A rotary power connection device

A technology of power connection and rotation, which is applied to the parts of the connection device, flexible/rotatable wire connectors, connections, etc., which can solve the problem that the ultrasonic signal of the ultrasonic generator cannot be smoothly transmitted to the vibrator head, affecting water quality, and inconvenient to handle and other problems, to achieve the effect of good waterproof function, good sealing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

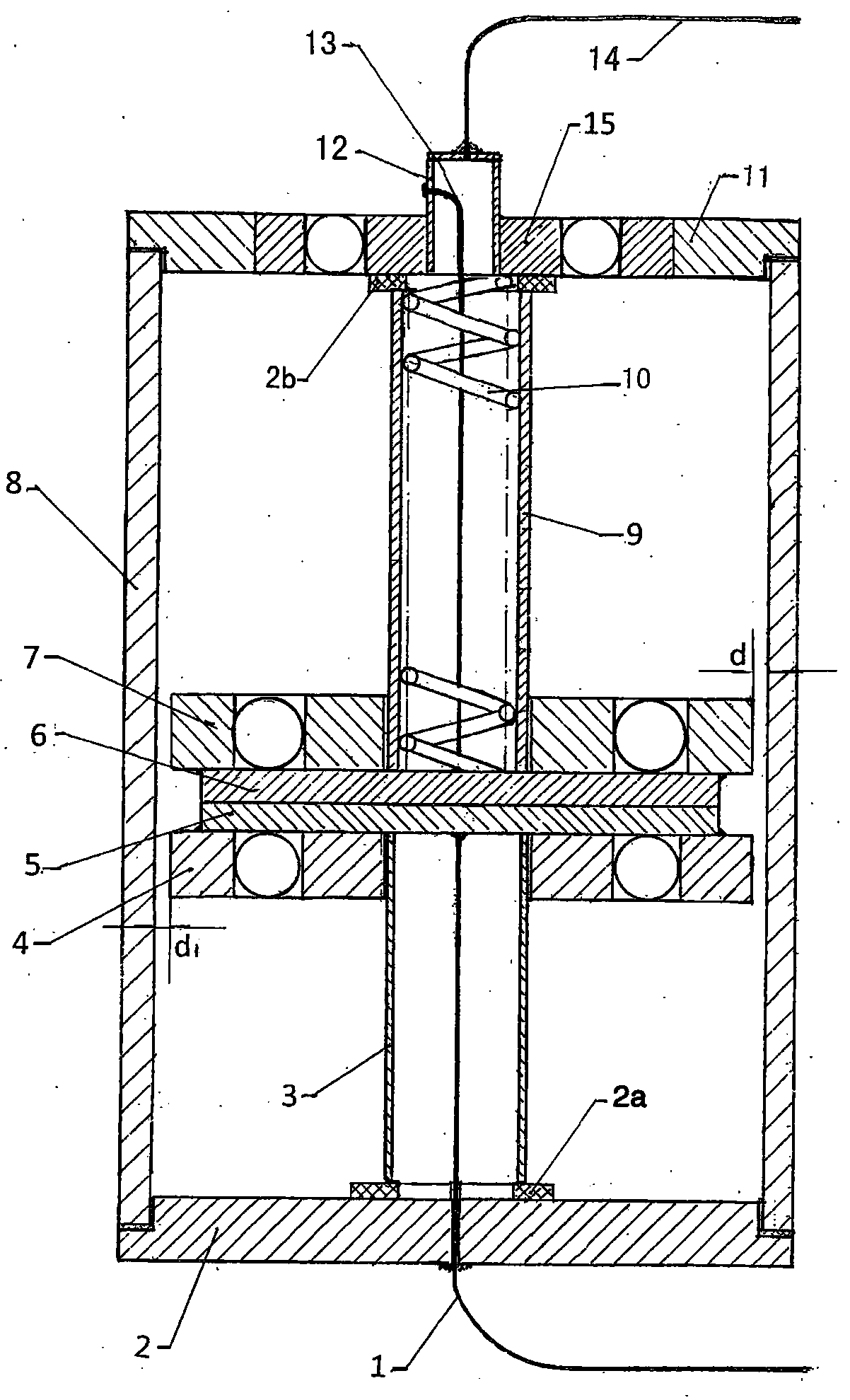

[0007] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0008] as attached figure 1 As shown, a rotary power supply connection device (also called a rotary signal source connection device) according to the present invention includes a vibrator head wire 1, a screw-down sealing cover 2, a lower inner sealing ring 2a, a lower cavity Sleeve 3, lower rotating body 4, lower rotating conductive plate 5, upper rotating conductive plate 6, upper rotating body 7, sheath 8, upper cavity casing 9, spring ring 10, upper rotating sealing cover 11, upper inner sealing ring 2b. Terminal post / box 12, ultrasonic source wire 13, ultrasonic current output line 14 and top rotating body 15, wherein the lower rotating body 4, upper rotating body 7 and top rotating body 15 can use rolling bearings of different specifications or the same specification Or rolling bearing structural products, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com