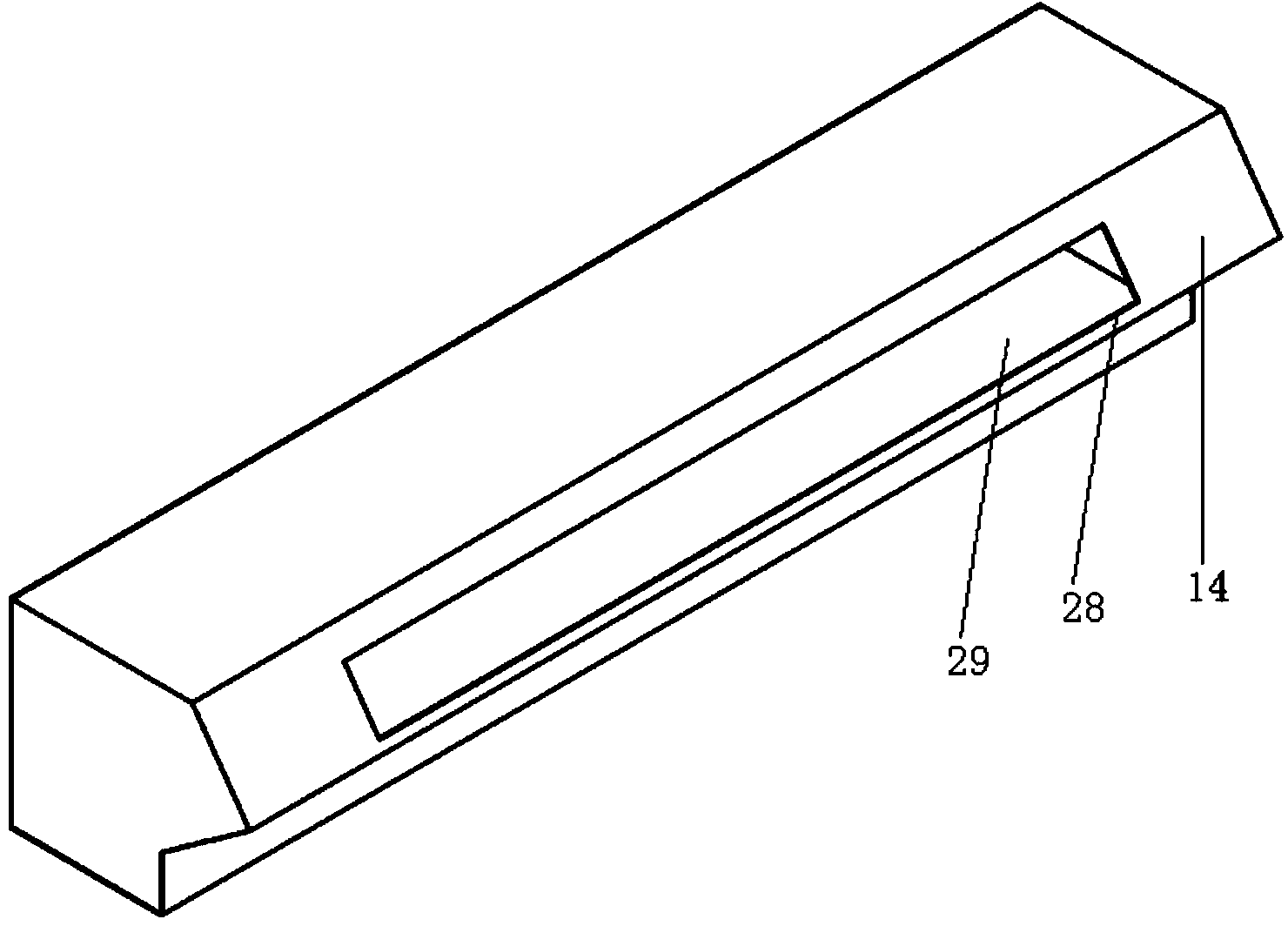

[0030] like Figure 4 , Figure 5 , Figure 6 As shown, the arc transition plate 3 , the glass run 4 and the chute support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com