Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Fast palletizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

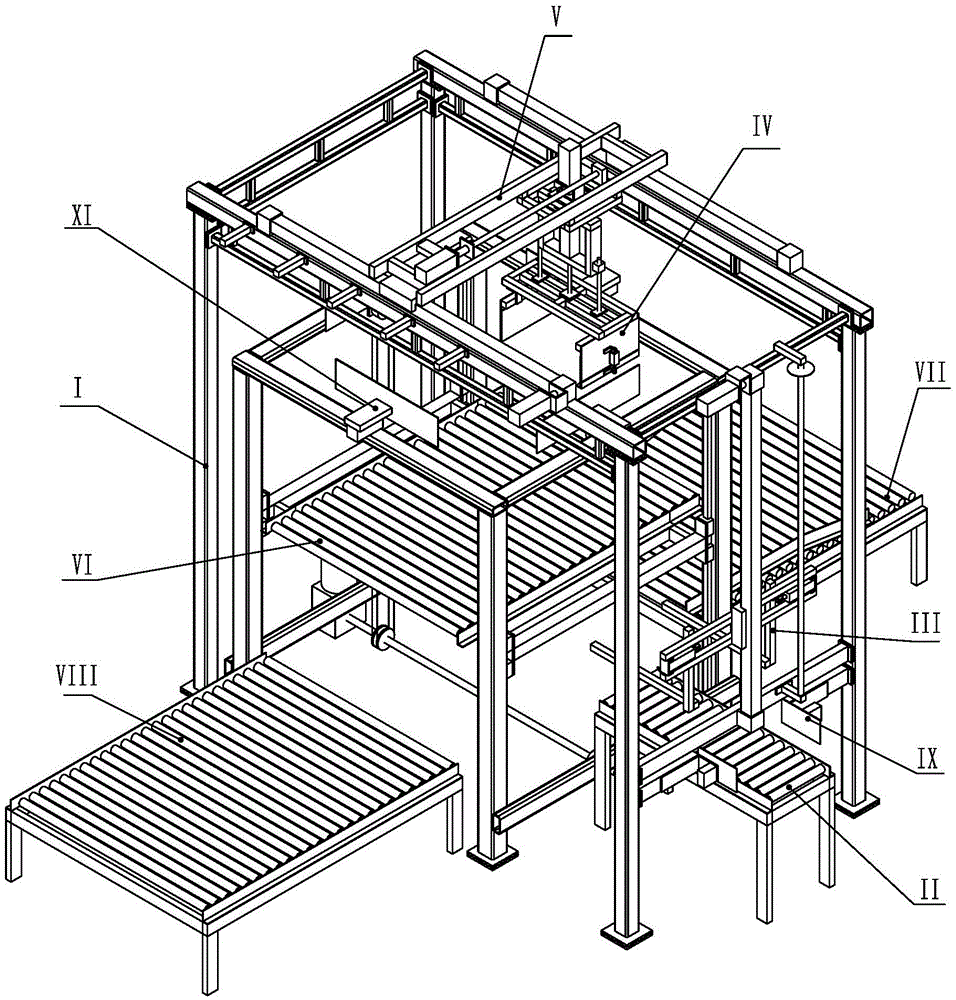

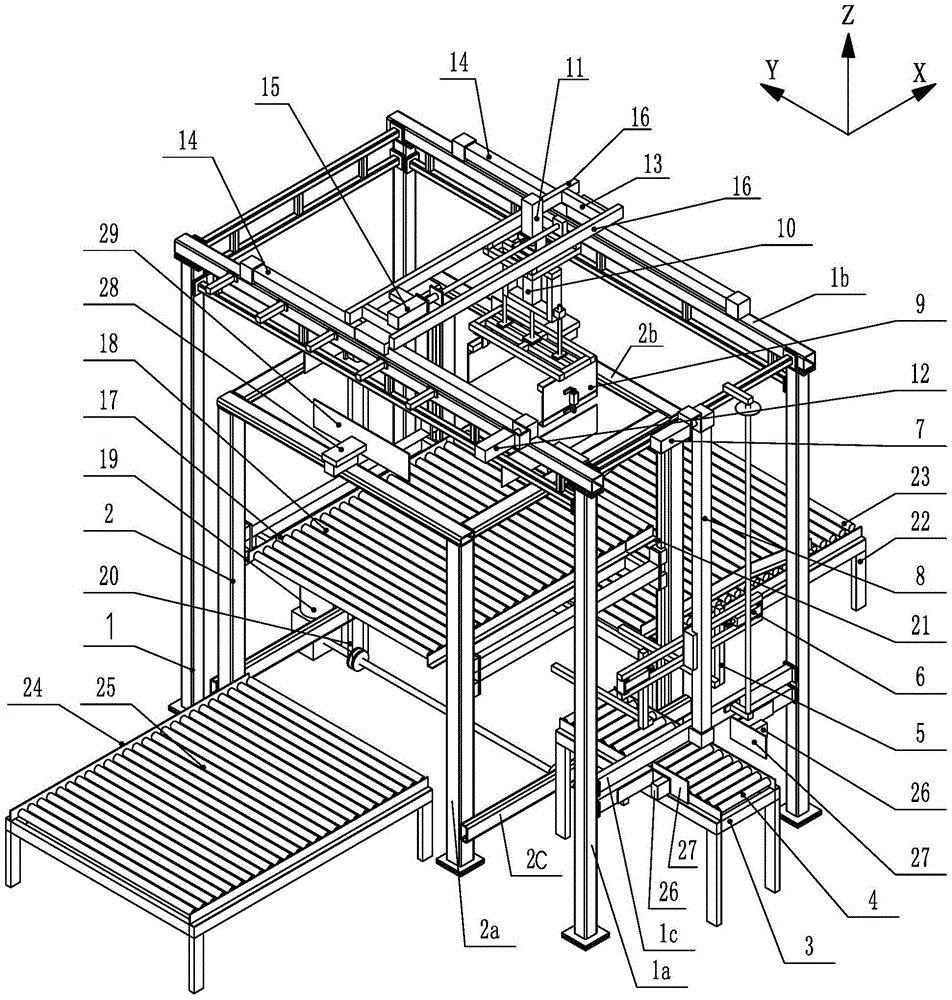

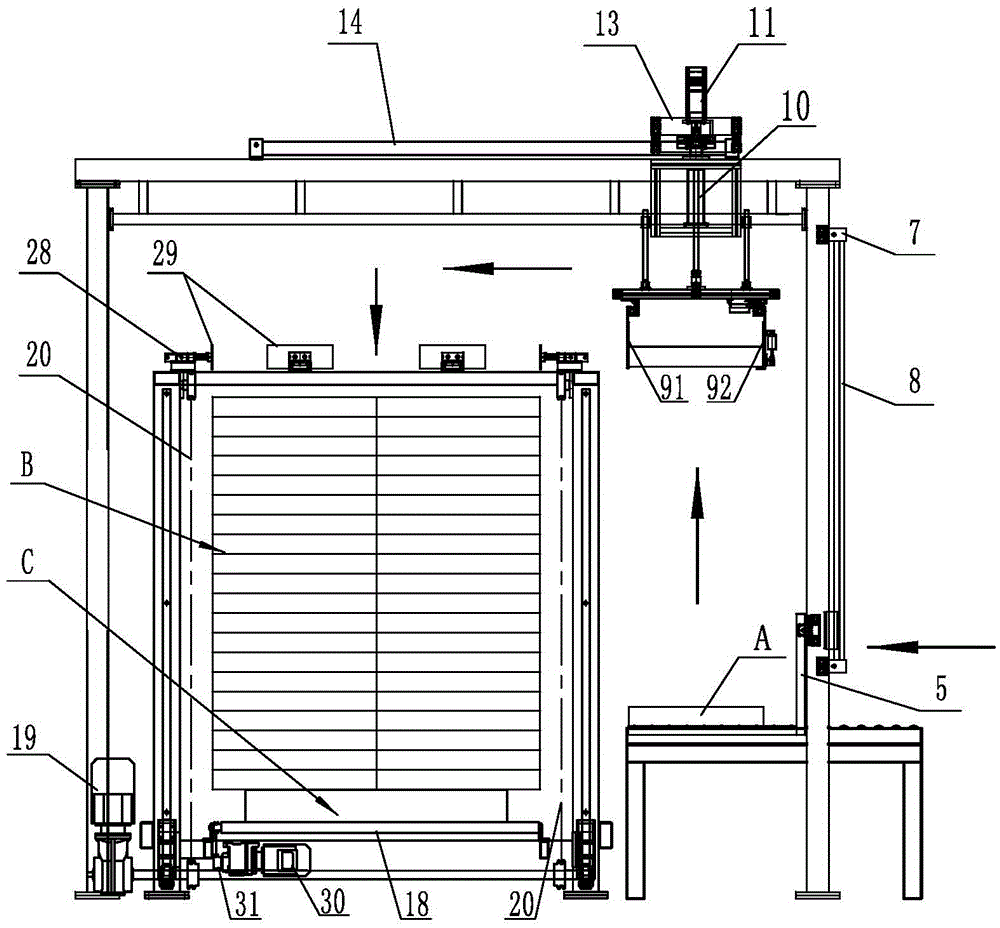

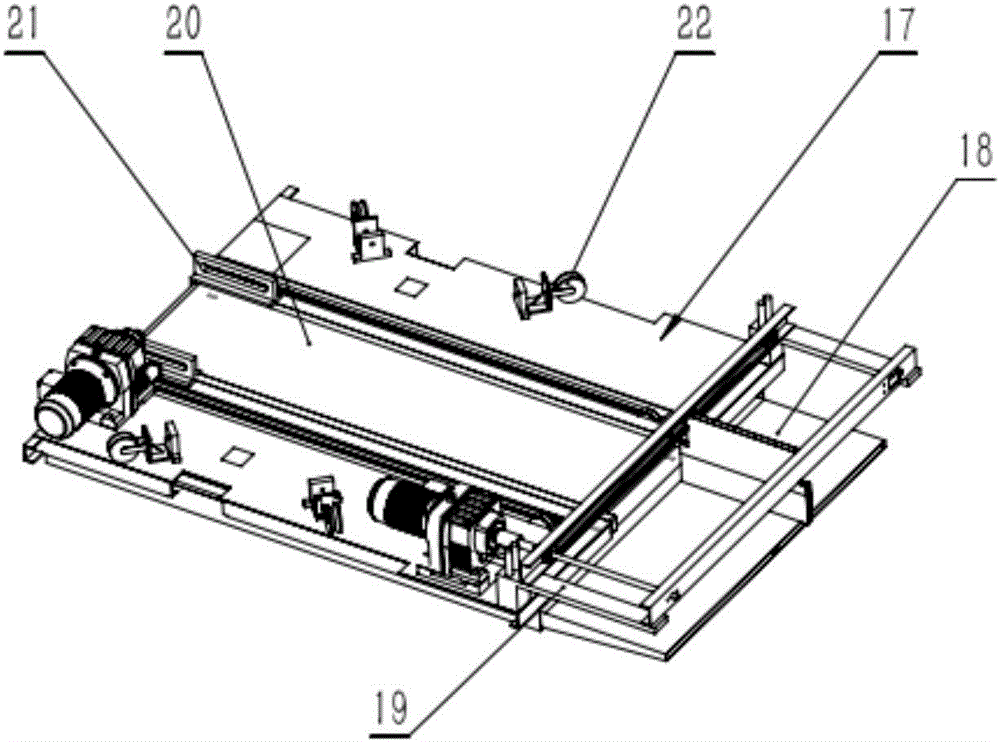

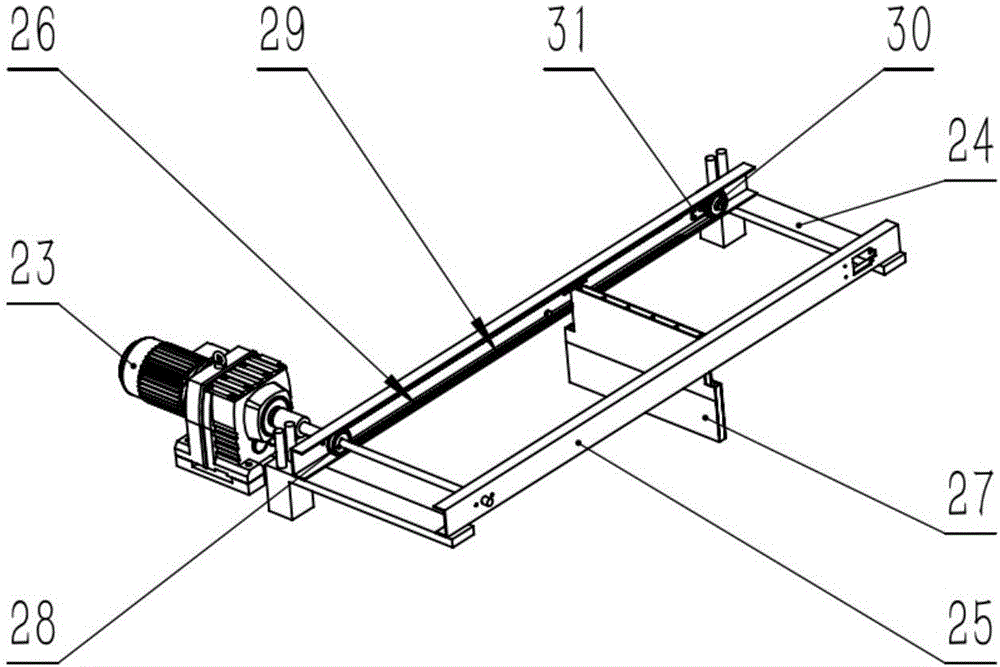

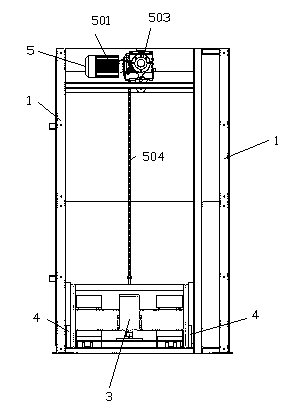

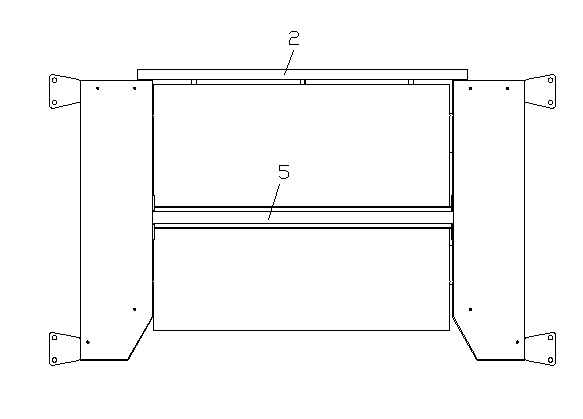

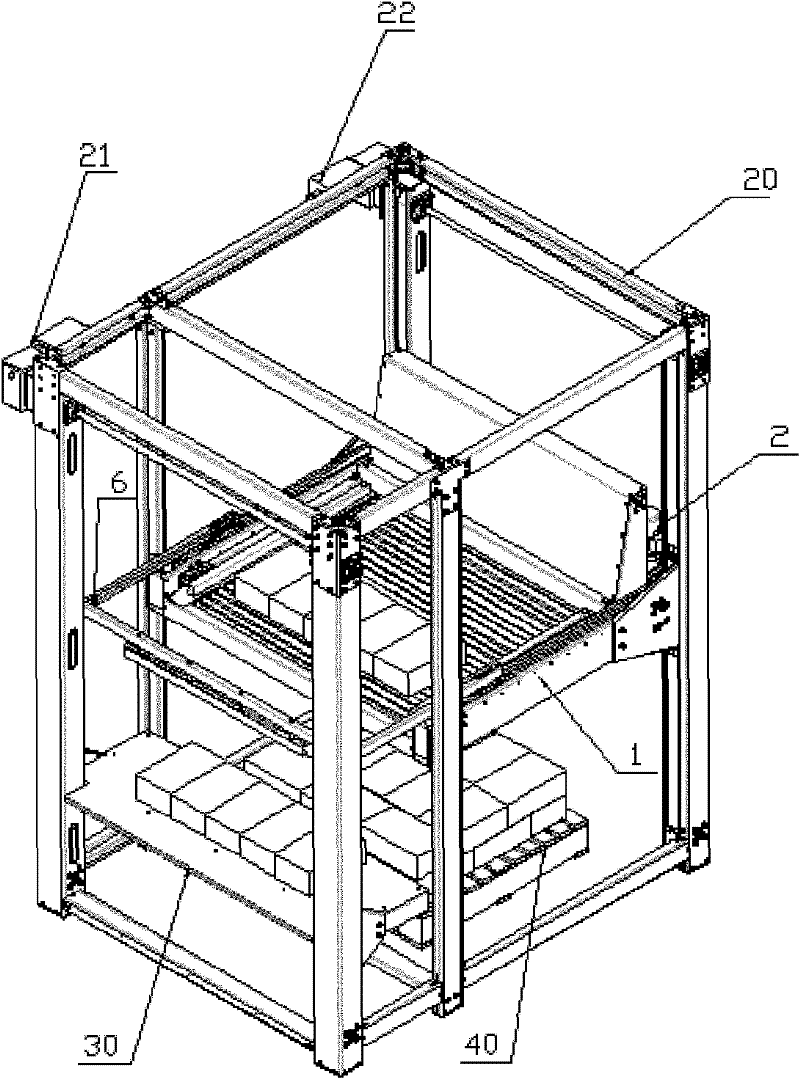

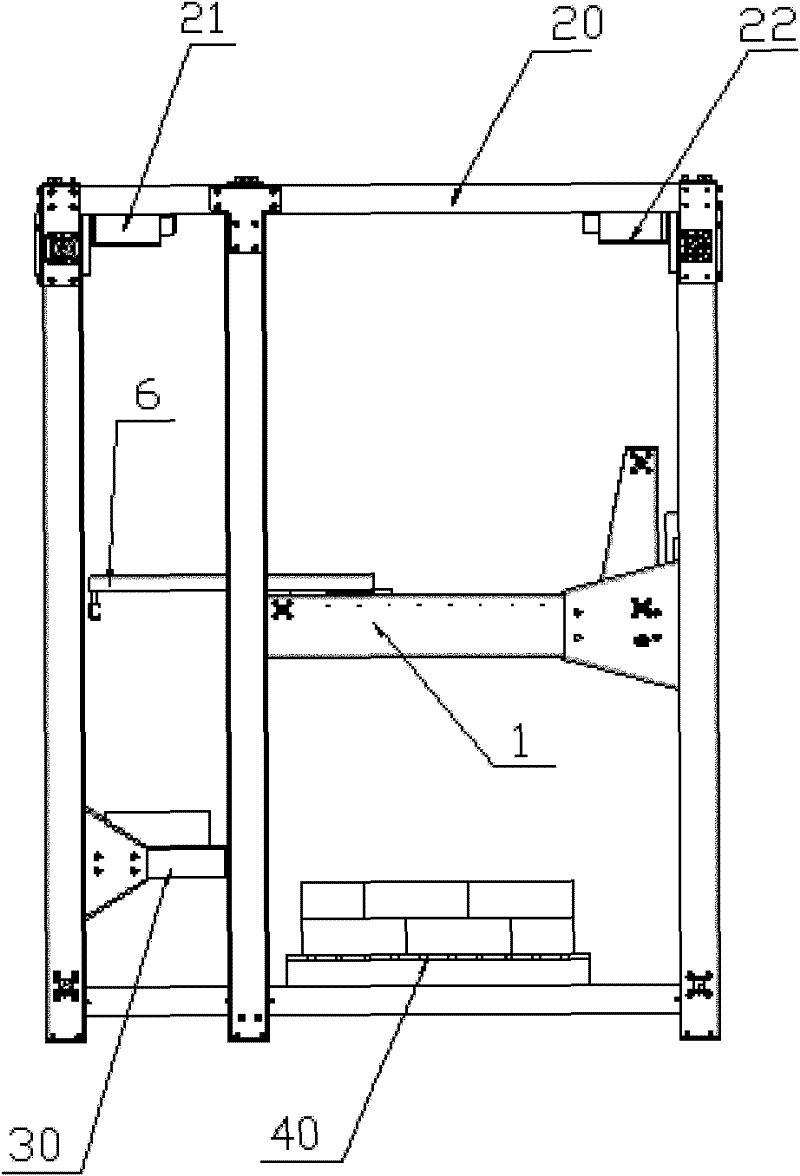

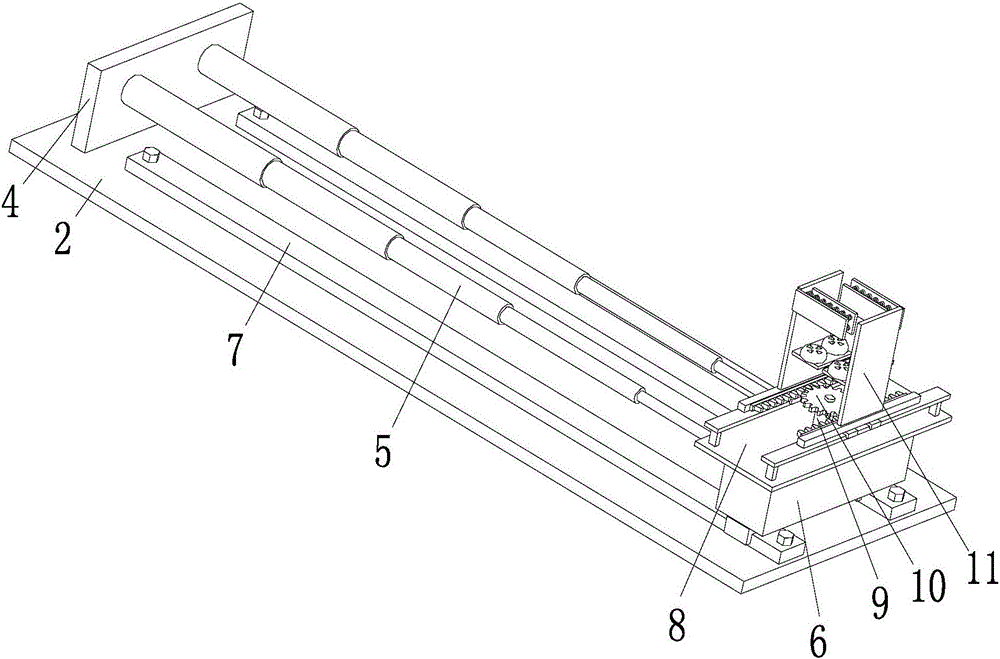

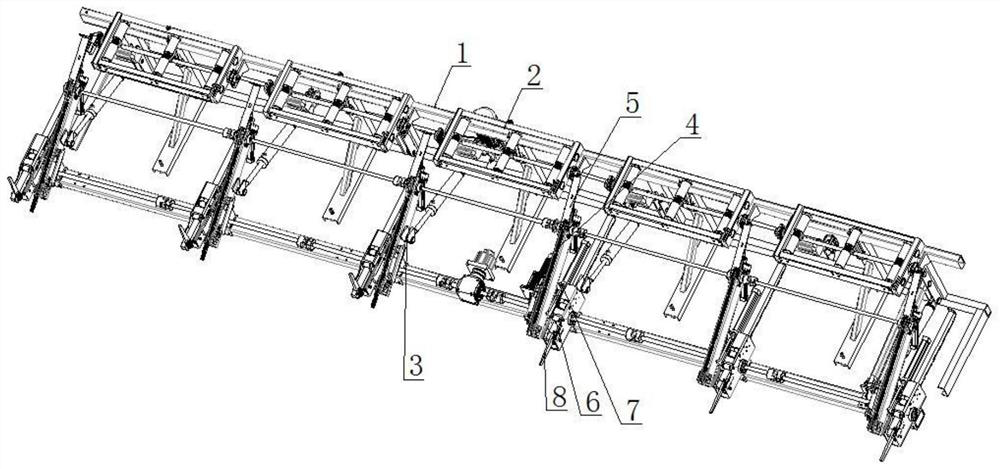

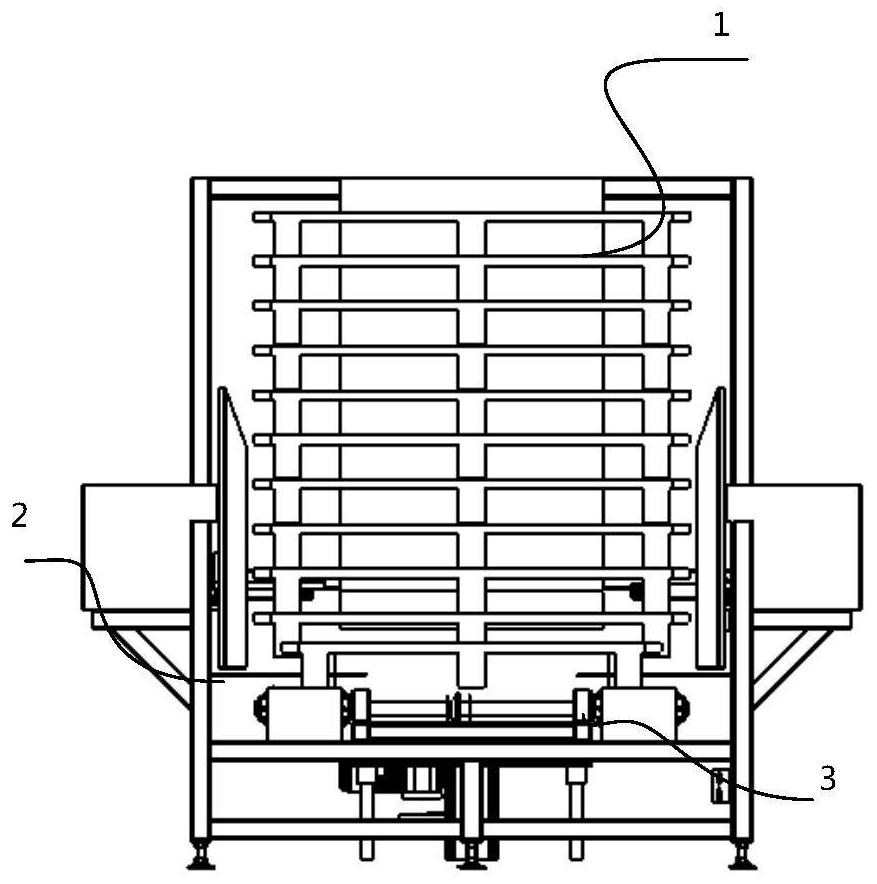

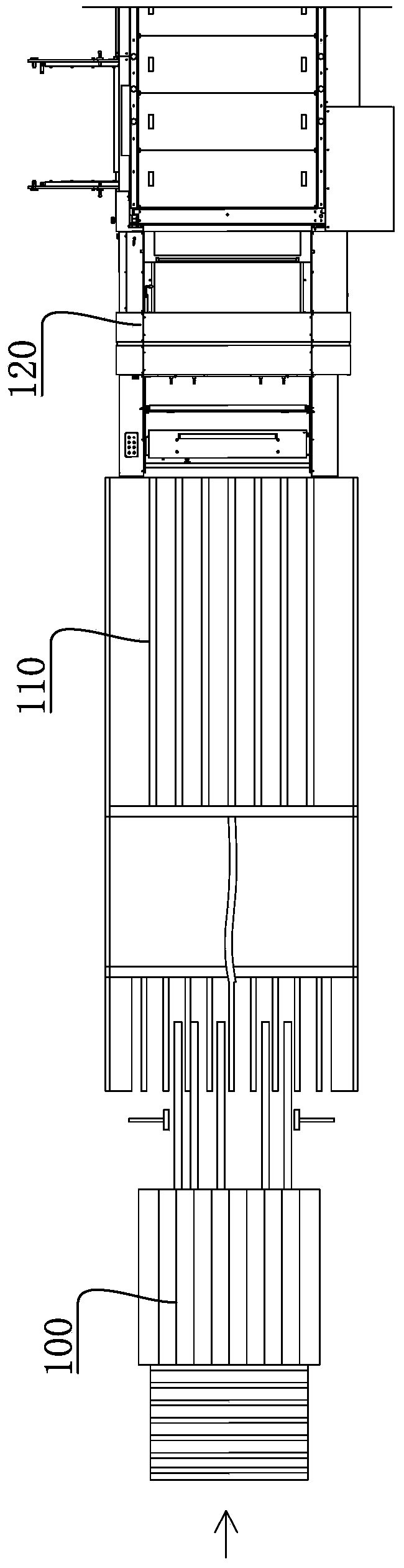

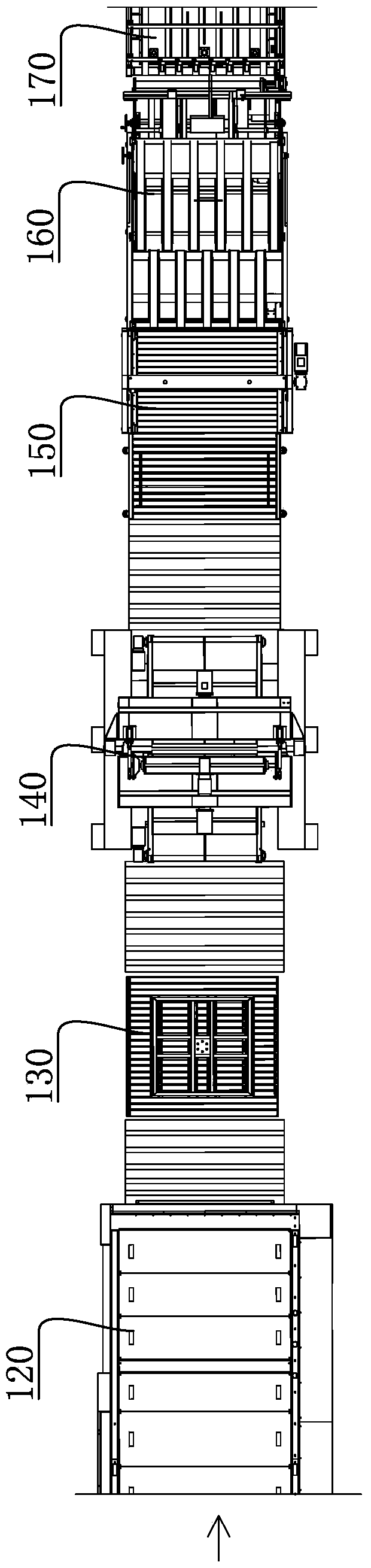

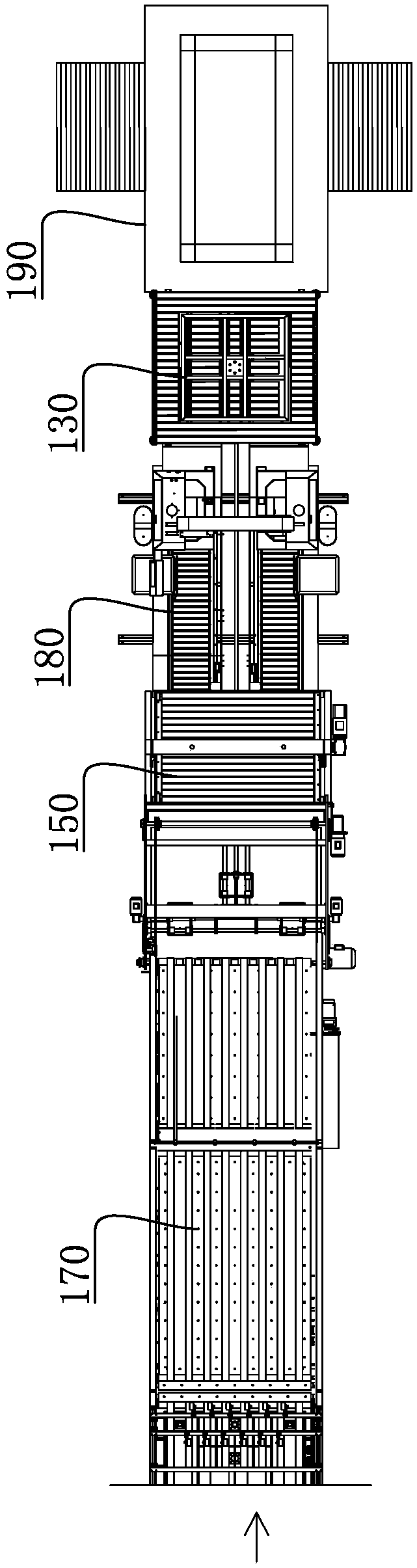

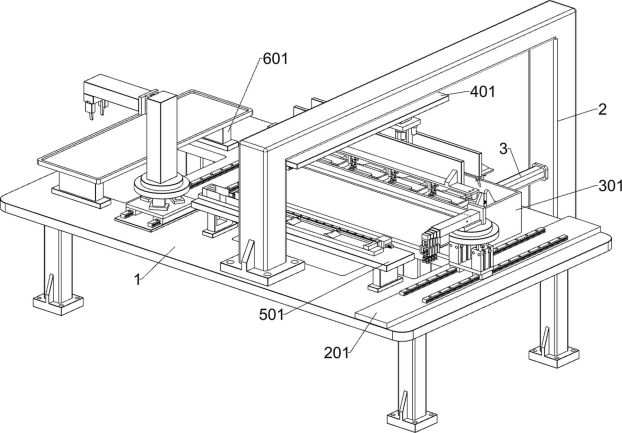

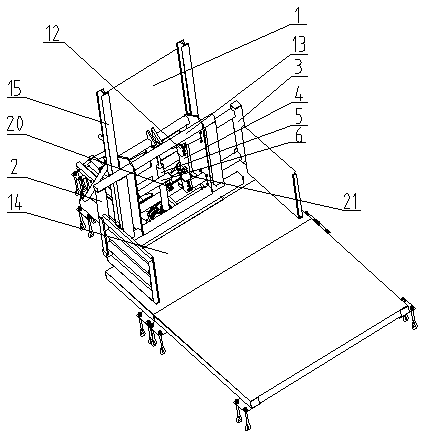

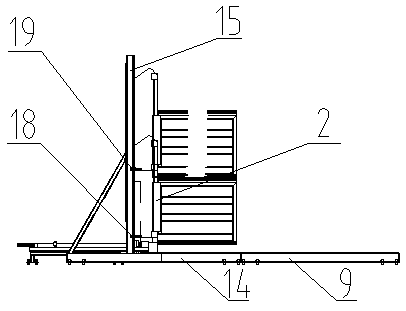

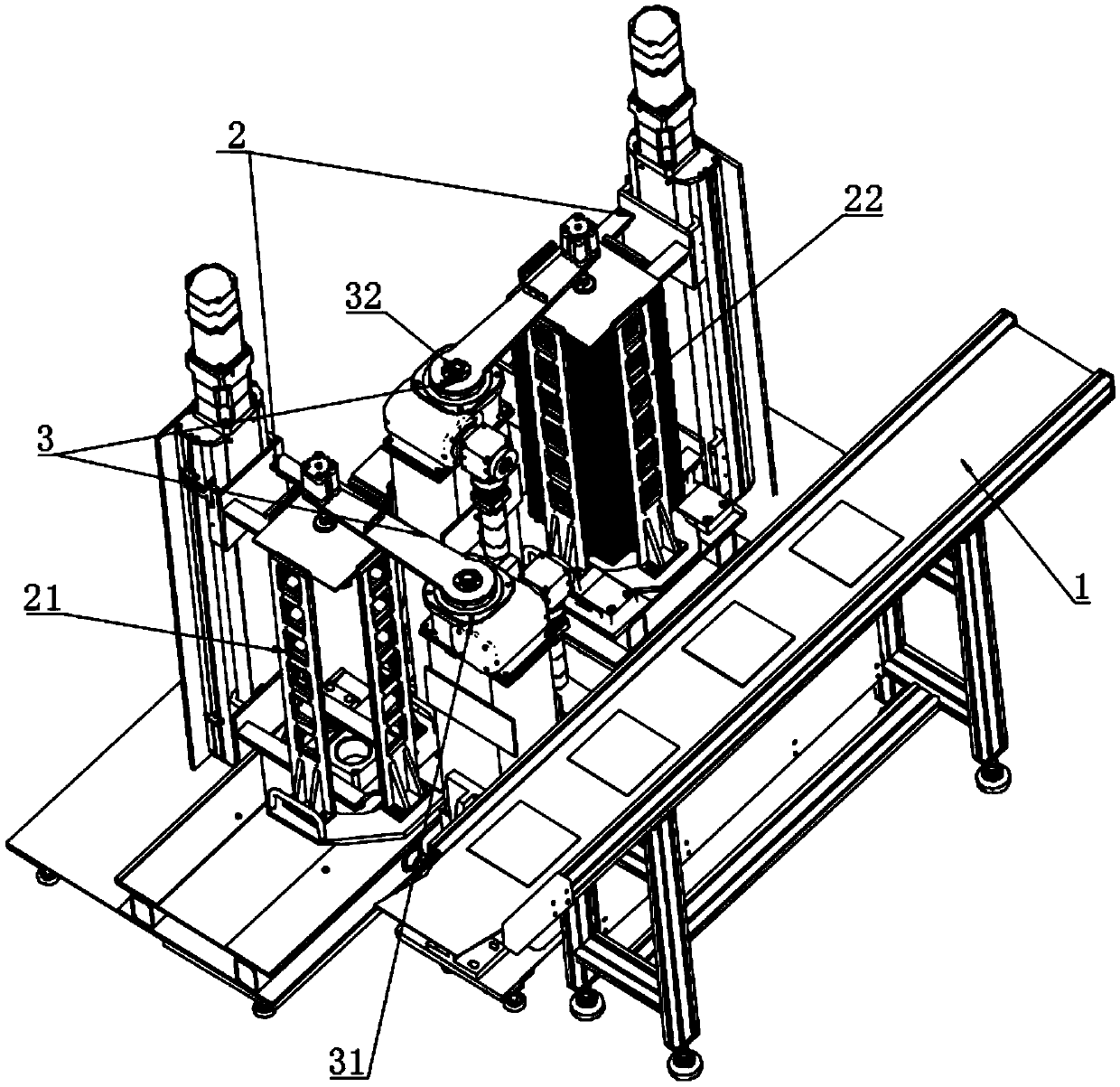

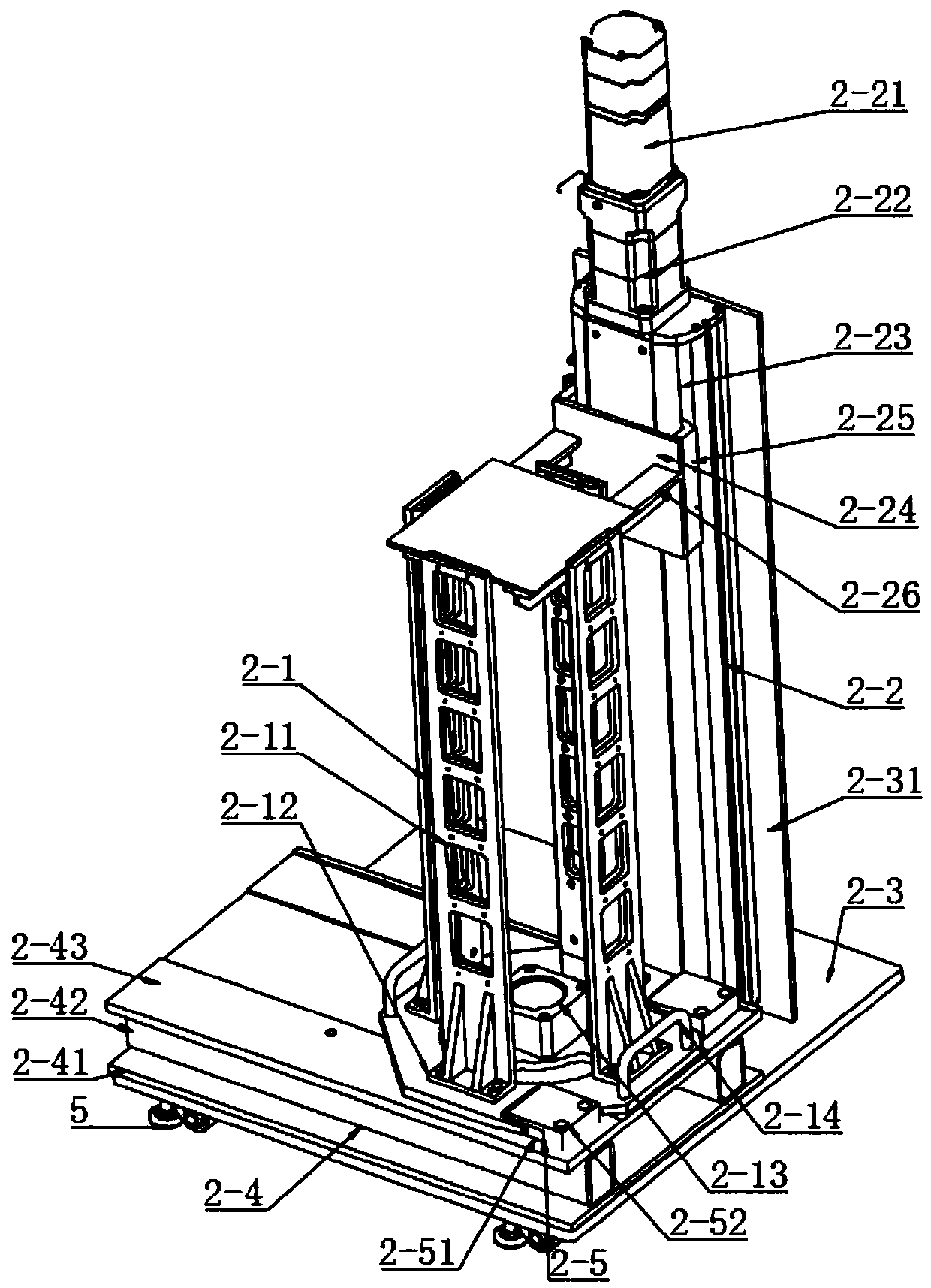

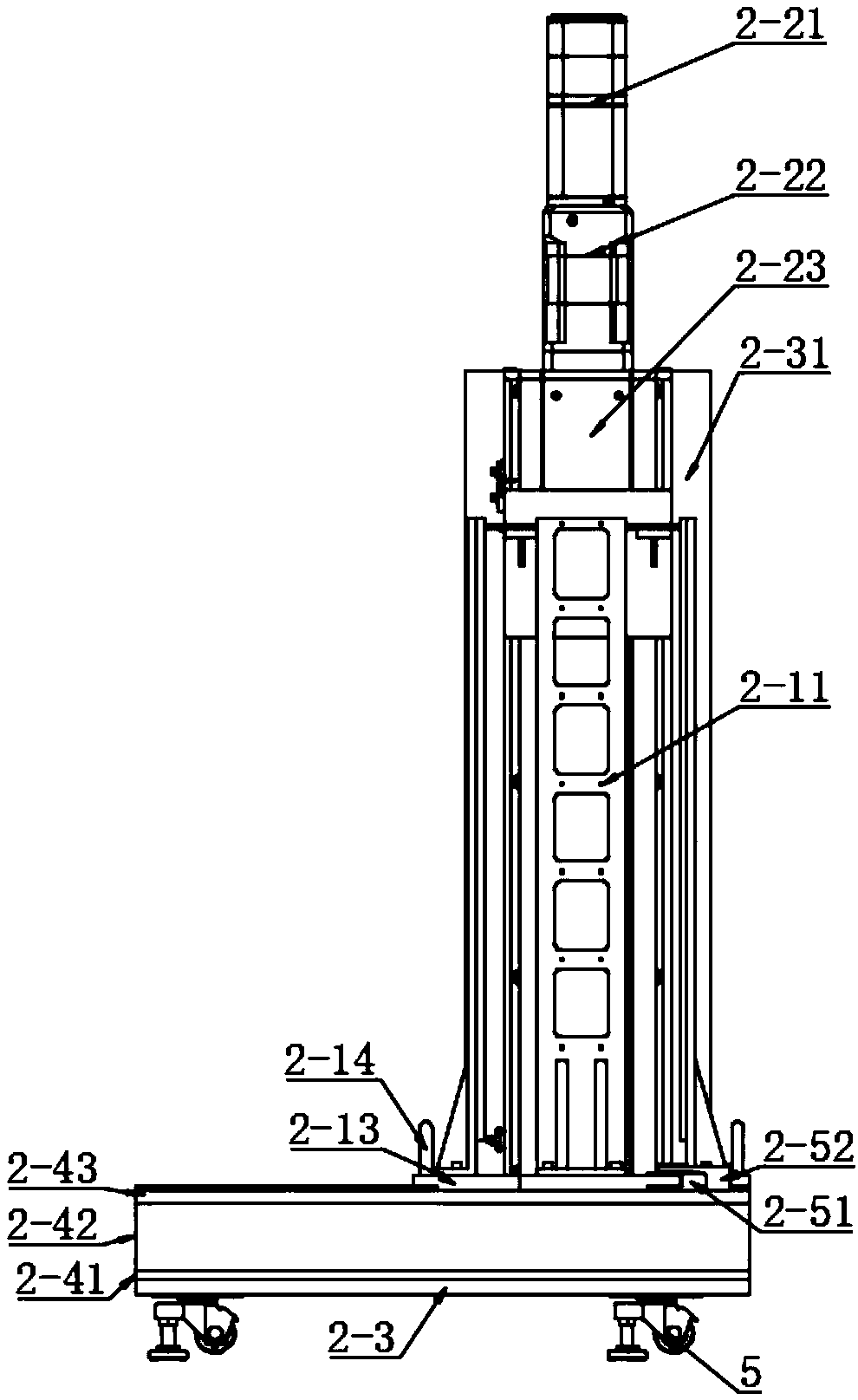

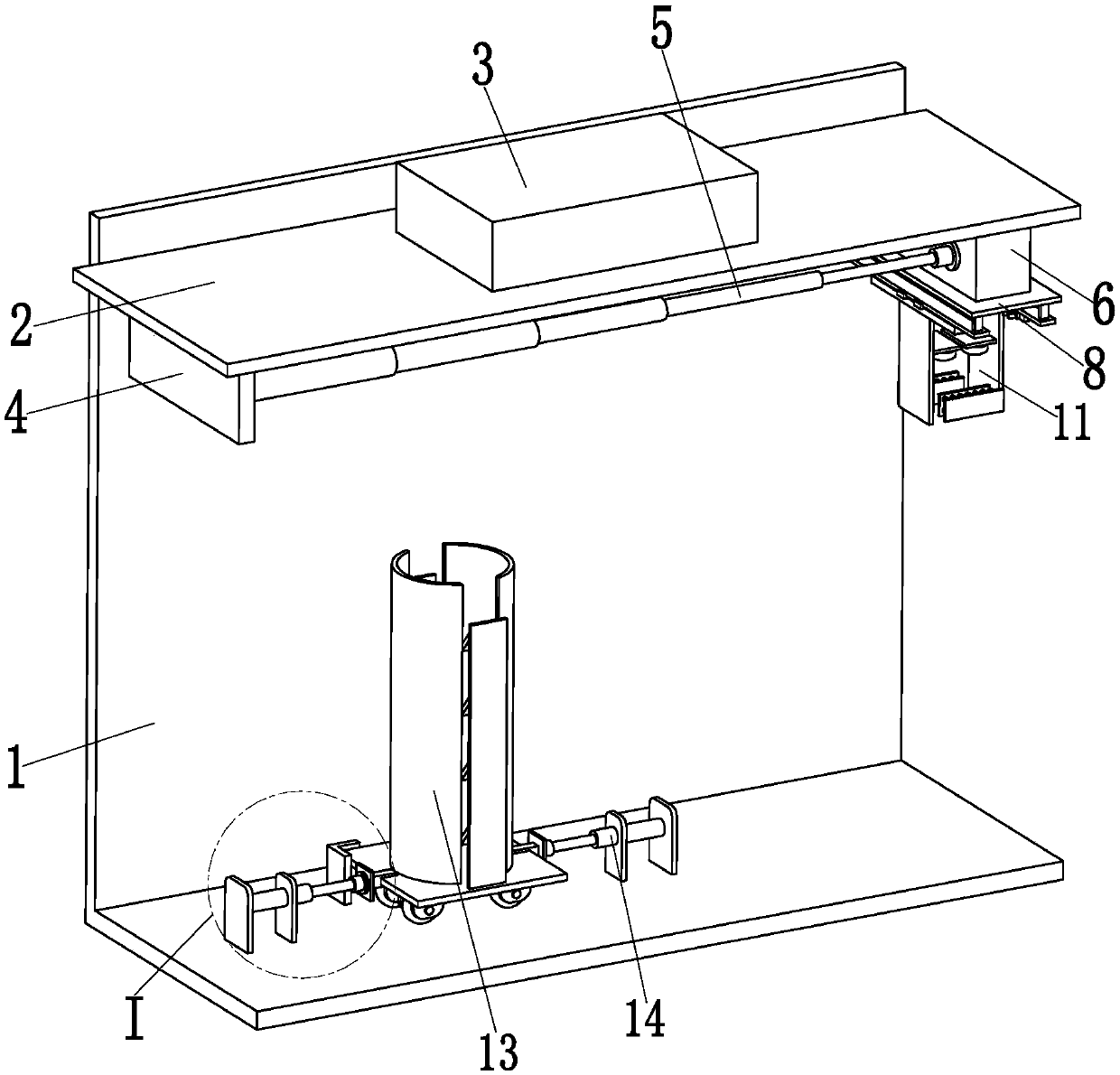

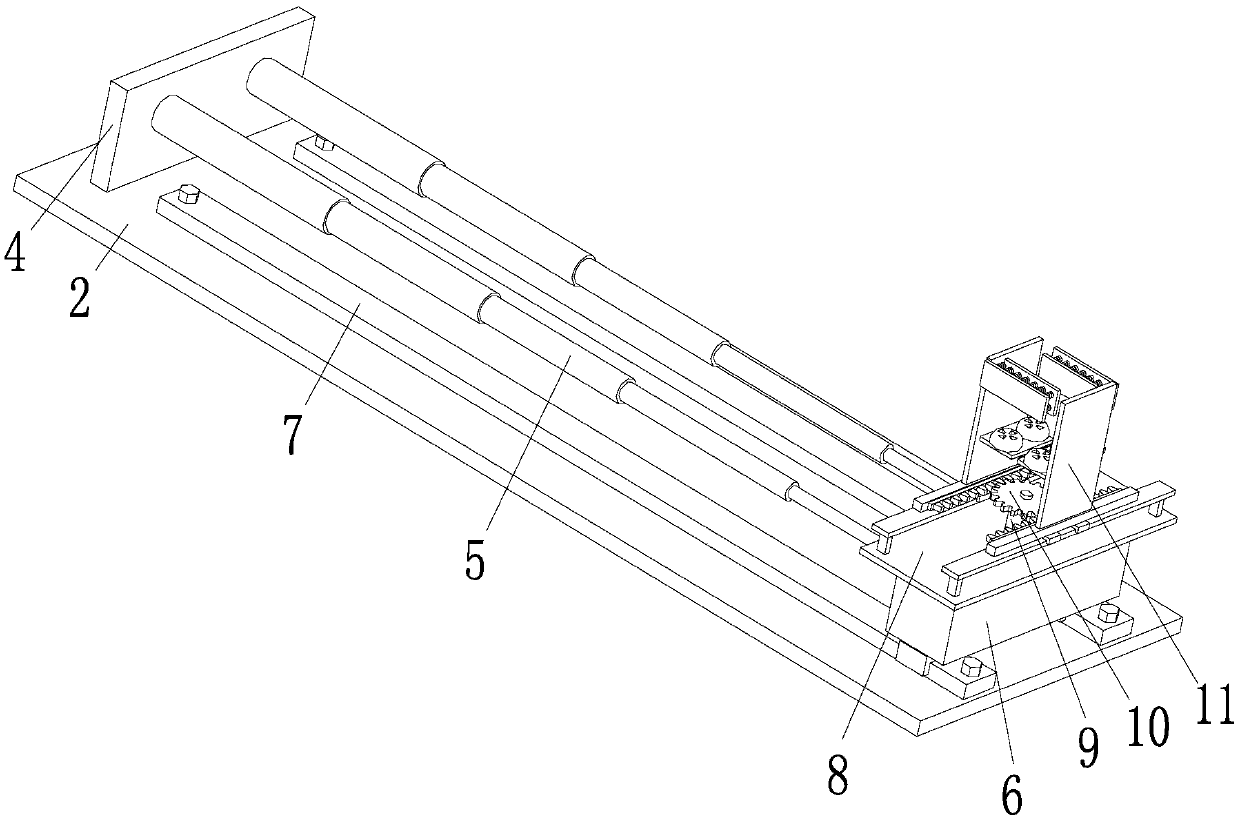

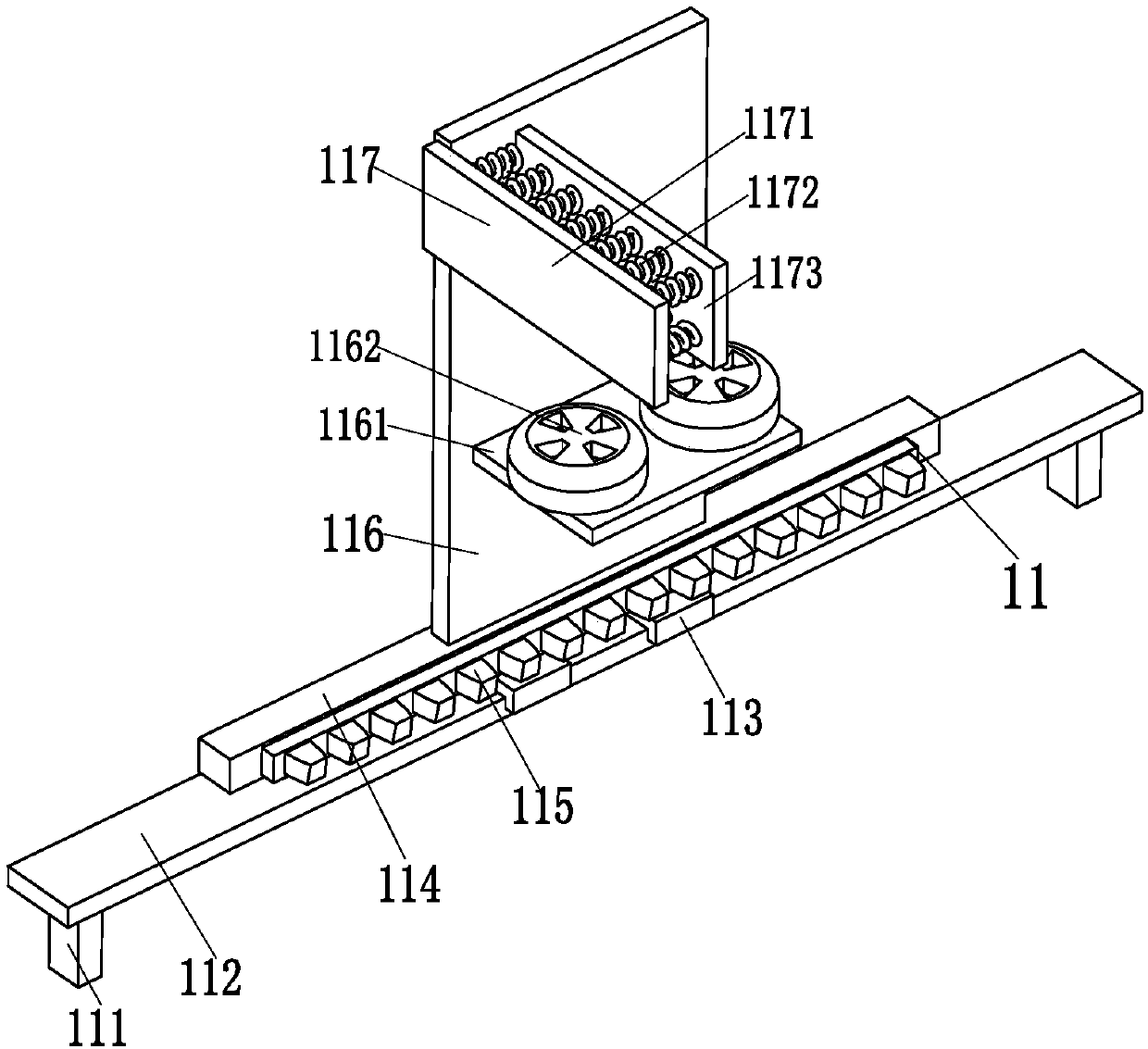

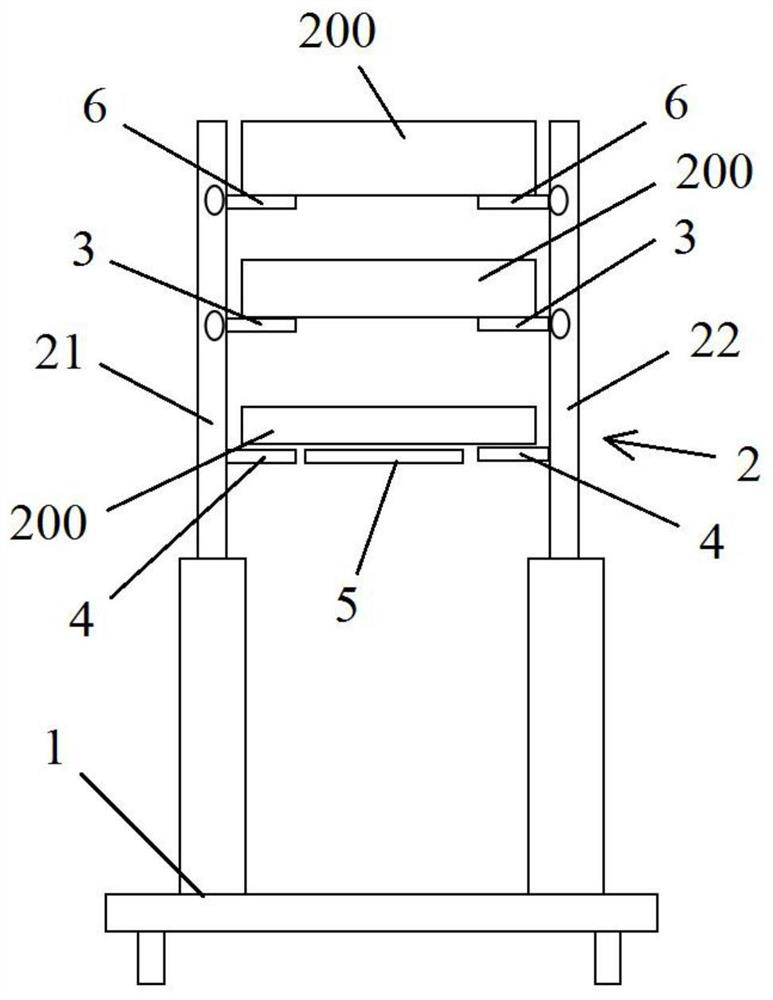

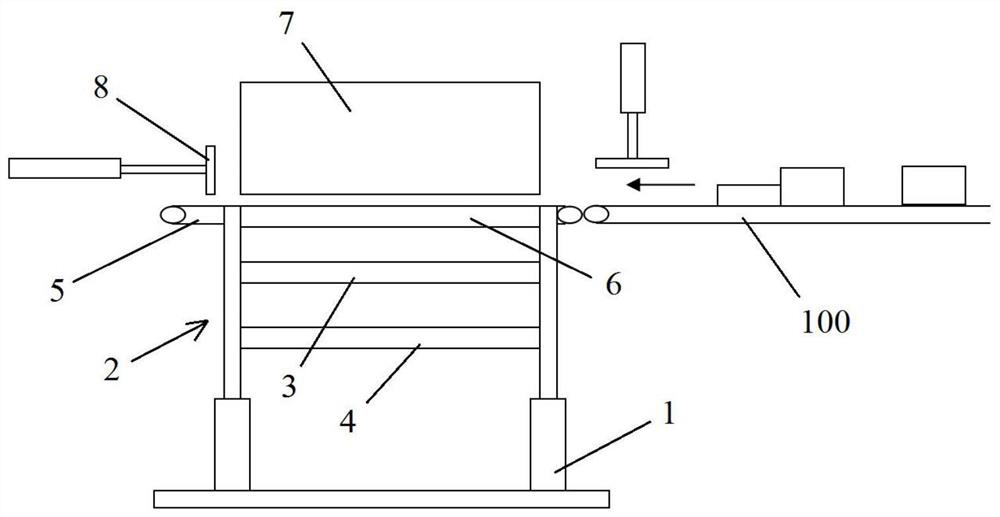

Paperboard stacking device and paperboard stacking machine

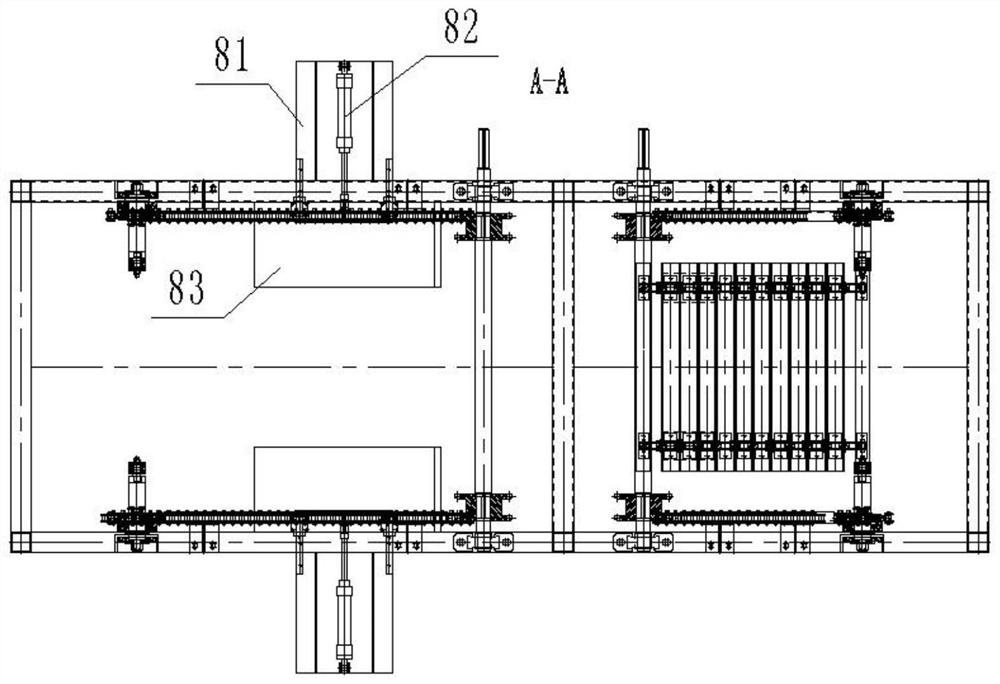

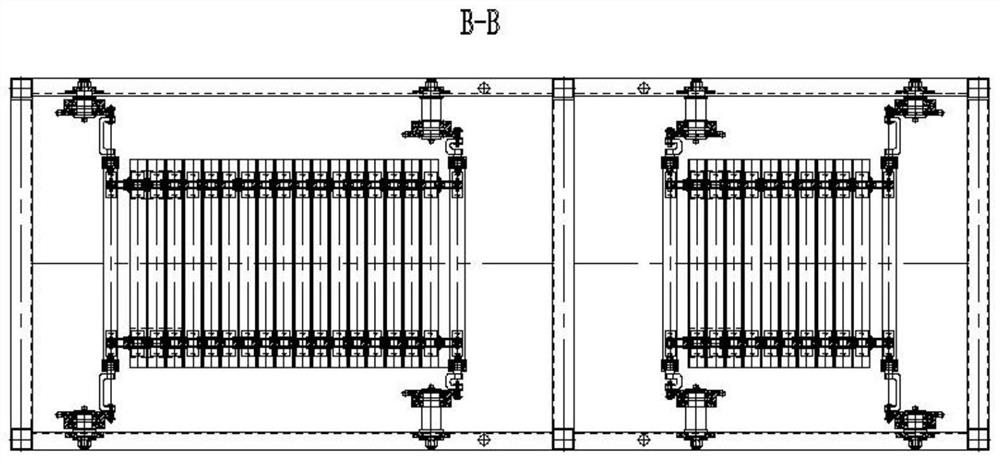

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

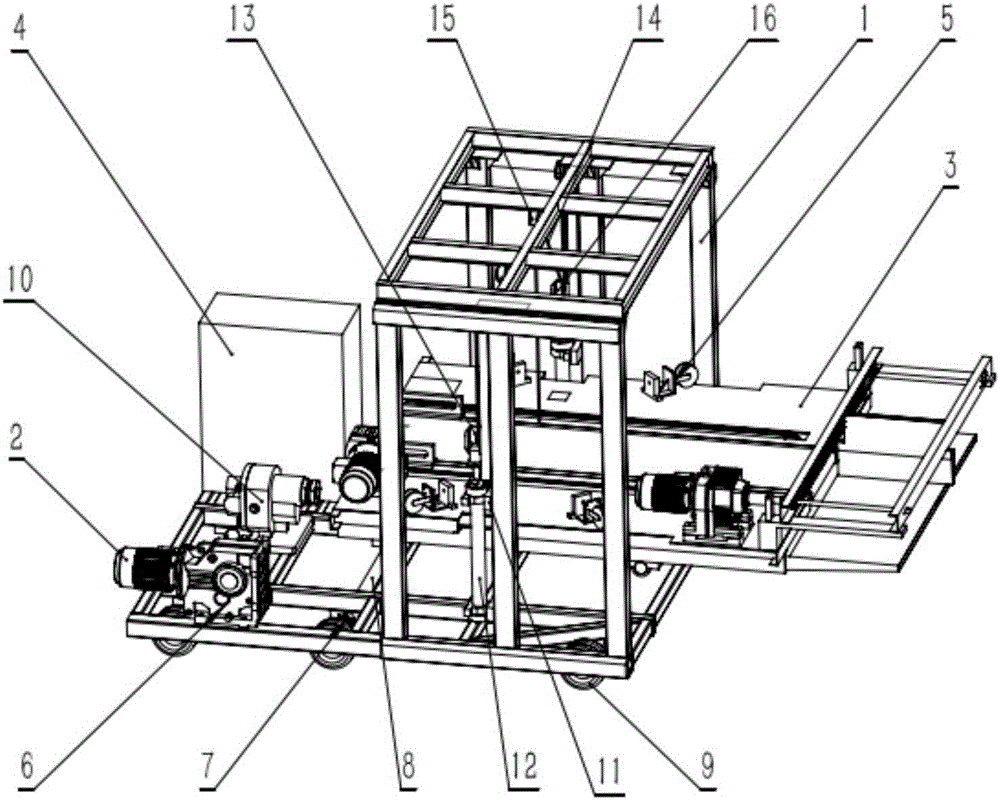

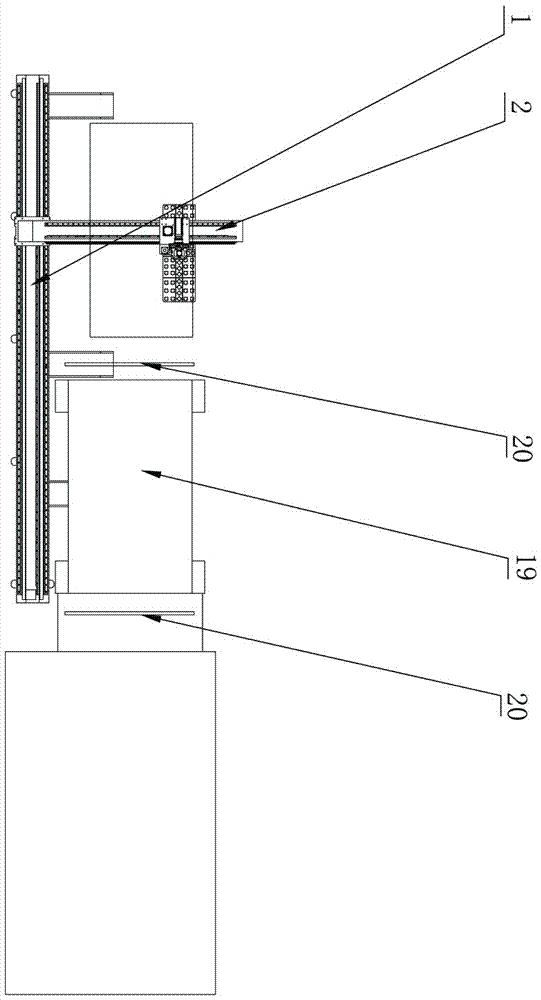

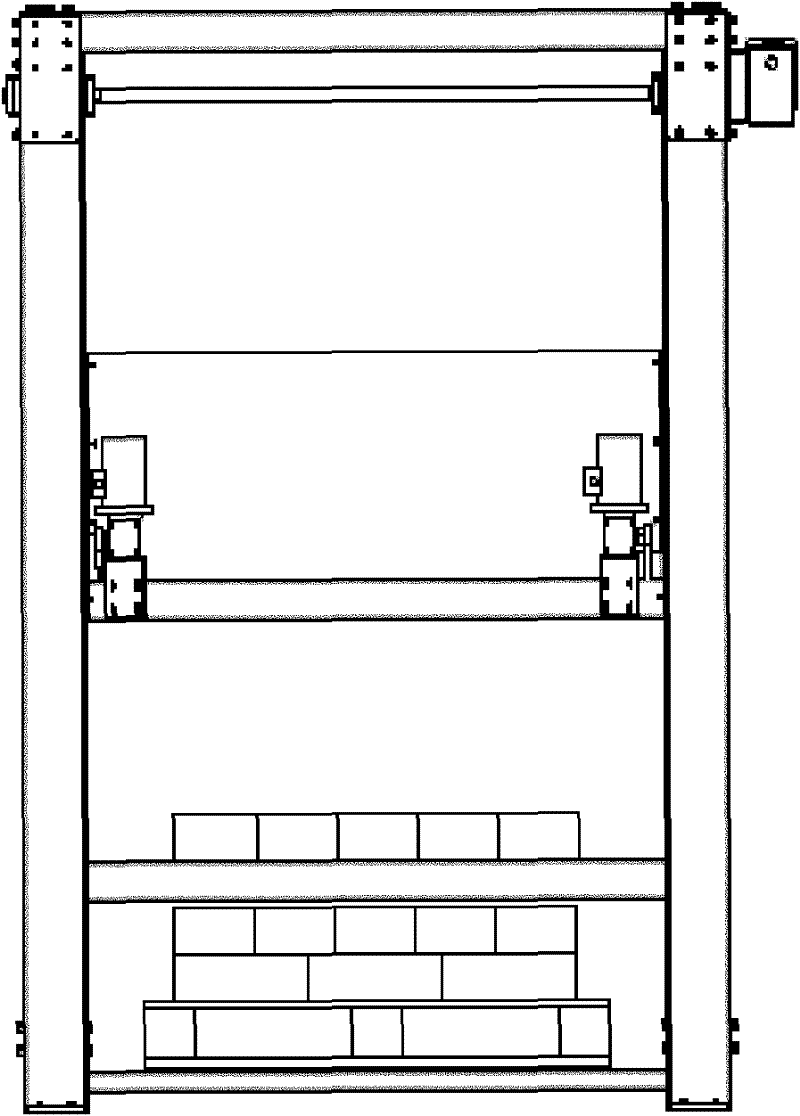

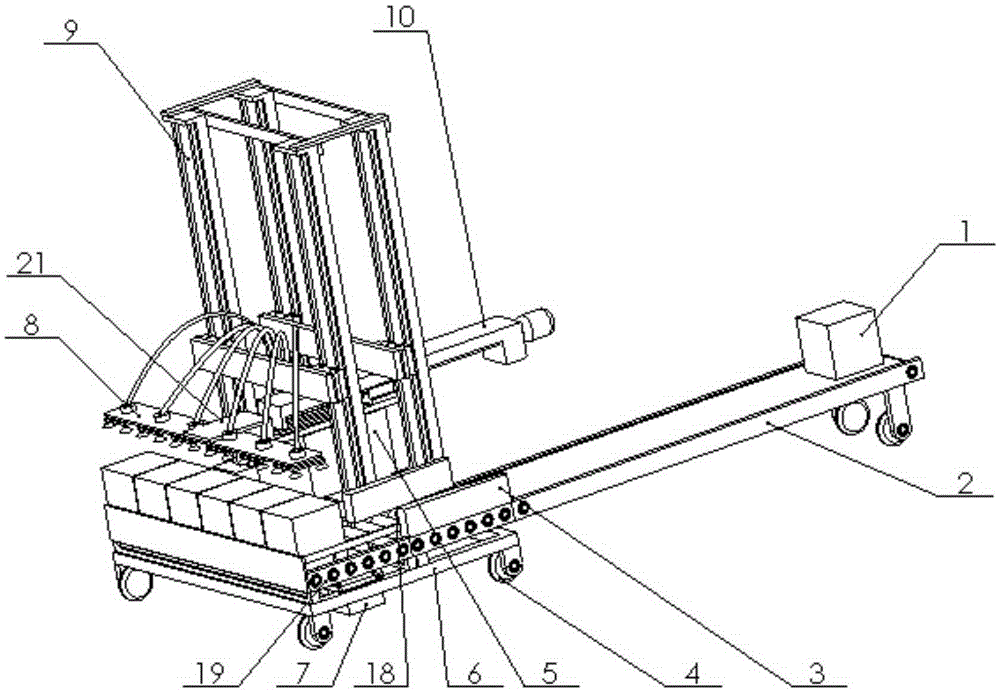

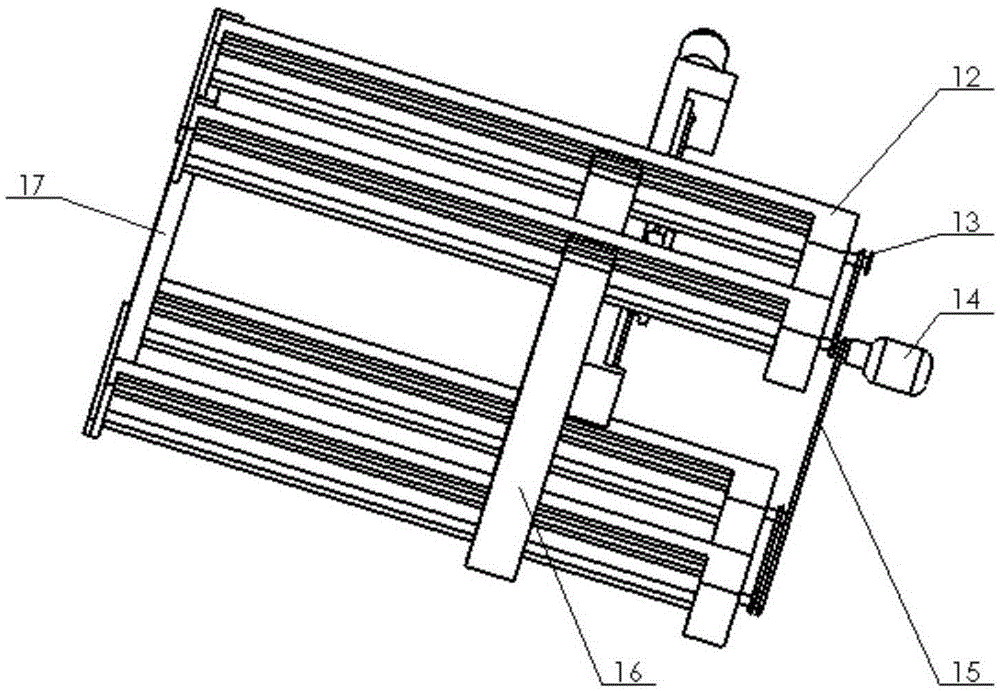

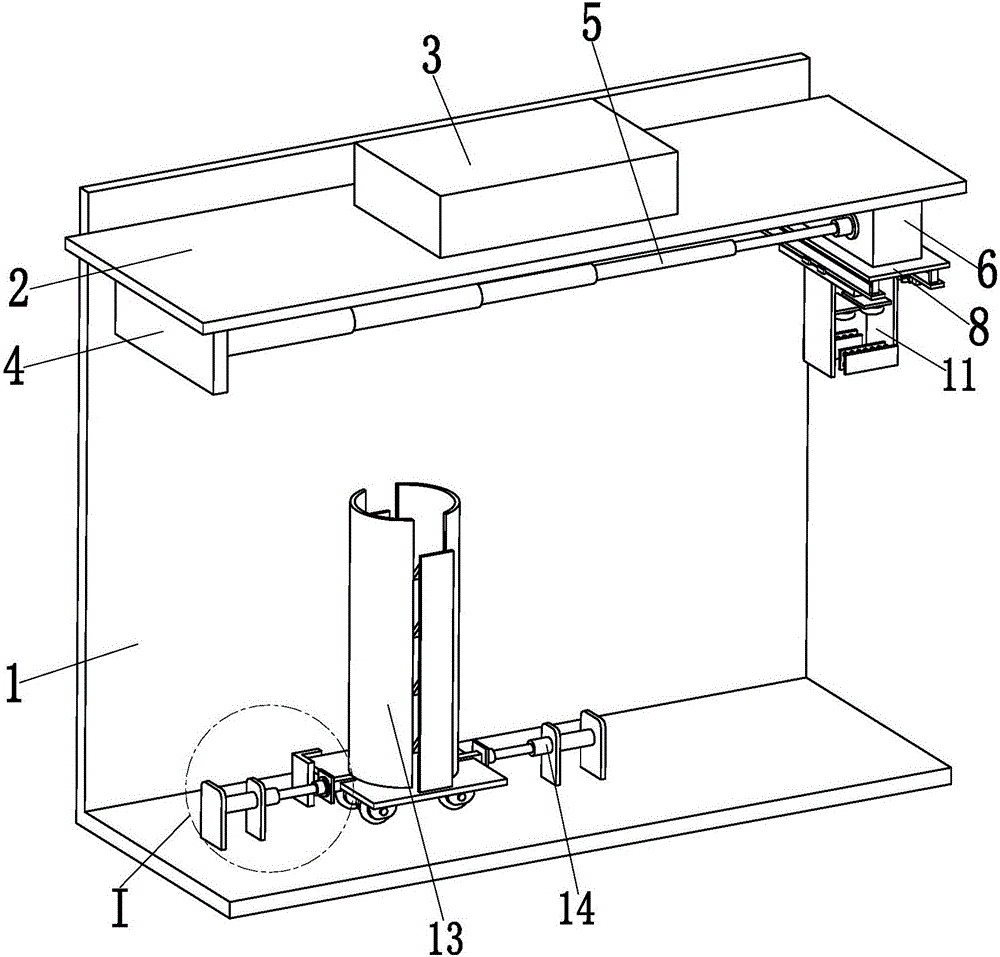

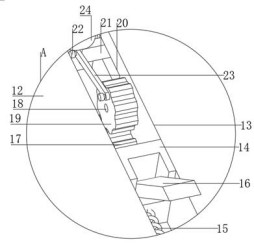

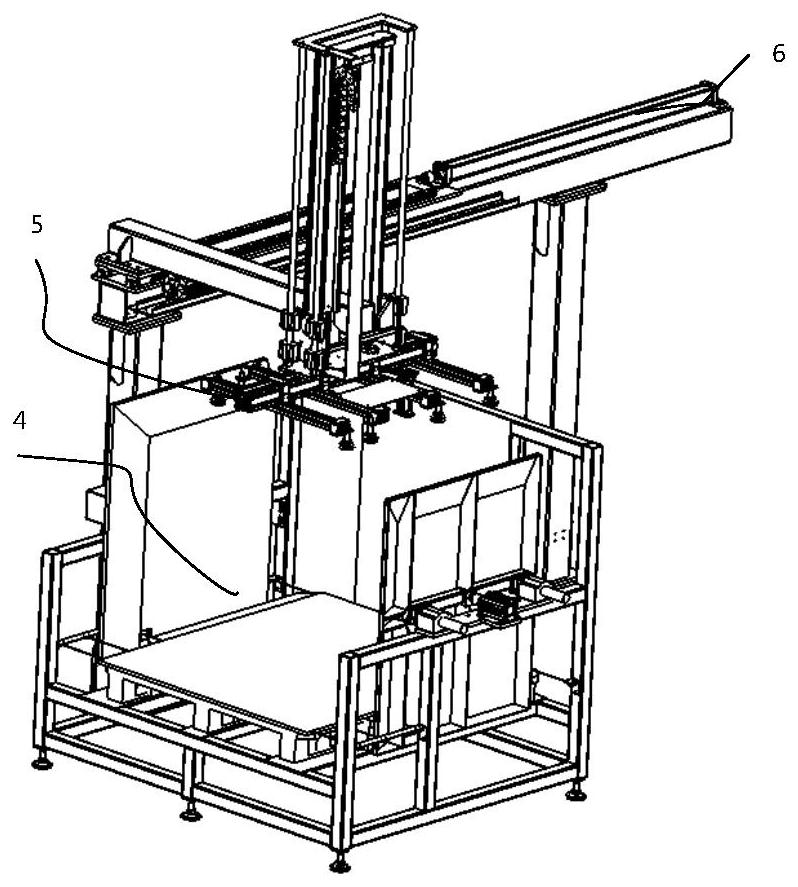

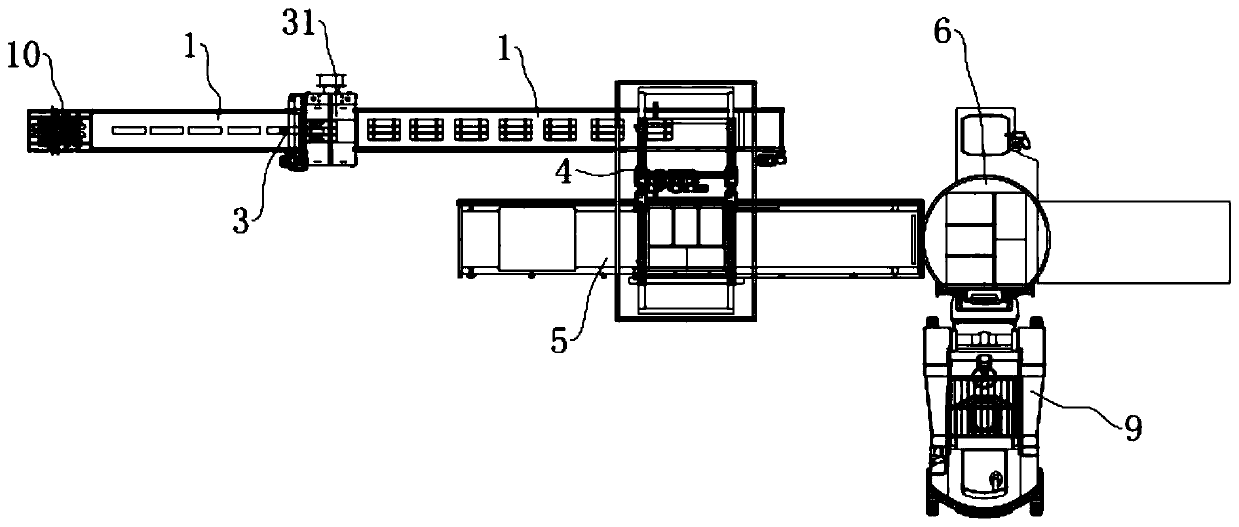

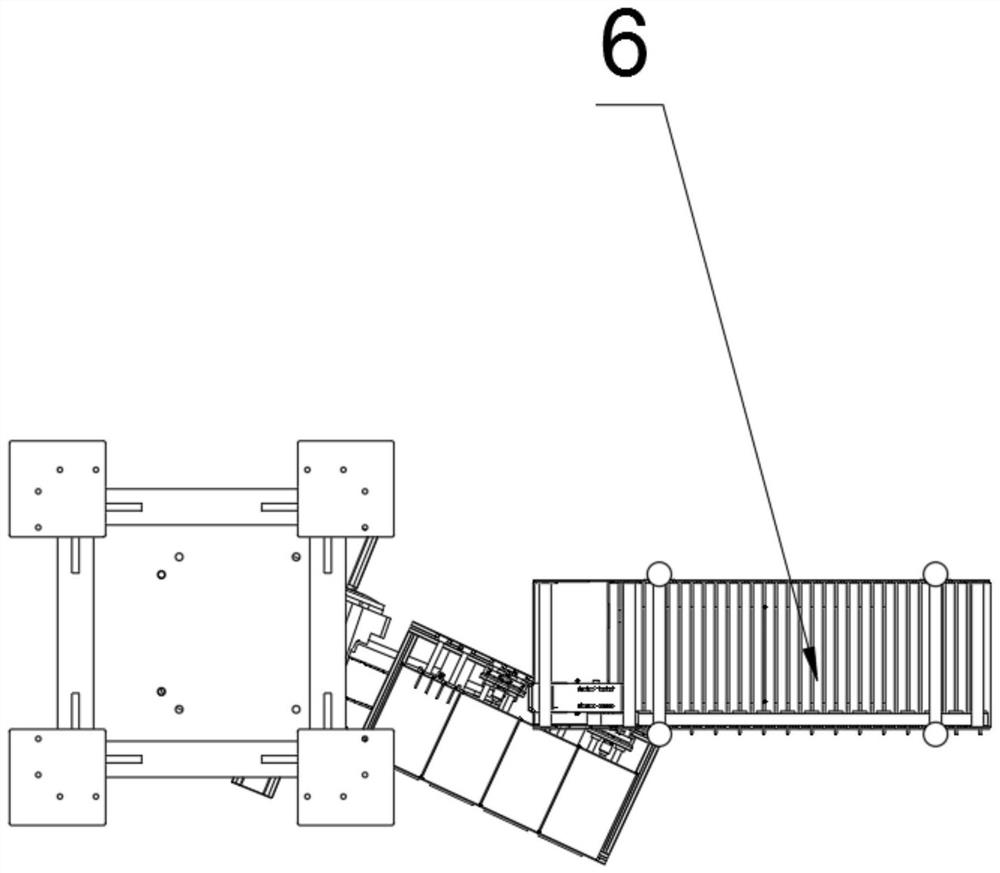

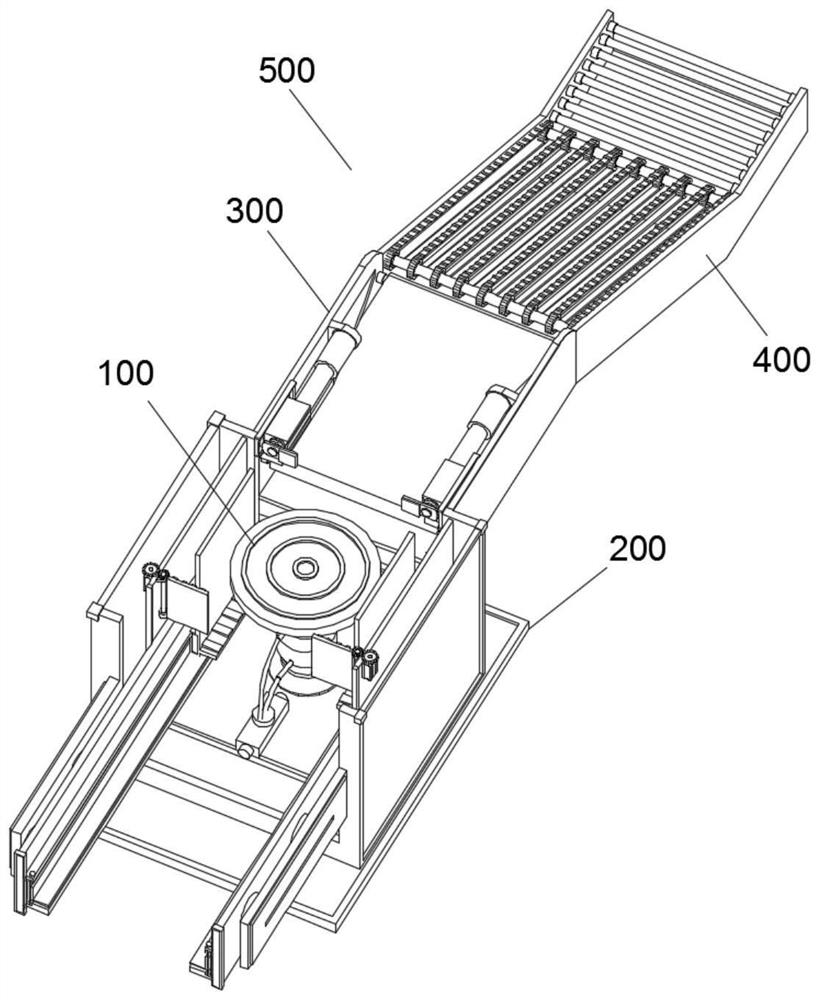

Rapid stacking machine in container

ActiveCN106429492AAvoid accumulationFast palletizingConveyorsStacking articlesControl systemStack machine

The invention provides a travelling stacking machine for goods stacking in a container, and particularly discloses a rapid stacking machine in the container. The rapid stacking machine comprises an automatic travelling frame type rack, and a rack driving mechanism, a lifting platform and a control system that are arranged on the automatic travelling frame type rack; the automatic travelling frame type rack drives the lifting platform to move together; the lifting platform realizes the effect of lifting motion in the vertical direction through a lifting driving mechanism, and simultaneously accomplishes conveying, arrangement and stacking work of goods; the lifting platform comprises a platform plate, a longitudinal telescopic sliding door, a transverse bag pushing mechanism, a longitudinal conveyer, a conveying belt hinging device and a guide device; the longitudinal conveyer arranged in the middle of the lifting platform conveys the goods onto a telescopic plate at the front of the lifting platform; a transverse pushing plate capable of moving transversely on the telescopic plate is used for arranging the goods in a row transversely; when the telescopic plate retracts to the lower side of the lifting platform under the control of a motor, the goods fall down automatically, and the stacking of a layer of goods is accomplished. The rapid stacking machine can enter the container to carry out full-automatic high-efficiency stacking on the goods conveyed by the longitudinal conveyer.

Owner:SHANGHAI JIAO TONG UNIV

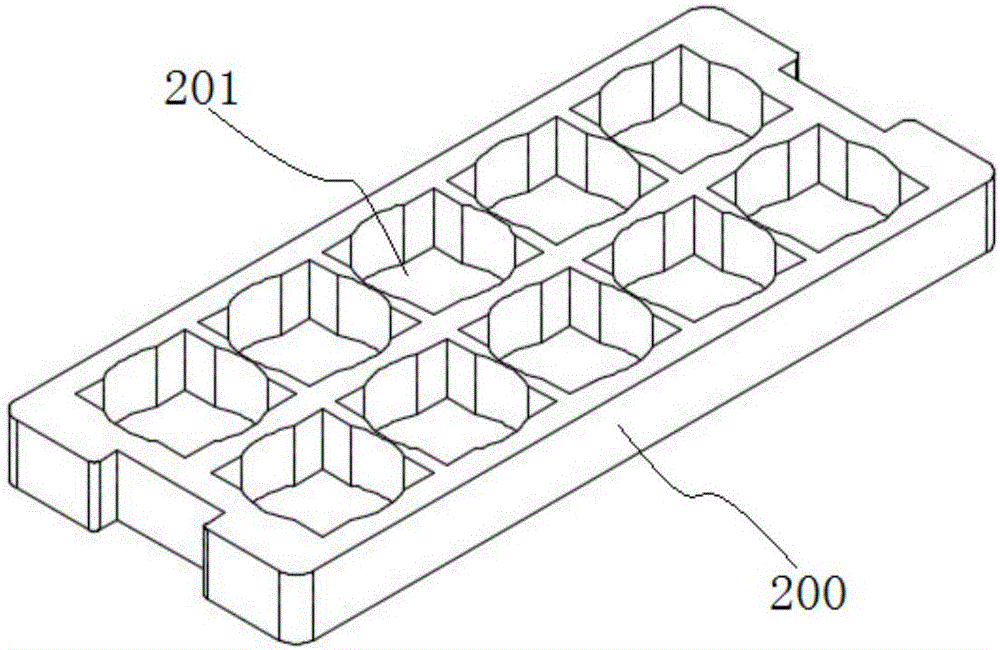

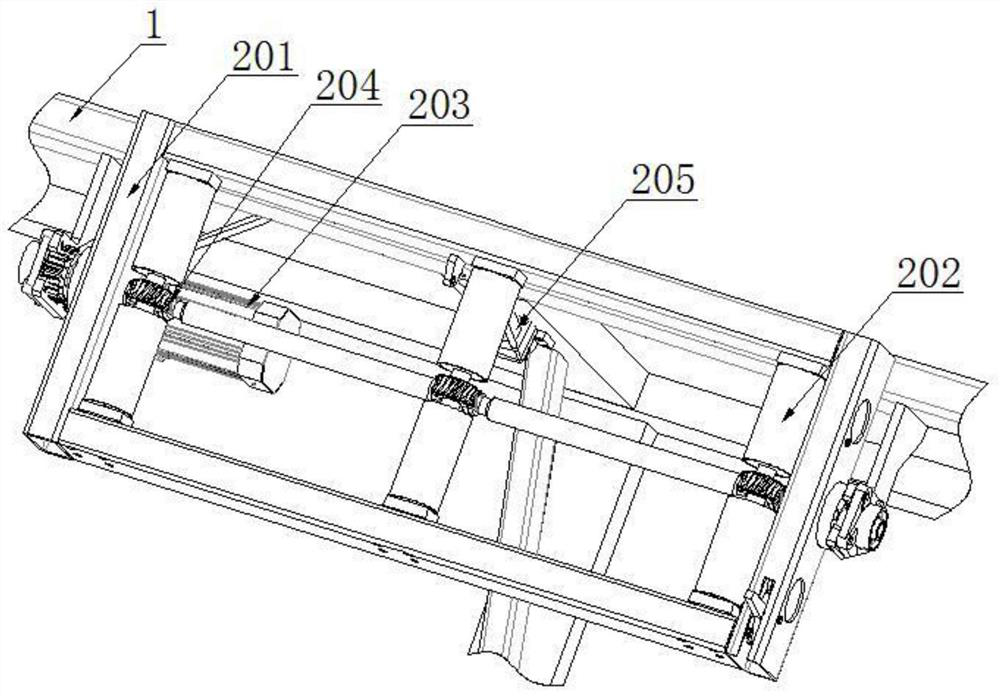

Empty pallet splitting and stacking machine and using method thereof

ActiveCN103287861AQuick splitFast palletizingStacking articlesDe-stacking articlesDrive shaftMachine

Owner:浙江德能物流装备科技有限公司

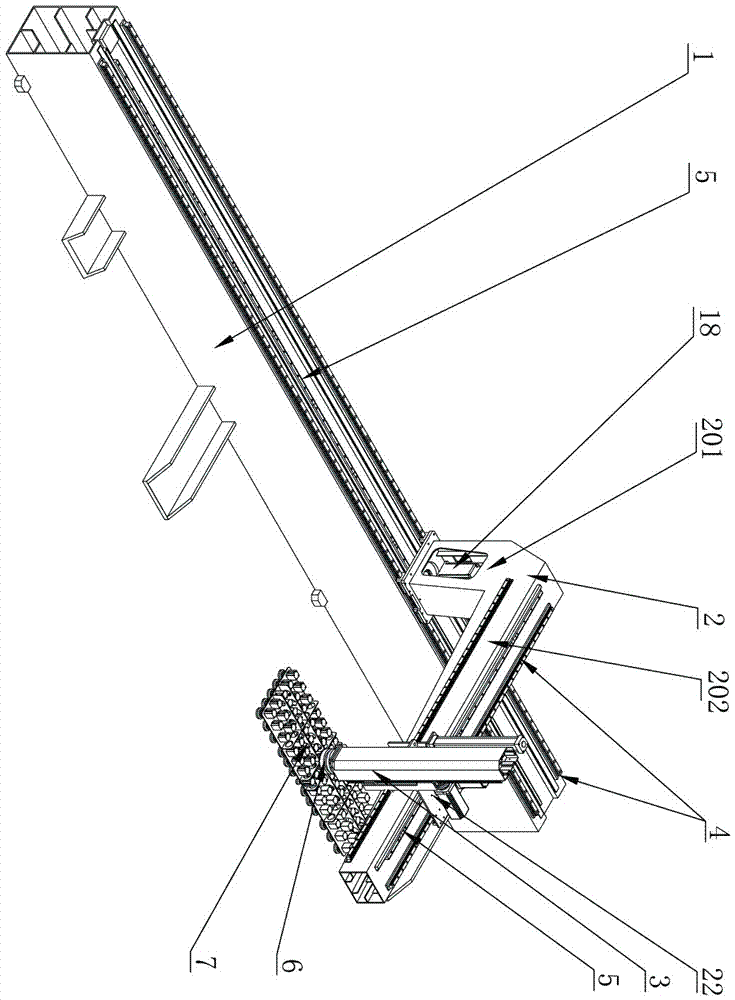

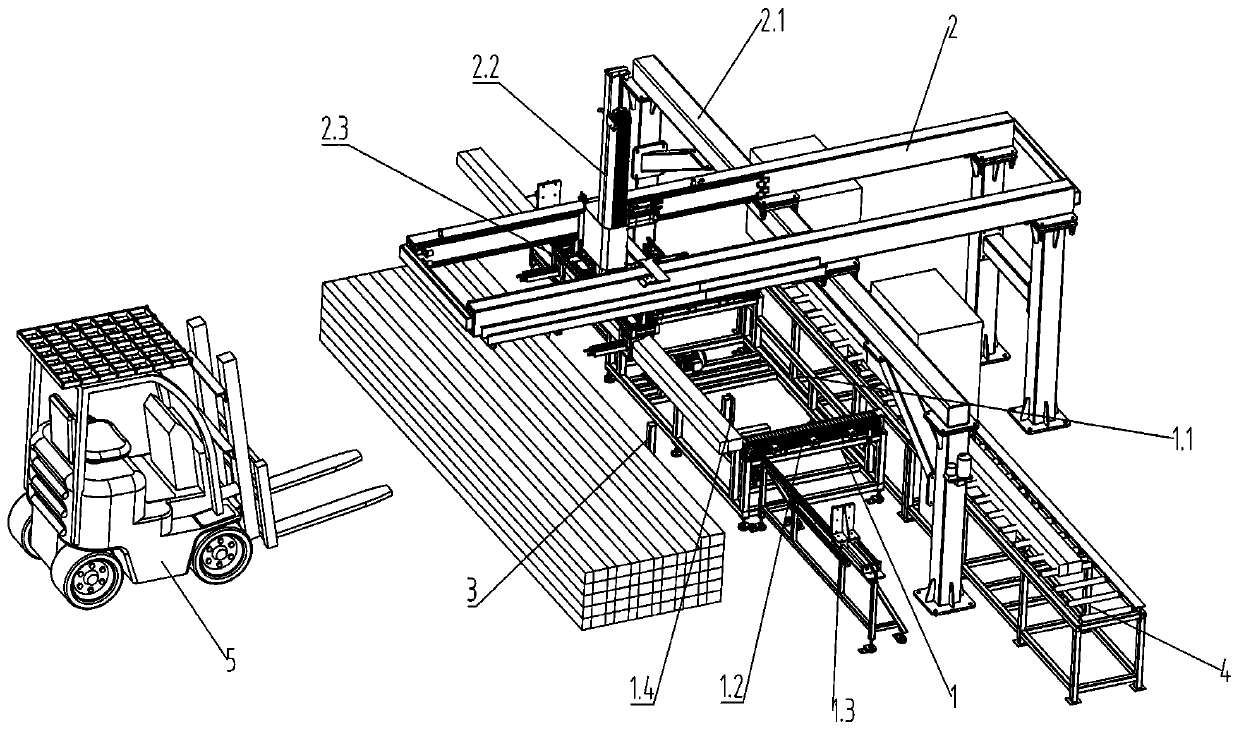

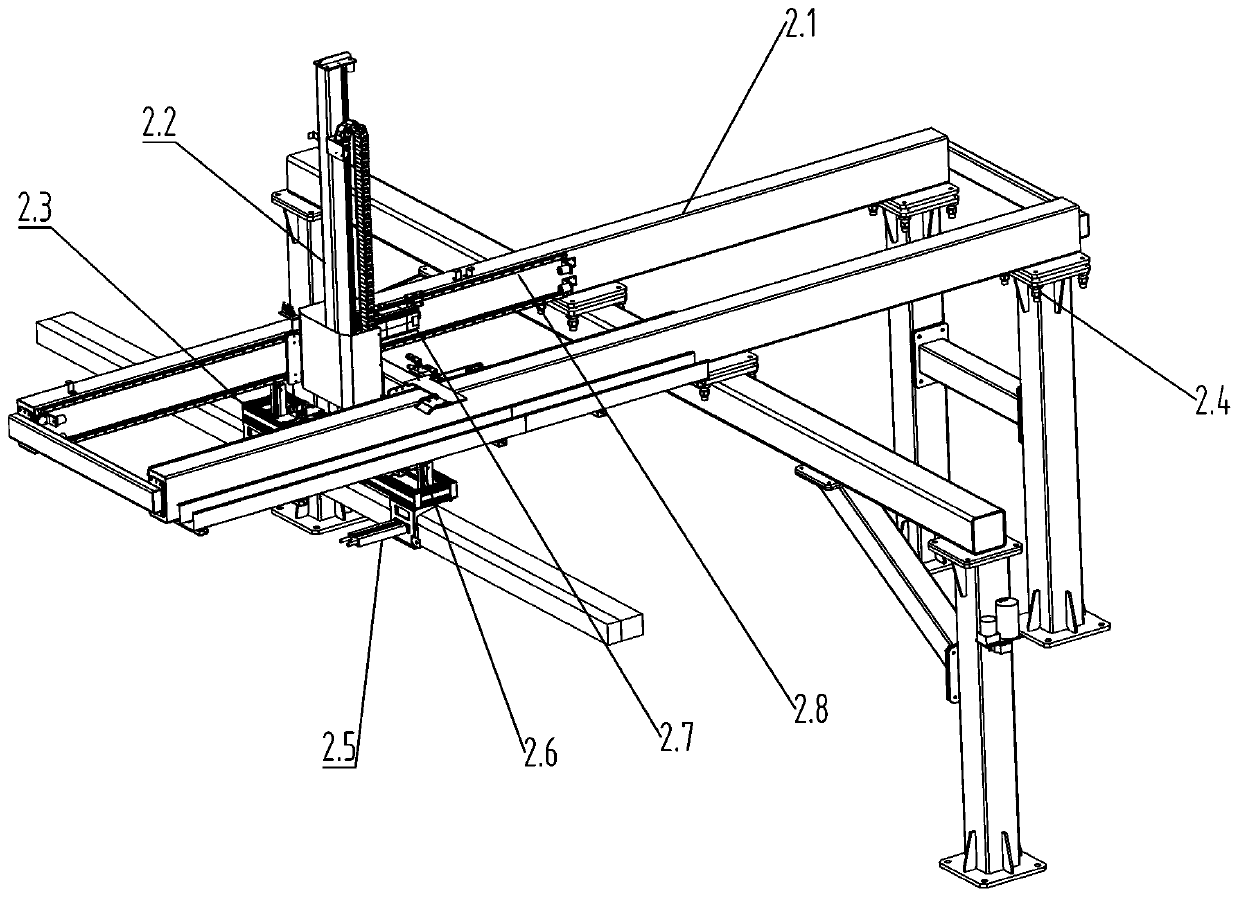

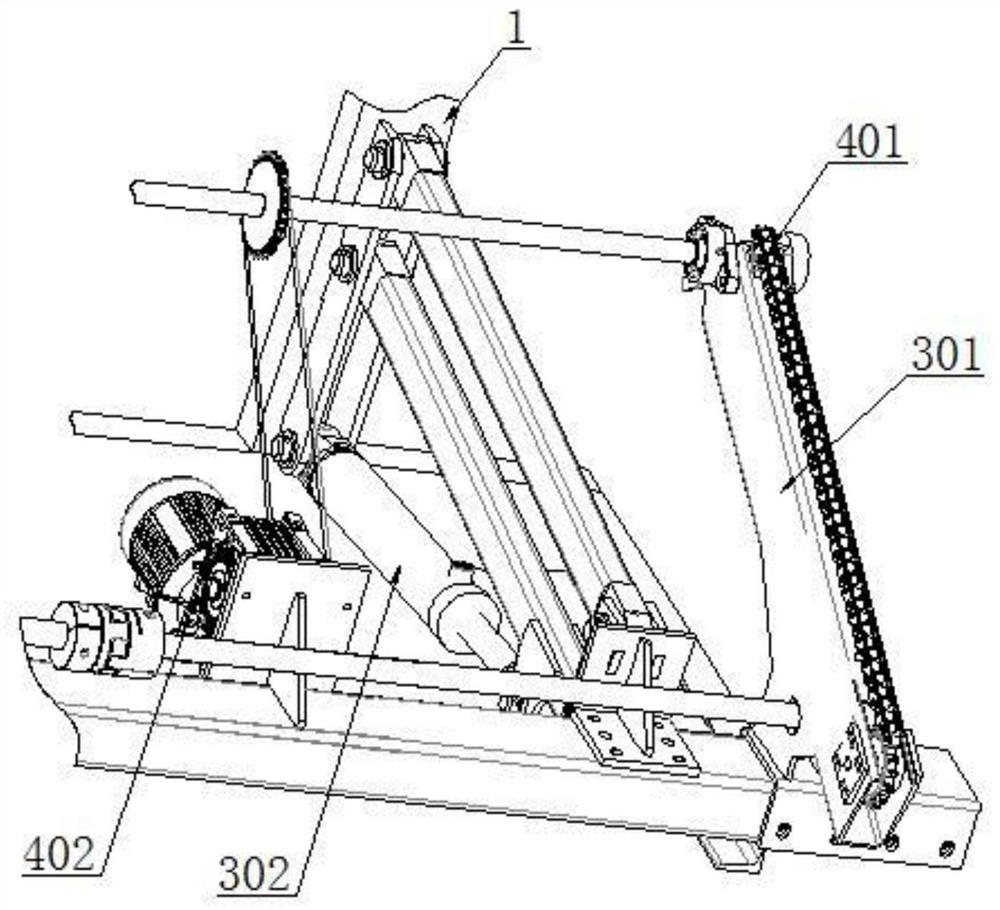

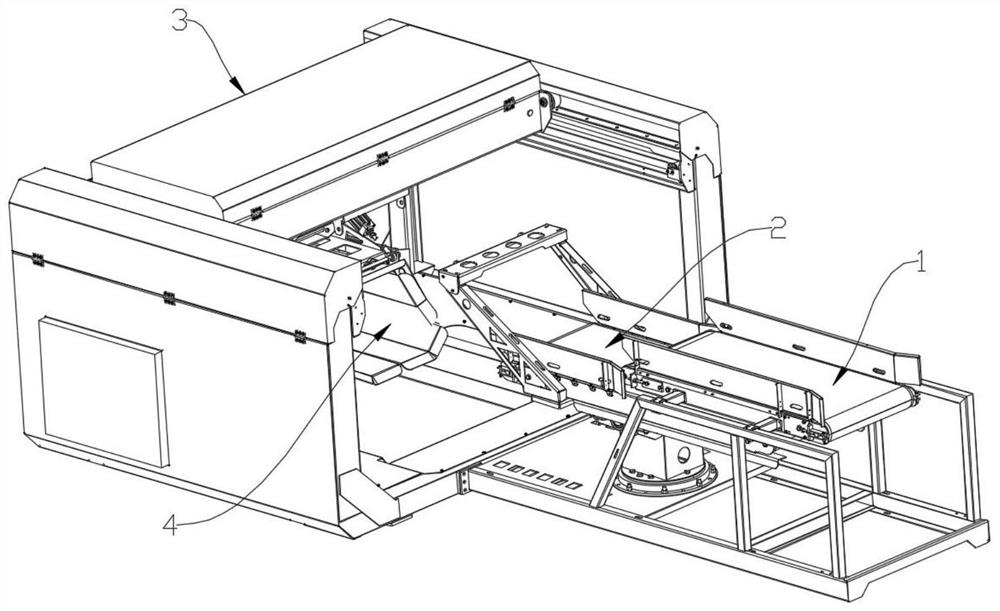

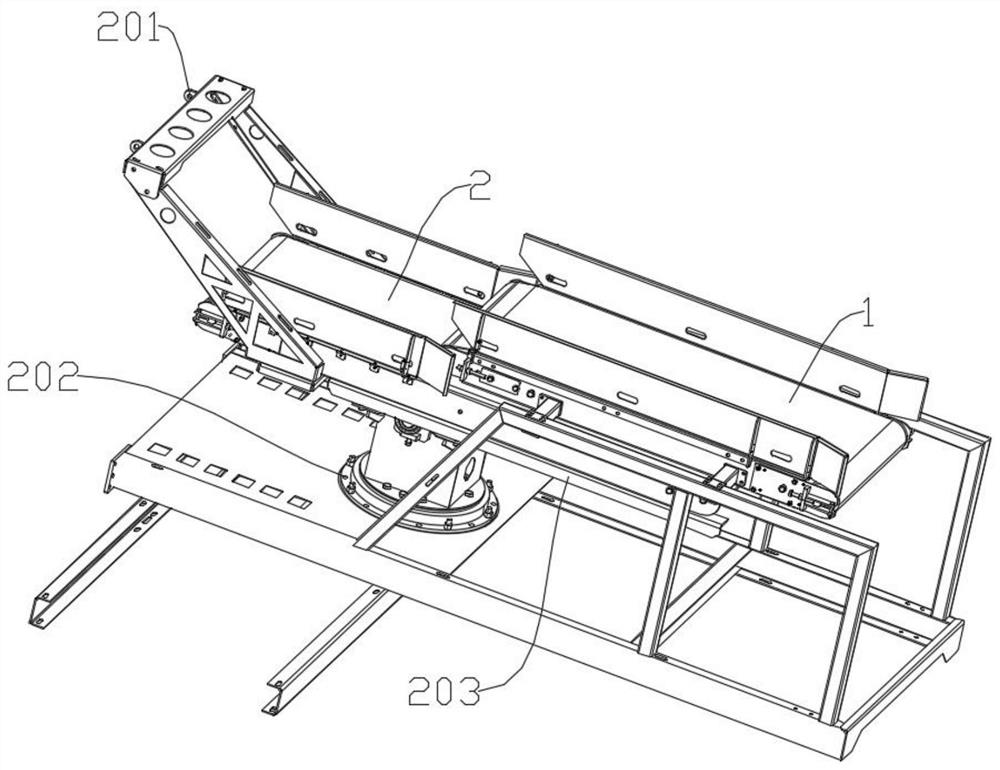

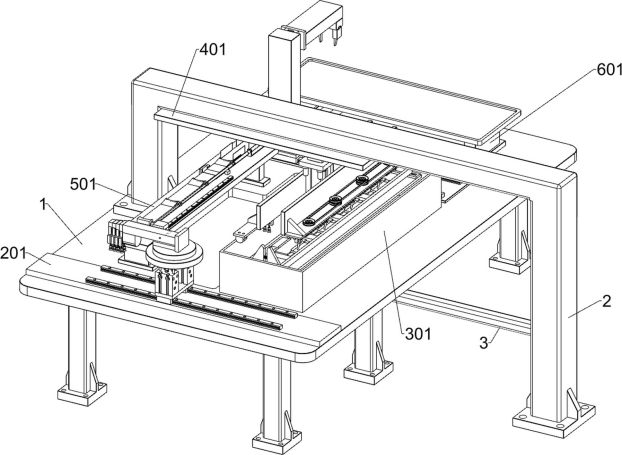

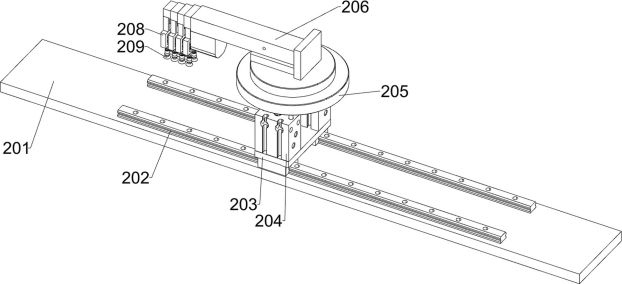

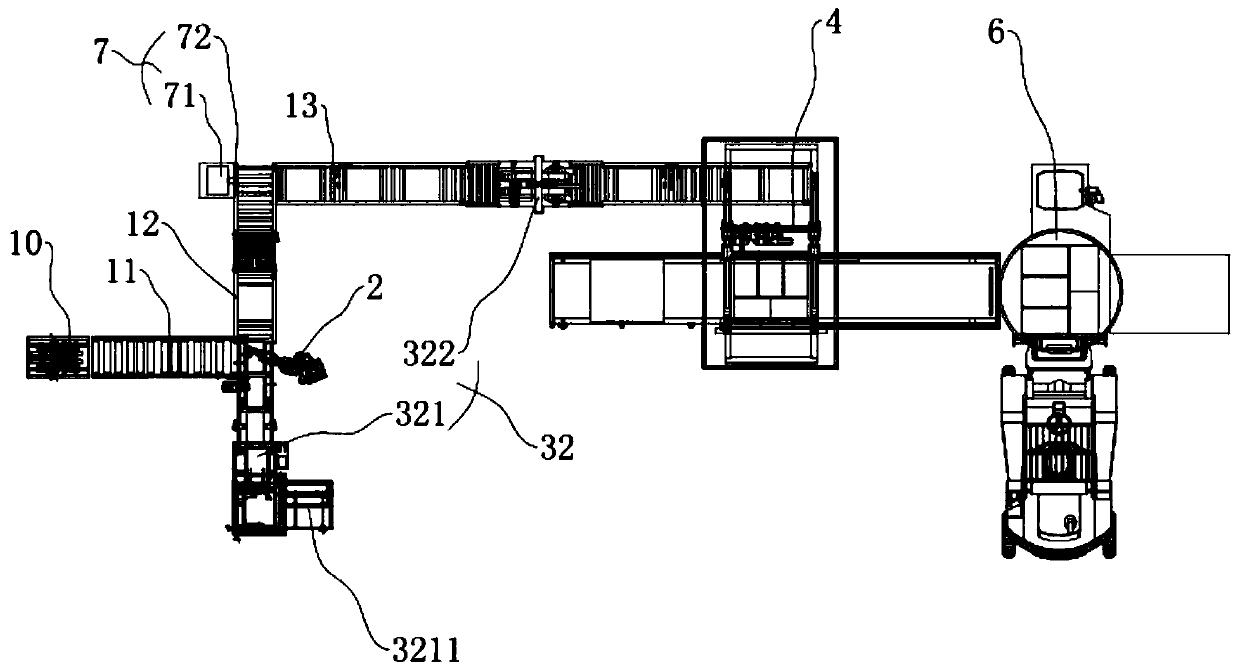

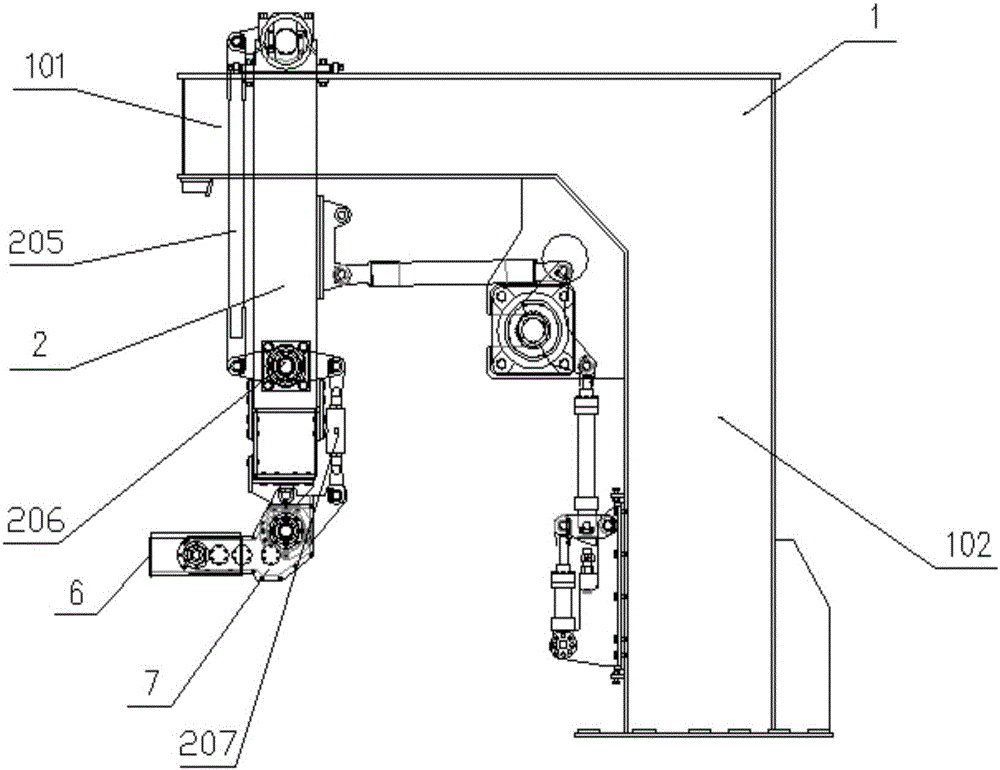

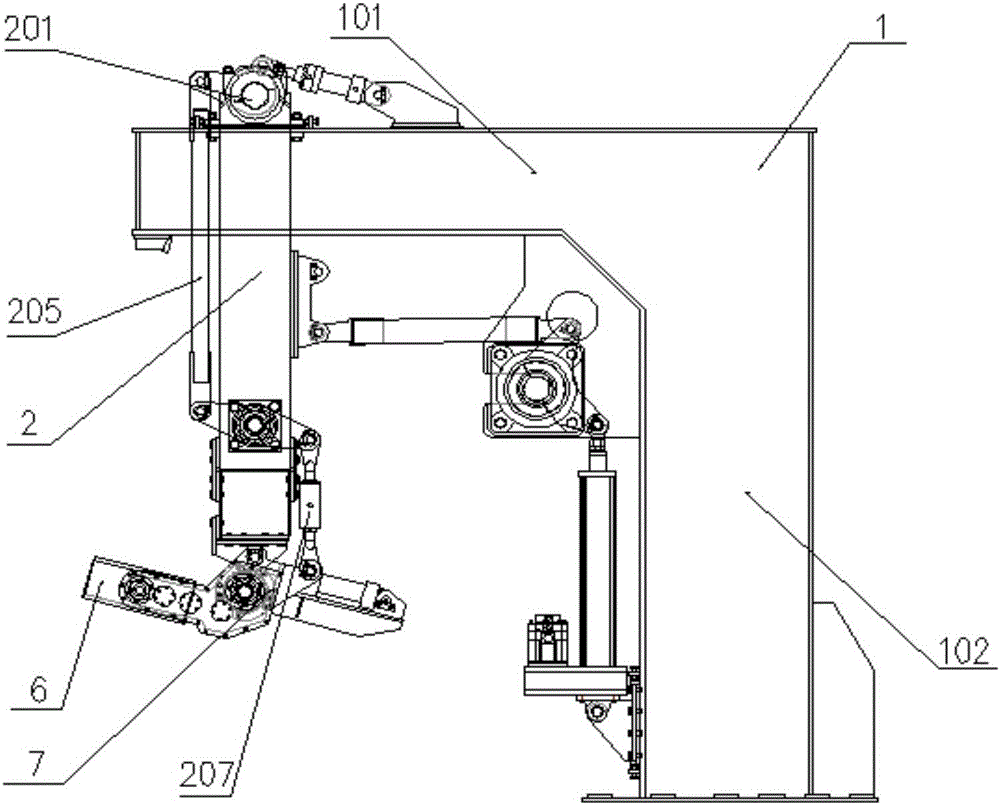

Sorting robot of laser cutting machine and part sorting method of sorting robot

ActiveCN107020459AQuick sortingFast palletizingProgramme-controlled manipulatorSortingEngineeringLaser cutting

The invention discloses a sorting robot of a laser cutting machine and a part sorting method of the sorting robot and belongs to the field of machine tools. A Y-axis support seat comprise a Y-axis longitudinal support seat and a Y-axis transverse support seat; the Y-axis longitudinal support seat is matched with a rail on an X-axis support seat through a sliding mechanism; a Z-axis support seat and the Y-axis transverse support seat are connected through a connecting piece; a C-axis support seat is matched with the Z-axis support seat; the C-axis support seat is driven by a driving device and is connected with a sorting tool; the sorting tool comprises a master panel; a plurality of air cylinders are arranged on the master panel in an array; and each air cylinder is separately connected with a sucking disc. The sorting robot of the laser cutting machine can replace the laser cutting machine for manual sorting, can identify a finished product cut by laser, and rapidly sort and stack the cut finished product.

Owner:YANGZHOU HENGJIA AUTOMATION EQUIP CO LTD

Stacker

The invention discloses a stacker, which is characterized in that both a movable platform and a stacking system can longitudinally move to be positioned on a frame, a frame structure is arranged on a fixing frame, a roll chain driving device is used for driving a roll chain to stretch out and draw back from one end to the other end along the frame structure of the fixing frame, two sides of the roll chain, perpendicular to the moving direction of the roll chain, are completely covered on two sides above the frame structure of the fixing frame, two clamp mechanisms are symmetrically and fixedly arranged on two sides, perpendicular to the moving direction of the roll chain, above the fixing frame respectively, opposite sides of the two clamp mechanisms can oppositely move along the direction perpendicular to the moving direction of the roll chain, one end of a box pulling rod is capable of moving along the moving direction of the roll chain and being positioned on the fixing frame, a protruding baffle plate is fixedly arranged on the lower side of the other end of the box pulling rod, and projection of the movable platform on a horizontal plane and projection of the frame structure of the fixing frame of the stacking system on the horizontal plane are a continuous plane. The stacker is simple in structure, quick in stacking speed, small in occupied space, wide in application range, convenient in use, safe and reliable.

Owner:苏州澳昆智能机器人技术有限公司

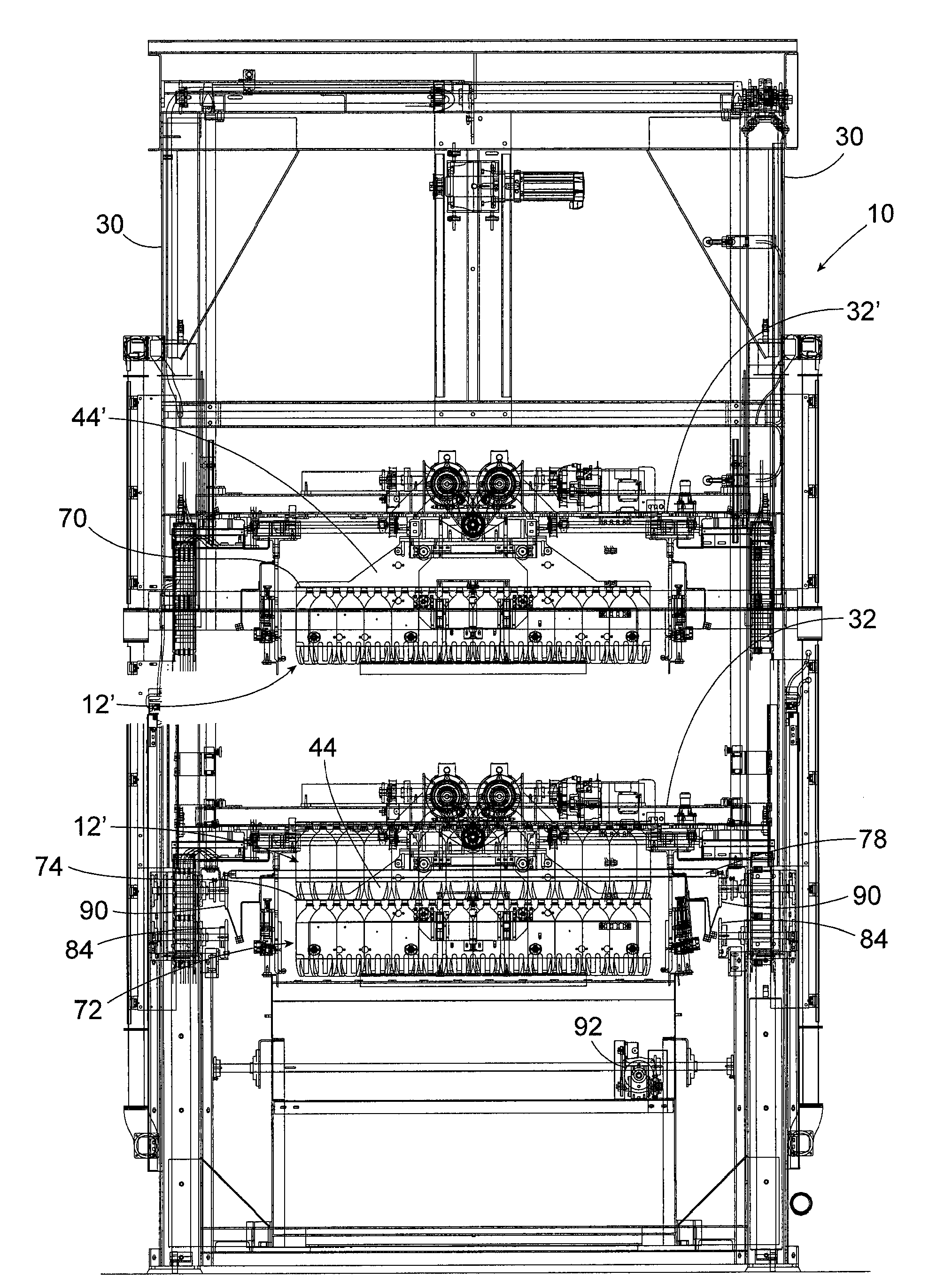

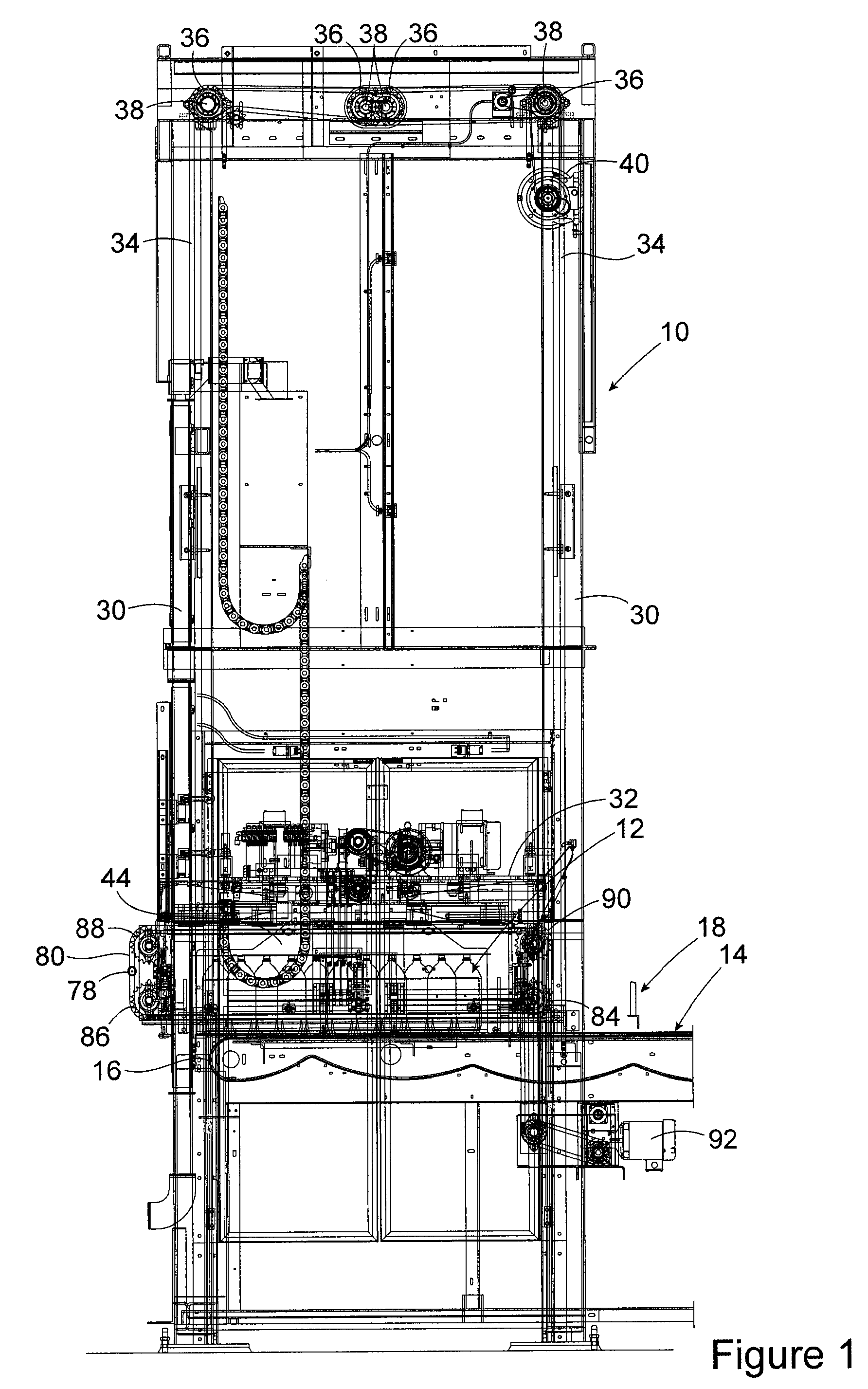

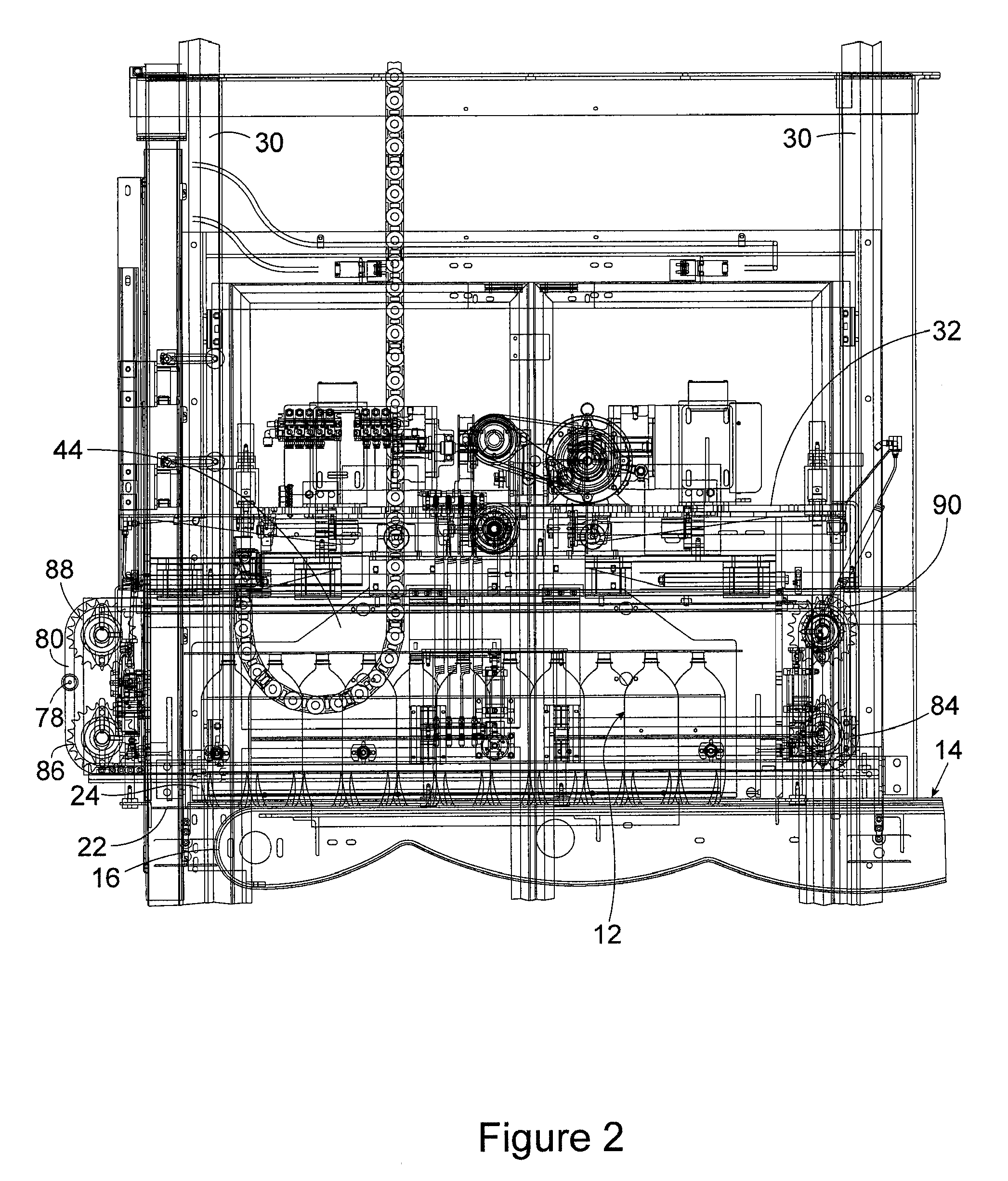

Conveyor System Apparatus for Stacking Arrayed Layers of Objects

ActiveUS20080124208A1Fast palletizingEffective timeSemiconductor/solid-state device manufacturingPortable liftingTime efficientEngineering

A stacking apparatus for a conveyor system raises a two-dimensionally arrayed layer of objects conveyed by the conveyor system and stacks the raised layer of objects on a subsequent layer of objects conveyed by the conveyor system. The apparatus then dispenses the stacked layers of objects from the apparatus, whereby the stacked layers of objects can be received by a palletizer for loading on a pallet in a more time efficient manner.

Owner:OUELLETTE MACHINERY SYST

Packing and stacking device for smoke alarm assembly production line

PendingCN106742421AFast packFast palletizingConveyorsStacking articlesMechanical equipmentEngineering

The invention discloses a packing and stacking device for a smoke alarm assembly production line, belonging to the field of product assembly equipment. The packing and stacking device comprises a packing box feeding device, a grabbing and packing device, a conveying device and a stacking device, wherein the conveying device is arranged between the packing box feeding device and the stacking device; the packing box feeding device comprises a package pushing and conveying mechanism and a baffling mechanism; the package pushing and conveying mechanism and the baffling mechanism are arranged on one end of the conveying device; the grabbing and packing device stretches over the conveying device and the product assembly line; the stacking device comprises a stacking pushing and conveying mechanism, a stacking pushing-out mechanism and a lifting stacking mechanism; the stacking pushing and conveying mechanism is arranged on one side of the conveying device; the lifting stacking mechanism is arranged on the other side of the conveying device; and the stacking pushing-out mechanism is arranged on one side of the lifting stacking mechanism. According to the packing and stacking device, manual packing and stacking work is replaced by mechanical equipment, so that packing and stacking efficiency for smoke alarms is greatly improved; and manual labor intensity and labor cost are lowered.

Owner:常州赛凯电器设备有限公司

Conveyor system apparatus for stacking arrayed layers of objects

ActiveUS7798763B2Improve time efficiencyFast palletizingSemiconductor/solid-state device manufacturingControl devices for conveyorsTime efficientEngineering

A stacking apparatus for a conveyor system raises a two-dimensionally arrayed layer of objects conveyed by the conveyor system and stacks the raised layer of objects on a subsequent layer of objects conveyed by the conveyor system. The apparatus then dispenses the stacked layers of objects from the apparatus, whereby the stacked layers of objects can be received by a palletizer for loading on a pallet in a more time efficient manner.

Owner:OUELLETTE MACHINERY SYST

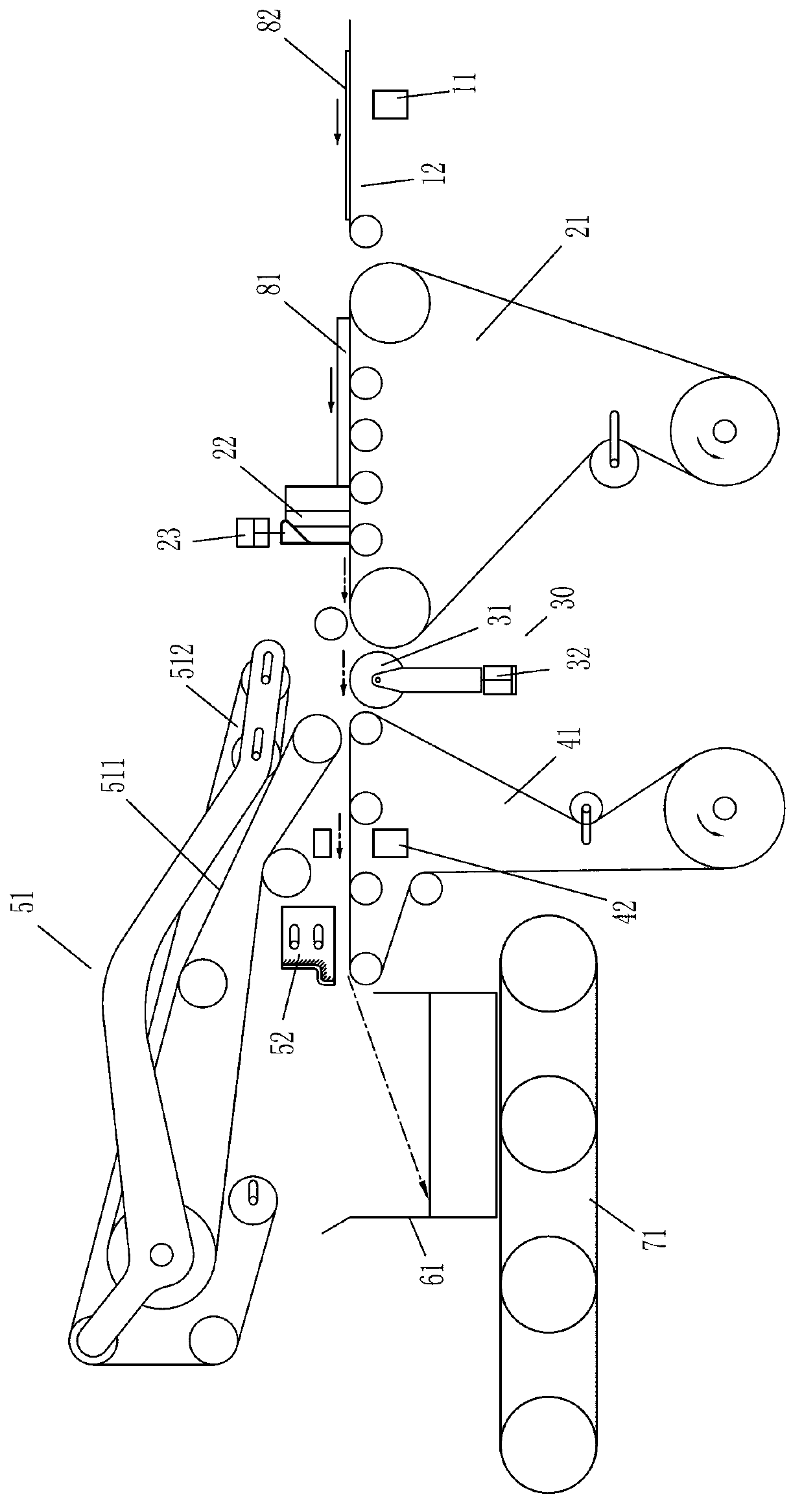

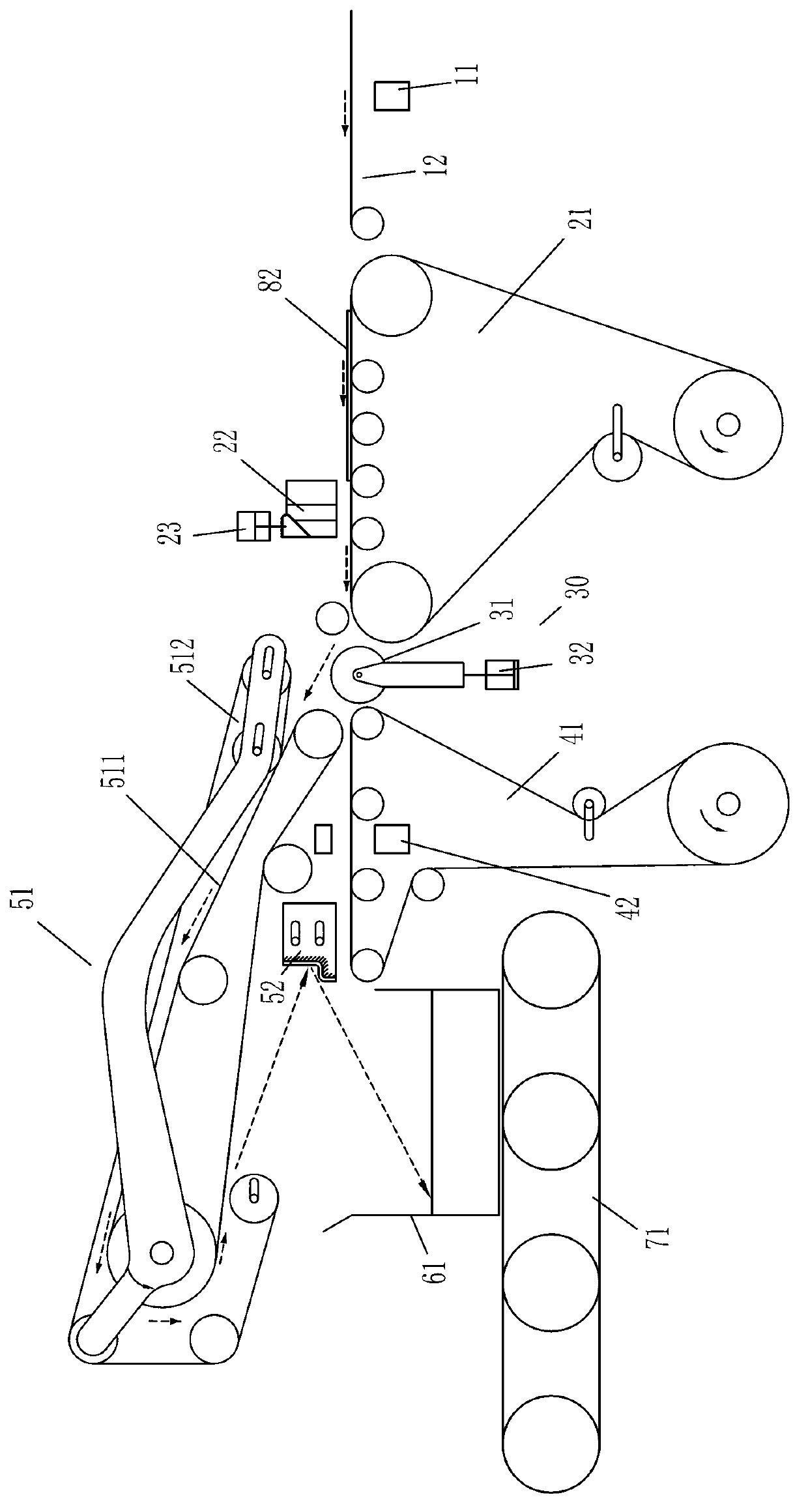

Abrasive paper stacker and abrasive paper stacking method thereof

The invention discloses an abrasive paper stacker and an abrasive paper stacking method thereof. The abrasive paper stacker comprises an abrasive paper conveying device, an output port of the abrasive paper conveying device corresponds to an input port of an intermittent feeding device, an output port of the intermittent feeding device, which is provided with an abrasive paper gathering and bundling gate, is opposite to an input port of a feed forward device, a normal-reverse switching guiding device comprising switching guide wheels is arranged between the output port of the intermittent feeding device and the input port of the feed forward device, an upper surface of a switching guide wheel located at a lower position is flush with an upper surface of a conveyor belt of the intermittent feeding device and the feed forward device, a conveying inlet of an overturn conveying device which turns over abrasive paper for 180 degrees corresponds to an upper surface of a switching guide wheel located at an upper position, a conveying outlet of the overturn conveying device corresponds to a somersault table, an abrasive paper collecting box is disposed below an output port of the feed forward device, and abrasive paper output from the overturn conveying device impacts the somersault table to be blocked to fall into the abrasive paper collecting box. The abrasive paper stacking method includes looping execution of front and reverse side stacking processes. By means of the abrasive paper stacker and the abrasive paper stacking method thereof, front and reverse side stacking of abrasive paper can be automatically achieved, the stacking speed is high, the stacked abrasive paper is orderly, errors not easily occur, and the efficiency is high.

Owner:HEBEI TIANYUHENG TECH CO LTD

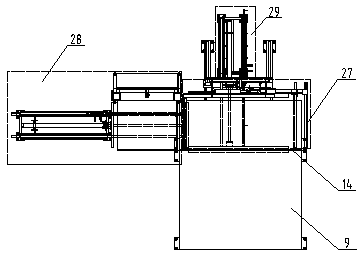

Pneumatic quick stacker crane for container

InactiveCN105347054AImprove delivery efficiencyFast palletizingStacking articlesDe-stacking articlesSlide plateConveyor belt

The invention discloses a pneumatic quick stacker crane for a container. An existing stacker crane is complex in structure and low in stacking efficiency. A roller platform is arranged at a front portion of a frame of the pneumatic quick stacker crane; a transverse box pushing mechanism transversely pushes packaging boxes conveyed by a conveyor belt mechanism on the roller platform; a longitudinal pushing mechanism comprises a lead rod guide rail sliding table, a longitudinal push plate, and two equal-height sliding plates arranged with a distance therebetween; the two ends of each sliding plate are fixed with sliding tables of two lead screw guide rail sliding tables of an elevator mechanism; a guide rail of the lead rod guide rail sliding table of the longitudinal pushing mechanism is fixed with the two sliding plates; the longitudinal push plate is fixed with a sliding table of the lead rod guide rail sliding table of the longitudinal pushing mechanism and a sucker mechanism; a lead screw of the lead rod guide rail sliding table of the longitudinal pushing mechanism is driven by a servo motor. The conveyor belt mechanism and the transverse box pushing mechanism of the pneumatic quick stacker crane for the container are capable of continuously conveying the packaging boxes to the roller platform, thereby improving the box conveying efficiency; after the packaging boxes are gathered into a row, all the packaging boxes are sucked up by the sucker mechanism and once conveyed into the container by the longitudinal pushing mechanism, and therefore, a stacking speed is increased.

Owner:河南小大机器人股份公司

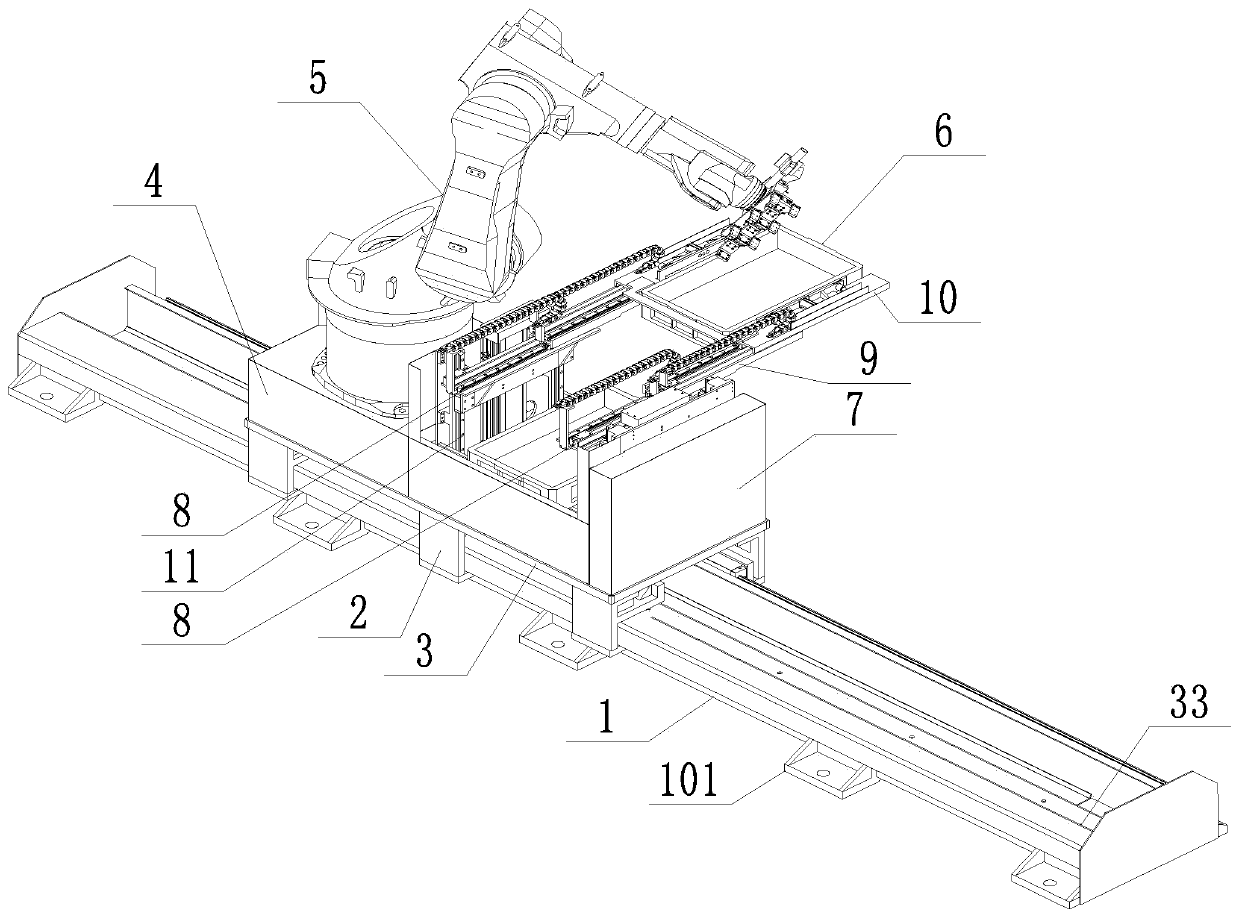

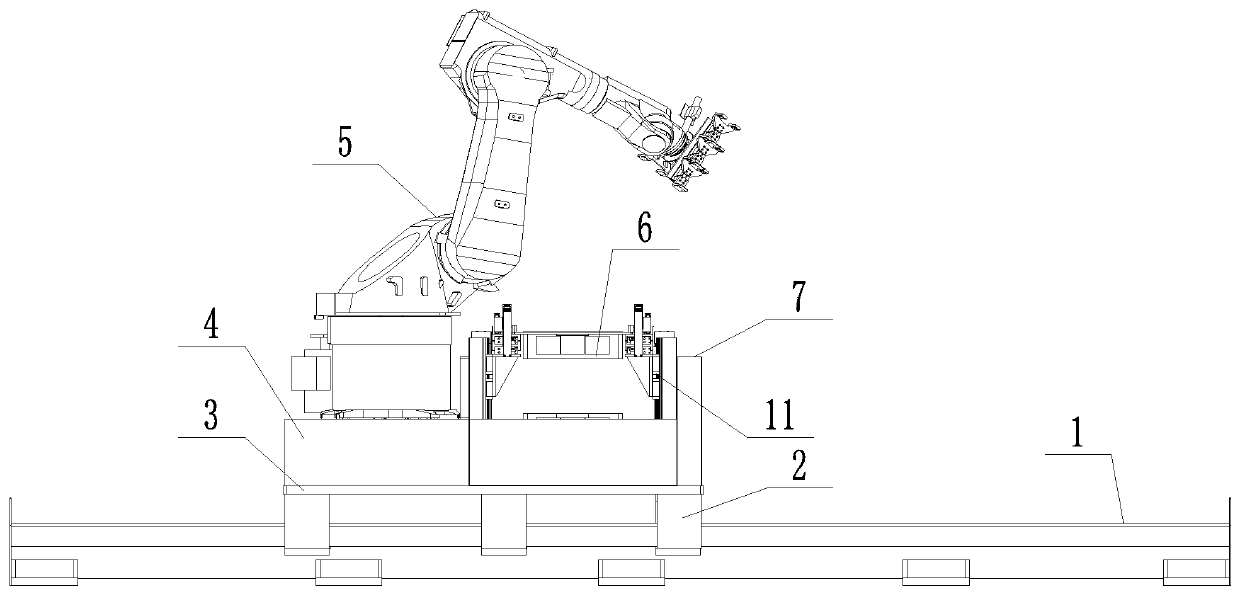

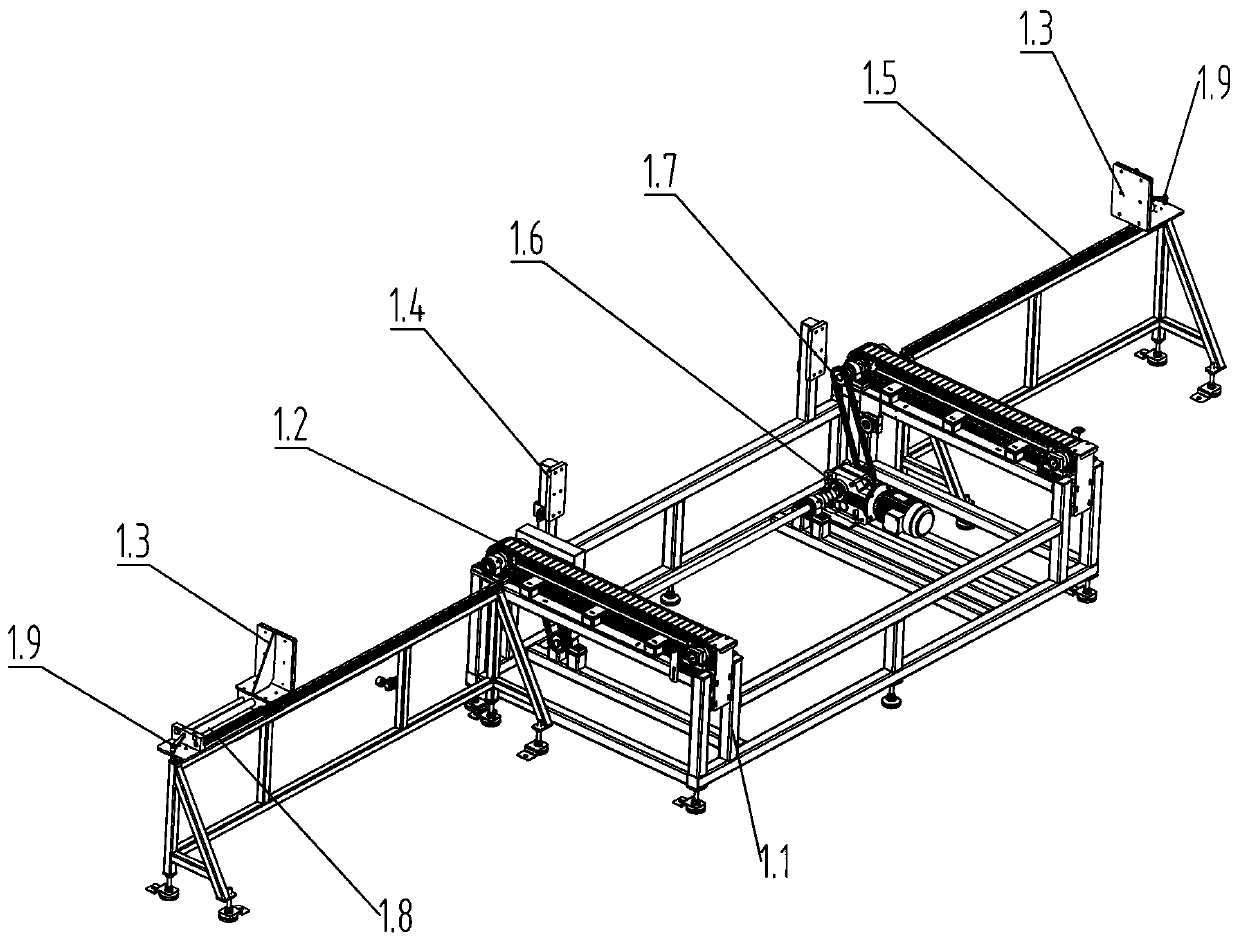

Feeding and blanking device and method for automatically conveying electric energy meters based on rail guided vehicle (RGV)

PendingCN110422620AImprove crawling efficiencyAccelerateConveyorsConveyor partsElectric energyGround track

The invention discloses feeding and blanking device and method for automatically conveying electric energy meters based on a rail guided vehicle (RGV). The device comprises a transfer box, a horizontally arranged walking device, a robot for grabbing the electric energy meters, and a carrier for supporting the transfer box, wherein the N electric energy meters are placed in the transfer box; the walking device comprises a ground track; a sliding seat is slidably connected above the ground track and is connected with a drive device; the robot is arranged above the sliding seat; and a linear module for driving the carrier to move up and down is arranged on the bottom part of the carrier, and is perpendicularly arranged on the sliding seat and located on one side of the robot. According to thefeeding and blanking device and the method for automatically conveying the electric energy meters based on the RGV provided by the invention, the robot can feed and blank at different positions, so that the defect of single feeding and blanking position of an original robot is overcome; by utilizing the carrier, the transfer box and the robot move synchronously, and meanwhile, the stacking of transfer boxes is realized; and the carrier is arranged in a secondary telescoping way, so that no space is occupied, the speed is fast, and the working efficiency is high.

Owner:ELECTRIC POWER RES INST STATE GRID JIBEI ELECTRIC POWER COMPANY +1

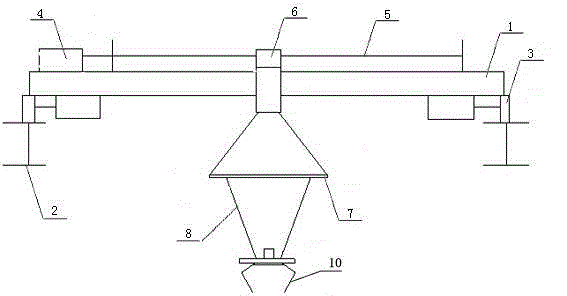

Packed pesticide stacking manipulator

InactiveCN103818732AAutomatic palletizingFast palletizingStacking articlesDe-stacking articlesPulp and paper industryManipulator

The invention provides a packed pesticide stacking manipulator and belongs to the field of automatic machining equipment. The packed pesticide stacking manipulator comprises a crossbeam and two parallel guide rails. Two sides of the crossbeam support the corresponding guide rails through driving wheels. The crossbeam is perpendicular to the guide rails, a screw structure is arranged above the crossbeam, a motion block sleeves a screw of the screw structure, and the lower end sleeves the crossbeam. The packed pesticide stacking manipulator further comprises a fixed mount, telescopic rods, a shaft loaded plate and two claws. The upper end of the fixed mount is fixedly connected with the motion block, the telescopic rods are respectively connected to two sides of the bottom surface of the fixed mount through spherical hinges, the bottom ends of the telescopic rods are respectively correspondingly connected with two sides of a bottom plate through spherical hinges, the bottom plate is provided with a shaft hole, a central shaft is fixed on the upper end face of the shaft loaded plate, a guide sleeve protrudes from the lower end face of the shaft loaded plate, a positioning nut sleeves on the central shaft which penetrates the shaft hole of the bottom plate from bottom to top and supports on the upper end face of the bottom plate, and two sliders sleeves the guide sleeve.

Owner:JIANGNAN UNIV

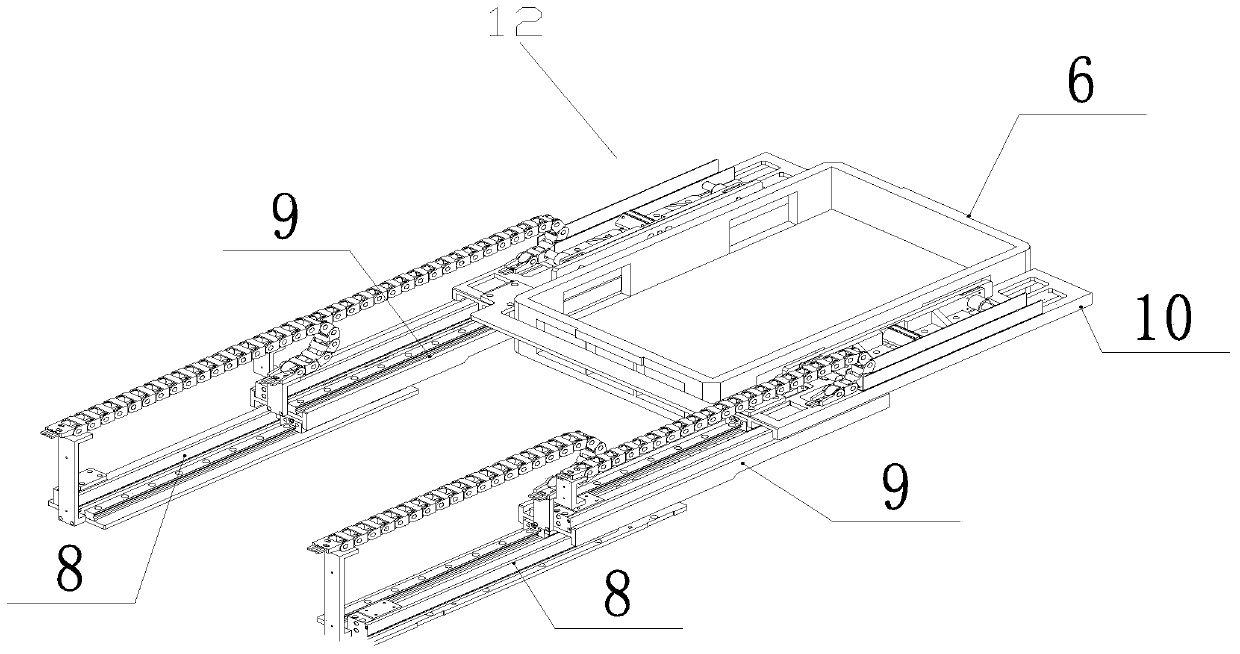

Keel stacking device

PendingCN111115248APrecise deliveryFast deliveryConveyorsControl devices for conveyorsKeelSoftware engineering

The invention relates to a keel stacking device. The keel stacking device comprises a positioning module, a grabbing and carrying module and a control module, wherein the control module coordinates the positioning module and the grabbing and carrying module to perform corresponding actions in sequence, all keels are positioned through the positioning module, and the positioned keels are carried toa stacking frame through the grabbing and carrying module, and stacking is carried out according to a preset arrangement mode of a system. By adopting the keel stacking device, the keels can be accurately and rapidly conveyed and stacked, the working efficiency is improved, the production cost is reduced, and automation and intelligence of keel stacking are achieved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

Industrial automatic stacking robot

ActiveCN106743717AAutomatic palletizing function NoneThe automatic palletizing function does not requireStacking articlesDe-stacking articlesHydraulic cylinderControl system

The invention relates to an industrial automatic stacking robot which comprises a fixing rack. A fixing plate is installed at the upper end of the front side face of the fixing rack, a control system is installed on the upper end face of the fixing plate, and the industrial automatic stacking robot is controlled by the control system to automatically stack high temperature forge pieces; a vertical plate is arranged on the left side of the lower end of the fixing plate, two stroke hydraulic cylinders are symmetrically installed on the inner wall of the vertical plate, installation bases are installed at the top ends of the two stroke hydraulic cylinders through flanges, the upper end faces of the installation bases are symmetrically installed on two linear sliding rails, and the two linear sliding rails are symmetrically installed on the lower end face of the fixing plate; and a clamping table is installed on the lower end face of the installation base, a driving motor is installed at the middle portion of the lower end face of the clamping table through a motor base, a driving gear is installed at an output shaft of the driving motor, and two forge piece clamping mechanisms are meshed to the two sides of the driving gear. By means of the industrial automatic stacking robot, the automatic stacking function of the high temperature forge pieces can be achieved, and manual operation is not needed.

Owner:BEIJING C H L ROBOTICS CO LTD

Autoclaved aerated concrete slab AAC-S finished product discharging continuous stacking device and method

The invention belongs to the technical field of stacking devices, and particularly relates to an autoclaved aerated concrete slab AAC-S finished product discharging continuous stacking device. For solving the problem that slags are prone to deflection during stacking, the following scheme is provided, the device comprises a bottom plate, a mounting plate is arranged above the bottom plate, and second sliding grooves symmetrically distributed at the two sides are formed at the top of the mounting plate. Second sliding blocks are slidably connected into the second sliding grooves, springs are fixed between the second sliding blocks and the inner walls of the second sliding grooves, supporting rods are connected to the inner sides of the second sliding blocks, supporting plates are rotatably connected to the tops of the multiple supporting rods, toothed plates are fixed to the outer sides of the second sliding blocks through bolts, and inserting rods are rotatably connected to the inner walls of one ends of the second sliding grooves through bearings. Gears fixedly sleeve the inserting rods. According to the device, the supporting rods are driven to press downwards through the gravity of concrete slabs, so that extrusion rods move towards the inner end face along third sliding grooves along with third sliding blocks, and therefore extrusion towards the middle position is formed on the concrete slabs, and the concrete slabs are effectively prevented from deflecting.

Owner:宁国华滋筑友建材科技有限公司

Profile steel buckling stacking method and stacking equipment

PendingCN112407971AImprove efficiencyFast palletizingStacking articlesClassical mechanicsStructural engineering

Owner:辽宁鑫硕智能机械有限公司

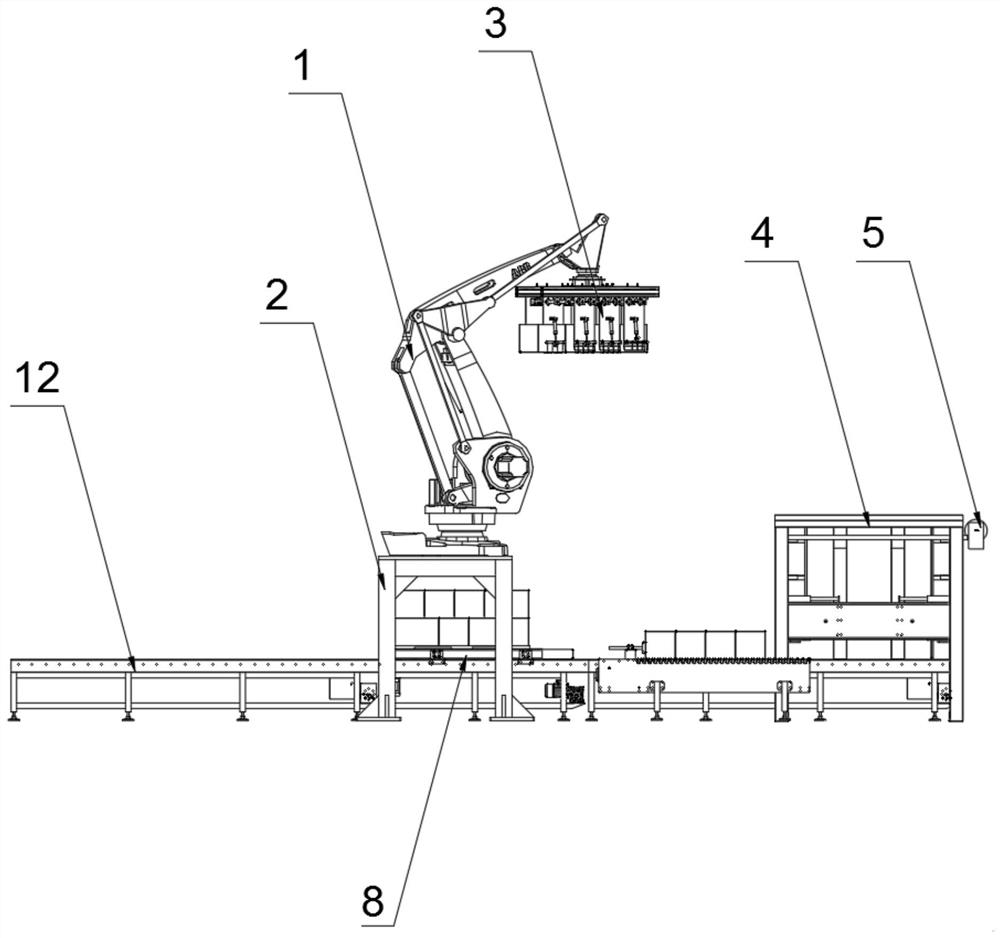

Automatic aluminum wheel stacking system and method

ActiveCN112110212AFully automatedRealize unmannedControl devices for conveyorsStacking articlesControl cellPack material

The invention provides an automatic aluminum wheel stacking system and method. The automatic aluminum wheel stacking system comprises a packing material feeding mechanism, a packing material conveyingchain, an aluminum wheel conveying chain, a stacking robot and a composite clamp, a stacked finished product conveying chain, a finished product conveying AGV, a finished product abutting conveying chain and an automatic stacking control unit, wherein the automatic stacking control unit controls and dispatches mutual cooperation of the packing material feeding mechanism, the packing material conveying chain, the aluminum wheel conveying chain, the stacking robot and the composite clamp, the stacked finished product conveying chain, the finished product conveying AGV and the finished product abutting conveying chain to achieve automatic stacking and conveying. The robot, the AGV, an automatic three-dimensional storage technology and the like are used for achieving whole-process automationand unmanned operation of stacking, conveying and storage; and the stacking speed, precision, repeatability and storage speed are improved, and meanwhile, the aesthetic feeling of products and the safety of the process are improved.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

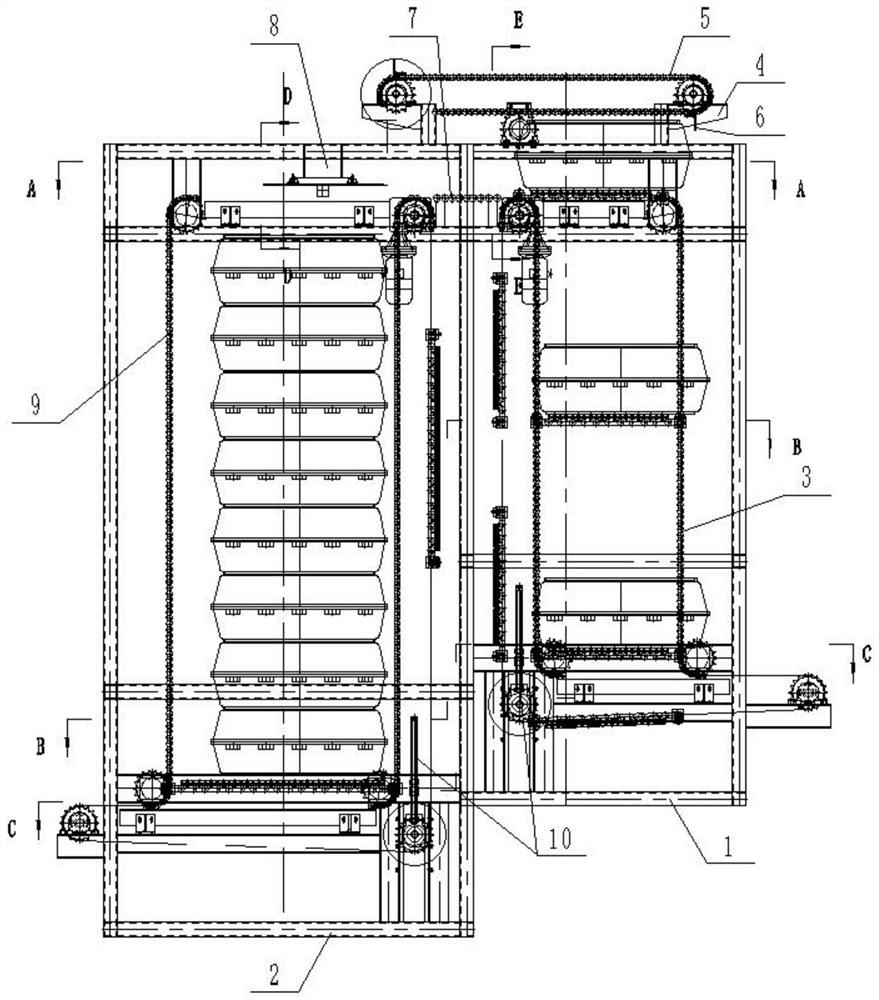

Continuous automatic poultry cage stacking machine

PendingCN112875311AEfficient collectionFast transferConveyorsStacking articlesControl engineeringPalletizer

The invention discloses a continuous automatic poultry cage stacking machine, and belongs to the field of automation. The stacking machine comprises an ascending support and a descending support, a vertical elevator is arranged on the ascending support, a vertical landing machine is arranged on the descending support, a translation support is arranged above the ascending support and the descending support, a translation device is arranged on the translation support, and the translation device can be used for transferring a poultry cage on the vertical elevator to the upper side of the vertical landing machine; and a carrying device is arranged above the descending support, and the carrying device is used for transferring the poultry cage on the translation device to the vertical landing machine.

Owner:山东省博兴县长征食品机械制造厂

Full-automatic shaping and stacking device and method

The invention discloses a full-automatic shaping and stacking device and method. The full-automatic shaping and stacking device comprises a conveying mechanism, a mechanical arm, a stacking mechanism and an output mechanism, wherein the conveying mechanism is capable of conveying materials to the mechanical arm; the mechanical arm can receive the materials from the conveying mechanism, shape the left faces and the right faces of the materials and place the materials on an opening and closing door of an opening and closing door mechanism for preliminary stacking after shaping; the stacking mechanism comprises a lifting table; the lifting table receives the materials falling from the opening and closing door; the lifting table moves upwards to enable the upper surfaces of the materials to make contact with the lower surface of the opening and closing door to form shaping of the upper faces and the lower faces of the materials; and the output mechanism is used for outputting the material stacks on the lifting table. The full-automatic shaping and stacking device is compact in structure, small in occupied area, capable of stacking after automatic shaping, capable of achieving four-face shaping, capable of enabling stacked stacks to be flat, convenient to use and high in automation degree.

Owner:姚奎

Corrugated box linkage production method and production line

ActiveCN105538779BIncrease productivityGuarantee product qualityPaper-makingBox making operationsCardboardProduction line

The invention discloses a corrugated carton linkage production method. The corrugated carton linkage production method comprises the following steps, sequentially embodied on a production line, that die cutting and shaping are conducted on corrugated boards in a flat to flat die cutting machine, debris removing is conducted, and each shaped corrugated board has multiple board units which are connected together through connecting points; the connecting points among the board units are broken off on a slitting machine; the slit corrugated boards are separately inspected one by one on a product inspection machine, a qualifiedly printed product is sent to the next process, and an unqualifiedly printed product is taken out. The invention further discloses a linkage production line embodying the corrugated carton linkage production method. The linkage production line comprises the flat to flat die cutting machine, a board rotating machine, the slitting machine, a board feeding machine, the product inspection machine, a packing machine, a board rotating machine and a stacking machine which are sequentially arranged. Communication and speed synchronization of all single-machine devices of the production line is controlled by a central electric control system. By means of the corrugated carton linkage production method and production line, the production efficiency of corrugated cartons is improved, and the production cost is reduced.

Owner:SHANDONG CENTURY MACHINERY

Substrate scribing and carrying device

ActiveCN113879840ARealize clamping positioningMove quicklyCleaning using gasesStacking articlesEngineeringLaser cutting

The invention relates to the field of laser cutting, in particular to a substrate scribing and carrying device. The technical problems are as follows: all ceramic substrates after laser cutting fall into a void cabin below a laser cutting platform, an operator can take out the ceramic substrates from the void cabin of the cutting platform only when laser cutting is completed or stopped, and meanwhile, the ceramic substrates are easily scratched and broken when falling into the void cabin. According to the technical scheme, the substrate scribing and carrying device comprises a rack, a carrying system, a clamping system and the like; the carrying system is connected to the front portion of the upper side of the rack; and the clamping system is connected to the right portion of the upper side of the rack. According to the substrate scribing and carrying device, conveying of the oval ceramic substrates after laser cutting is achieved, manual collection of the ceramic substrates falling into the void cabin after laser cutting is replaced, and the situation that the product quality is affected due to the fact that the ceramic substrates fall off and are scratched is prevented.

Owner:张家港力勤机械有限公司

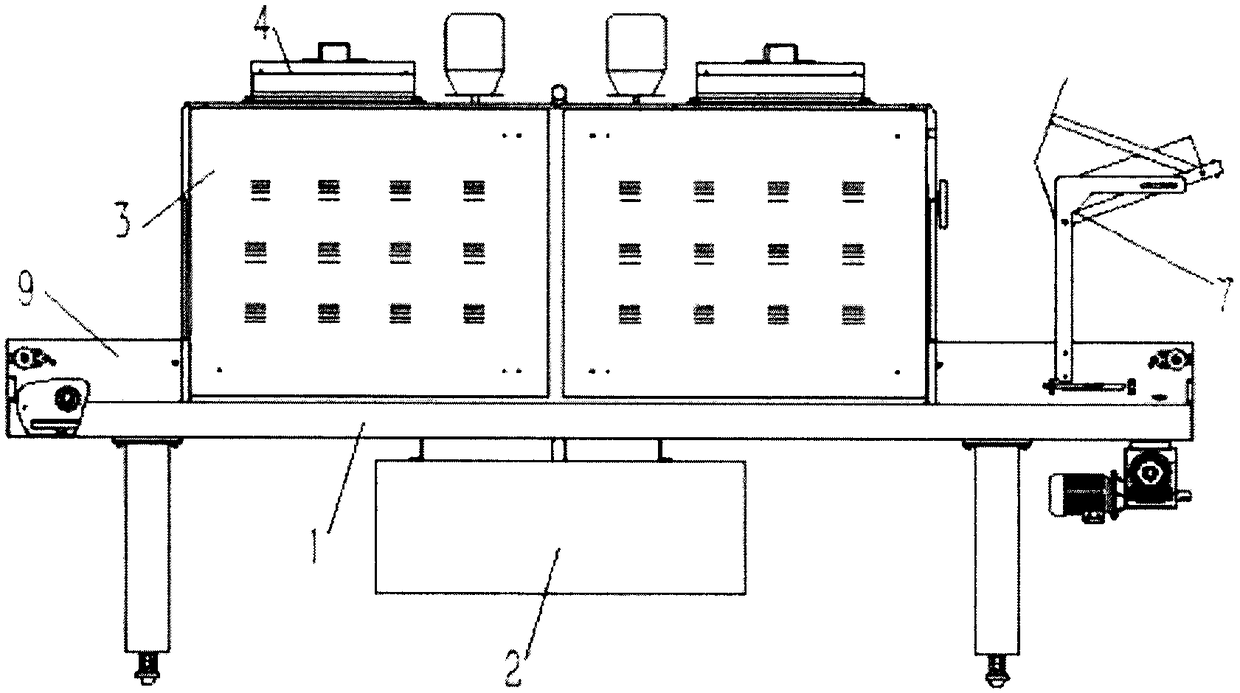

Distance adjustable pipeline type shrinkage furnace

Owner:廊坊永创包装机械有限公司

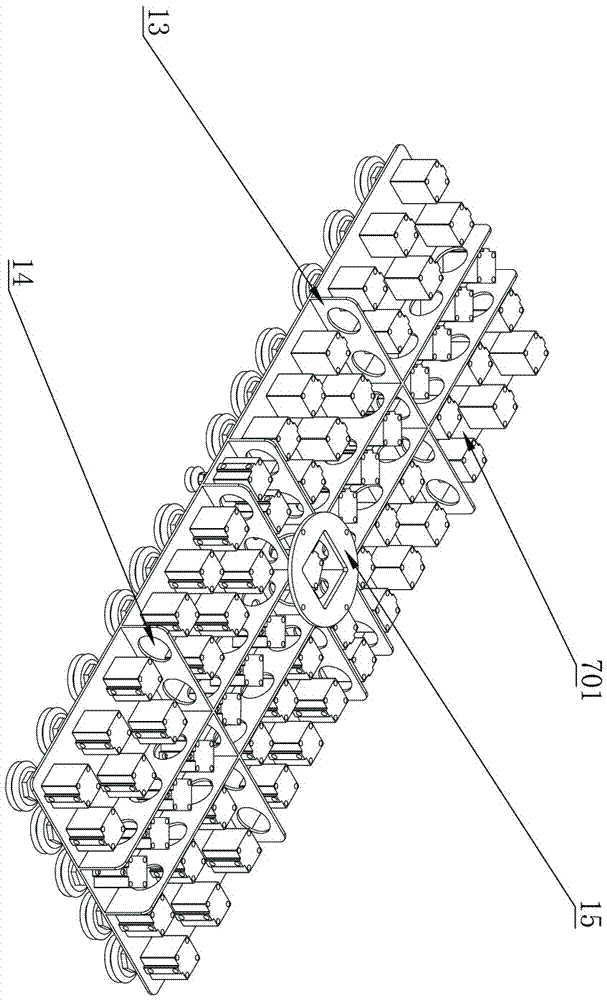

Square-bale hay palletizing device

ActiveCN108820838AFast palletizingEfficient palletizingStacking articlesConveyor partsEngineeringTruck

The invention discloses a square-bale hay palletizing device and belongs to the technical field of agricultural machines, which solves the problem that the pallet truck has low efficiency and low stacking stability. The technical solution of the invention comprises a stack-push device, a primary aggregate platform and a secondary aggregate platform connected in sequence; a feeding device is installed at a side surface of the primary aggregate platform; a clamping and packing device is arranged at the connection part of the stack-push device and the primary aggregate platform; the clamping andpacking device comprises a clamping and packing guiding support and a first clamping-packing structure and a second clamping-packing structure which are closely next to the clamping and packing guiding support; the device also comprises a clamping-packing structure connecting rod, a lifting oil cylinder, a clamping-packing oil cylinder and a connecting board; the first clamping-packing structure is connected with the primary aggregate platform through the lifting oil cylinder; the second clamping-packing structure is connected with the clamping-packing structure connecting rod through the connecting board; the clamping-packing structure connecting rod is connected with the first clamping-packing structure through the clamping-packing oil cylinder. The invention has the advantages that thebale palletizing is realized quickly and efficiently, and the stacking stability is high.

Owner:GANSU ACAD OF MECHANICAL SCI

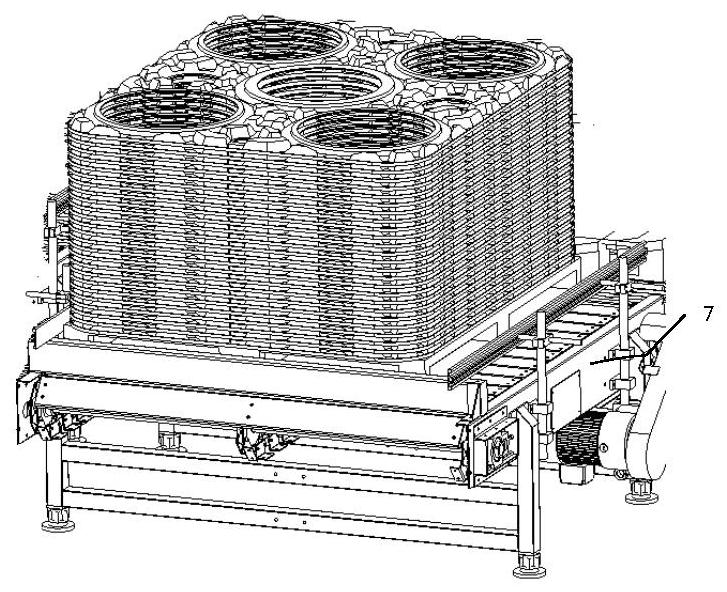

High-speed intelligent mushroom stick packaging production line

PendingCN110758858AIncrease productivityEasy to organizePackaging machinesWinding machineProduction line

The invention discloses a high-speed intelligent mushroom stick packaging production line and relates to the technical field of packaging equipment. According to the main points of the technical scheme, the high-speed intelligent mushroom stick packaging production line comprises a conveying line, a mushroom stick grabbing manipulator, a mushroom stick arranging mechanism and a stacking machine, and the mushroom stick grabbing manipulator, the mushroom stick arranging mechanism and the stacking machine are arranged in the conveying direction of the conveying line sequentially; the mushroom stick grabbing manipulator is used for putting mushroom sticks into the mushroom stick arranging mechanism; the mushroom stick arranging mechanism is used for arranging the mushroom sticks into mushroomstick packages preliminarily; the side, located in the position of the stacking machine, of the conveying line is provided with a pallet conveyer for conveying pallets; the stacking machine is used for stacking the mushroom stick packages onto the pallets of the pallet conveyer one by one; and a film winding machine for winding films around the stacked mushroom sticks for packaging is connected tothe discharge end of the pallet conveyer. Through the high-speed intelligent mushroom stick packaging production line, the mushroom sticks can be automatically stacked and packaged, and the effect ofthe improvement of production efficiency is achieved.

Owner:厦门祺安达自动化设备有限公司

Assembled foam stacking and unstacking equipment

InactiveCN109607221AFast palletizingHigh degree of automationStacking articlesDe-stacking articlesControl systemAssembly line

The invention discloses assembled foam stacking and unstacking equipment. The assembled foam stacking and unstacking equipment comprises a belt assembly line for conveying foam, stacking tools on theside surface of the belt assembly line, manipulators on the side surface of the belt assembly line, an inspection system and a control system. The stacking tools comprise the mixed stacking tool for cross-stacking of the foam and hard pressing plates and the hard pressing plate stacking tool for separately stacking the hard pressing plates. The manipulators include the foam grabbing manipulator which transfers the foam between the belt assembly line and the mixed stacking tool and the hard pressing plate grabbing manipulator which transfers the hard pressing plates between the hard pressing plate stacking tool and the mixed stacking tool. The assembled foam stacking and unstacking equipment realizes quick stacking and unstacking of the foam through the coordination work of the manipulators, the stacking tools, various sensors and the control system; and meanwhile, users can assemble the equipment freely by moving the manipulators and the tools by casters and combined with the belt assembly line according to actual production requirements to perform stacking or unstacking on the foam.

Owner:CHENGDU UNIV OF INFORMATION TECH

High-speed stacking system with pre-tensioning device

InactiveCN106144634AImprove accuracyImprove efficiencyStacking articlesDe-stacking articlesEngineeringMagnet

The invention discloses a high-speed stacking system with a pre-tensioning device. The high-speed stacking system with the pre-tensioning device comprises a rack, a suspension arm, a drive device, a wrist part and an overturning permanent magnet. The rack comprises a horizontal section and a vertical section. The rear end of the horizontal section is connected with the top end of the vertical section. The front end of the horizontal section of the rack is hinged to the upper end of the suspension arm through a first hinge shaft. A retractor device is hinged to the front side of the vertical section of the rack and the suspension arm. The lower end of the suspension arm is connected with the wrist part. A wrist leveling mechanism is arranged on the wrist part. The overturning permanent magnet is arranged at the front end of the wrist part. A horizontal-moving guide toothed plate is arranged at the bottom end of the overturning permanent magnet. A pre-tensioning device used for balancing partial or all of the self weight and the load of the suspension arm is arranged on the vertical section of the rack. The high-speed stacking system with the pre-tensioning device is simple in structure, convenient to operate and capable of accurately stacking section bars at a high speed.

Owner:HUATIAN ENG & TECH CORP MCC

An industrial automatic palletizing robot

ActiveCN106743717BAutomatic palletizing function NoneThe automatic palletizing function does not requireStacking articlesDe-stacking articlesHydraulic cylinderControl system

The invention relates to an industrial automatic stacking robot which comprises a fixing rack. A fixing plate is installed at the upper end of the front side face of the fixing rack, a control system is installed on the upper end face of the fixing plate, and the industrial automatic stacking robot is controlled by the control system to automatically stack high temperature forge pieces; a vertical plate is arranged on the left side of the lower end of the fixing plate, two stroke hydraulic cylinders are symmetrically installed on the inner wall of the vertical plate, installation bases are installed at the top ends of the two stroke hydraulic cylinders through flanges, the upper end faces of the installation bases are symmetrically installed on two linear sliding rails, and the two linear sliding rails are symmetrically installed on the lower end face of the fixing plate; and a clamping table is installed on the lower end face of the installation base, a driving motor is installed at the middle portion of the lower end face of the clamping table through a motor base, a driving gear is installed at an output shaft of the driving motor, and two forge piece clamping mechanisms are meshed to the two sides of the driving gear. By means of the industrial automatic stacking robot, the automatic stacking function of the high temperature forge pieces can be achieved, and manual operation is not needed.

Owner:BEIJING C H L ROBOTICS CO LTD

Special-shaped cigarette rapid stacker and stacking method thereof

PendingCN111731859APalletizingFast palletizingConveyorsStacking articlesEngineeringStructural engineering

The invention discloses a special-shaped cigarette rapid stacker and a stacking method thereof. The stacker comprises a base, a lifting frame, first rotating cigarette receiving plates, fixed cigarette receiving plates and a stacking belt, wherein the lifting frame is installed on the base in a lifting manner, and comprises a first lifting frame and a second lifting frame which are arranged in thevertical direction horizontally; first rotating cigarette receiving plates are rotationally installed on the first lifting frame and the second lifting frame, and the two first rotating cigarette receiving plates are arranged oppositely and equal in height; the fixed cigarette receiving plates are horizontally and fixedly installed on the first lifting frame and the second lifting frame, and thetwo fixed cigarette receiving plates are arranged oppositely and equal in height, and are arranged below the first rotating cigarette receiving plates; the stacking belt is arranged between the firstlifting frame and the second lifting frame, and gaps for the stacking belt to pass through are arranged between the two fixed cigarette receiving plates and the two first rotating cigarette receivingplates. The special-shaped cigarette rapid stacker can effectively improve stacking speed and efficiency of special-shaped cigarettes, has simple structure and is convenient to operate.

Owner:湖南省长株潭烟草物流有限责任公司

Full-automatic material sucking and grabbing equipment

InactiveCN112722871AReduce usageFast palletizingStacking articlesDe-stacking articlesStructural engineeringMechanical engineering

The invention relates to full-automatic material sucking and grabbing equipment which comprises a robot, a base, a clamp, a bottom plate containing frame, a bottom plate elevator, a box feeding conveyor and a bottom plate. A finished product area, a stacking area and a bottom plate placing area are arranged on the bottom plate; a bottom plate positioning device and a finished product conveying belt assembly are arranged on the bottom plate; the feeding end of the conveying belt assembly is in butt joint with the box feeding conveyor; the finished product conveying belt assembly is arranged in the finished product area; the bottom plate positioning device is arranged in the stacking area; the base is arranged in the stacking area; the robot is arranged on the base; the end of the robot is provided with the clamp; the bottom plate elevator is arranged at the side part of the bottom plate placing frame; the bottom plate placing frame is arranged in the bottom plate placing area; and a bottom plate conveying belt assembly is arranged at the bottom of the bottom plate placing frame. According to the full-automatic material sucking and grabbing equipment provided by the invention, only one robot is adopted to complete barrel stacking and partition plate placing work, the full-automatic material sucking and grabbing equipment has the advantages of being high in stacking speed and flexible in stacking, the number of used robots is reduced on the whole, the cost is saved, and the occupied space is reduced.

Owner:武汉奥德隆机械设备制造有限责任公司

Automatic stacking and conveying equipment for plates

PendingCN114701865AWide range of applicationsLow costConveyorsStacking articlesEngineeringMechanical engineering

The invention discloses automatic stacking and conveying equipment for plates, and relates to the technical field of plate processing equipment.The automatic stacking and conveying equipment comprises an automatic stacking and conveying equipment body, a climbing device is installed at the right end of the automatic stacking and conveying equipment body, the left end of the climbing device is fixedly connected with an aligning device, and a stacking device is installed at the left end of the aligning device; a lifting device is installed on the inner wall of the bottom of the stacking device and further comprises a first roller conveying belt, one end of the first roller conveying belt is fixedly connected with a crawler belt conveying belt, the aligning device further comprises a second conveying belt, a centering plate is installed on the inner wall of one side of the aligning device, and the inner wall of one side of the aligning device is fixedly connected with an air cylinder. And a sliding rail is mounted on the inner wall of one side of the aligning device. The plate stacking device has the advantages that the plate stacking device is suitable for plates of different materials, the plates can be conveniently and automatically stacked, conveying is convenient, the aligning degree during stacking is improved, and the plate machining efficiency and stability are improved.

Owner:广东易典智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com