Reaming drill rod with spalling rock breaking function

A technology of reaming drilling and expansion cracking, which is applied to drill pipes, drill pipes, drilling tools, etc., can solve the problems of unsatisfactory rock breaking efficiency, heavy load of drill pipes, complicated structure, etc., and achieves good alignment and simplification. structure, the effect of improving the bursting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

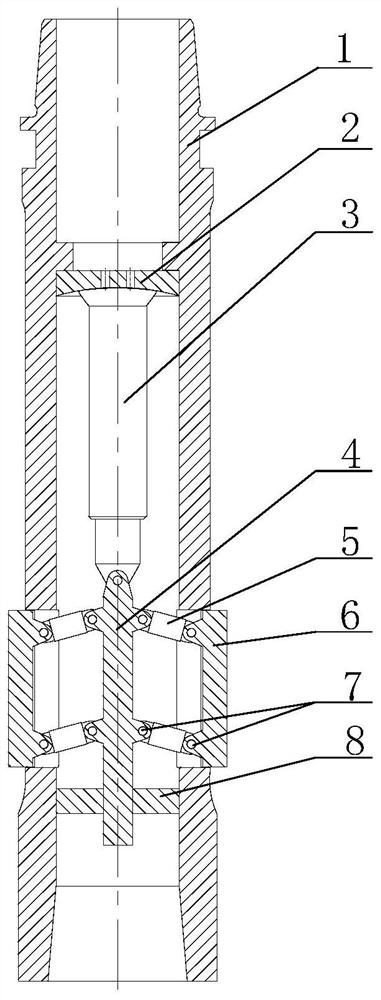

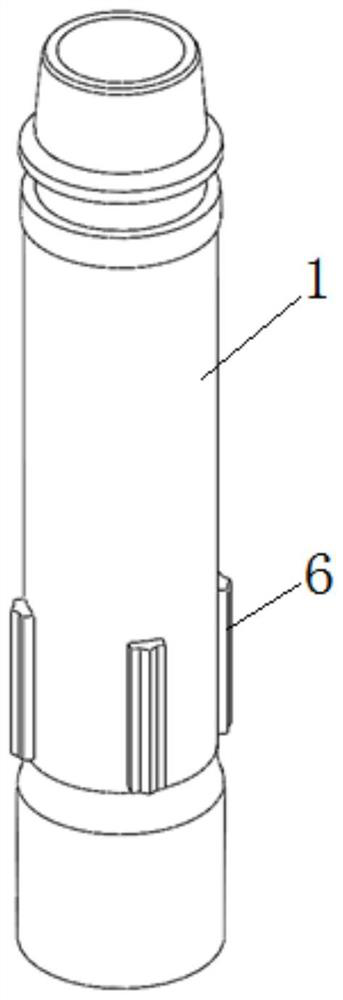

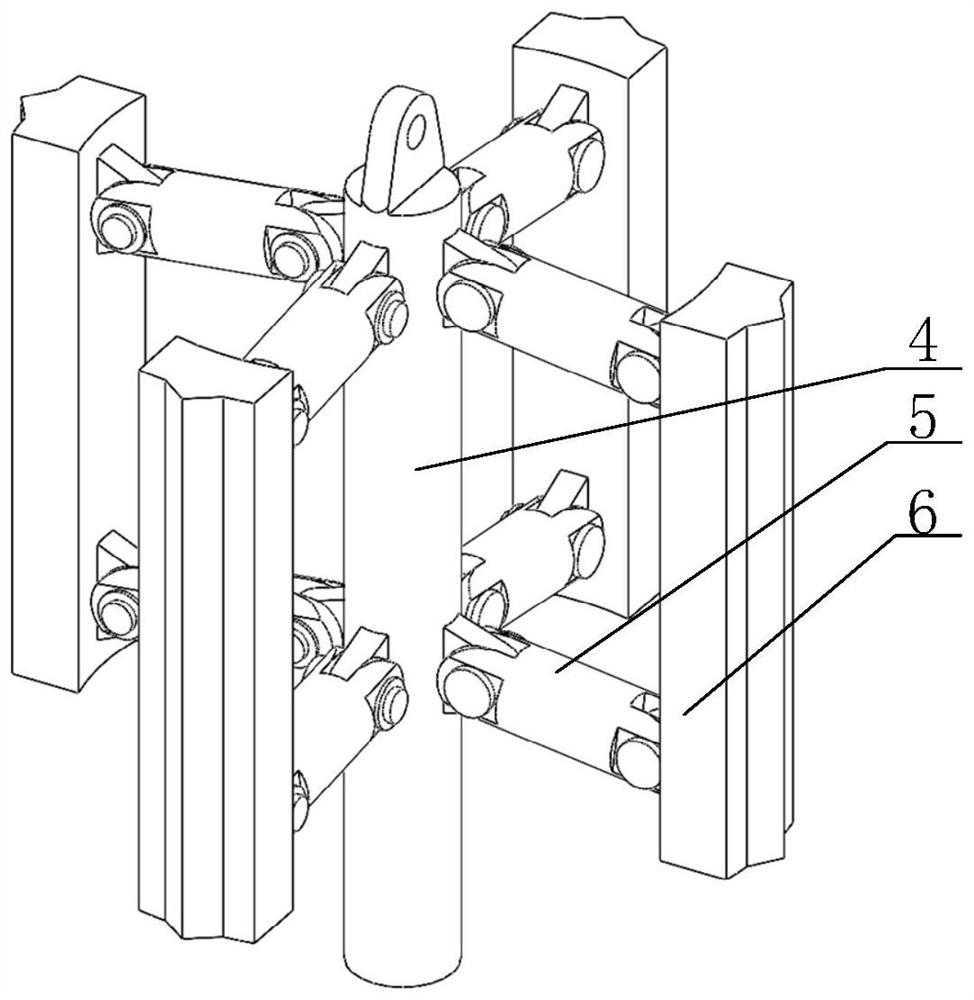

[0030] This embodiment provides a reaming drill pipe with the function of bursting and breaking rock, such as figure 1 and figure 2 As shown in the figure, it includes a drill rod body 1, a pushing mechanism, and a bursting head 6. The pushing mechanism is installed in the drilling rod body 1, and a plurality of bursting heads 6 are evenly arranged along the circumferential direction of the drilling rod body 1, and the pushing mechanism is connected by a connecting rod assembly. Head 6, the pushing mechanism can drive the expansion head 6 to move to the outside or inside of the drill rod body 1.

[0031] Specifically, with figure 1 The directions shown are for reference, that is, when the drill rod body 1 is in a vertical state, one end is the top and the other end is the bottom. The drill rod body 1 has an installation cavity inside. The drill rod body 1 is provided with a plurality of through grooves at circumferential intervals near the bottom. The specific number of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com