Distance adjustable pipeline type shrinkage furnace

A ducted and spaced technology, applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problem of imperfect packaging effect, and achieve the effect of good packaging effect, convenient maintenance and good shrinkage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0031] The invention discloses a pipe-type shrinking furnace with adjustable spacing, which is a packaging device, in particular a heat-shrinking film packaging machine. The following are specific examples:

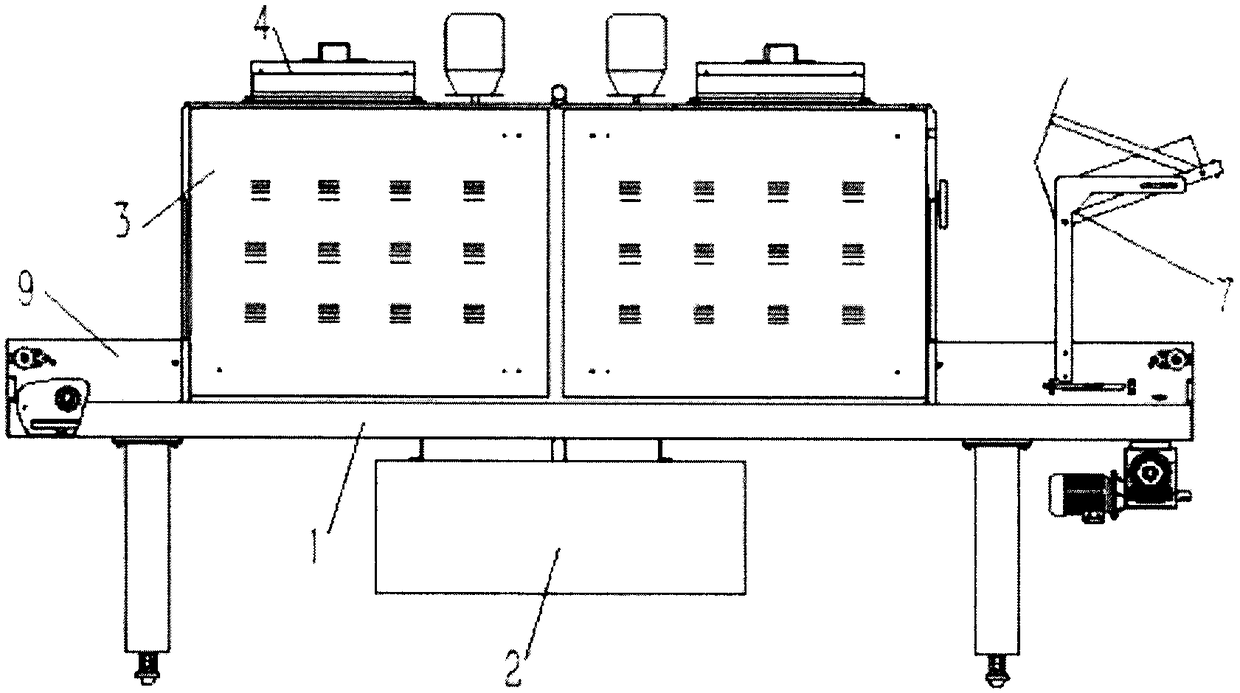

[0032] The pitch-adjustable pipe-type shrinking furnace of the present invention, such as figure 1 , figure 2 As shown, it includes a main body frame 1 , a conveying device and a constriction channel part arranged on the main body frame 1 , and a control box 2 . The part of the shrinking channel is covered above the conveying device, and the products that need to be heated after wrapping the heat shrinkable film are on the conveying device, and are driven forward on the conveying device to pass through the part of the shrinking channel. The part of the shrinking channel that can be heated is the heat shrinkable film. . The main body br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com