Continuous automatic poultry cage stacking machine

A palletizer and automatic technology, applied in the field of automation, can solve problems such as slow transfer speed of manipulators, enterprise troubles, and unsatisfied requirements for transfer speed of poultry cages, etc., to reduce failure and interference rate, improve palletizing efficiency, and overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

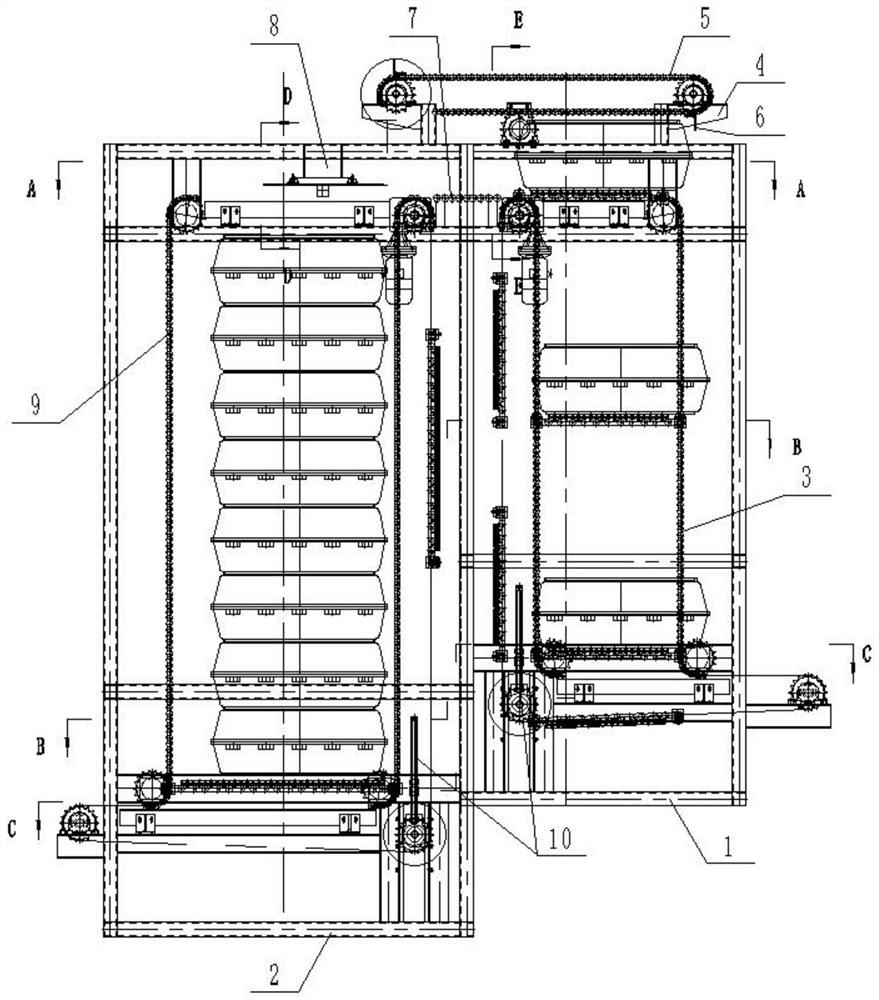

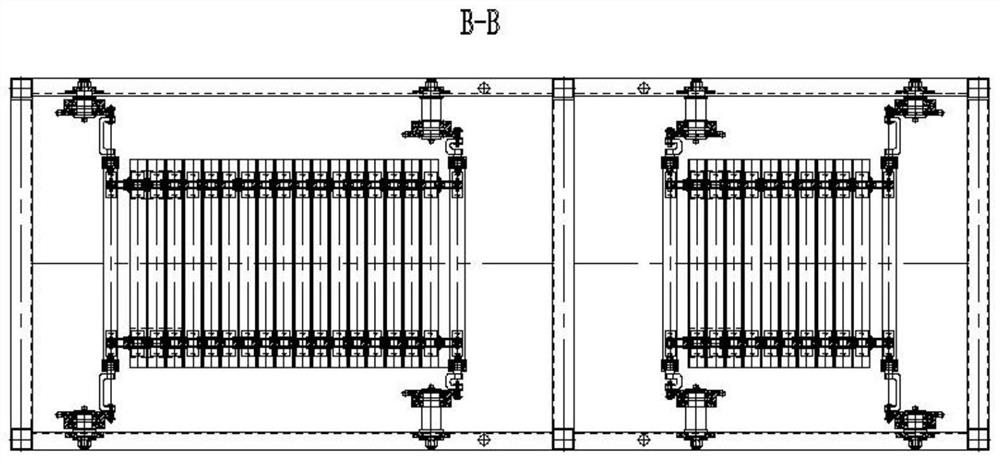

[0037] Such as Figure 1 to Figure 8 Shown, a kind of continuous type automatic poultry cage palletizer comprises uplink support 1 and downlink support 2, and uplink support 1 is provided with vertical hoist 3, and downlink support 2 is provided with vertical descending machine 9, and uplink support 1 top and The top of the descending support 2 is provided with a translation support, and the translation support is provided with a translation device, and the translation device can transfer the poultry cage on the vertical hoist 3 to the top of the vertical descender 9;

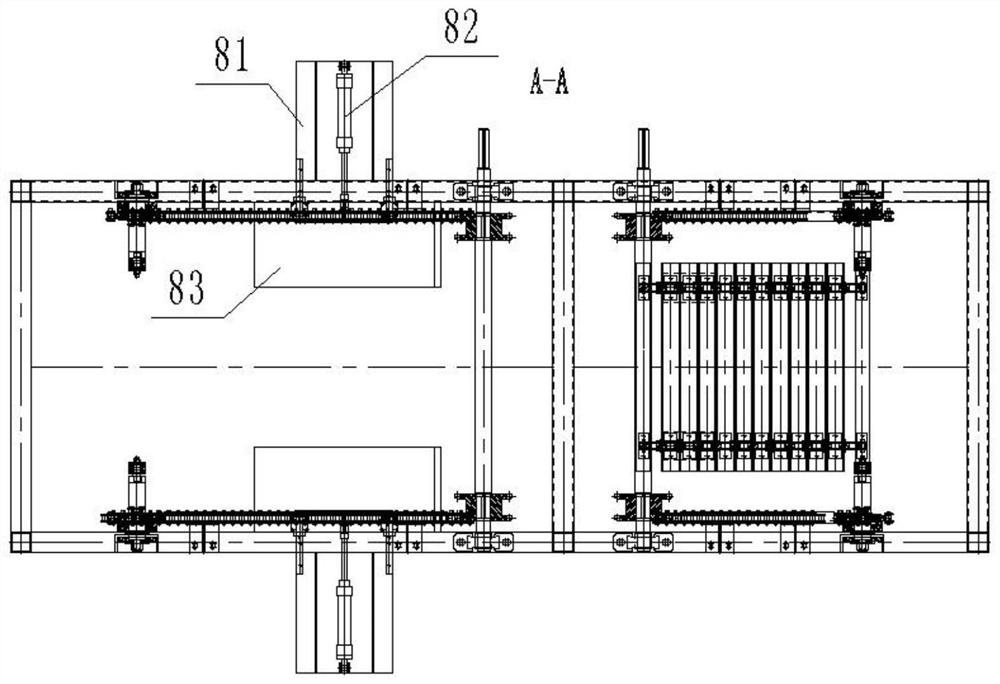

[0038] The top of the descending support 2 of the present invention is provided with a carrying device 8, and the carrying device 8 transfers the poultry cage on the translation device to the vertical descending machine 9.

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com