Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Guaranteed synchronous action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

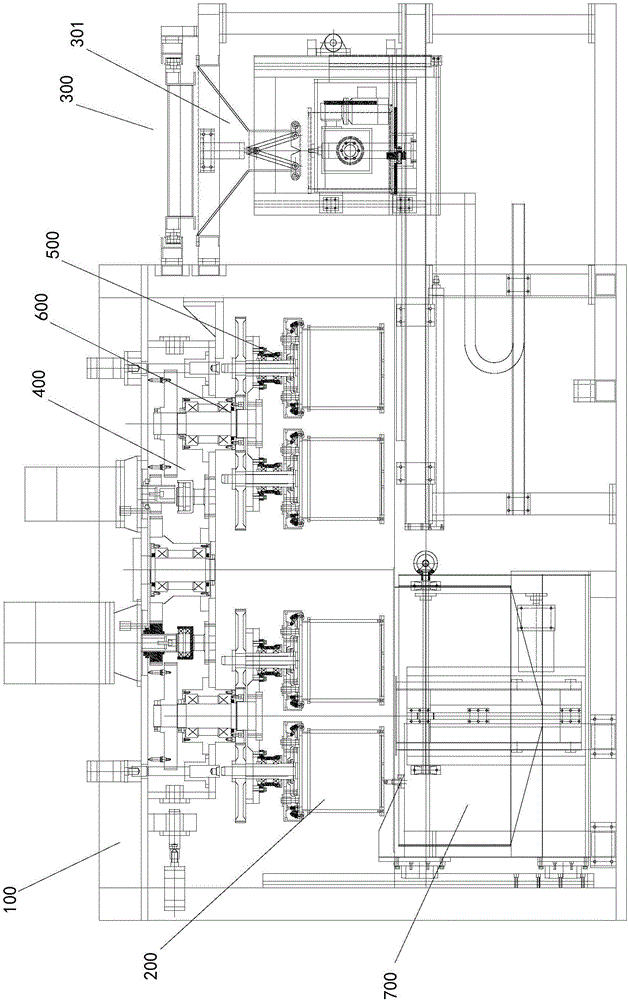

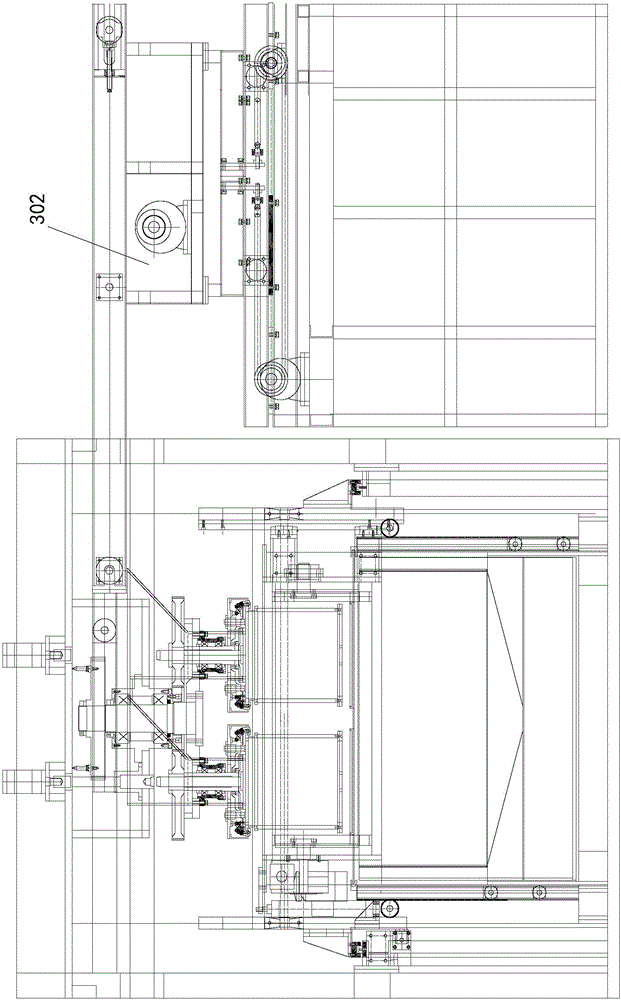

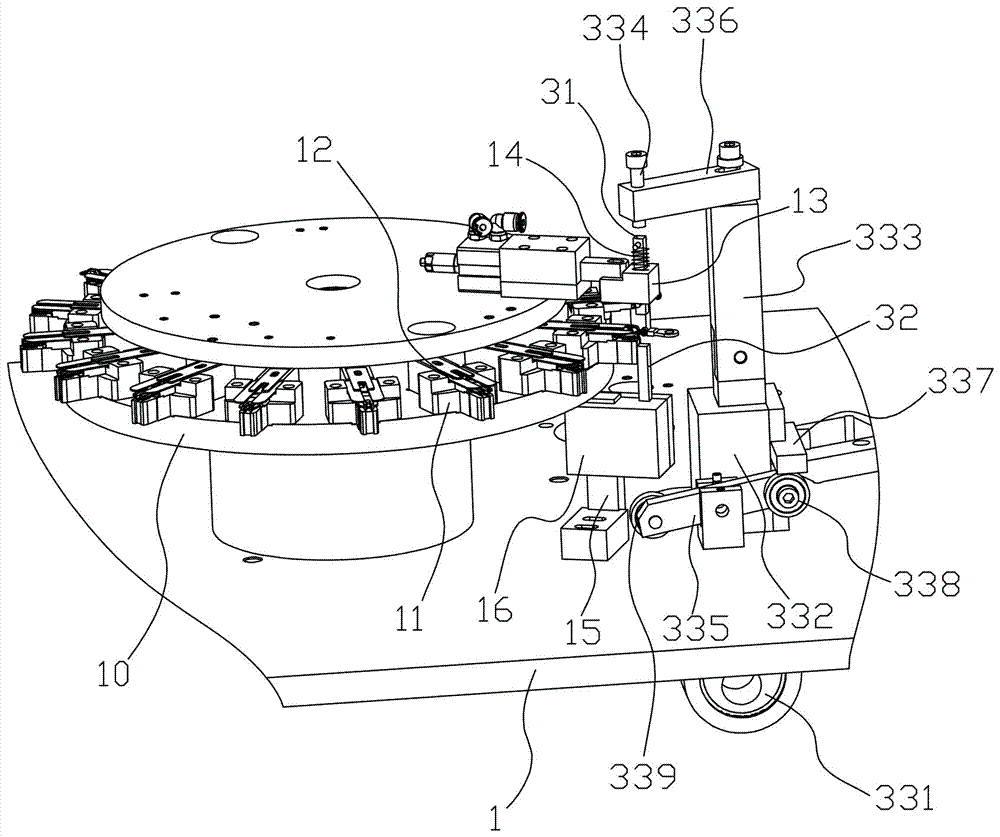

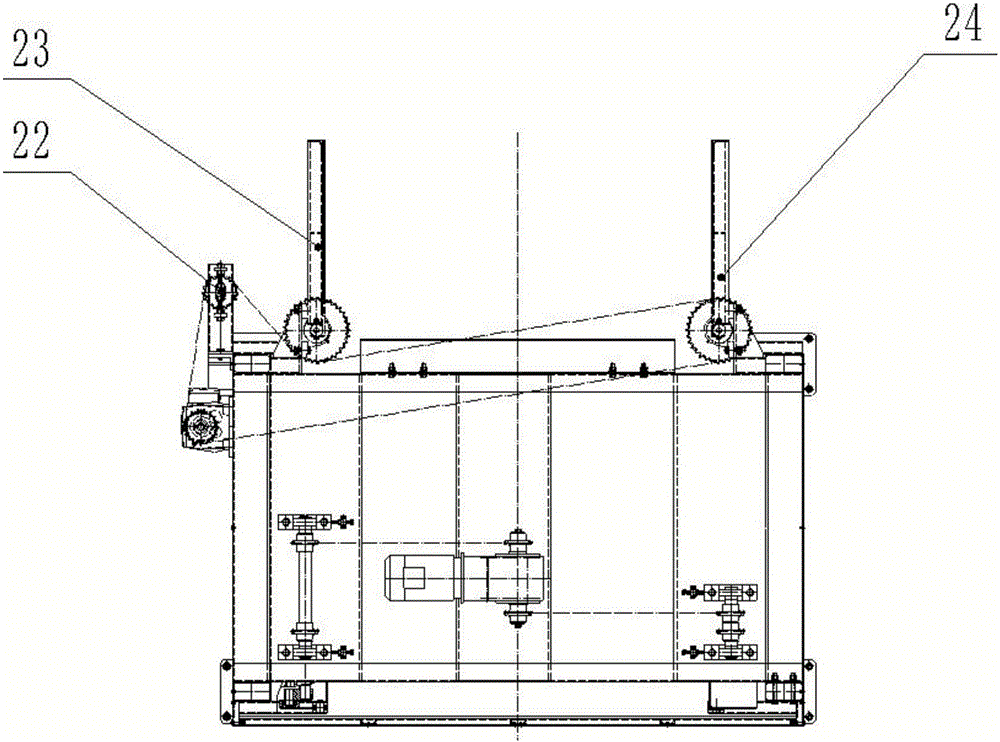

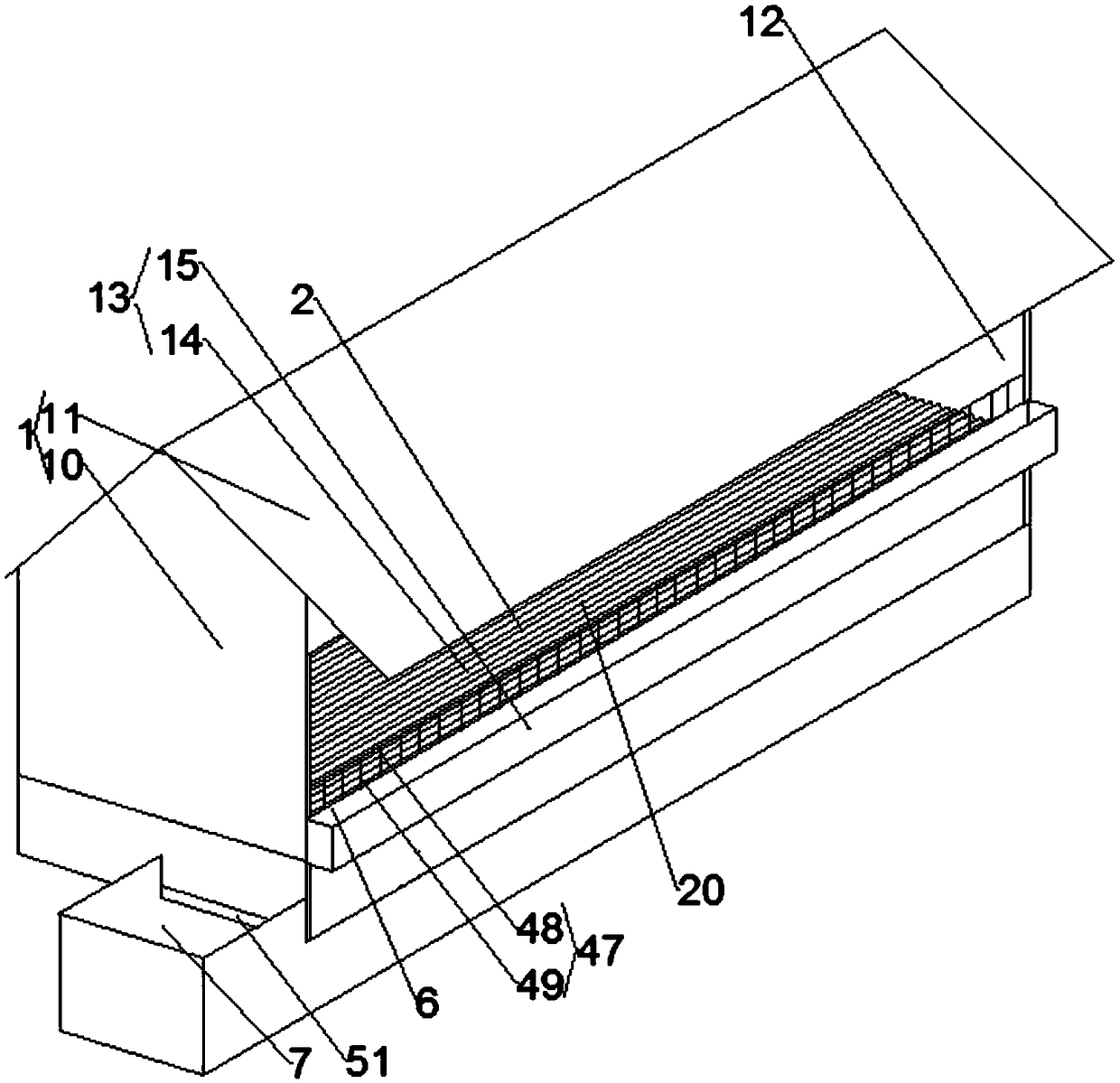

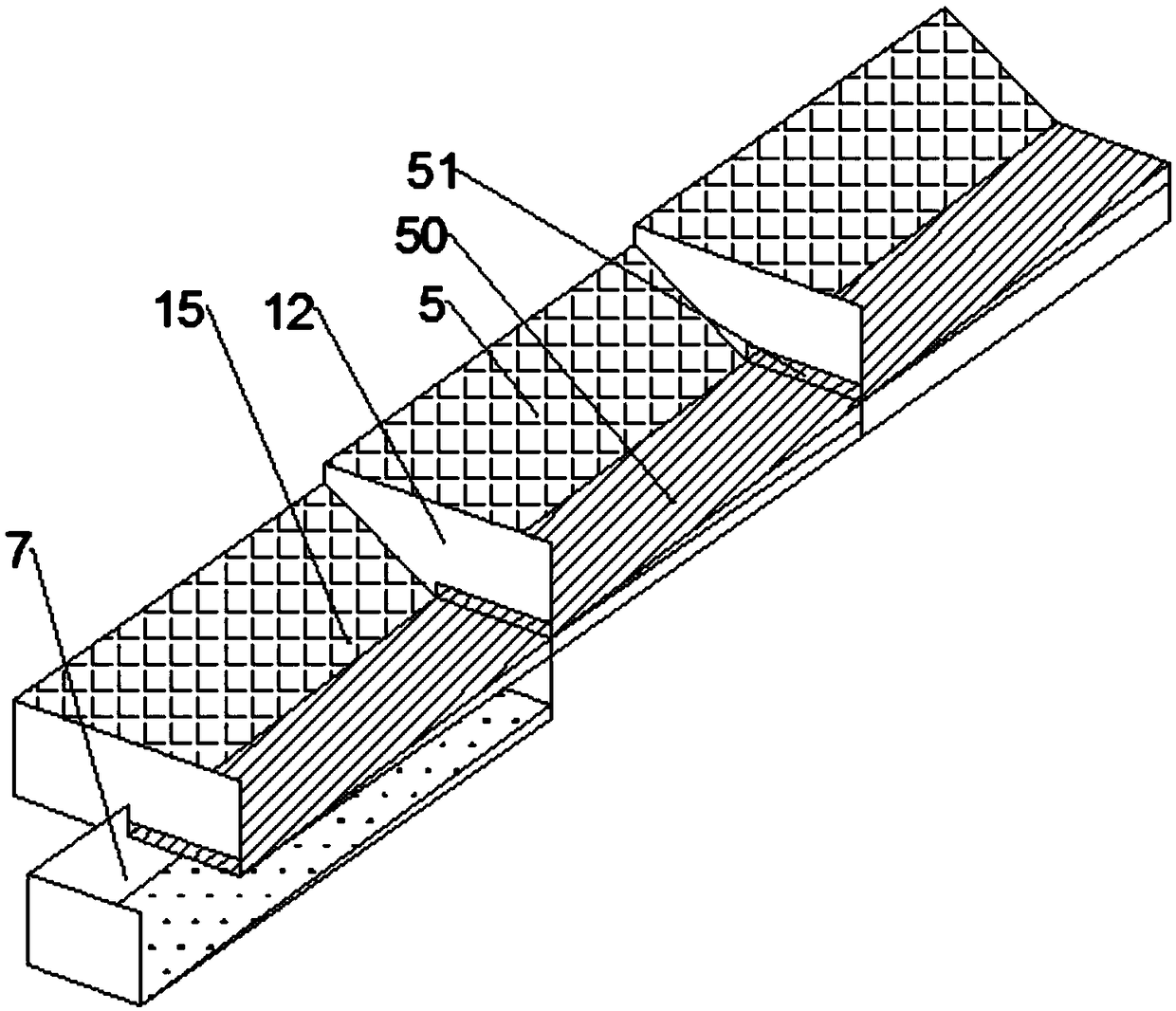

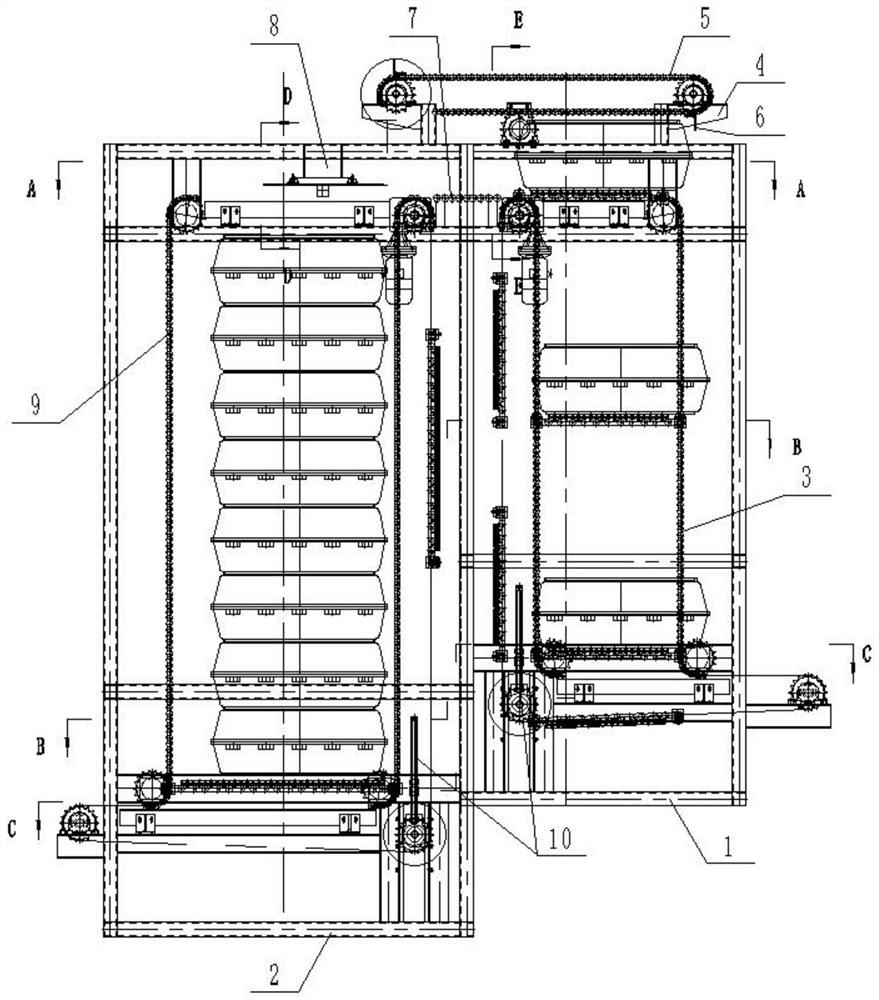

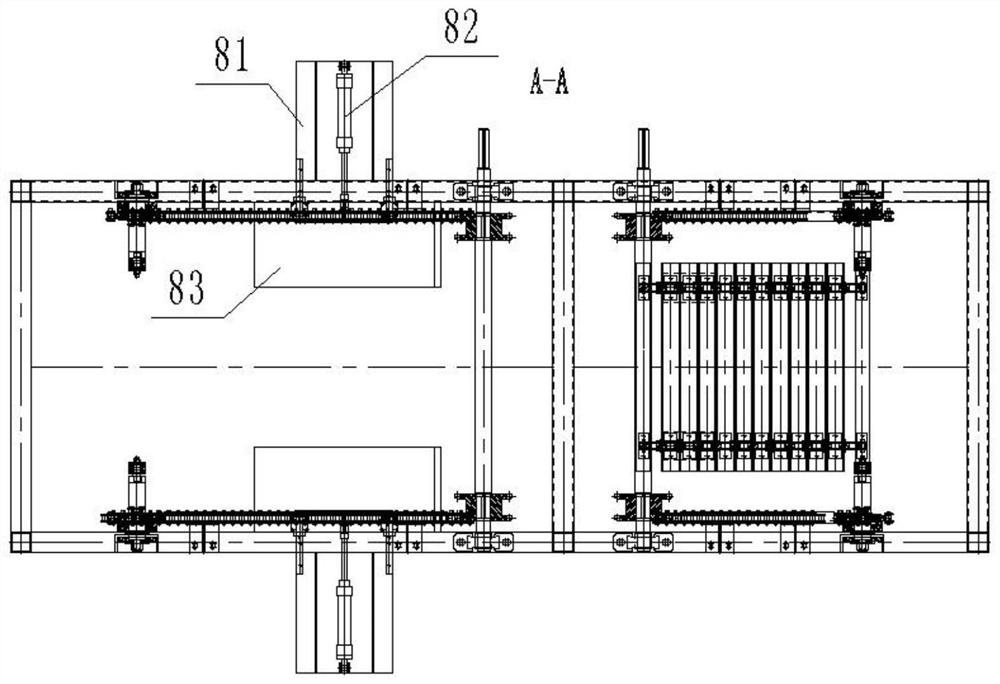

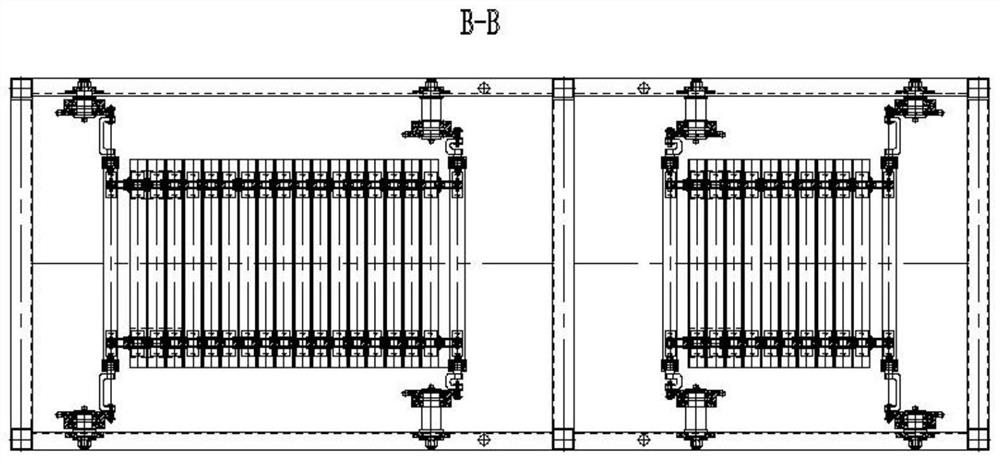

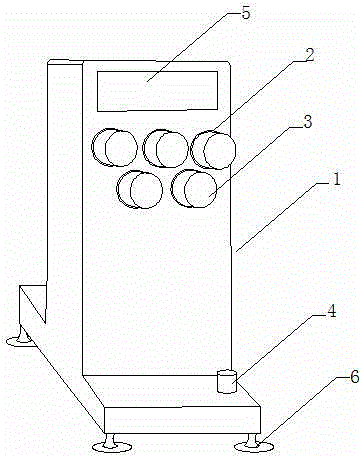

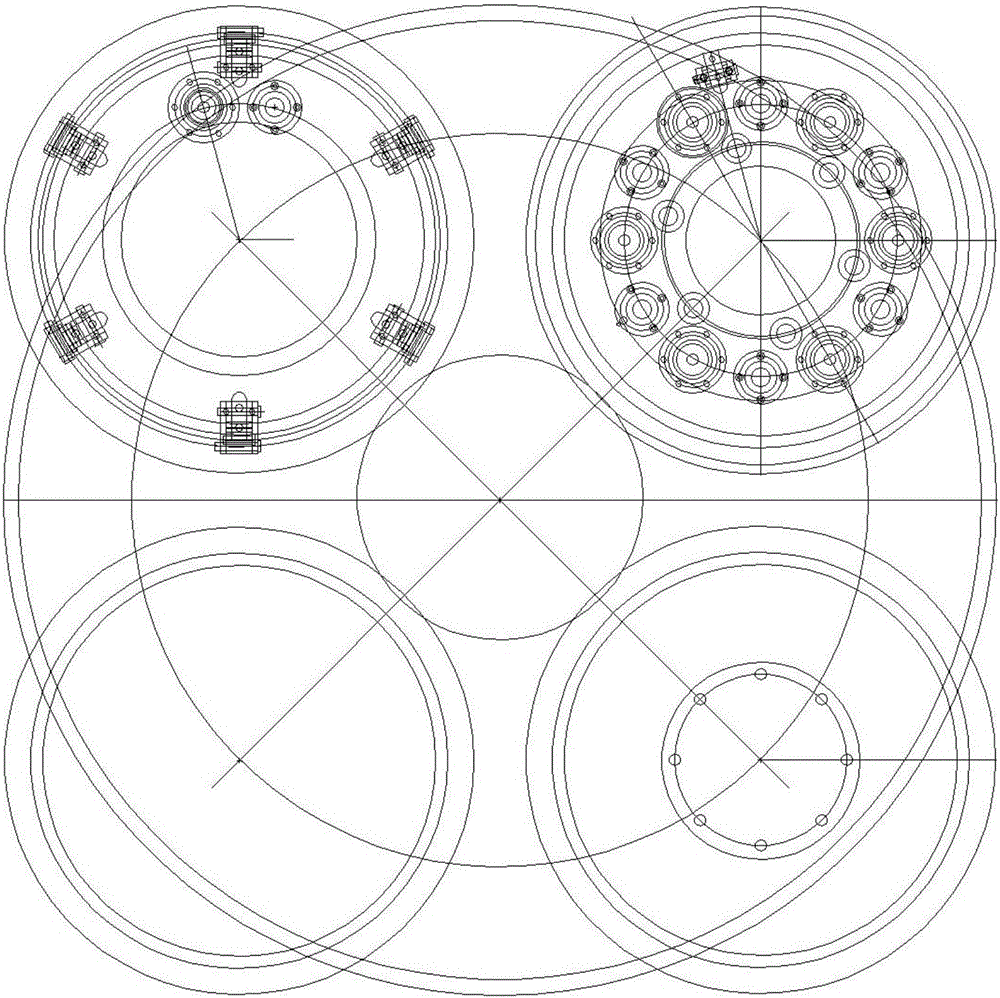

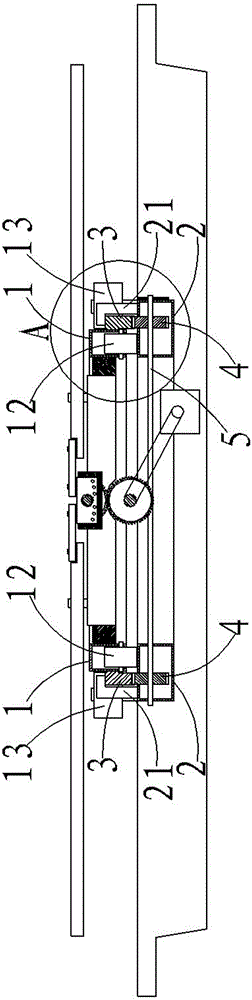

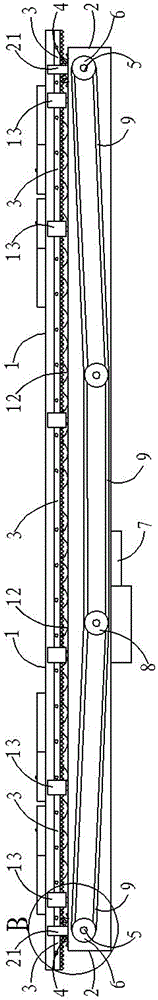

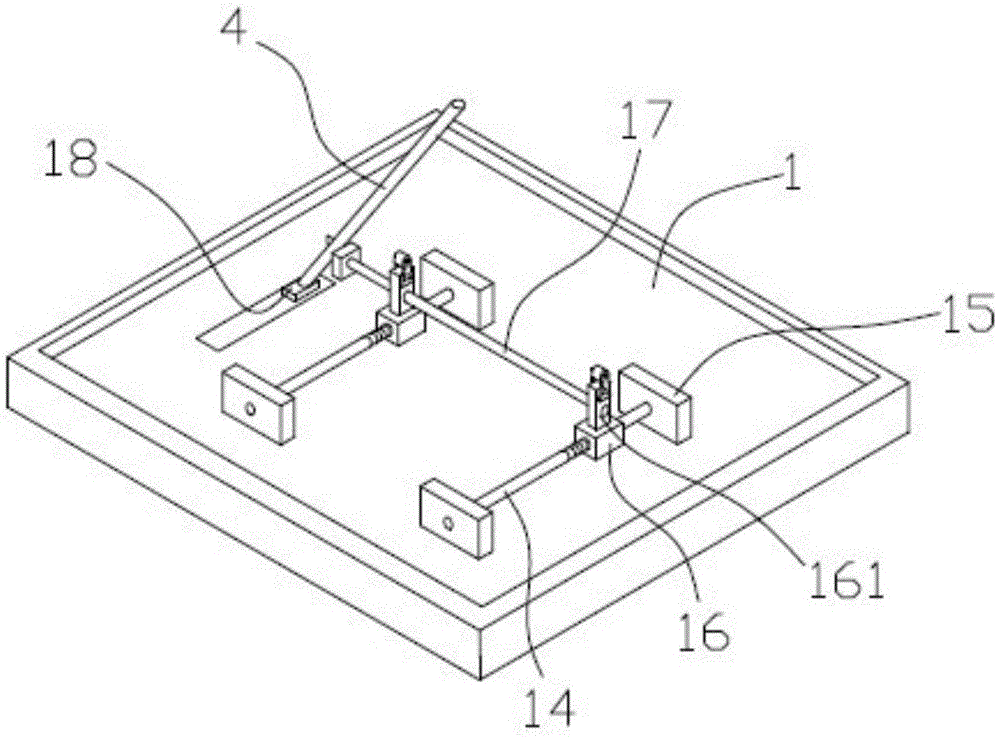

Coating machine

ActiveCN105709990AGuaranteed synchronous actionImprove clamping efficiencyLiquid surface applicatorsCoatingsEngineeringAutomation

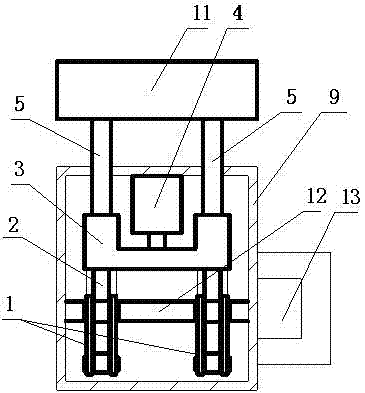

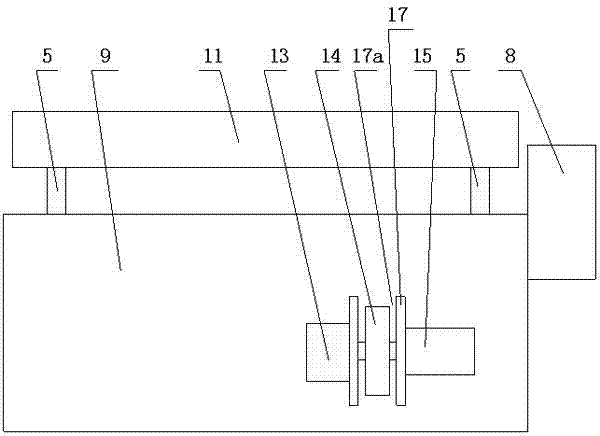

The invention discloses a coating machine which comprises a rack and a workpiece basket. The coating machine further comprises a feeding mechanism for adding workpieces into the workpiece basket. A working station rotating device for changing the work position of the workpiece basket is arranged on the rack and at least provided with two sets of clamping and rotating devices for clamping or loosening the workpiece basket and driving the workpiece basket to rotate, and centrifugal driving mechanisms arranged on the working station rotating device and used for driving the clamping and rotating devices to rotate. A dipping machine and a dipping machine lifting device for driving the dipping machine to enable the workpiece basket to be soaked therein, and a walking turnover device are arranged below the clamping and rotating devices, and the walking turnover device is used for conveying the fed workpiece basket to the positions of the clamping and rotating devices to be clamped by the clamping and rotating devices. The coating machine automatically conveys the workpieces needing to be coated into coating equipment, the coated workpieces are automatically discharged, the automation degree is high, and the coating efficiency is improved.

Owner:CHANGZHOU JUNHE TECH

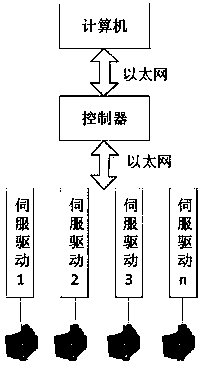

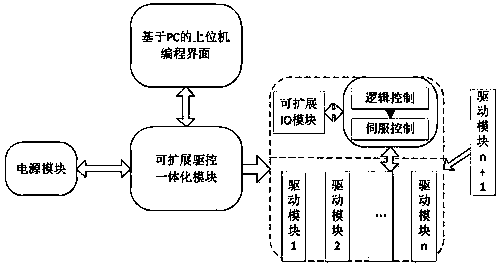

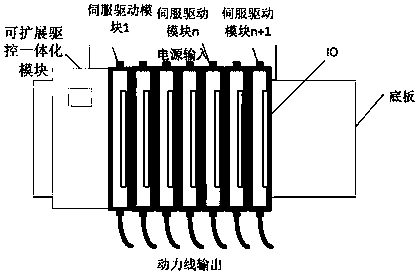

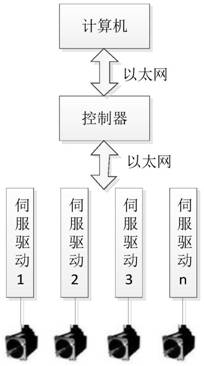

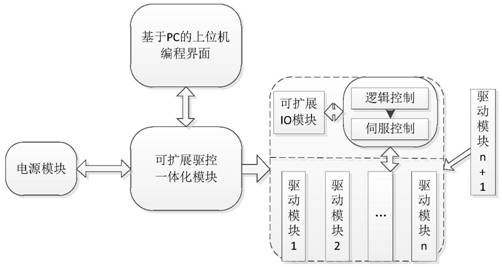

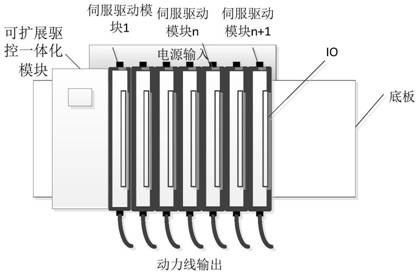

Drive and control integrated servo implementation method and system

ActiveCN109639187ARealize the integration of drive and controlOvercome the disadvantage of poor scalabilityElectric motor controlMultiple ac dynamo-electric motors controlControl theoryElectric power

The embodiment of the invention relates to the technical field of power electronics, and discloses a drive and control integrated servo implementation method and a drive and control integrated servo implementation system. The drive and control integrated servo implementation system comprises an upper computer interface and an extensible drive and control integrated module. The extensible drive andcontrol integrated module comprises a control module and an extensible driving module. The control module comprises a logic controller and a motor driver. The extensible driving module comprises a plurality of extensible driving modules. Each driving module is provided with an FPGA hardware current loop. The upper computer interface compiles a user logic control program and transmits the user logic control program to a logic control CPU. The logic control CPU calculates logic data according to an instruction and sends the logic data to the motor driver, and the motor driver controls the corresponding servo motor through a driving module in the extensible driving module. According to the invention, not only can the overall size and the application cost of the drive and control integrated servo system be effectively reduced, but also the requirement that the number of shafts of the servo motor can be expanded can be met.

Owner:SHANGHAI SIGRINER STEP ELECTRIC

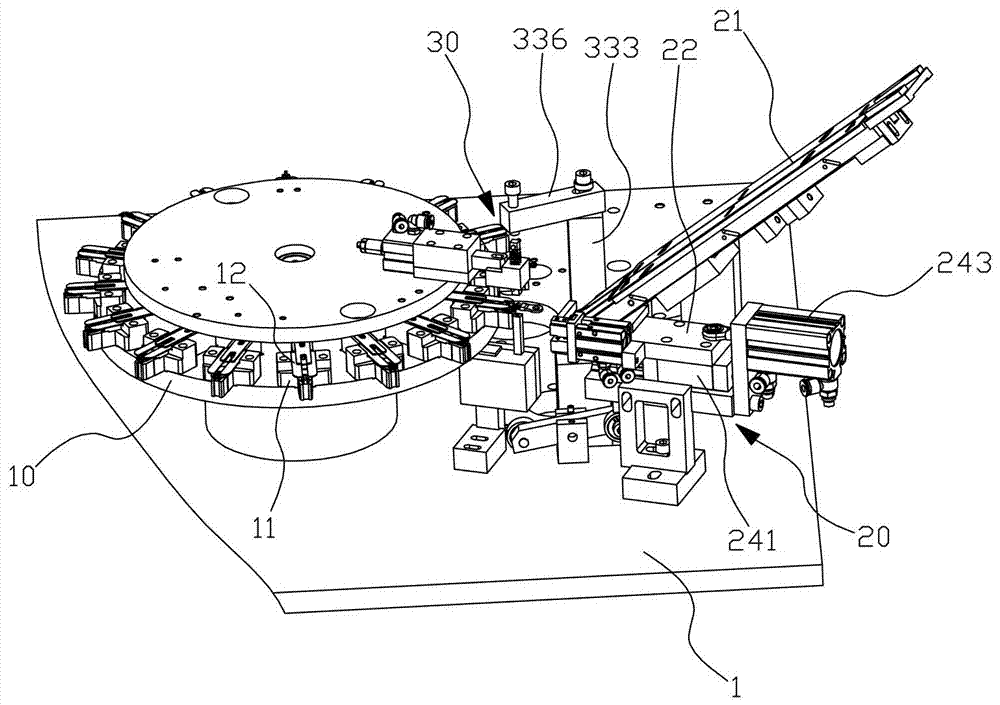

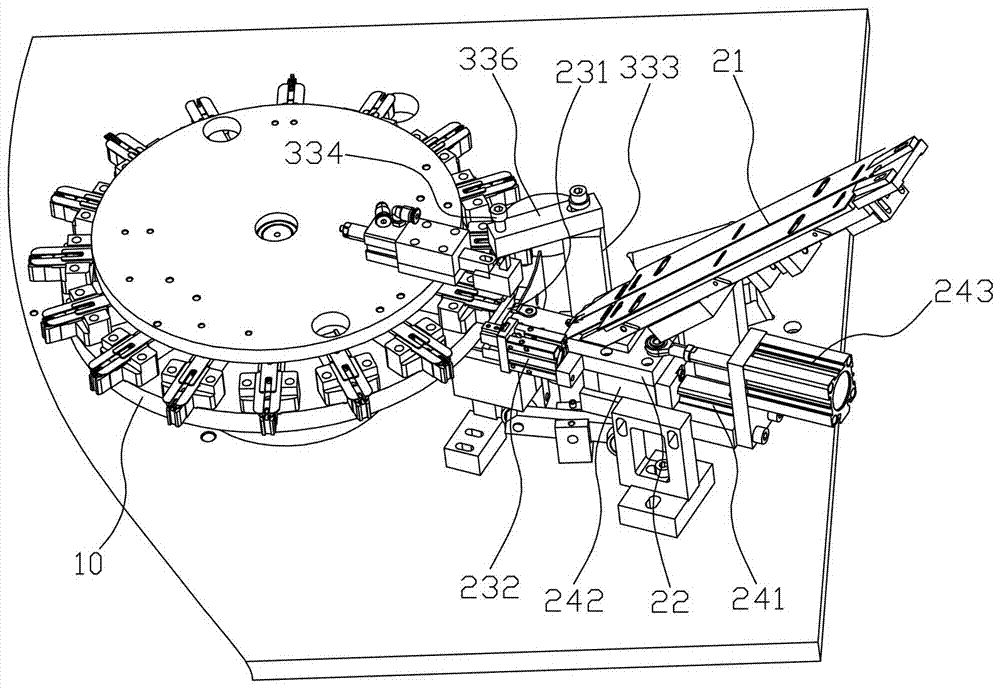

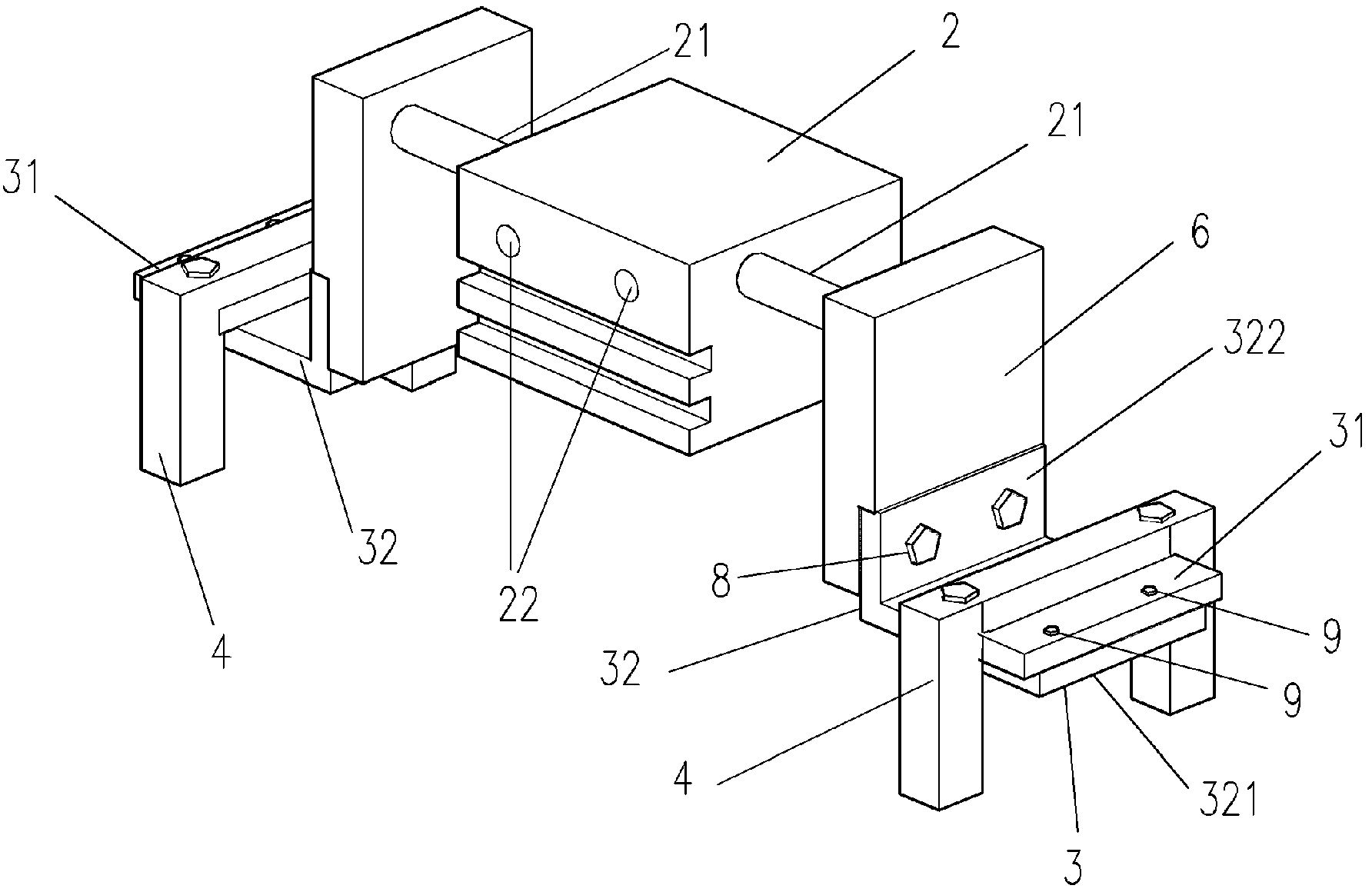

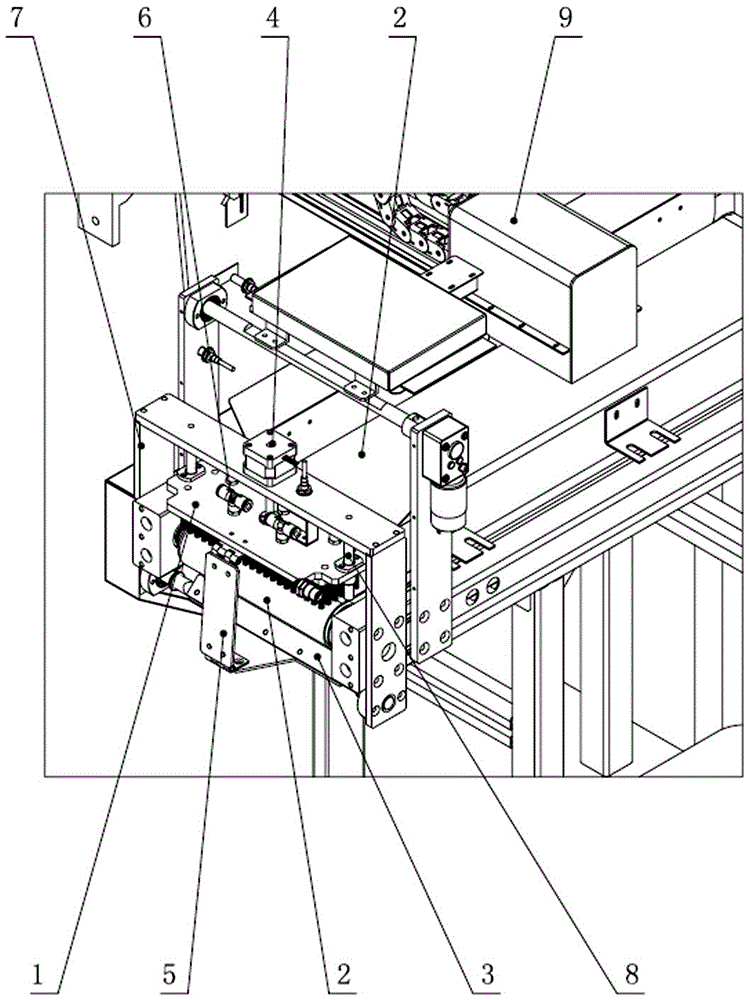

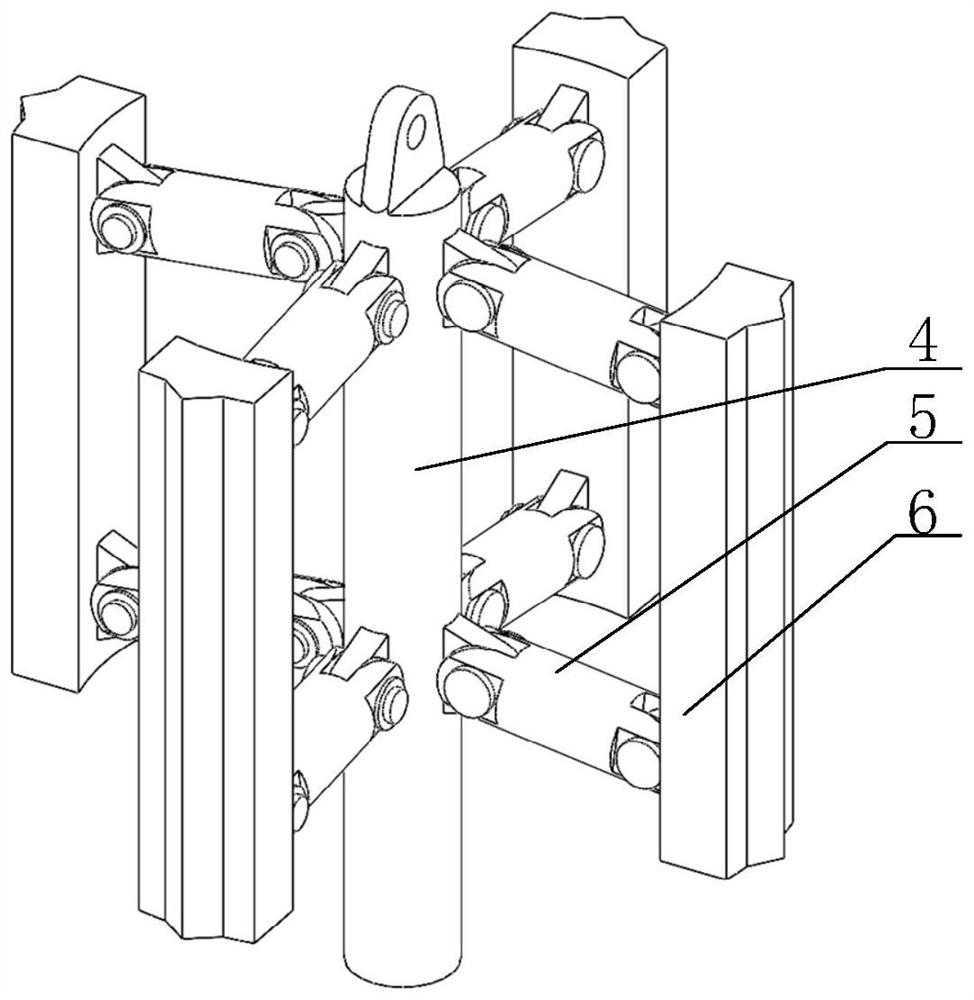

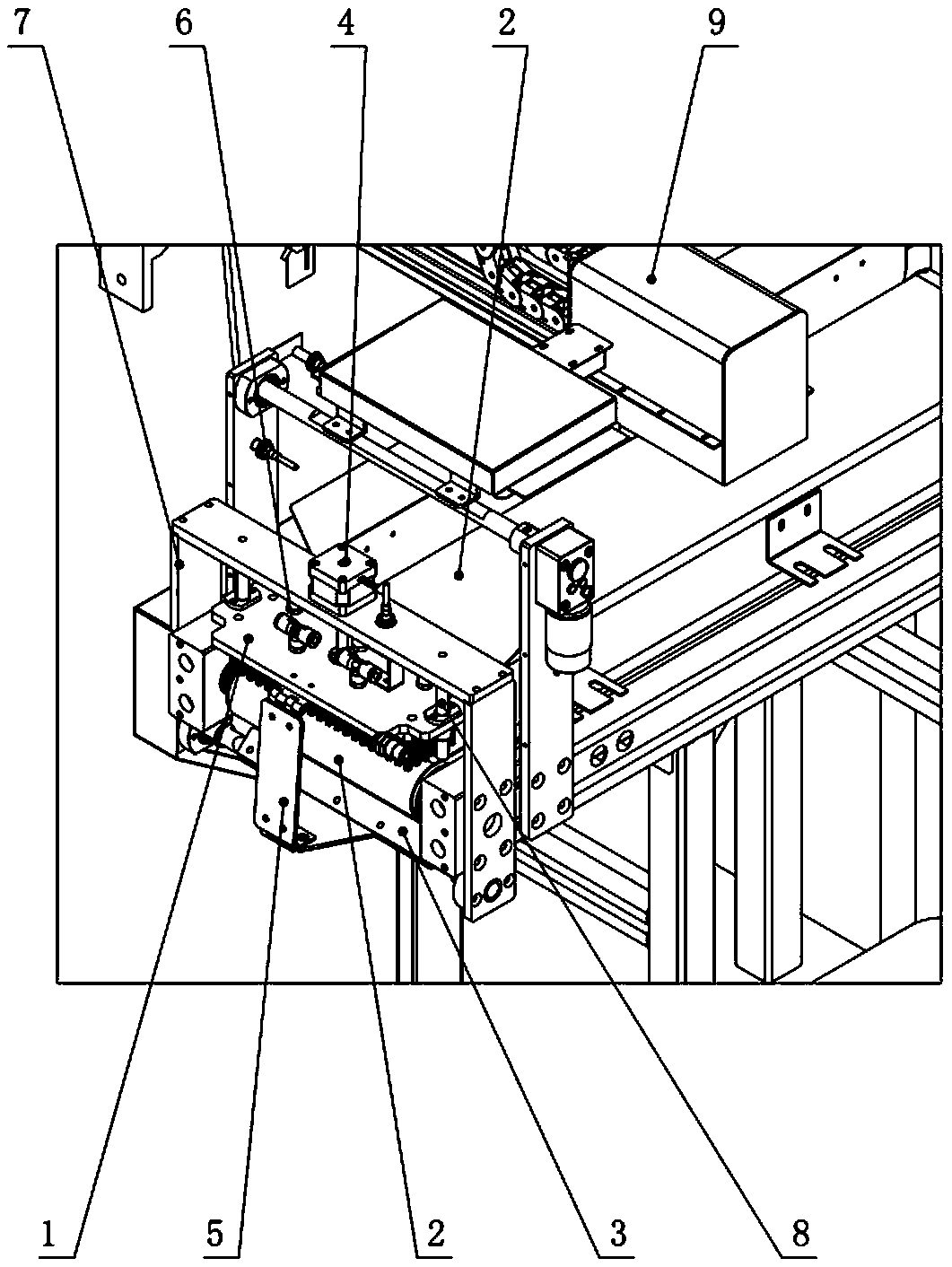

Automatic core drawing piece feeding assembling machine for pullers with rings in shape like Chinese character 'ri'

ActiveCN107052174AImprove riveting qualityImprove assembly efficiencySlide fastenersMetal-working feeding devicesEngineeringChinese characters

An automatic core drawing piece feeding assembling machine for pullers with rings in the shape like the Chinese character 'ri' comprises a rack and a circular rotary disc. A plurality of puller die cores are arranged on the circumferential face of the rotary disc. Each puller die core is provided with a U-shaped pressing sheet. A core drawing piece conveying device and a riveting device are arranged on the rack around the circular rotary disc. The core drawing piece conveying device comprises a pull piece track, a material distributing plate, a core drawing piece clamping mechanism and a core drawing piece pushing mechanism, wherein the pull piece track is obliquely and fixedly supported on the rack, the material distributing plate is arranged at the bottom of the discharging end of the puller track in a sliding manner, the core drawing piece clamping mechanism comprises a pair of clamping arms and a finger air cylinder, the clamping arms are arranged in front of the material distributing plate, the finger air cylinder is fixed to the side face of the material distributing plate, the clamping arms are fixed to the front end of the finger air cylinder, and the core drawing piece pushing mechanism comprises a sliding rail, a sliding block and an air cylinder. The assembling machine is simple in structure, core drawing pieces can be accurately clamped and conveyed to the corresponding positions of the rings in the shape like the Chinese character 'ri', and the assembling efficiency of the core drawing pieces and the rings in the shape like the Chinese character 'ri' and the quality and the qualification rate of puller products are greatly improved.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

Pneumatic correction device for cell transferring

ActiveCN103057985ARealize position correctionGuaranteed synchronous actionArticle feedersArticle deliveryTransfer cellMechanical wear

The invention discloses a pneumatic correction device for cell transferring. The pneumatic correction device for cell transferring comprises a base, a cylinder, a pair of combination baffles, a pair of U-shaped clamp arms, a proximity switch, and a sensing element. The base comprises a pair of side plates and a top plate located at the top of the side plates. The cylinder is disposed below the top plate. The combination baffles are symmetrically disposed on a guide bar on two sides of the cylinder respectively and located below the cylinder. The U-shaped clamp arms are symmetrically disposed on the combination baffles respectively. The sensing element is connected with an air hole of the cylinder. The proximity switch provides cylinder operation signals through the sensing element so as to allow the guide bar on the cylinder to contract or extend to drive the U-shaped clamp arms to move, thereby correcting the position of a cell. The pneumatic correction device is disposed on a travel arm used for transferring cells. The position of the cells on the travel arm can be corrected by the pneumatic correction device, and accordingly the problems of lower precision and proneness of cells to deflection and fragmentation in transfer process caused by mechanical wear of the travel arm in the prior art are solved.

Owner:JA SOLAR TECH YANGZHOU

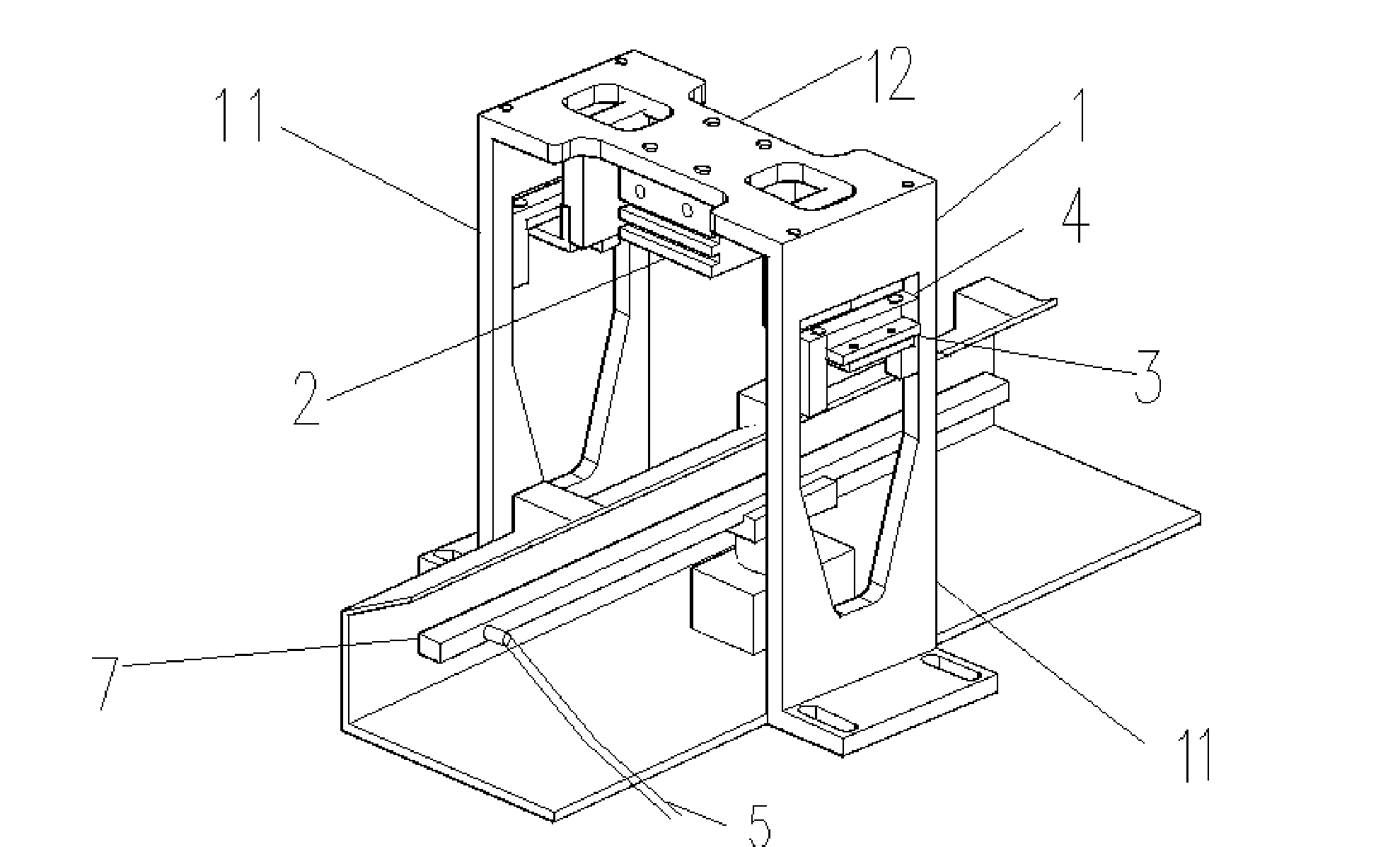

Precision four-post hydraulic cutting machine

InactiveCN102363308AGuaranteed synchronous actionCompact structureMetal working apparatusMachineCylinder block

The invention relates to a precision four-post hydraulic cutting machine, which comprises a machine body containing an oil tank, a pressure back and upright posts arranged in four corner holes of the machine body; the lower ends of two upright posts at the left and right sides are connected with a hinge seat, and the upper ends of the upright posts are fixedly connected with the lower end of the pressure back respectively; a cylinder is arranged between the upper end of the machine body and the hinge seat, the cylinder body of the cylinder is fixedly connected with the upper end of the machine body, and a piston rod of the cylinder is fixedly connected with the hinge seat; a linkage assembly is arranged below the hinge seat in the machine body; the linkage assembly comprises two groups of C-shaped rocker arms and linkage arms; the opening of the first C-shaped rocker arm positioned at the left side of the machine body is downward, the middle part of the first C-shaped rocker arm is hinged with the machine body, and the left end of the first C-shaped rocker arm is hinged with the hinge seat of the left side in the machine body; the opening of the second C-shaped rocker arm positioned at the right side of the machine body is upward, the middle part of the second C-shaped rocker arm is hinged with the machine body, and the right end of the second C-shaped rocker arm is hinged with the hinge seat of the right side in the machine body; and the right end of the first C-shaped rocker arm is in transmission connection with the left end of the second C-shaped rocker arm through the linkage arms.

Owner:QUZHOU TAIWEI PRECISE MASCH CO LTD

Tetrahedral shaping machine

The invention provides a tetrahedral shaping machine which comprises a tetrahedral stereoscopic support, a door plate rotating mechanism, plate pushing mechanisms, a conveying mechanism and a driving mechanism. The door plate rotating mechanism comprises a door plate mechanism and a tension mechanism, the door plate mechanism, the tension mechanism and the driving mechanism are sequentially connected, the plate pushing mechanisms are arranged on two side faces of the support, a rear baffle is arranged at the back of the support, the conveying mechanism penetrates the support and is arranged at the lower end of the door plate mechanism, the driving mechanism is connected with the door plate mechanism, the plate pushing mechanisms and the conveying mechanism, and fixed rods are fixedly arranged at the lower end of the stereoscopic support. The front and the back of a cargo are shaped by the door plate mechanism, the side faces of the cargo are shaped by the plate pushing mechanisms, the tetrahedral shaping machine is convenient to drive and low in cost, and crank mechanisms are arranged on the side fasces of the tetrahedral shaping machine, so that the tetrahedral shaping machine is circular in motion, safe and reliable.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

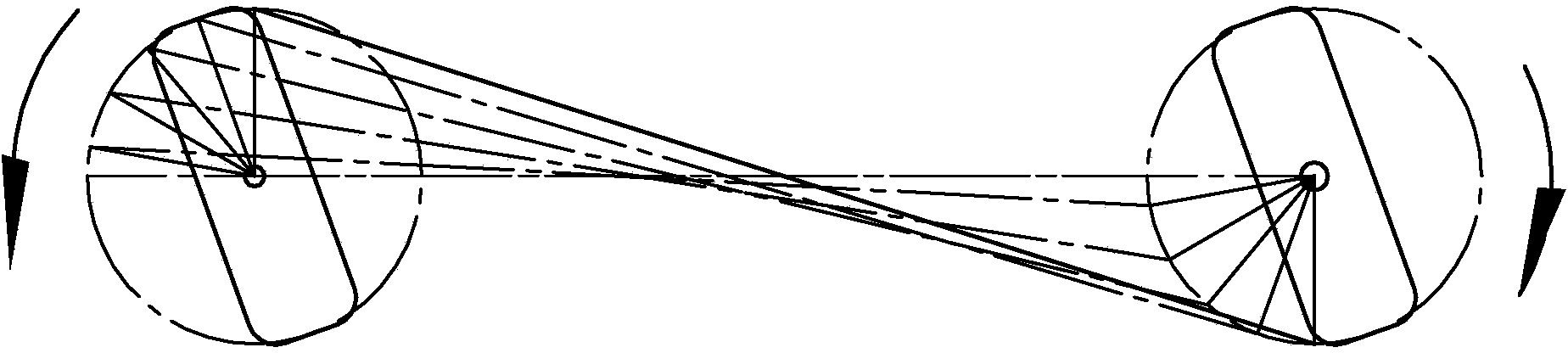

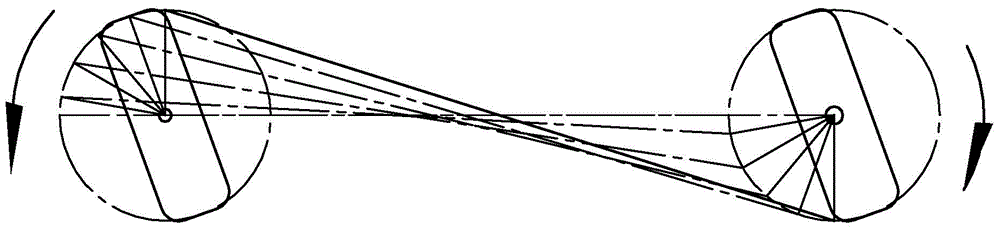

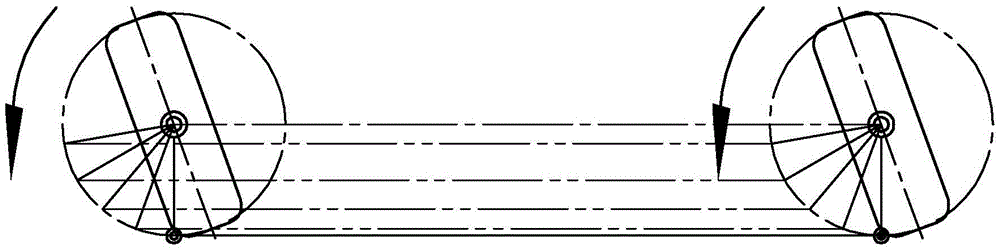

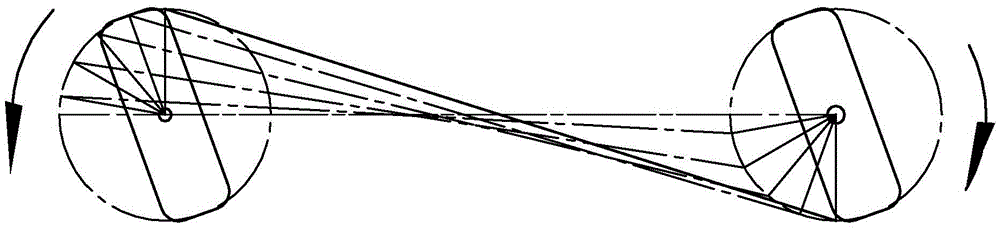

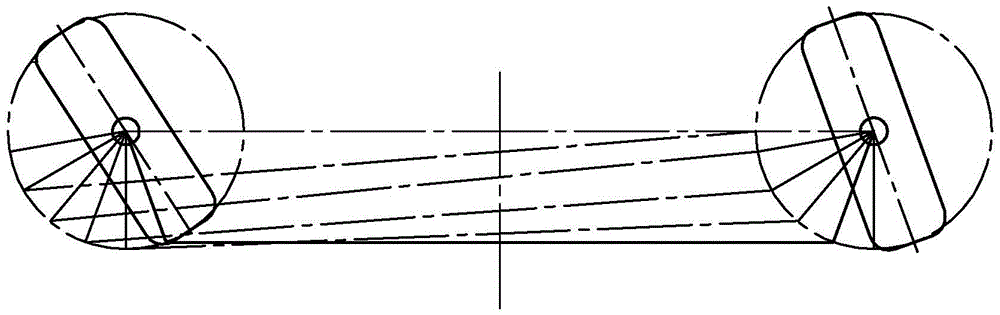

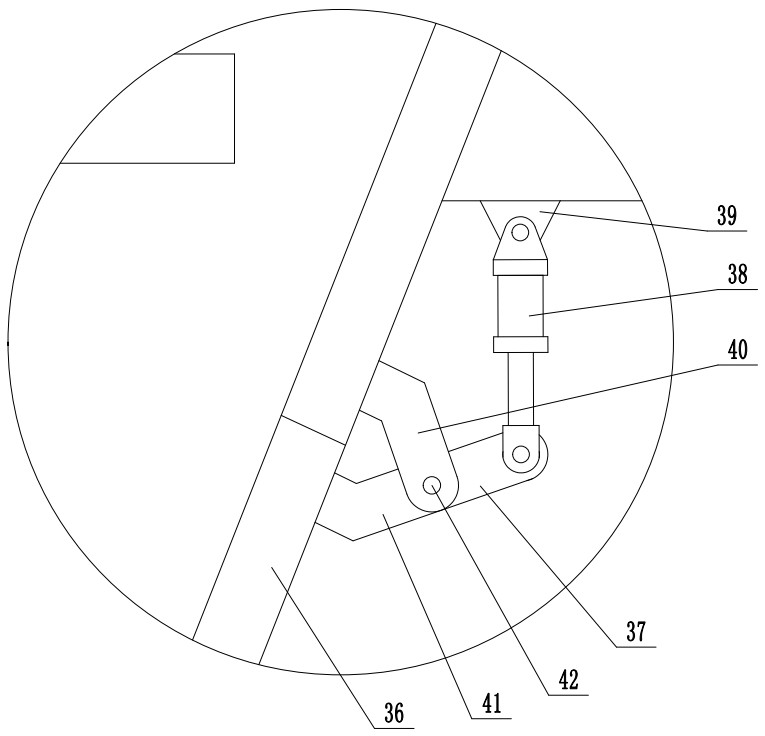

Vehicle longitudinal travel steering mechanism

ActiveCN104071218AMeet the requirements of longitudinal drivingGuaranteed synchronous actionSteering linkagesFluid steeringComputer programmingHydraulic pressure

The invention discloses a vehicle longitudinal travel steering mechanism. The vehicle longitudinal travel steering mechanism is characterized in that a left steering oil cylinder and a right steering oil cylinder are arranged at the two sides of two front steering wheels in sequence; one ends of the left steering oil cylinder and the right steering oil cylinder are hinged to respective steering arms, and the other ends of the left steering oil cylinder and the right steering oil cylinder are hinged to a frame; a rod cavity of the left steering oil cylinder is in oil way connection with a rodless cavity of the right steering oil cylinder, and the rod cavity of the left steering oil cylinder is equal to the rodless cavity of the right steering oil cylinder in section area; and when the left and right steering is occurred, four axle lines of the front and rear steering wheels at the left and right side of a vehicle are intersected at one point of the symmetrical axis between the left and right steering wheels. The vehicle longitudinal travel steering mechanism controls the steering modes of four motors by adopting the manners of hydraulic pressure and mechanical components to replace the computer programming, so that the reliability of the vehicle longitudinal travel steering mechanism is improved, and the cost is reduced.

Owner:NINGBO RUYI

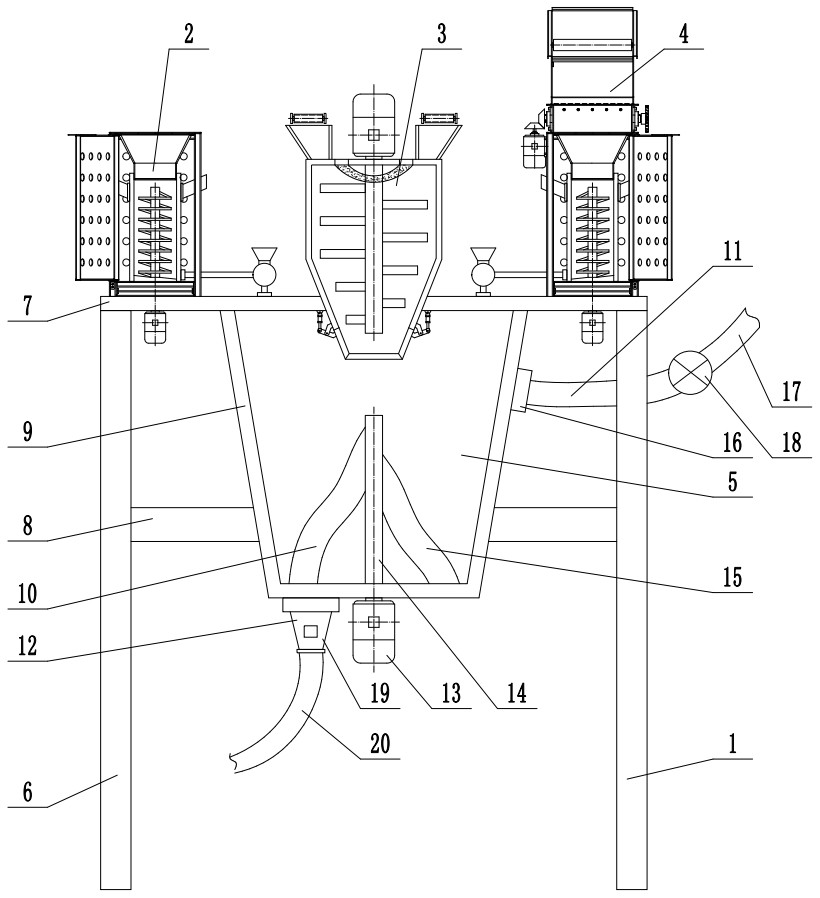

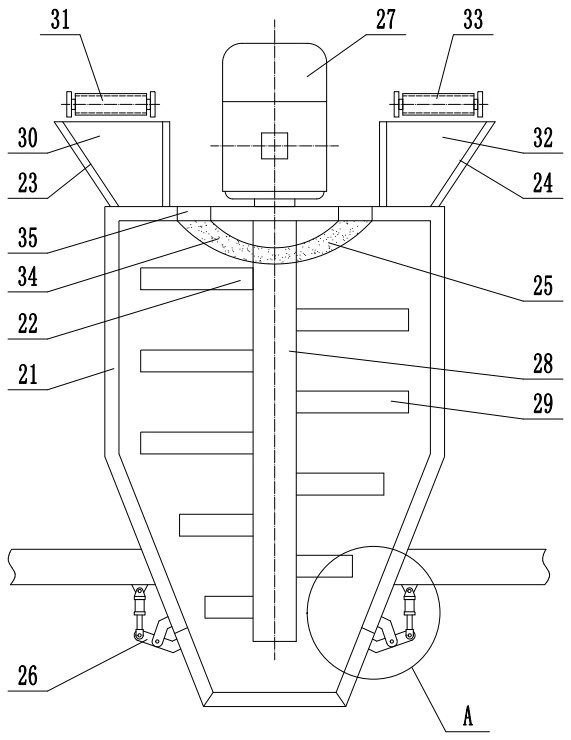

Anti-corrosion concrete special for building and production system thereof

ActiveCN112358253AImprove fusion effectImprove compactnessSolid waste managementMixing operation control apparatusArchitectural engineeringStructural engineering

The invention provides an anti-corrosion concrete special for a building, and belongs to the technical field of concrete. The anti-corrosion concrete is prepared by stirring the following components in parts by weight: 95-105 parts of an anti-corrosion concrete gel base material, 375-412 parts of an anti-corrosion concrete base material, 10-17 parts of an anti-corrosion concrete filling base material and 40-45 parts of water. A production system of the anti-corrosion concrete special for a building comprises a production rack device, an anti-corrosion concrete gel base material production device, an anti-corrosion concrete base material production device, an anti-corrosion concrete filling base material production device and a mixing and stirring device. The corrosion resistance of the concrete is greatly improved, the service life of a building is greatly prolonged, the production system is reasonable in structure, continuous processing of the anti-corrosion concrete special for a building is facilitated, and the automation degree is high.

Owner:桐乡市钟大建材有限公司

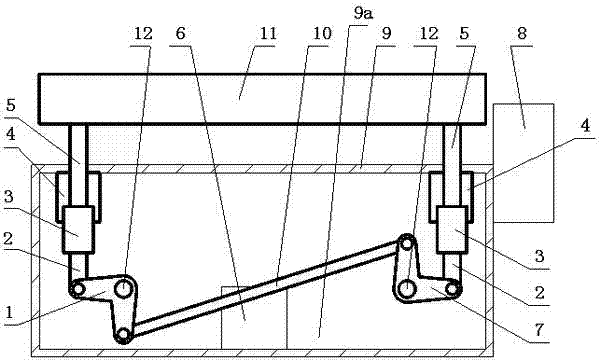

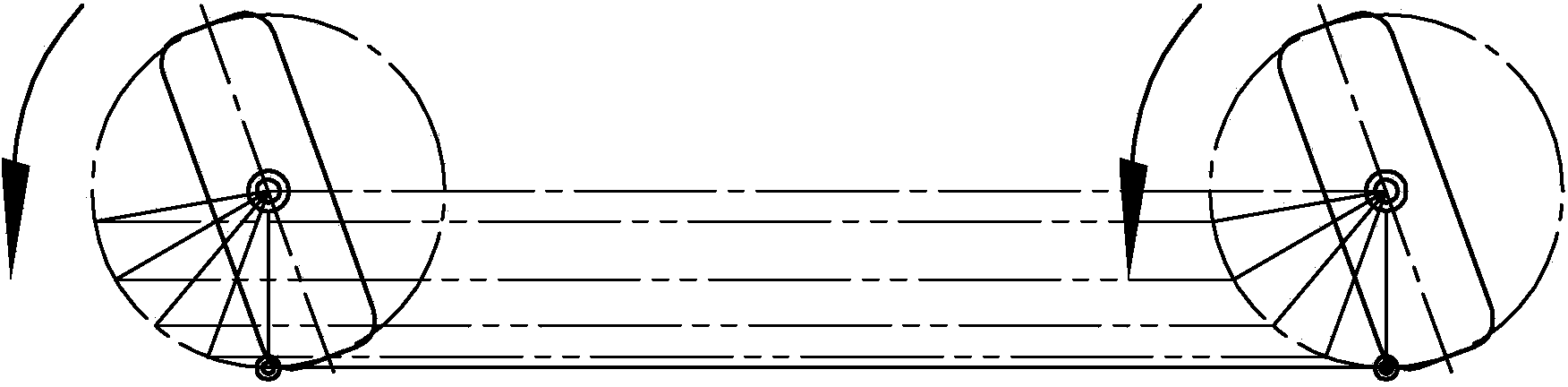

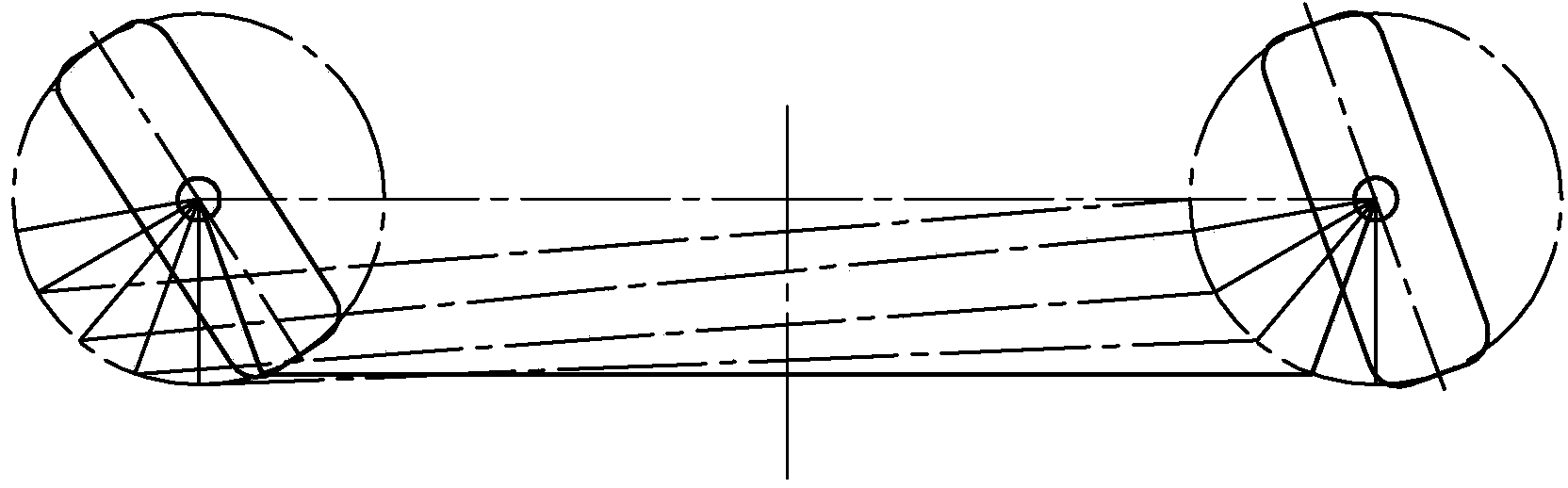

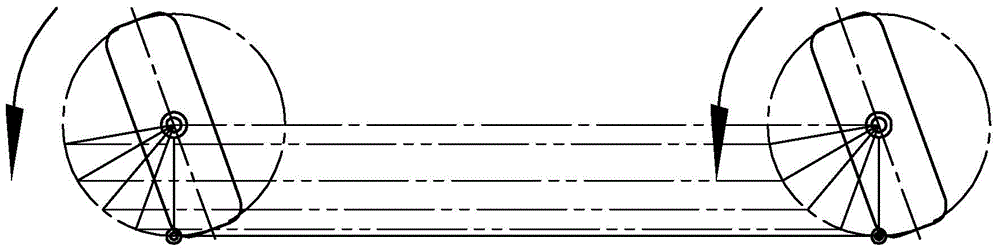

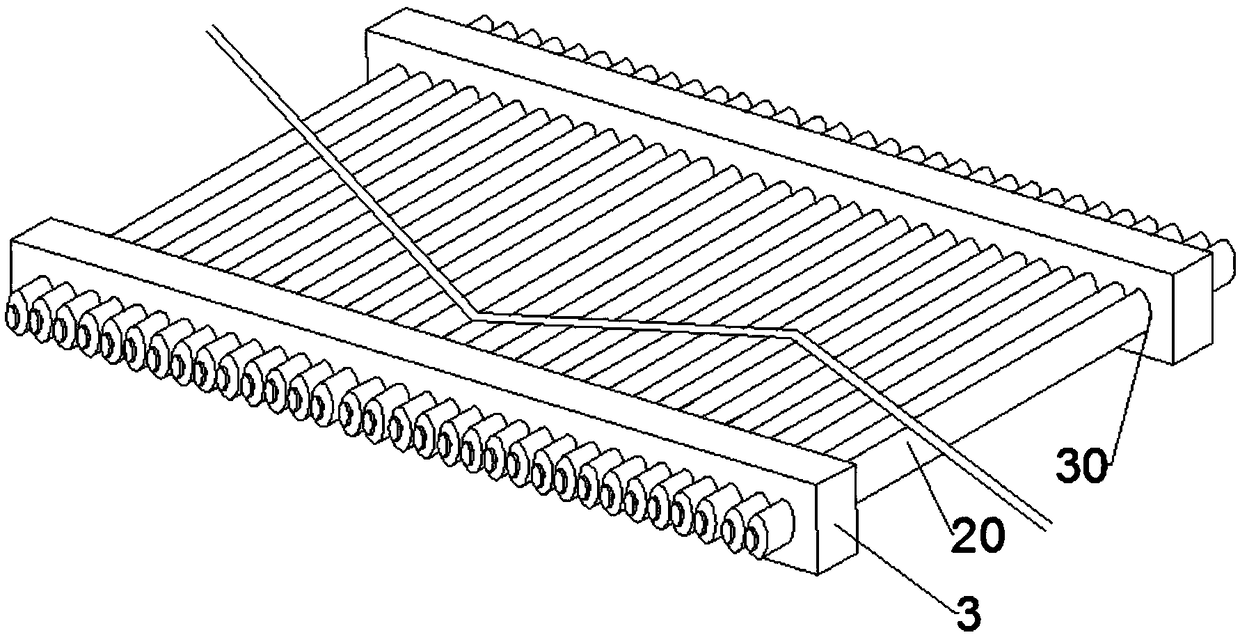

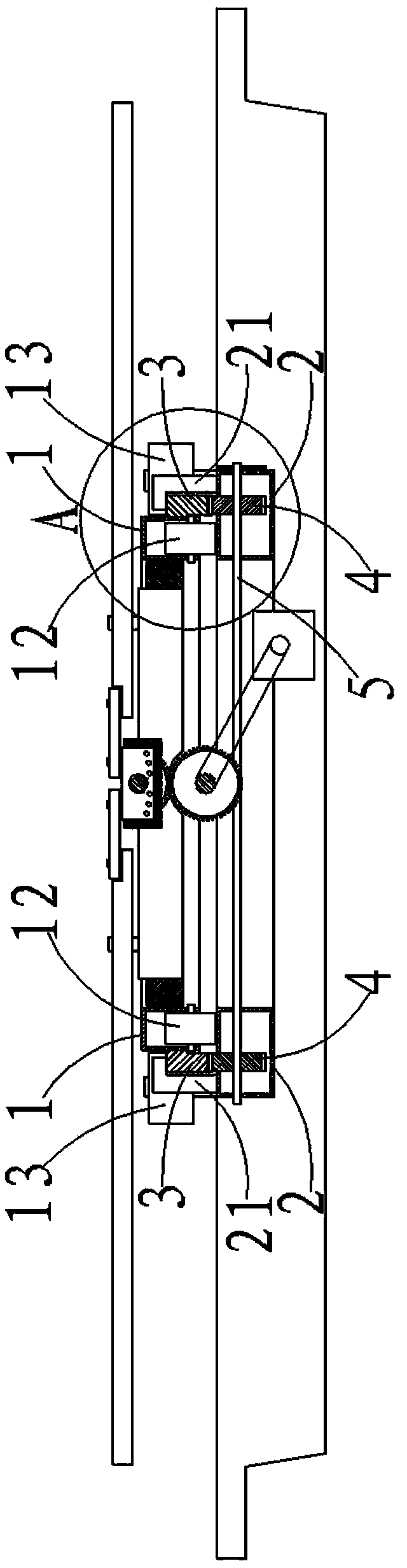

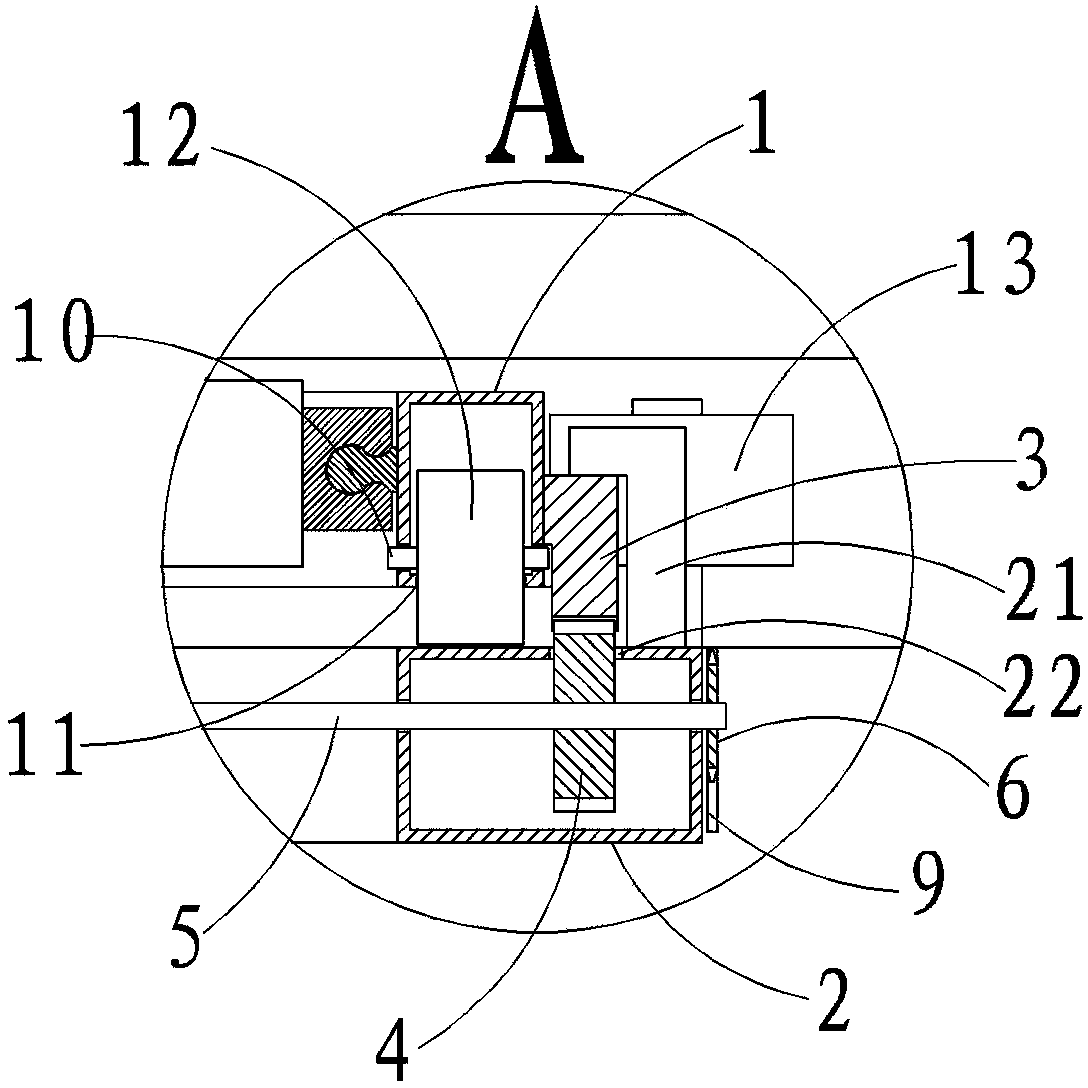

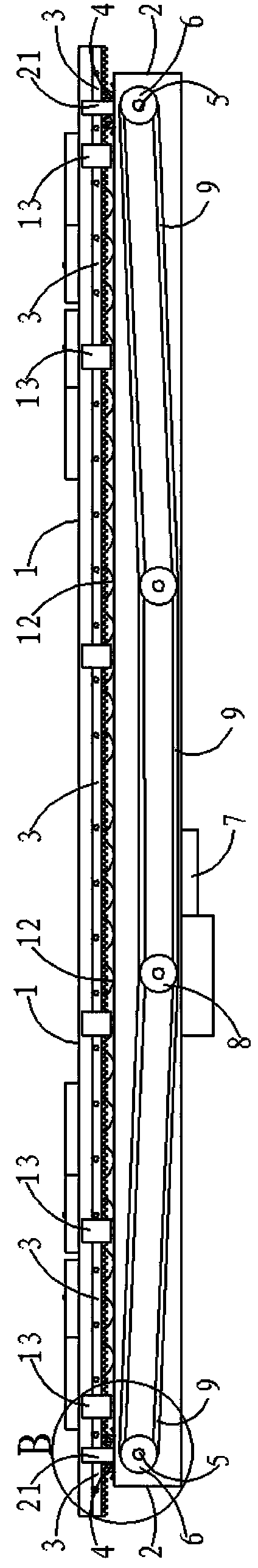

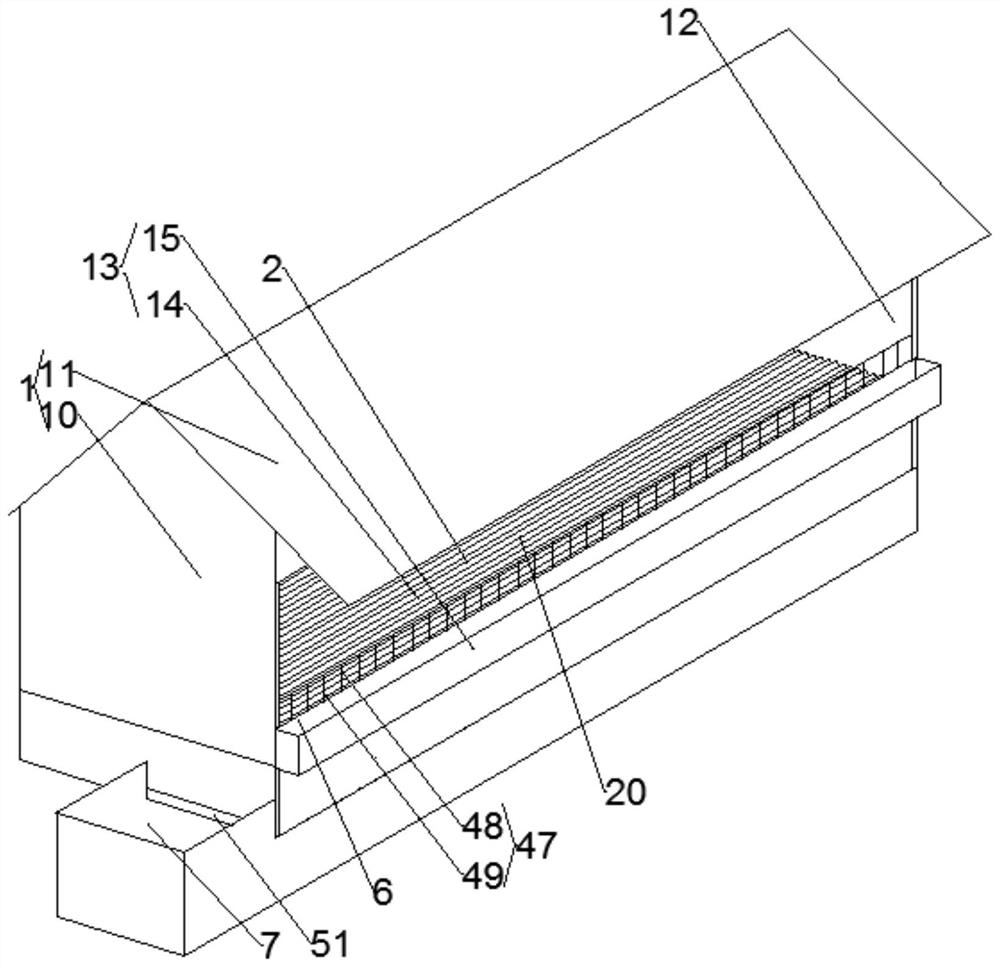

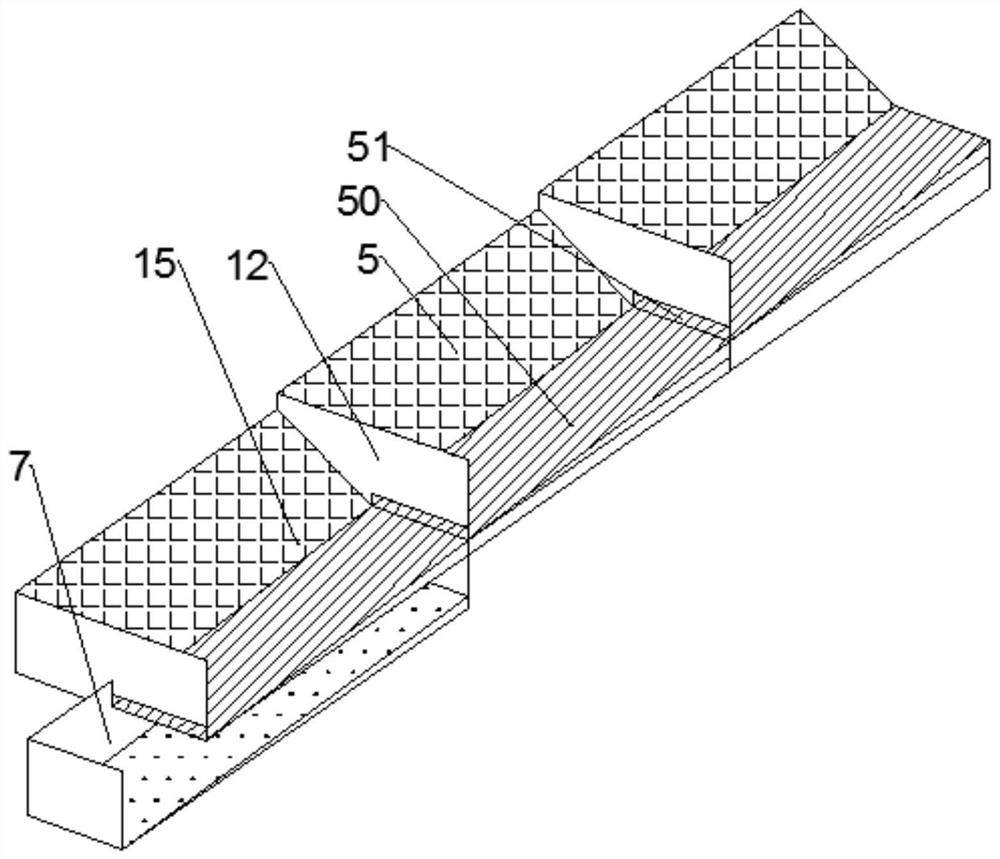

Floating roll device for splitting machine

ActiveCN101519169BGuaranteed synchronous actionReduce jitterMetal working apparatusWebs handlingBall bearingEngineering

The invention discloses a floating roll device for a splitting machine. Linear guide rails are vertically arranged at corresponding positions inside a wallboard, both ends of a floating roll are arranThe invention discloses a floating roll device for a splitting machine. Linear guide rails are vertically arranged at corresponding positions inside a wallboard, both ends of a floating roll are arranntee that both ends of the floating roll can move up and down simultaneously.antee that both ends of the floating roll can move up and down simultaneously.ged on a mounting plate first through a ball bearing with a lug boss and a circular outer ball surface and then integrally arranged on the linear guide rails to ensure that the floating roll can vertiged on a mounting plate first through a ball bearing with a lug boss and a circular outer ball surface and then integrally arranged on the linear guide rails to ensure that the floating roll can vertically move up and down, wherein the power for driving the floating roll to move only comes from a double-pole double-acting air cylinder, an extending end of the double-pole double-acting air cylindercally move up and down, wherein the power for driving the floating roll to move only comes from a double-pole double-acting air cylinder, an extending end of the double-pole double-acting air cylinder is connected with the upper part of one end of the floating roll through a pull rope, the other extending end of the double-pole double-acting air cylinder is connected with the lower part of the othis connected with the upper part of one end of the floating roll through a pull rope, the other extending end of the double-pole double-acting air cylinder is connected with the lower part of the other end of the floating roll through the pull, and the remained upper end of the floating roll is connected with the remained lower end by a pull rope. The action of the air cylinder structure can guarer end of the floating roll through the pull, and the remained upper end of the floating roll is connected with the remained lower end by a pull rope. The action of the air cylinder structure can guara

Owner:南京安顺电气科技有限公司

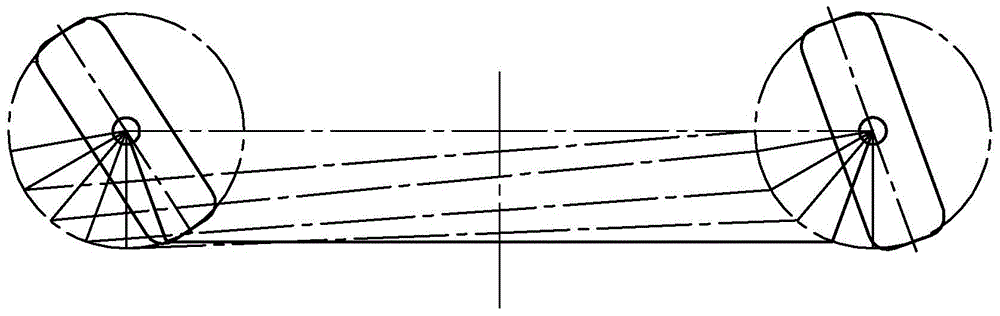

Steering device of vehicle with four wheels and four driving directions

ActiveCN104058002AMeet the requirements of longitudinal drivingGuaranteed synchronous actionSteering linkagesFluid steeringComputer programmingControl theory

The invention discloses a steering device of a vehicle with four wheels and four driving directions. The steering device is characterized in that the sides of two front steering wheels are provided with a left steering cylinder and a right steering cylinder in sequence; the four axis lines of the front steering wheel and a rear steering wheel at the left side of the vehicle and the front steering wheel and a rear steering wheel at the right side of the vehicle are intersected onto one point of the symmetrical axis line between the left steering wheels and the right steering wheels; in addition, four-station double-acting cylinders are hinged between a front steering arm and a rear steering arm at the left side as well as between a front steering arm and a rear steering arm at the right side; when the front steering wheels are fixed and the rear steering wheels steer, the axis lines of the left steering wheel and the right steering wheel in the rear steering wheels are intersected on the connecting line of the central lines of the two front steering wheels. The steering device disclosed by the invention has the advantages that a mode of hydraulic and mechanical members is adopted for replacing the mode of using computer programming to control steering of four motors, so that the reliability of the steering device of the vehicle with the four wheels and four driving directions is improved, and the cost is reduced.

Owner:NINGBO RUYI

Mutton sheep breeding fence house capable of achieving automatic manure cleaning

The invention discloses a mutton sheep breeding fence house capable of achieving automatic manure cleaning. The mutton sheep breeding fence house comprises a fence house body and three support cleaning components; the fence house body comprises a wall body and a shed cover, the fence house body is divided into three fence house compartments, and one support cleaning component is arranged in each fence house compartment so as to divide the corresponding compartment into an upper feeding space and a lower collecting space; each feeding space is provided with a railing along an opening formed inthe side along the length direction of the corresponding feeding space; a first feed guide plate is clamped in each collecting space in the width direction of the corresponding collecting space, and asecond feed guide plate is fixedly connected to the lower end, in the length direction, of the first feed guide plate; and a sewage outlet is formed in the lowest end of the side wall of each collecting space so as to achieve communication of arbitrary two adjacent collecting spaces and communication of the two collecting spaces with the outside. The mutton sheep breeding fence house has the advantages of large space separation feeding, unified intensive collection of manure under the action of gravity and self-rinsing; and blocking of gap for communication of each feeding space and the corresponding collecting space by manure can be avoided effectively.

Owner:甘宗琳

Cleaning system of rubbish sorting machine

The invention discloses a cleaning system of a rubbish sorting machine. The cleaning system comprises a cleaning brush, a water scraper plate, a cleaning fluid supply system providing cleaning fluid for the cleaning brush and a cleaning bin used for collecting wasted cleaning fluid. The cleaning brush and the water scraper plate are arranged in the cleaning bin which is connected with a rubbish conveying part of the rubbish sorting machine in a butt-joint mode. The cleaning system further comprises a connecting rod. The cleaning brush and the water scraper plate are rotatably connected to the two ends of the connecting rod correspondingly. The cleaning brush or the water scraper plate is connected with a driving mechanism. When the driving mechanism acts, the cleaning brush and the water scraper plate can be driven to synchronously approach or depart from a rubbish conveying system through the driving function of the connecting rod. The cleaning system is applied to the medical rubbish sorting machine, the cross contamination phenomenon of various rubbish can be avoided, cleanness and sanitation of the rubbish conveying part are ensured, and the good medical environment is better maintained.

Owner:JIANGSU BVM INTELLIGENT TECH

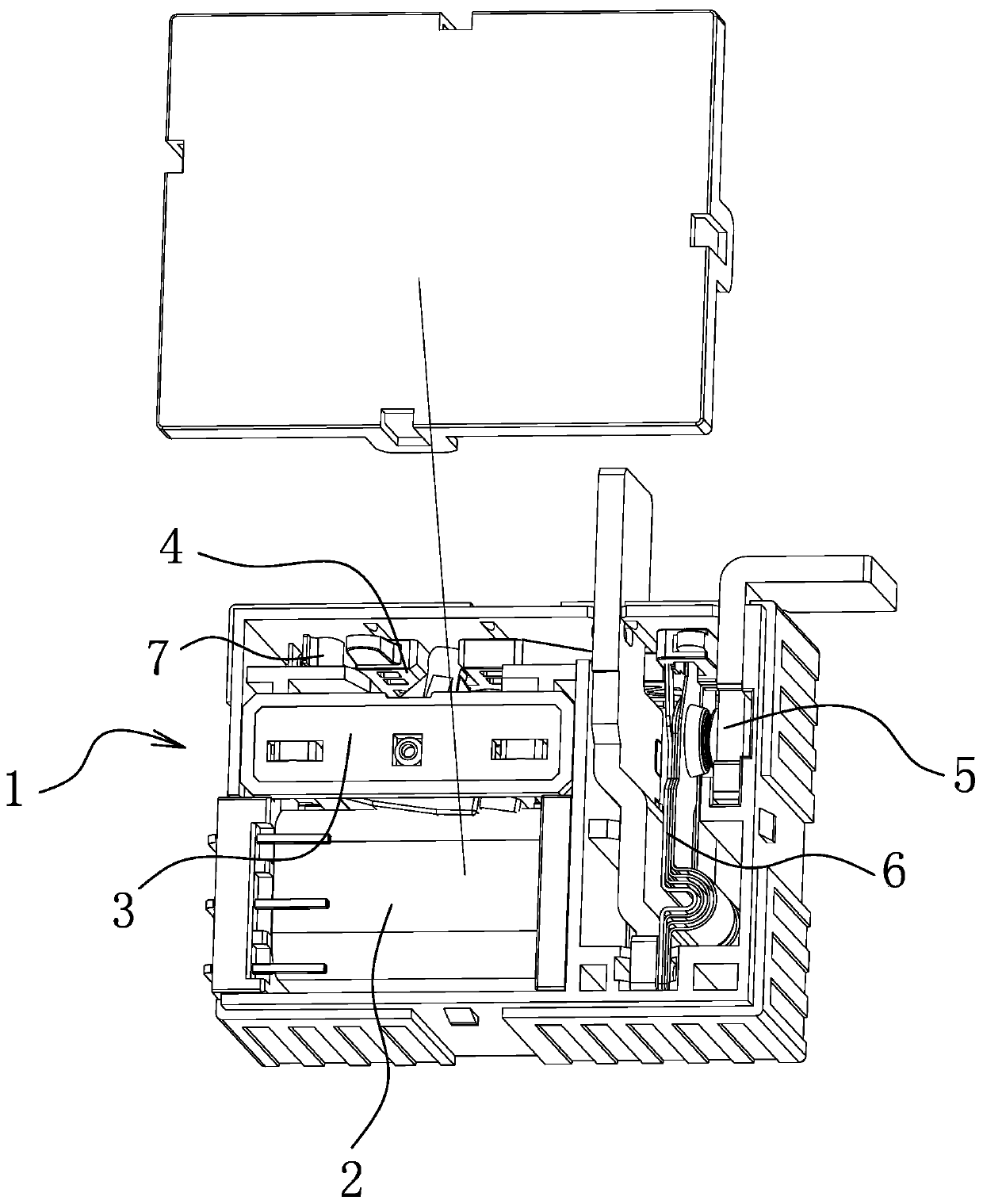

Double Contact Latching Relay

ActiveCN106876217BGuaranteed synchronous actionGuaranteed flexibilityElectromagnetic relay detailsState of artMechanical engineering

The invention belongs to the technical field of relays, especially relates to a double contact magnetic latching relay, and solves the technical problem of poor rebound performance of the prior art. The double contact magnetic latching relay comprises a shell; the shell is internally provided with a coil assembly and an armature assembly; the armature assembly is connected with a push block, which can force the armature assembly to move when the coil assembly is powered on so that the push block moves relative to the shell; and the shell is also internally provided with a double contact stable sheet component and a double contact movable sheet component, and the movement of the push block can drive the double contact movable sheet component to be close to the double contact stable sheet component or away from the double contact stable sheet component. The double contact magnetic latching relay provided by the invention has the advantage that the rebound performance can be improved.

Owner:浙江格蕾特电器股份有限公司

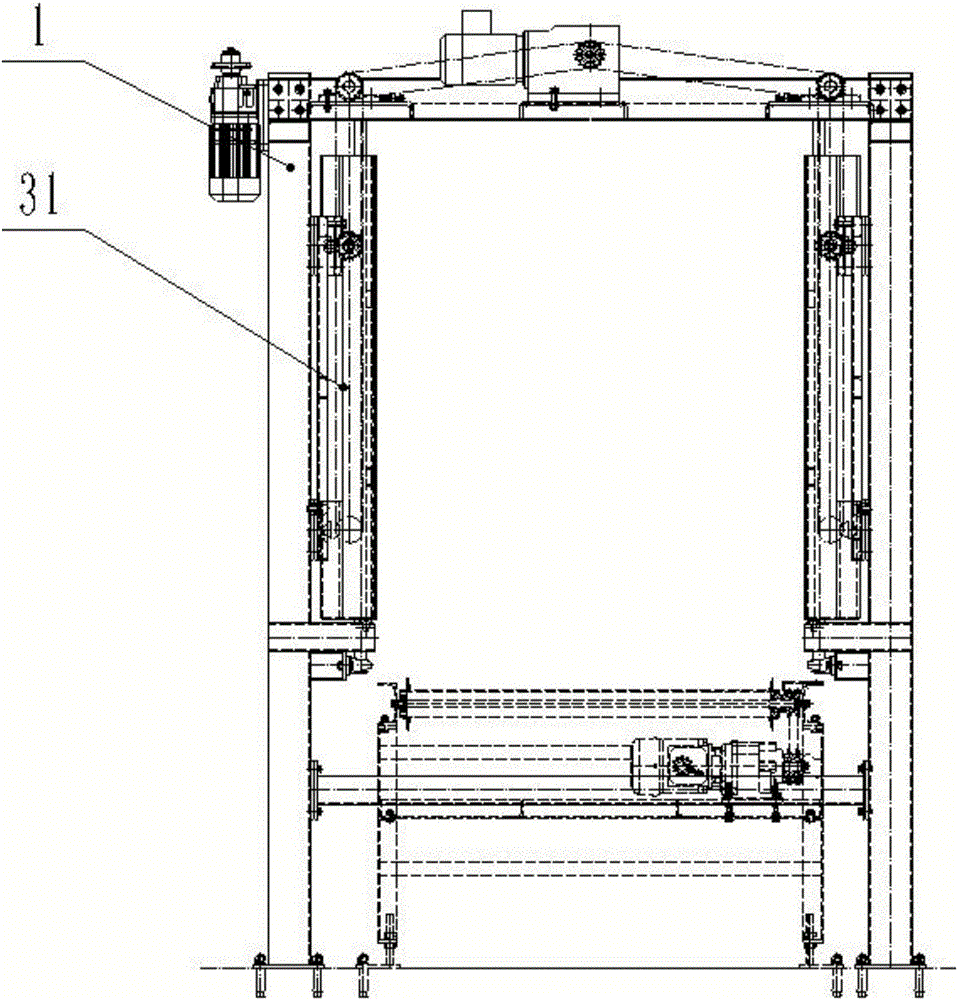

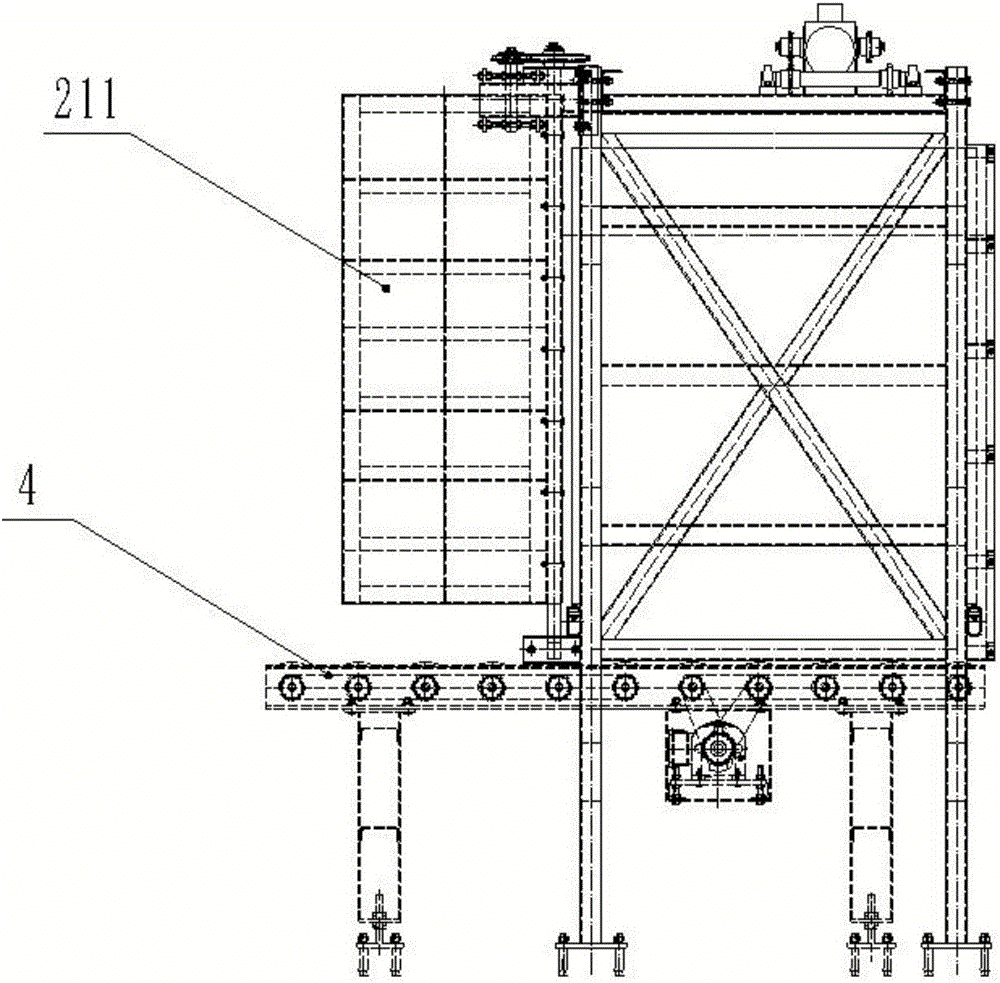

Continuous automatic poultry cage stacking machine

PendingCN112875311AEfficient collectionFast transferConveyorsStacking articlesControl engineeringPalletizer

The invention discloses a continuous automatic poultry cage stacking machine, and belongs to the field of automation. The stacking machine comprises an ascending support and a descending support, a vertical elevator is arranged on the ascending support, a vertical landing machine is arranged on the descending support, a translation support is arranged above the ascending support and the descending support, a translation device is arranged on the translation support, and the translation device can be used for transferring a poultry cage on the vertical elevator to the upper side of the vertical landing machine; and a carrying device is arranged above the descending support, and the carrying device is used for transferring the poultry cage on the translation device to the vertical landing machine.

Owner:山东省博兴县长征食品机械制造厂

A vehicle longitudinal travel steering mechanism

ActiveCN104071218BMeet the requirements of longitudinal drivingGuaranteed synchronous actionSteering linkagesFluid steeringMechanical componentsEngineering

The invention discloses a vehicle longitudinal travel steering mechanism. The vehicle longitudinal travel steering mechanism is characterized in that a left steering oil cylinder and a right steering oil cylinder are arranged at the two sides of two front steering wheels in sequence; one ends of the left steering oil cylinder and the right steering oil cylinder are hinged to respective steering arms, and the other ends of the left steering oil cylinder and the right steering oil cylinder are hinged to a frame; a rod cavity of the left steering oil cylinder is in oil way connection with a rodless cavity of the right steering oil cylinder, and the rod cavity of the left steering oil cylinder is equal to the rodless cavity of the right steering oil cylinder in section area; and when the left and right steering is occurred, four axle lines of the front and rear steering wheels at the left and right side of a vehicle are intersected at one point of the symmetrical axis between the left and right steering wheels. The vehicle longitudinal travel steering mechanism controls the steering modes of four motors by adopting the manners of hydraulic pressure and mechanical components to replace the computer programming, so that the reliability of the vehicle longitudinal travel steering mechanism is improved, and the cost is reduced.

Owner:NINGBO RUYI JOINT CO LTD

Medium-five-roller constant speed conveyor

The invention discloses a medium-five-roller constant speed conveyor. The medium-five-roller constant speed conveyor comprises a box body, and five-circle through holes are formed in one face of the box body; conveying rollers are arranged on the inner sides of the five-circle through holes, and an original yarn cone mounting position is arranged at the bottom of the box body; a double-closed-loop direct-current speed regulation system is arranged on the inner side of the box body, and a motor of the double-closed-loop direct-current speed regulation system and the conveying rollers are mounted through the same belt; the double-closed-loop direct-current speed regulation system and a PLC are mounted in a matched manner; a conveying roller state instrument position is mounted on the upper sides of the five-circle through holes and is electrically connected with the PLC; and according to the medium-five-roller constant speed conveyor, the double-closed-loop direct-current speed regulation system is adopted, meanwhile the conveying rollers are driven through the same belt, and therefore it can be ensured that the conveying rollers provide yarn for a thread spinner at the constant speed. Meanwhile, it also can be ensured that the conveying rollers act synchronously, and the possibility of yarn breaking and crossing is reduced.

Owner:TIANJIN HAOSHI CARPET

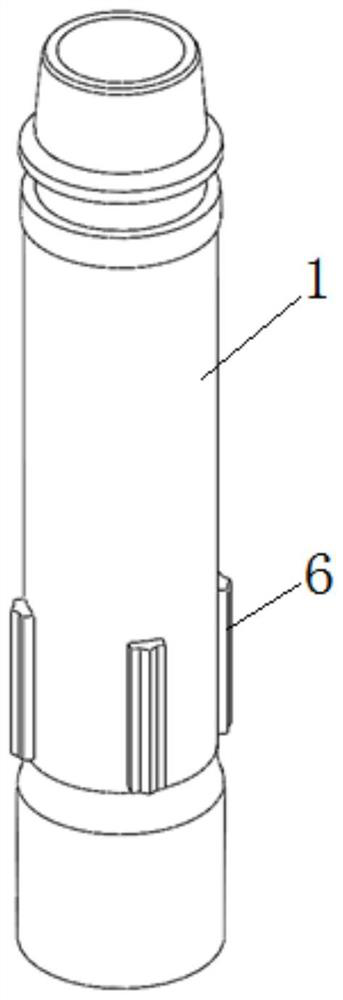

Reaming drill rod with spalling rock breaking function

PendingCN114837563AReduce loadSimple structureEarth drilling toolsDrilling rodsRock breakingDrill pipe

The invention discloses a chambering drill rod with a spalling rock breaking function, and relates to the technical field of well building equipment, the chambering drill rod comprises a drill rod body, a pushing mechanism is coaxially arranged in the drill rod body, the pushing mechanism is circumferentially connected with a plurality of spalling heads through a connecting rod assembly, and the pushing mechanism can drive the spalling heads to move towards the outer side or the inner side of the drill rod body. The multiple spalling heads are connected with the same propelling mechanism, so that the load of the drill rod is reduced; and the rock breaking efficiency of the raise boring machine is improved in cooperation with the spalling head structure.

Owner:TAISHAN UNIV

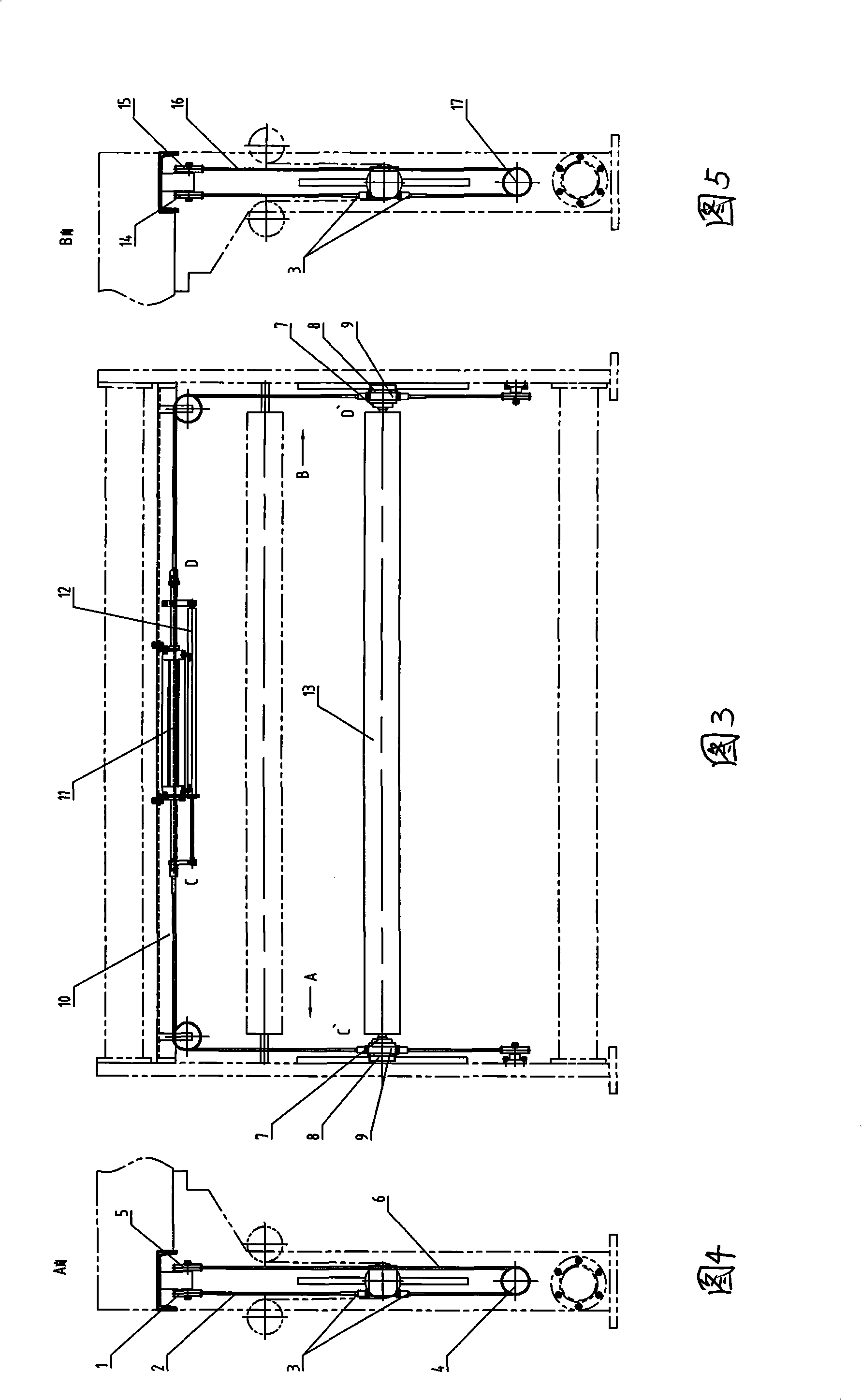

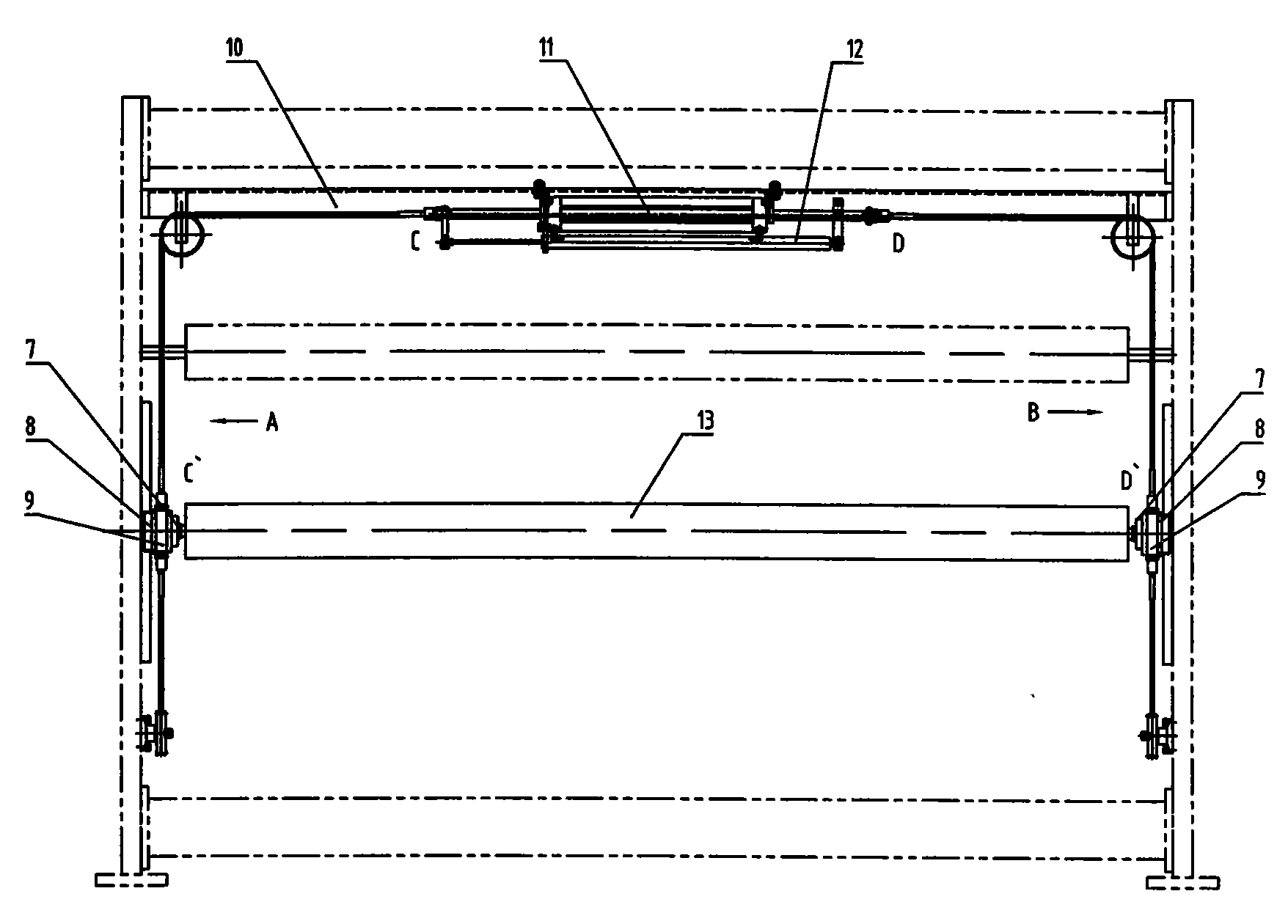

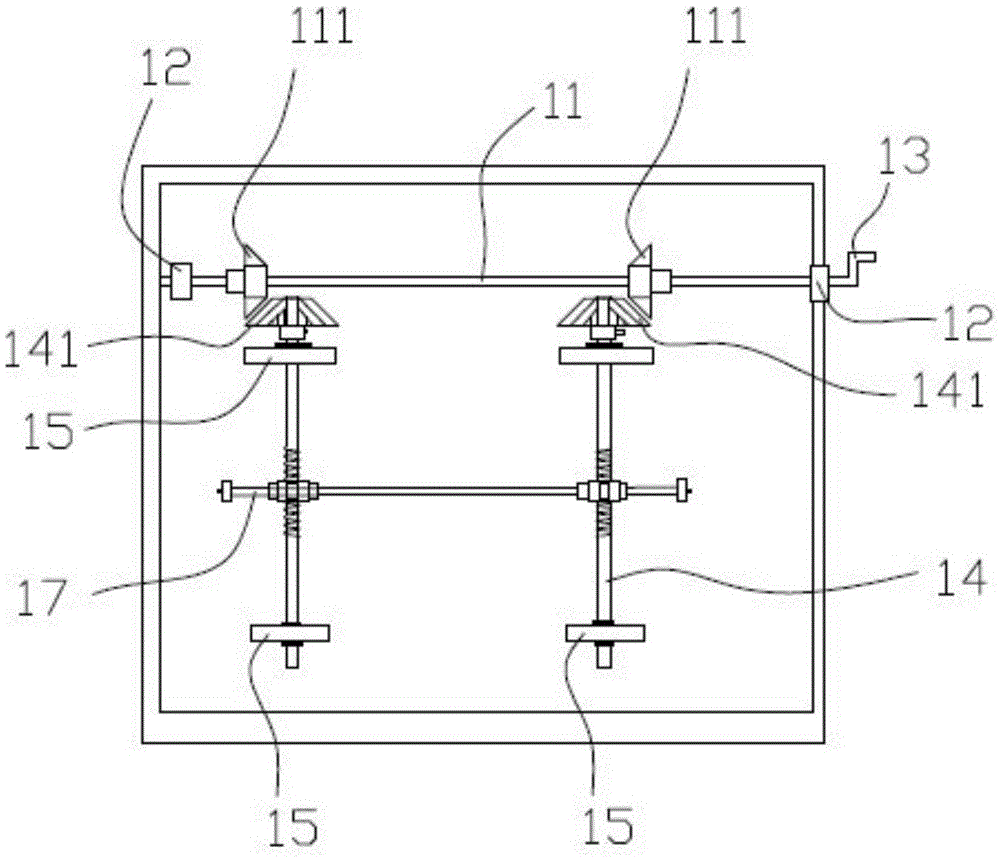

Horizontal platform joining mechanism for mechanical garage

The invention relates to a horizontal platform joining mechanism for a mechanical garage. The horizontal platform joining mechanism comprises a bearing mechanism for carrying vehicles, a pushing mechanism and a joining mechanism. The bearing mechanism comprises an upper ring beam, clamping mechanisms and transmission racks, wherein the clamping mechanisms are arranged at both ends of the upper ring beam and are used for lifting up vehicles; the transmission racks are arranged in parallel to the moving direction of the upper ring beam; sliding mechanisms joined with parking space slides are set into a plurality of traveling wheels, so that the upper ring beam is uniformly stressed and the weight is gradually transferred to the parking space slides; and gears and racks are used for transmission in power. The horizontal platform joining mechanism for a mechanical garage has a simple structure, is accurate to take the transmission action; and a traveling mechanism and a transmission mechanism have simple structures and small sizes. A power structure for pushing the vehicles is arranged on the bearing mechanism and the structure of a pushing platform is reduced so as to reduce the thickness of the pushing platform, and thus, the horizontal platform joining mechanism for the mechanical garage is applied to vehicles with low underpans.

Owner:黄朝英

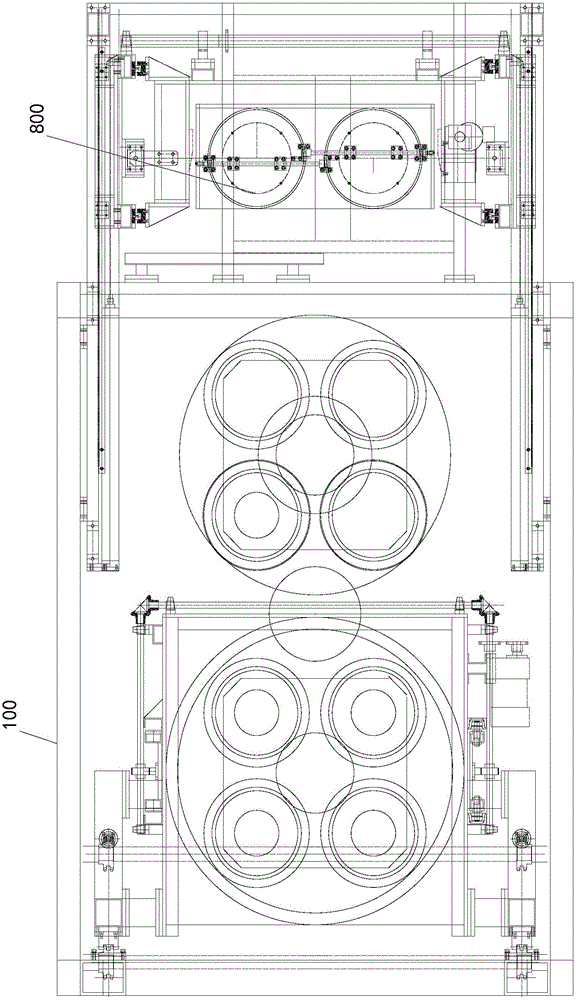

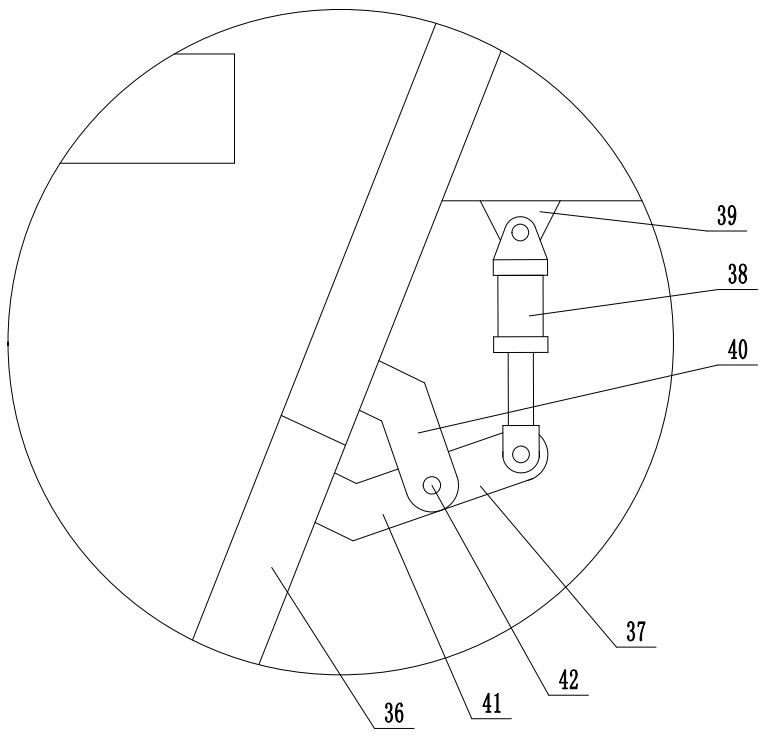

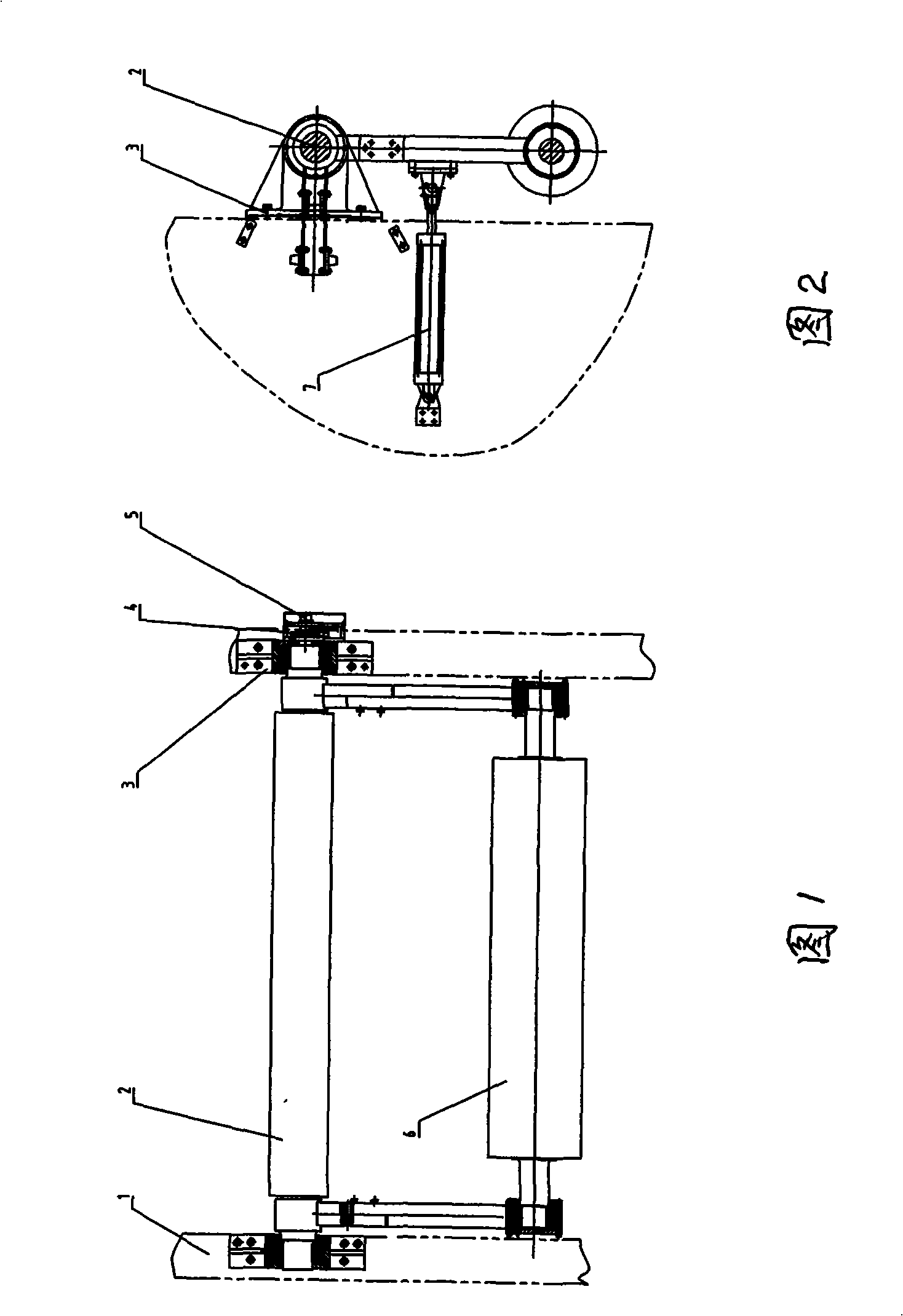

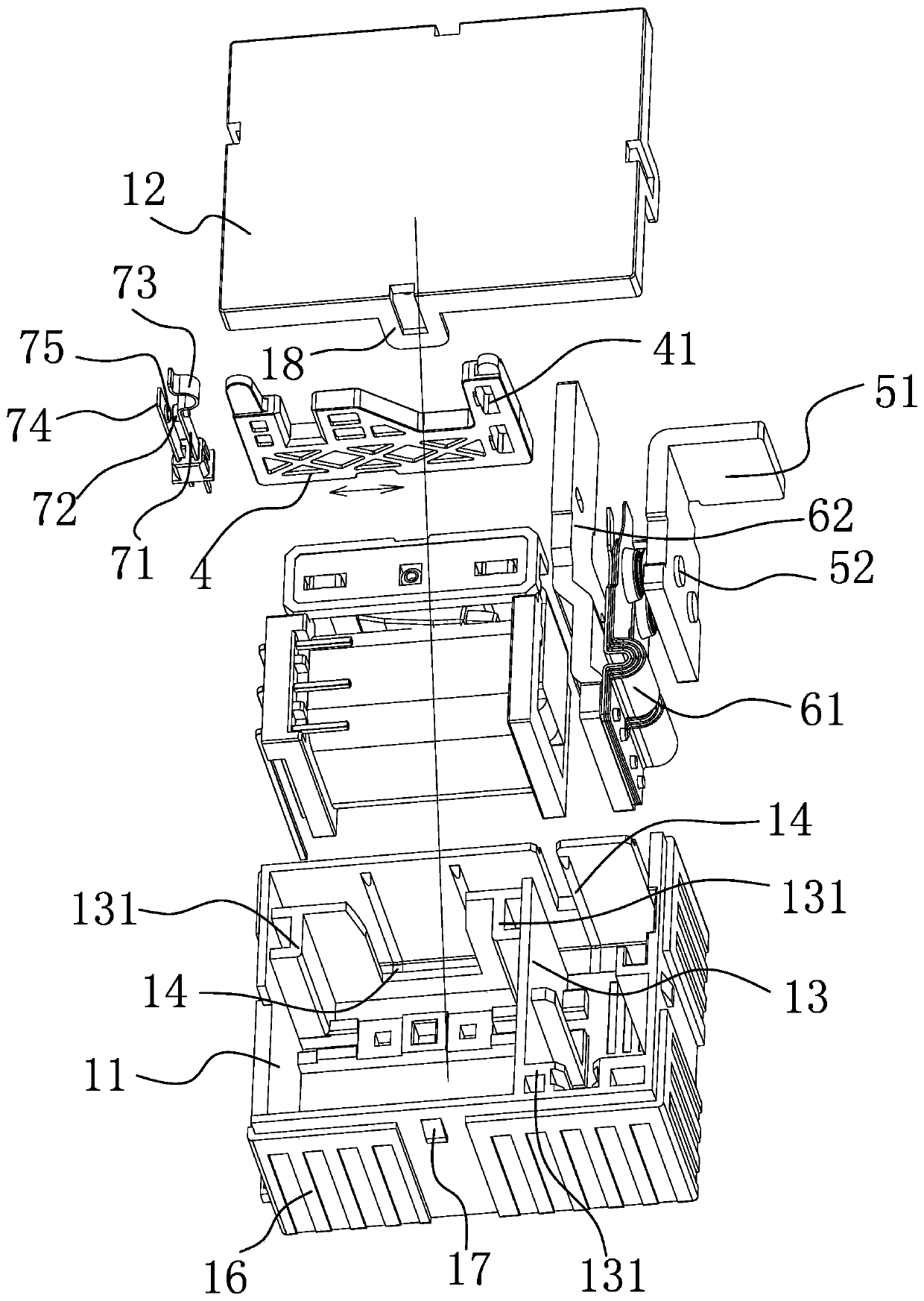

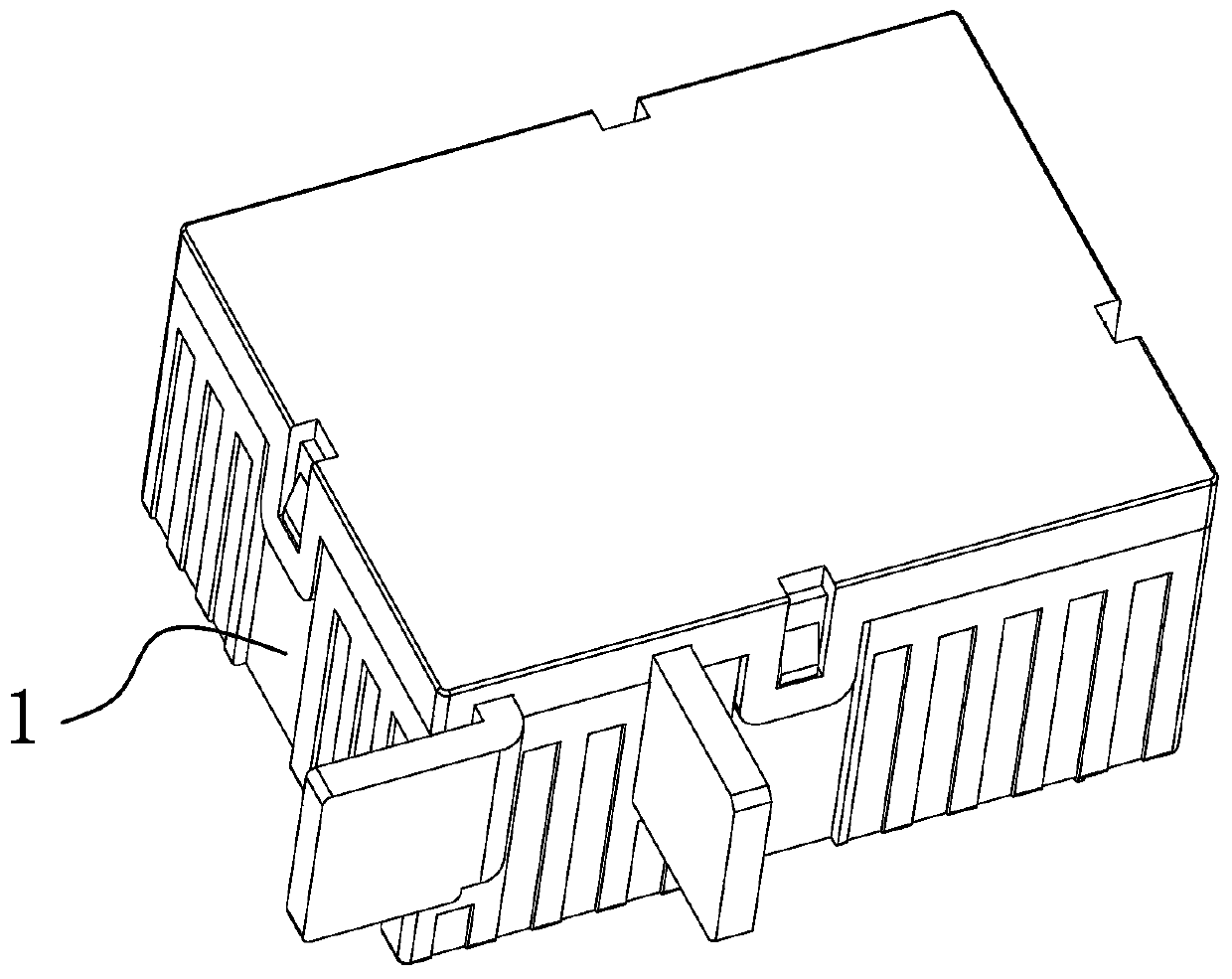

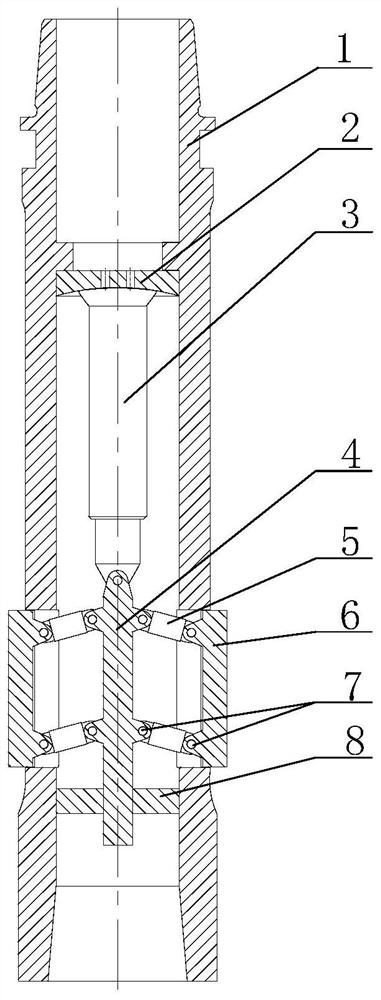

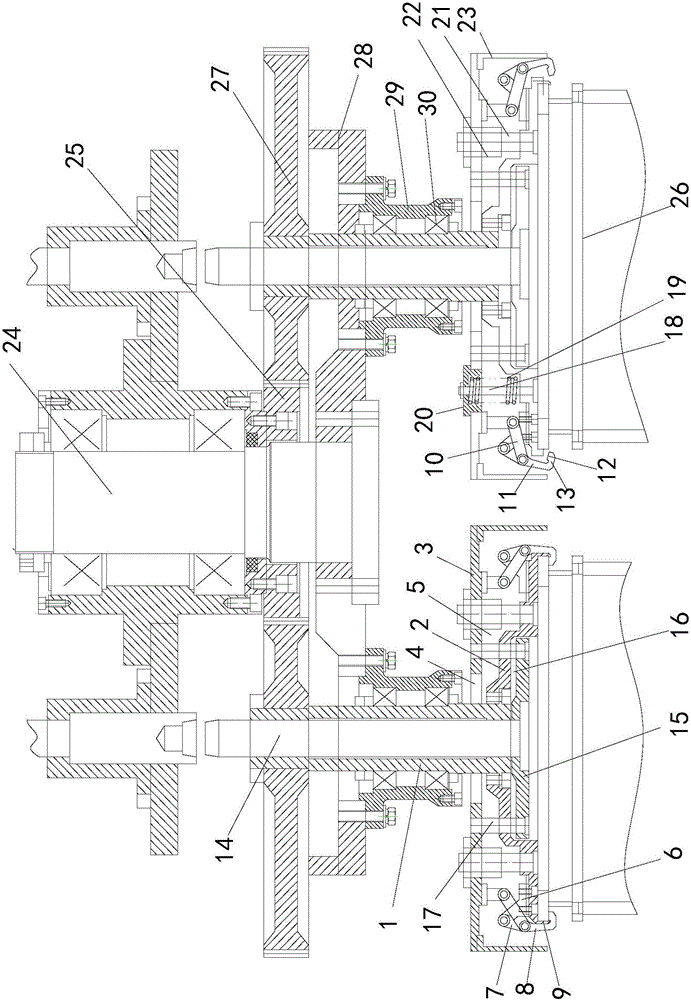

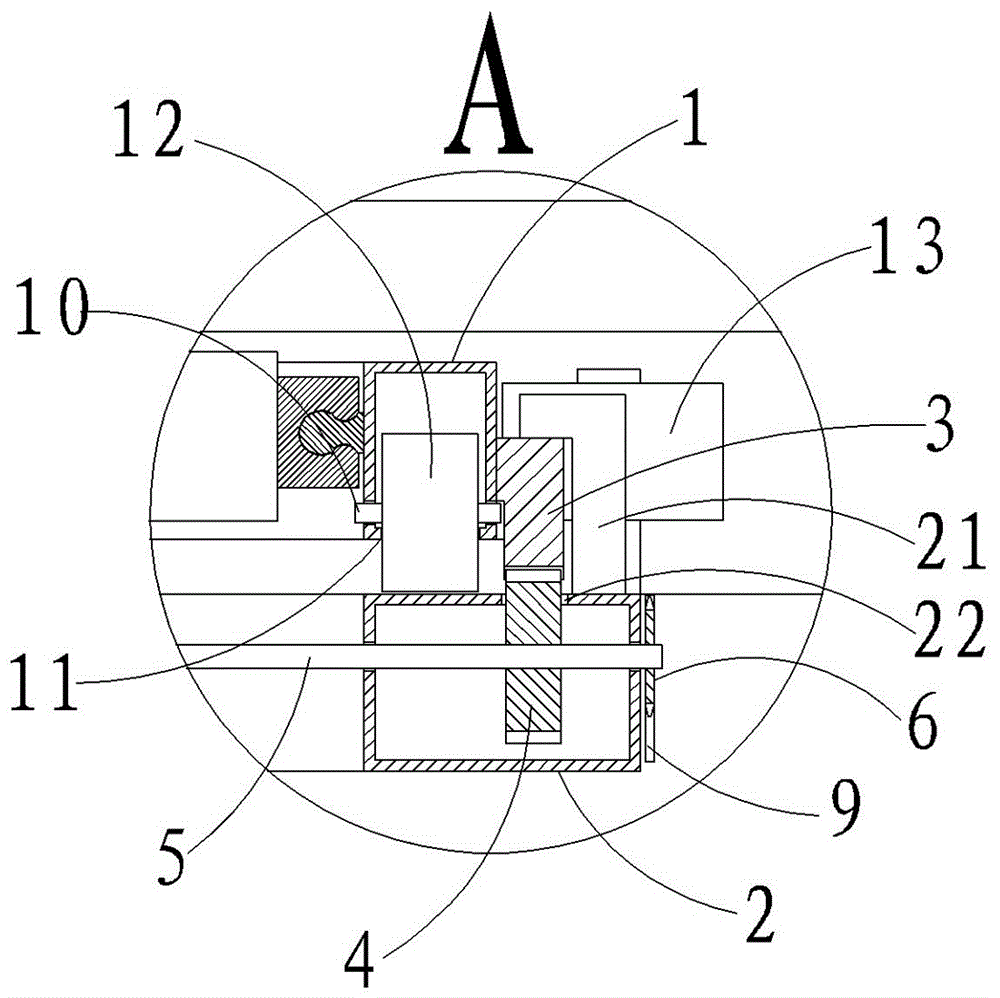

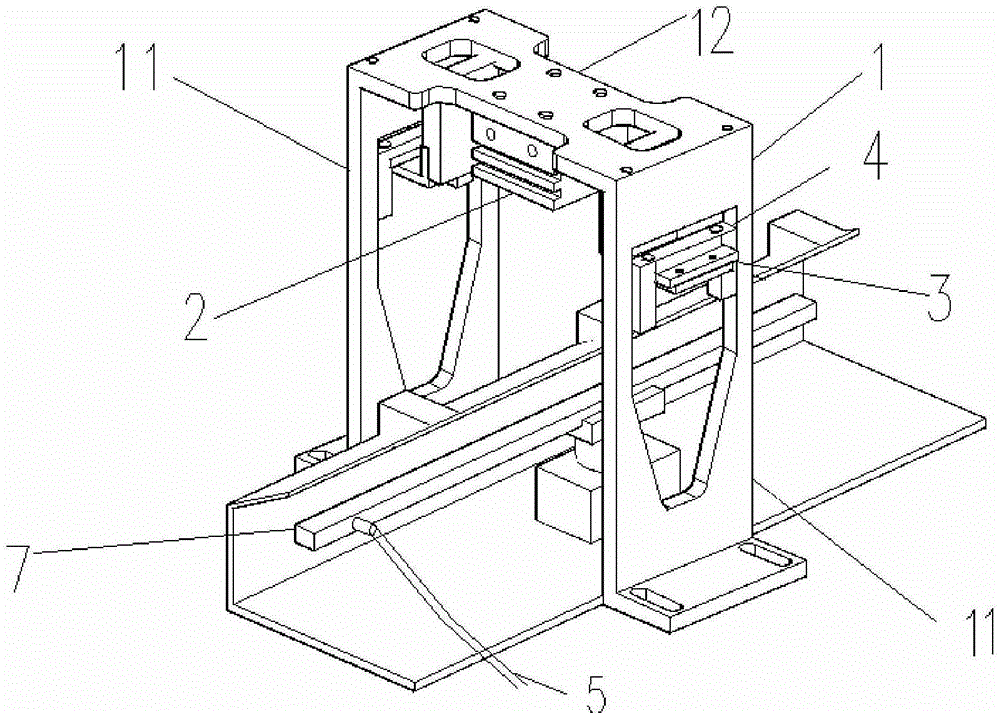

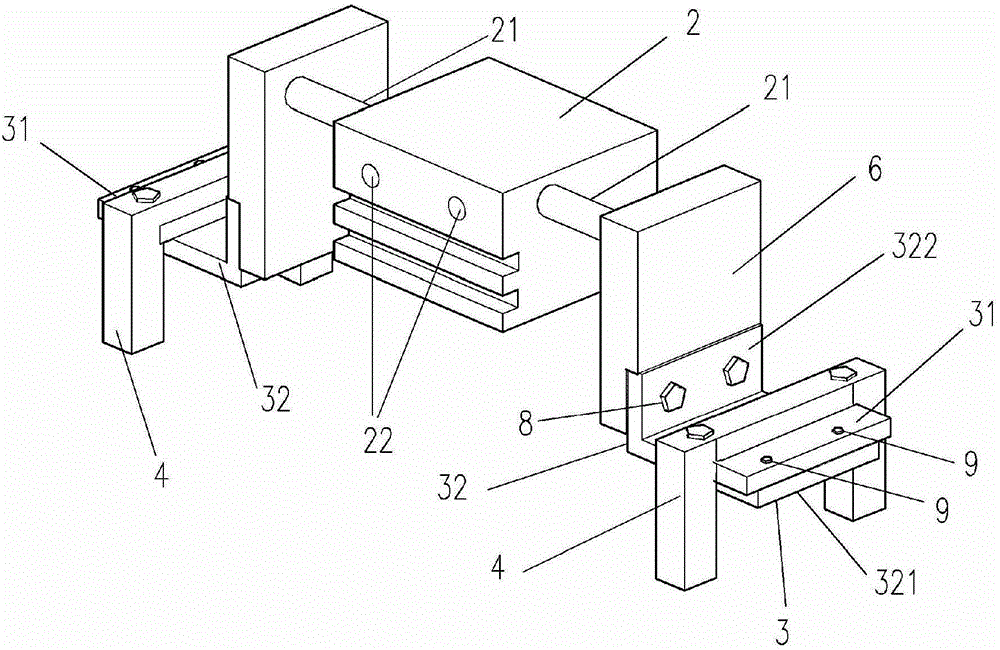

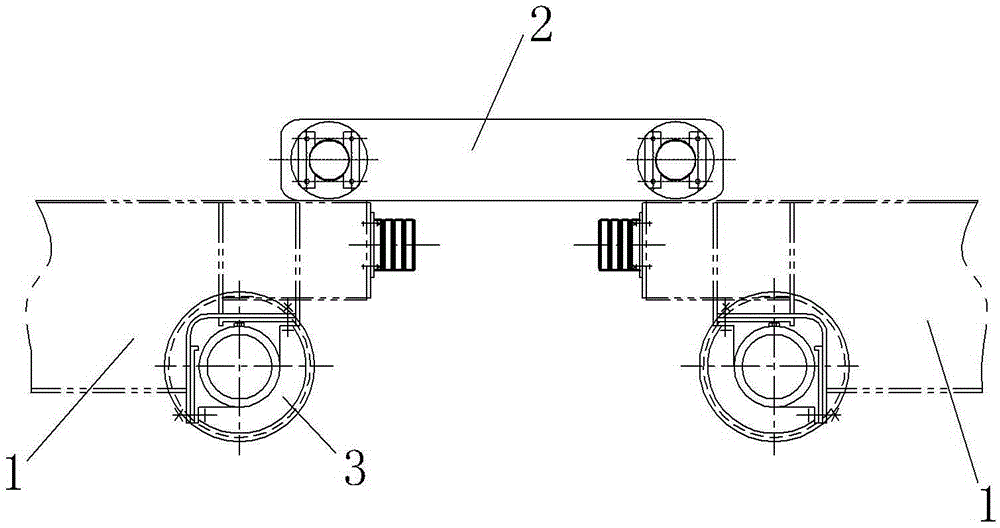

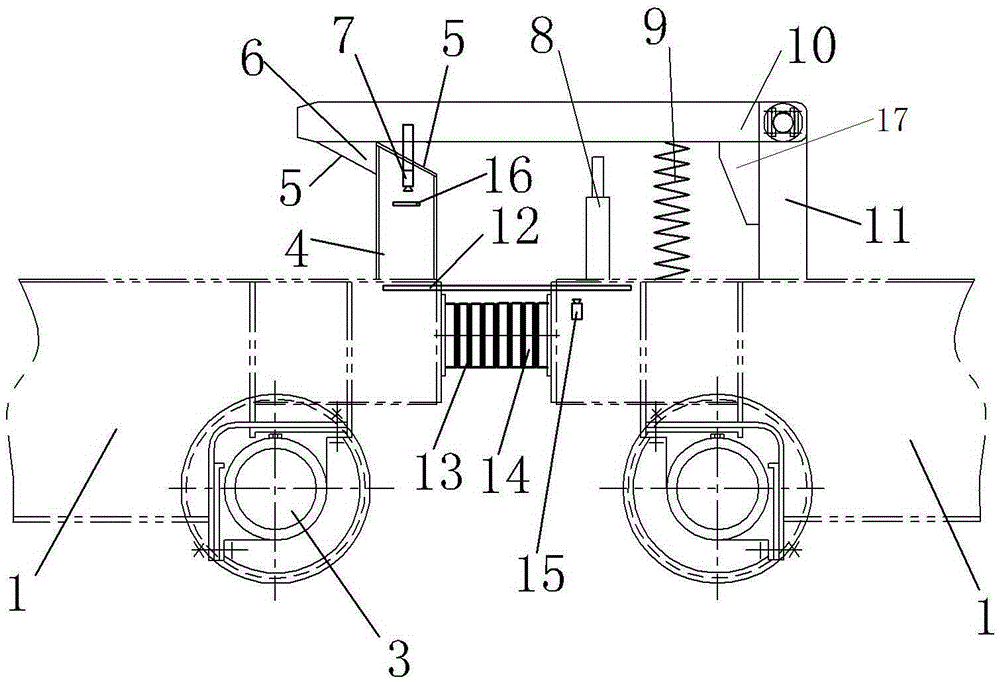

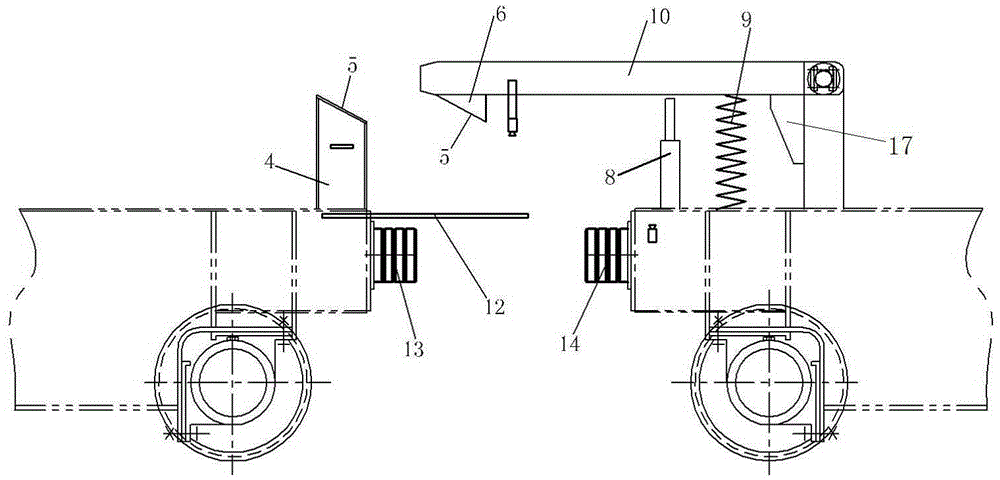

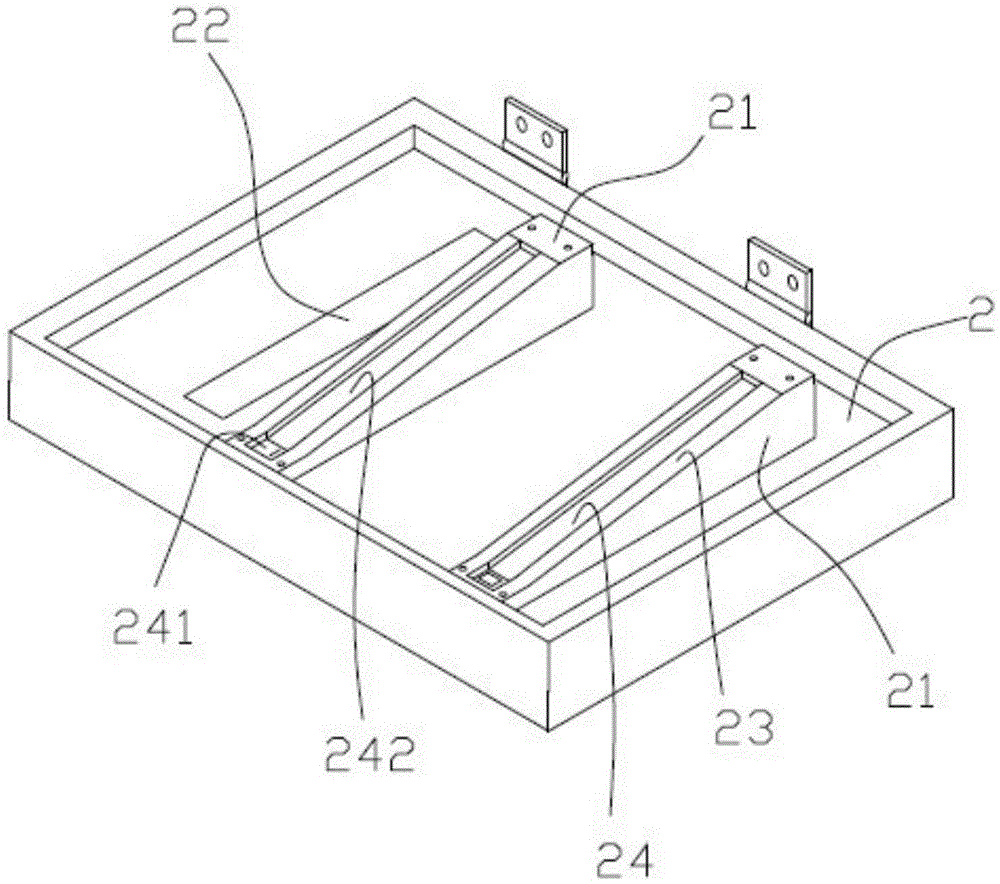

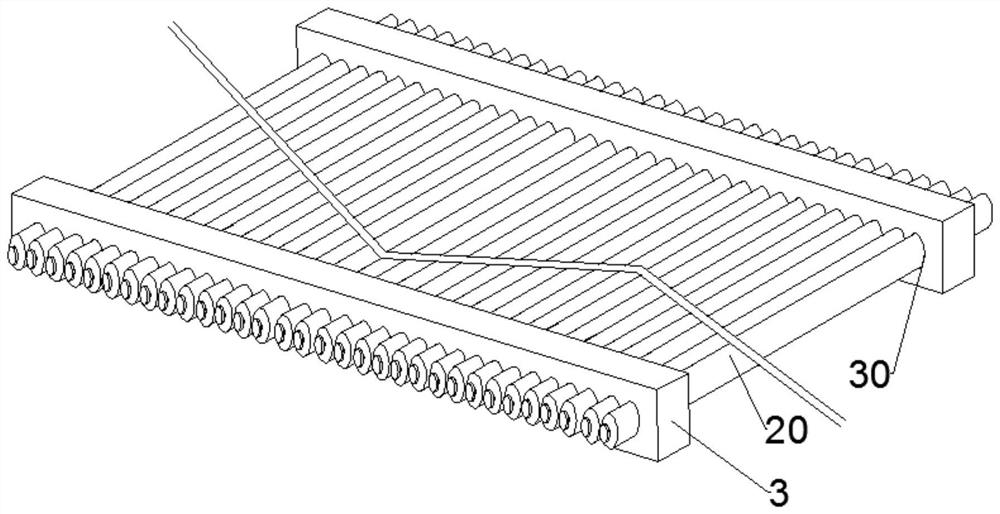

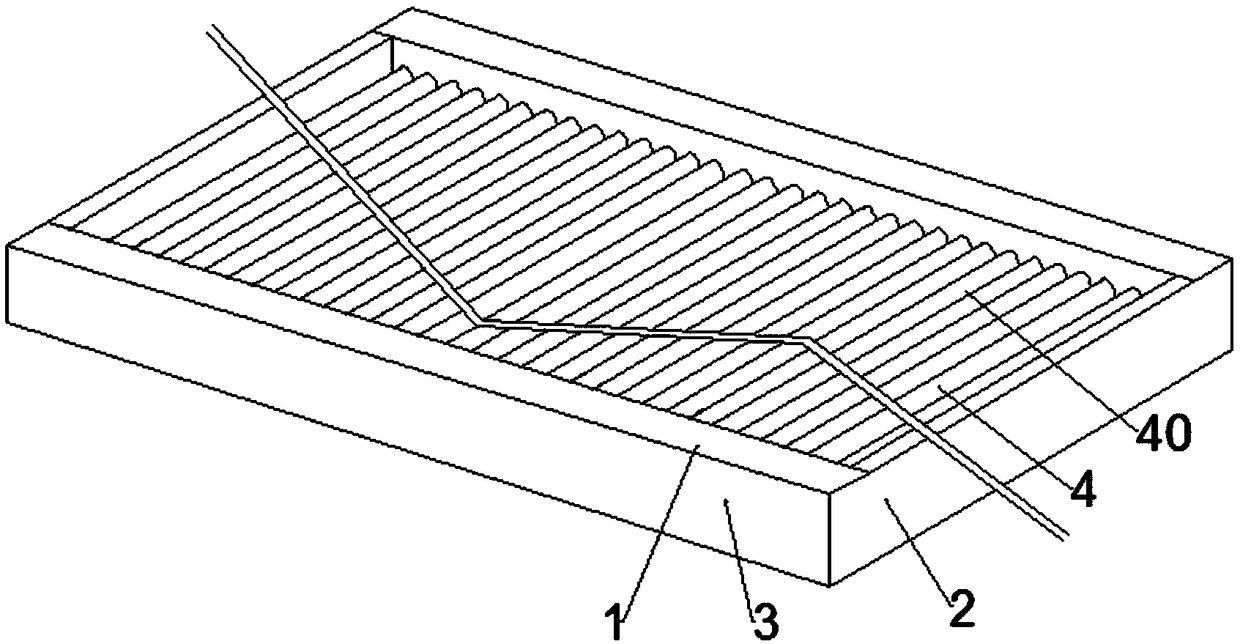

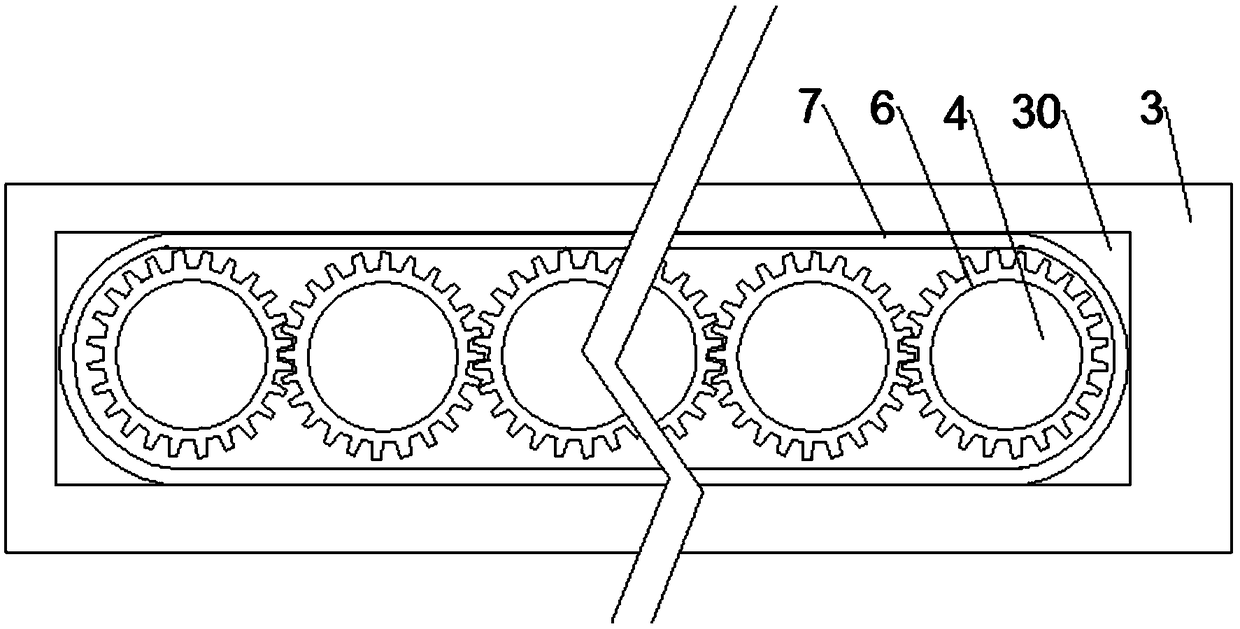

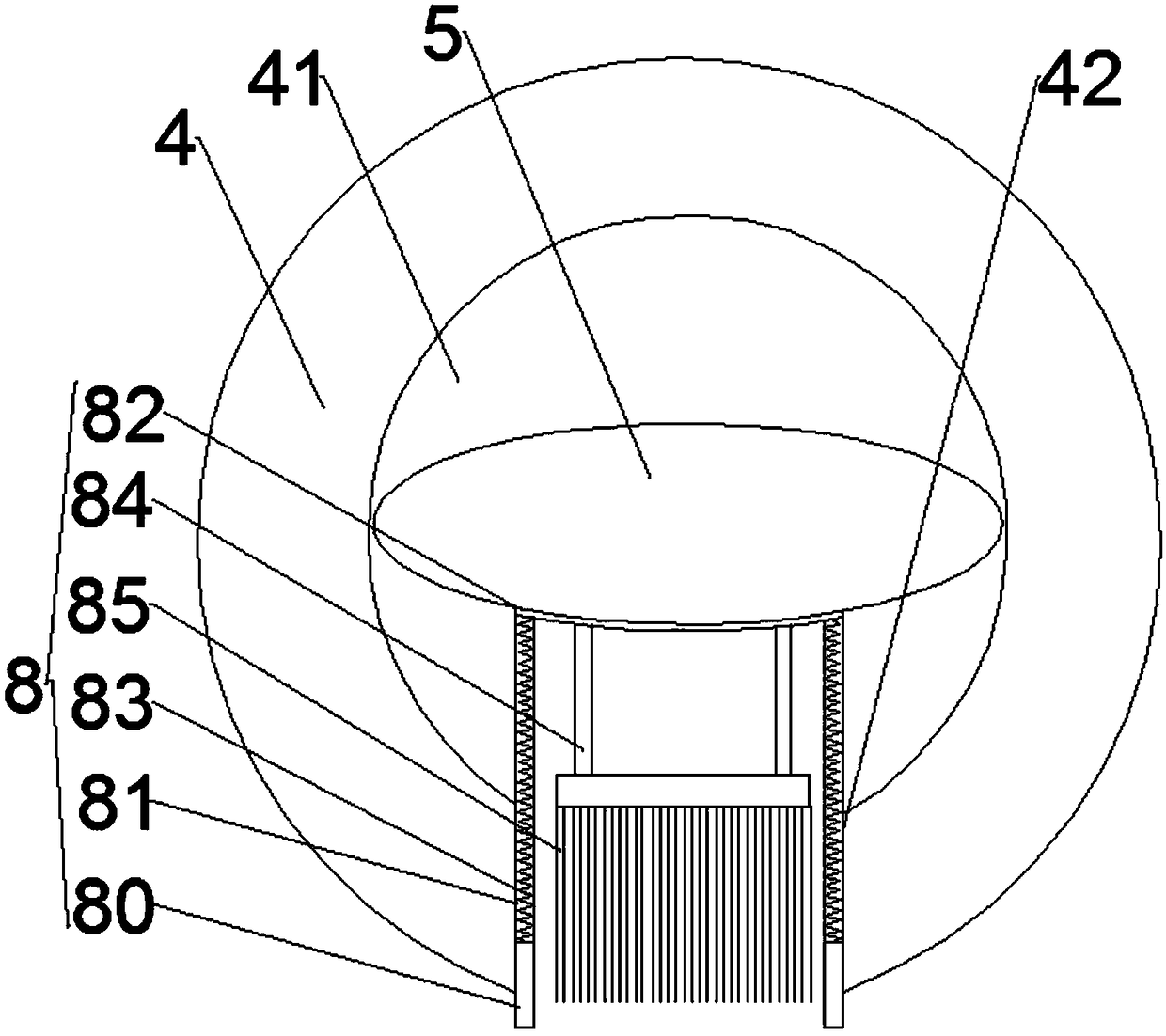

Workpiece basket clamping and rotating device

InactiveCN105710004AImprove clamping efficiencyEasy to assembleLiquid surface applicatorsCoatingsMechanical engineering

The invention discloses a workpiece basket clamping and rotating device in a coating machine, which comprises a hollow rotating shaft, a positioning plate sleeved on one end of the rotating shaft and rotated with the rotating shaft, and a pressing plate sleeved on the rotating shaft above the positioning plate , there are several pressing mechanisms arranged between the positioning plate and the pressing plate, which include a claw seat fixed on the positioning plate, a pressing claw set on the claw seat through a linkage arm, and one end of the pressing claw is connected to the The pressing plate is connected, and a pressing space is formed between the other end of the pressing claw and the lower surface of the positioning plate, and the ejector rod is installed in the rotating shaft. One end of the ejector rod is provided with a top plate, and the top plate is located below the lower surface of the positioning plate. The top plate and the pressing plate are connected as a whole by a connecting device, and an elastic device compressed by the positioning plate and the pressing plate is arranged between the positioning plate and the pressing plate. Compared with the previous clamping device, the present invention is optimized in structure, occupies less space, ensures the clamping force on the workpiece basket, and improves the clamping efficiency of the workpiece basket.

Owner:CHANGZHOU JUNHE TECH

A mechanical garage horizontal platform connecting mechanism

The invention relates to a horizontal platform joining mechanism for a mechanical garage. The horizontal platform joining mechanism comprises a bearing mechanism for carrying vehicles, a pushing mechanism and a joining mechanism. The bearing mechanism comprises an upper ring beam, clamping mechanisms and transmission racks, wherein the clamping mechanisms are arranged at both ends of the upper ring beam and are used for lifting up vehicles; the transmission racks are arranged in parallel to the moving direction of the upper ring beam; sliding mechanisms joined with parking space slides are set into a plurality of traveling wheels, so that the upper ring beam is uniformly stressed and the weight is gradually transferred to the parking space slides; and gears and racks are used for transmission in power. The horizontal platform joining mechanism for a mechanical garage has a simple structure, is accurate to take the transmission action; and a traveling mechanism and a transmission mechanism have simple structures and small sizes. A power structure for pushing the vehicles is arranged on the bearing mechanism and the structure of a pushing platform is reduced so as to reduce the thickness of the pushing platform, and thus, the horizontal platform joining mechanism for the mechanical garage is applied to vehicles with low underpans.

Owner:王景保

Drive-control integrated servo implementation method and system

ActiveCN109639187BGuaranteed synchronous actionLower latencyElectric motor controlMultiple ac dynamo-electric motors controlControl engineeringElectric machinery

The embodiment of the present invention relates to the technical field of power electronics, and discloses a method and system for implementing a drive-control integrated servo. The drive-control integrated servo implementation system of the present invention includes a host computer interface and an expandable drive-control integrated module; the expandable drive-control integrated module includes a control module and an expandable drive module, wherein the control module includes logic control and motor drive, which can be The extended driver module includes multiple scalable driver modules, and each driver module has an FPGA hardware current loop; the host computer interface compiles the user logic control program and transmits it to the logic control CPU, and the logic control CPU calculates the logic data according to the instructions and sends them For the motor drive, the motor drive controls the corresponding servo motor through the drive module in the scalable drive module. The present invention can not only effectively reduce the overall volume and application cost of the drive-control integrated servo, but also meet the requirement of expandable axes of the servo motor.

Owner:SHANGHAI SIGRINER STEP ELECTRIC

Pneumatic correction device for cell transferring

ActiveCN103057985BRealize position correctionGuaranteed synchronous actionArticle feedersArticle deliveryMechanical wearEngineering

The invention discloses a pneumatic correction device for cell transferring. The pneumatic correction device for cell transferring comprises a base, a cylinder, a pair of combination baffles, a pair of U-shaped clamp arms, a proximity switch, and a sensing element. The base comprises a pair of side plates and a top plate located at the top of the side plates. The cylinder is disposed below the top plate. The combination baffles are symmetrically disposed on a guide bar on two sides of the cylinder respectively and located below the cylinder. The U-shaped clamp arms are symmetrically disposed on the combination baffles respectively. The sensing element is connected with an air hole of the cylinder. The proximity switch provides cylinder operation signals through the sensing element so as to allow the guide bar on the cylinder to contract or extend to drive the U-shaped clamp arms to move, thereby correcting the position of a cell. The pneumatic correction device is disposed on a travel arm used for transferring cells. The position of the cells on the travel arm can be corrected by the pneumatic correction device, and accordingly the problems of lower precision and proneness of cells to deflection and fragmentation in transfer process caused by mechanical wear of the travel arm in the prior art are solved.

Owner:JA SOLAR TECH YANGZHOU

A cleaning system for a garbage sorting machine

Owner:JIANGSU BVM INTELLIGENT TECH

Anti-corrosion concrete for building and its production system

ActiveCN112358253BImprove compactnessHigh strengthSolid waste managementMixing operation control apparatusProcess engineeringSystem structure

The invention provides a special anti-corrosion concrete for buildings, which belongs to the technical field of concrete. It is formed by stirring anti-corrosion concrete gel base material, anti-corrosion concrete base material, anti-corrosion concrete filling base material and water, and in parts by weight: the anti-corrosion concrete gel base material is 95-105 parts, so The anti-corrosion concrete base material is 375-412 parts, the anti-corrosion concrete filling base material is 10-17 parts, and the water is 40-45 parts. A production system for anti-corrosion concrete specially used for buildings, which includes a production frame device, a production device for anti-corrosion concrete gel substrate, a production device for anti-corrosion concrete base material, a production device for anti-corrosion concrete filling base material, and a mixing and stirring device. The invention greatly improves the anti-corrosion performance of the concrete, greatly increases the service life of the building, and the structure of the production system is reasonable, which is beneficial to the continuous processing of the special anti-corrosion concrete for the building, and has a high degree of automation.

Owner:桐乡市钟大建材有限公司

A rotary power connection device

PendingCN109149233ASimple structureEasy to useCouplings bases/casesFlexible/turnable line connectorsEngineeringUltrasonic generator

The invention discloses a rotary power supply connecting device, An upper rotate conductive plate and a lower rotate conductive plate are respectively that same as the upper rotating conductive plate,the surface of the lower rotating body is fixedly connected, An upper part is fit in a central circular hole of that upper and lower rotary body, lower lumen cannula, the lower end of the spring coildisposed in the upper cavity sleeve is in contact with the surface of the upper rotating conductive plate, located above the barrel lumen, The lower rotating body is spaced apart from the protectivebarrel wall, and upper and lower rotating seal caps with sealing rings are screwed on the upper and lower ends of the protective barrel, and a top rotating body is arranged at the center of the upperrotating seal cap, and upper and lower inner seal rings are arranged between the top rotating body and the upper cavity sleeve, and the lower rotating seal cap and the lower cavity sleeve, so as to form a multi-level mechanical seal. The two ends of the vibrator head conductor are connected with the lower rotating conductive plate and the contact of the vibrator head, the two ends of the ultrasonic source conductor are connected with the upper rotating conductive plate and the terminal, and the two ends of the ultrasonic current output line are connected with the output point of the ultrasonicgenerator. The device matched with the ultrasonic generator is easy to operate and has high practical value.

Owner:HUNAN LOUDI TAIYANG TECH

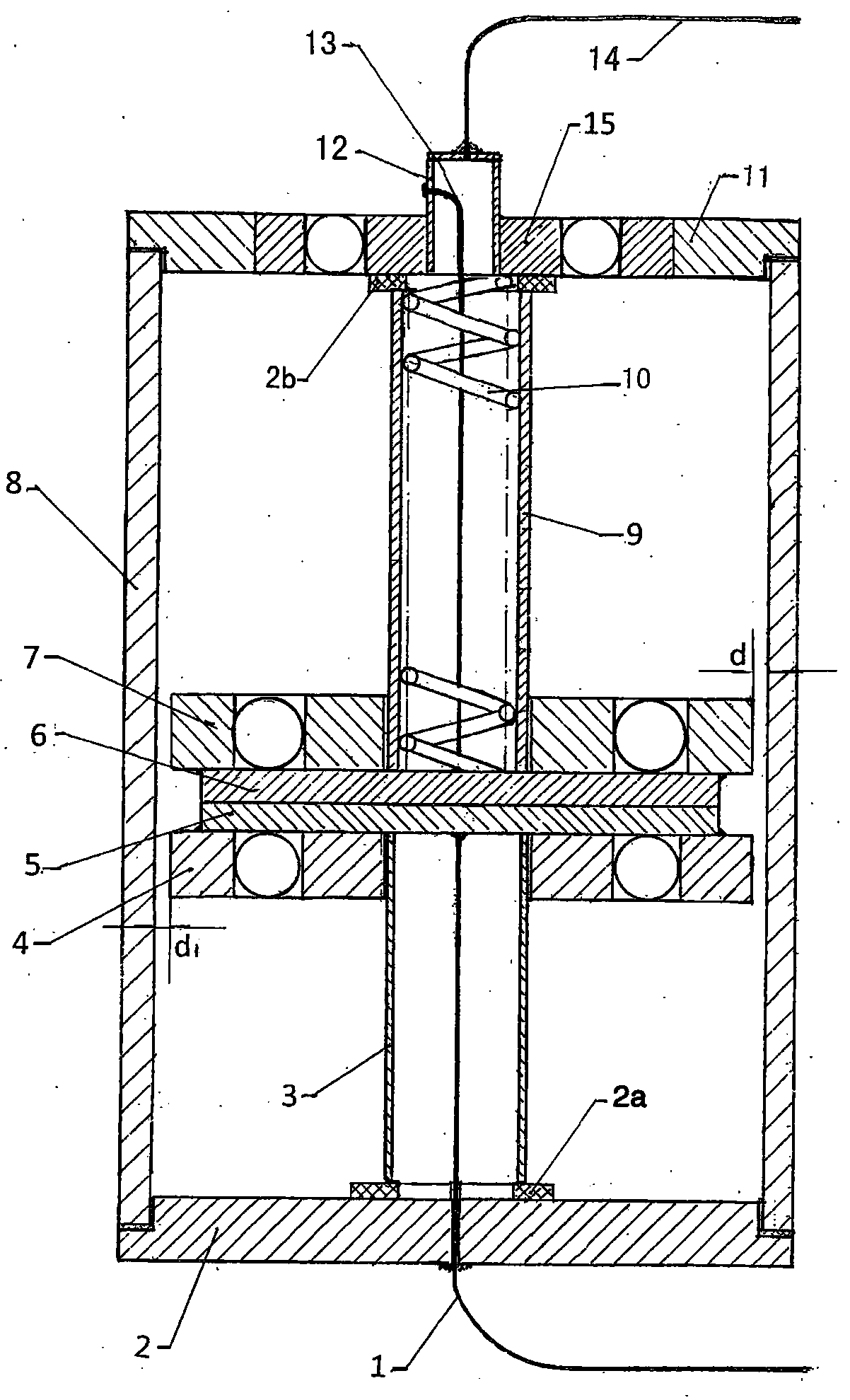

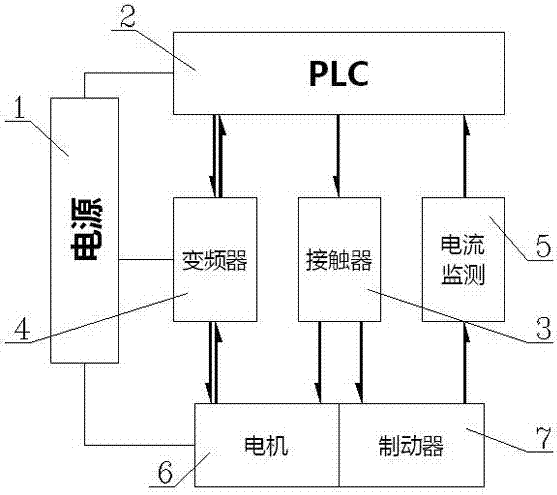

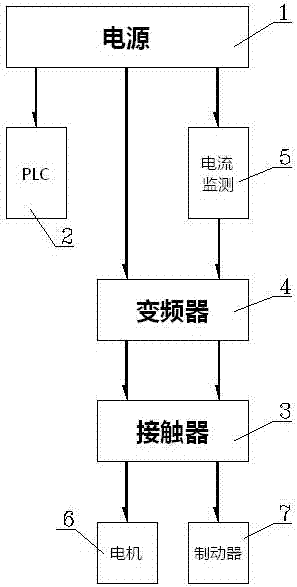

Stereo garage frequency conversion speed regulation control system with brake monitoring

ActiveCN105604370BGuaranteed synchronous actionMotor/generator/converter stoppersDynamo-electric converter controlFrequency changerLoop control

The invention provides a three-dimensional garage frequency conversion and speed regulation control system with a brake monitoring function. The system comprises a power supply, a PLC control unit, a contactor, a frequency converter and a current-controlled relay detection feedback unit K4. According to the three-dimensional garage frequency conversion and speed regulation control system with the brake monitoring function, a single frequency converter is used for conducting open-loop control on multiple motors; meanwhile, a current controller is used for monitoring a working current of a target motor brake and feeding back monitoring information to the PLC control unit to conduct comprehensive judgment, and therefore synchronous action of the motor brake in the open-loop control process of the frequency converter is effectively guaranteed.

Owner:JIANGSU JINGUAN PARKING IND

A crane component and its linkage connection device

ActiveCN103935891BImprove connection efficiencyAvoid collisionTravelling gearRelative motionEngineering

The invention relates to a crane assembly and a linked connecting device thereof. The linked connecting device comprises a bracket and a baffle block which are arranged on travelling beams of two adjacent cranes, respectively, wherein a swinging rod capable of swinging up and down is hinged on the bracket; a hook part is arranged on the rear end of the swinging rod and is provided with a hooking working positing matched with the rear side surface of the baffle block in a hooking way in a process of swinging up and down along with the swinging rod. When the two adjacent cranes need to be connected, the travelling beams of the two adjacent cranes oppositely move, and the swinging rod swings for making way for the baffle block; when the distance between the travelling beams of the adjacent two cranes enables the hook part to be at the rear side of the baffle block, the travelling beams stop movement, and the hook part can swing to the hooking working position with the swinging rod to match the rear side surface of the baffle block in a hooking manner, so that the front crane can drive the rear crane to link by virtue of hooking matching of the hook part and the baffle block, a bolt or a pin roll does not need to be installed when the crane linkage is realized, and the connecting efficiency of cranes is improved.

Owner:北京云中未来科技有限公司

Pillow

Owner:杨小东

Automated manure cleaning pens for mutton sheep farming

The invention discloses a mutton sheep breeding fence house capable of achieving automatic manure cleaning. The mutton sheep breeding fence house comprises a fence house body and three support cleaning components; the fence house body comprises a wall body and a shed cover, the fence house body is divided into three fence house compartments, and one support cleaning component is arranged in each fence house compartment so as to divide the corresponding compartment into an upper feeding space and a lower collecting space; each feeding space is provided with a railing along an opening formed inthe side along the length direction of the corresponding feeding space; a first feed guide plate is clamped in each collecting space in the width direction of the corresponding collecting space, and asecond feed guide plate is fixedly connected to the lower end, in the length direction, of the first feed guide plate; and a sewage outlet is formed in the lowest end of the side wall of each collecting space so as to achieve communication of arbitrary two adjacent collecting spaces and communication of the two collecting spaces with the outside. The mutton sheep breeding fence house has the advantages of large space separation feeding, unified intensive collection of manure under the action of gravity and self-rinsing; and blocking of gap for communication of each feeding space and the corresponding collecting space by manure can be avoided effectively.

Owner:甘宗琳

Culturing bed for sheep

The invention discloses a culturing bed for sheet. The culturing bed comprises a pair of short rods, a pair of long rods, rotating rods, and cleaning assemblies; each long rod is connected to the twoends of each short rod to form a cuboid frame, and includes a cavity; the rotating rods are arranged in the frame side by side at equal interval to form a shoe surface where the sheep can stand, and gears, positioned in the same cavity, of any two adjacent rotating rods are engaged with each other; and each rotating rod corresponds to one cleaning assembly, each cleaning assembly comprises a guiding frame fixedly arranged in the circumferential direction, a telescoping frame positioned in the top side of the guiding frame and a cover plate covering the top side of the telescoping frame, the sidewall of the telescoping frame is vertically and separately provided with springs, an installing plate is horizontally and fixedly connected in the telescoping frame and under the cover plate, and the side, far from the cover plate, of the installing plate is provided with brush hairs along the direction far from the installing plate. The culturing bed is capable of scrubbing by itself, and can effectively avoids sheep manure from accumulating and plugging slits through which a breeding space is communicated with a collecting space.

Owner:甘宗琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com