Horizontal platform joining mechanism for mechanical garage

A mechanical garage, horizontal technology, applied in the direction of the buildings, building types, buildings, etc. where cars are parked, can solve the problems of the pick-and-place mechanism being unable to pick and place low-chassis vehicles, inconvenient promotion of underground garages, vehicle injuries, etc., to reduce equipment. Maintenance time, simple structure, reduced effect of fastening parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

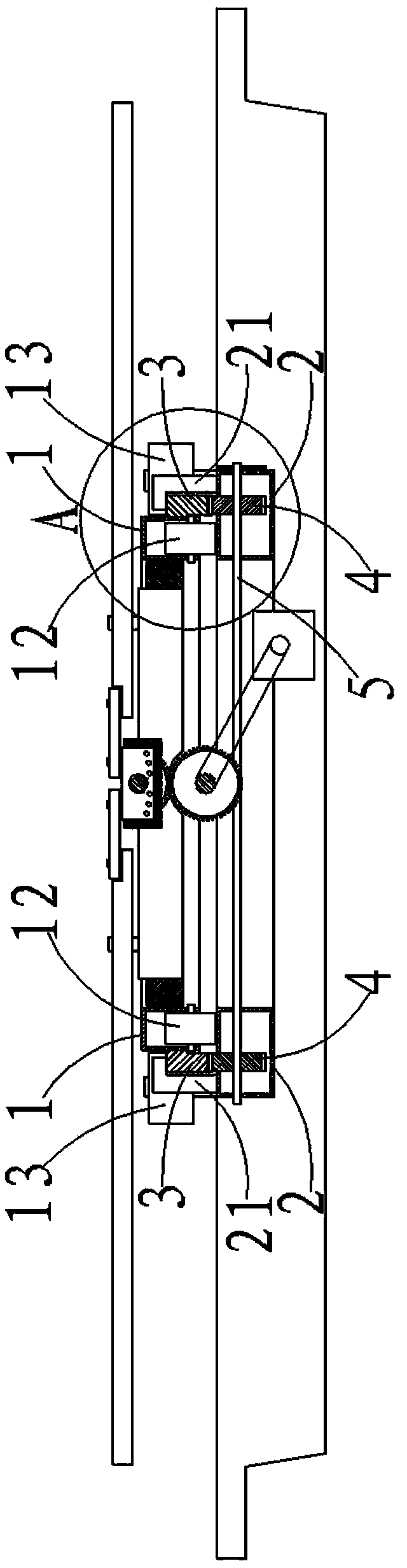

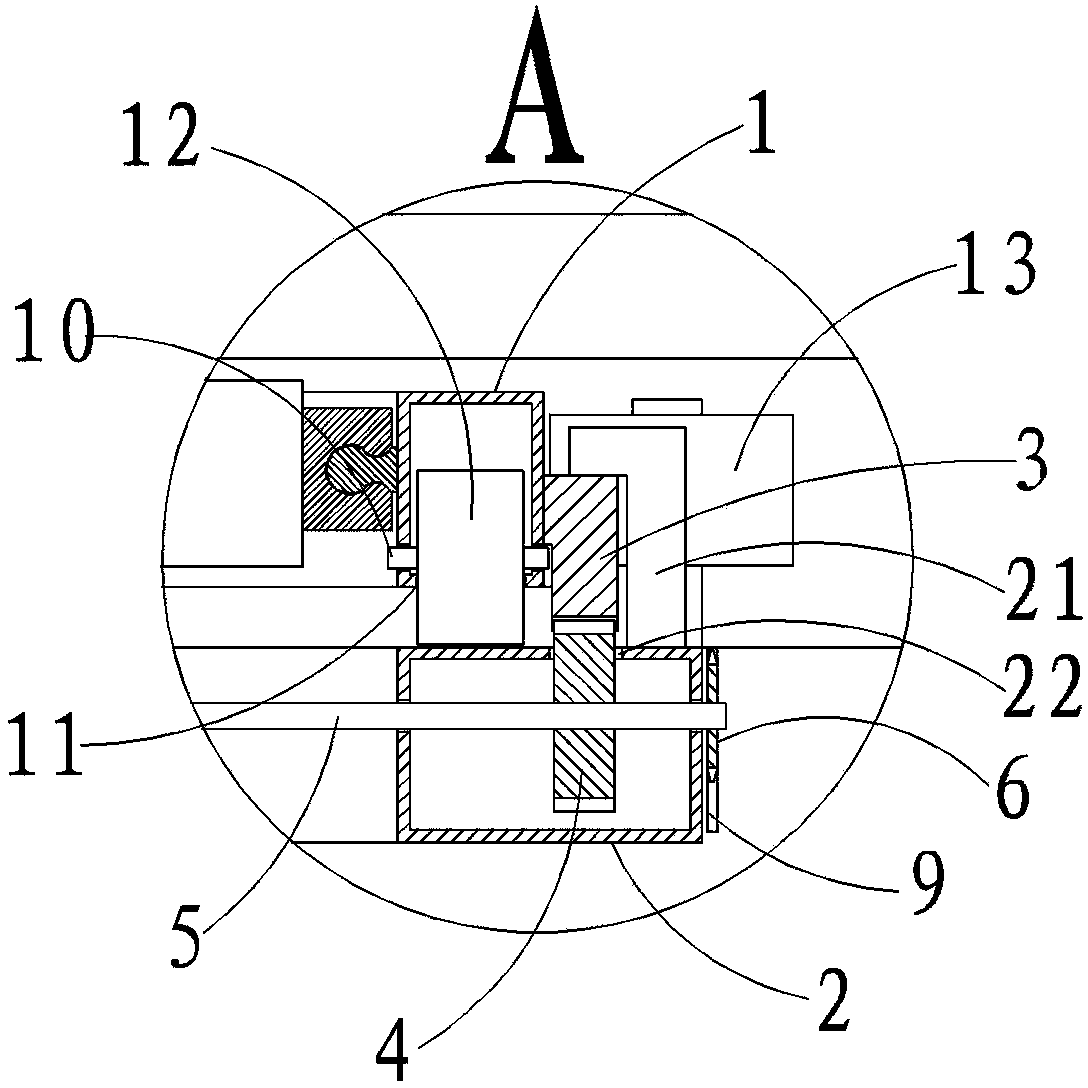

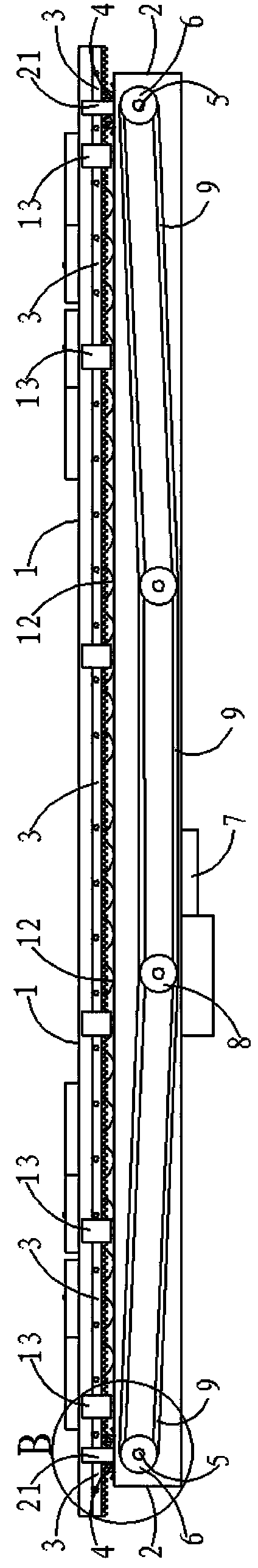

[0027] See attached Figures 1 to 8 In this embodiment, a connecting mechanism for a horizontal platform of a mechanical garage includes a carrying mechanism for carrying automobiles, a pushing mechanism, and a connecting mechanism; The clamping mechanism is a transmission rack 3 arranged parallel to the movement direction of the upper ring beam 1; the pushing mechanism includes: a lower ring beam 2, a pushing gear 4 arranged on the lower ring beam 2 and engaged with the rack 3; the engaging mechanism includes : Two rows of parallel traveling wheels 12 embedded in the upper ring beam, and a slideway 14 corresponding to the traveling wheels 12 arranged on the parking space; the upper ring beam 1 is pressed on the lower ring beam 2 by the traveling wheels 12 The upper ring beam 1 corresponds to the lower ring beam 2 .

[0028] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com