Floating roll device for splitting machine

A floating roller and slitting machine technology, which is used in transportation and packaging, metal processing, coiling strips, etc., can solve the problems of high requirements for floating roller material and processing, not meeting economic indicators and requirements, and difficult to improve, etc. Achieve the effect of simple structure, easy control and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

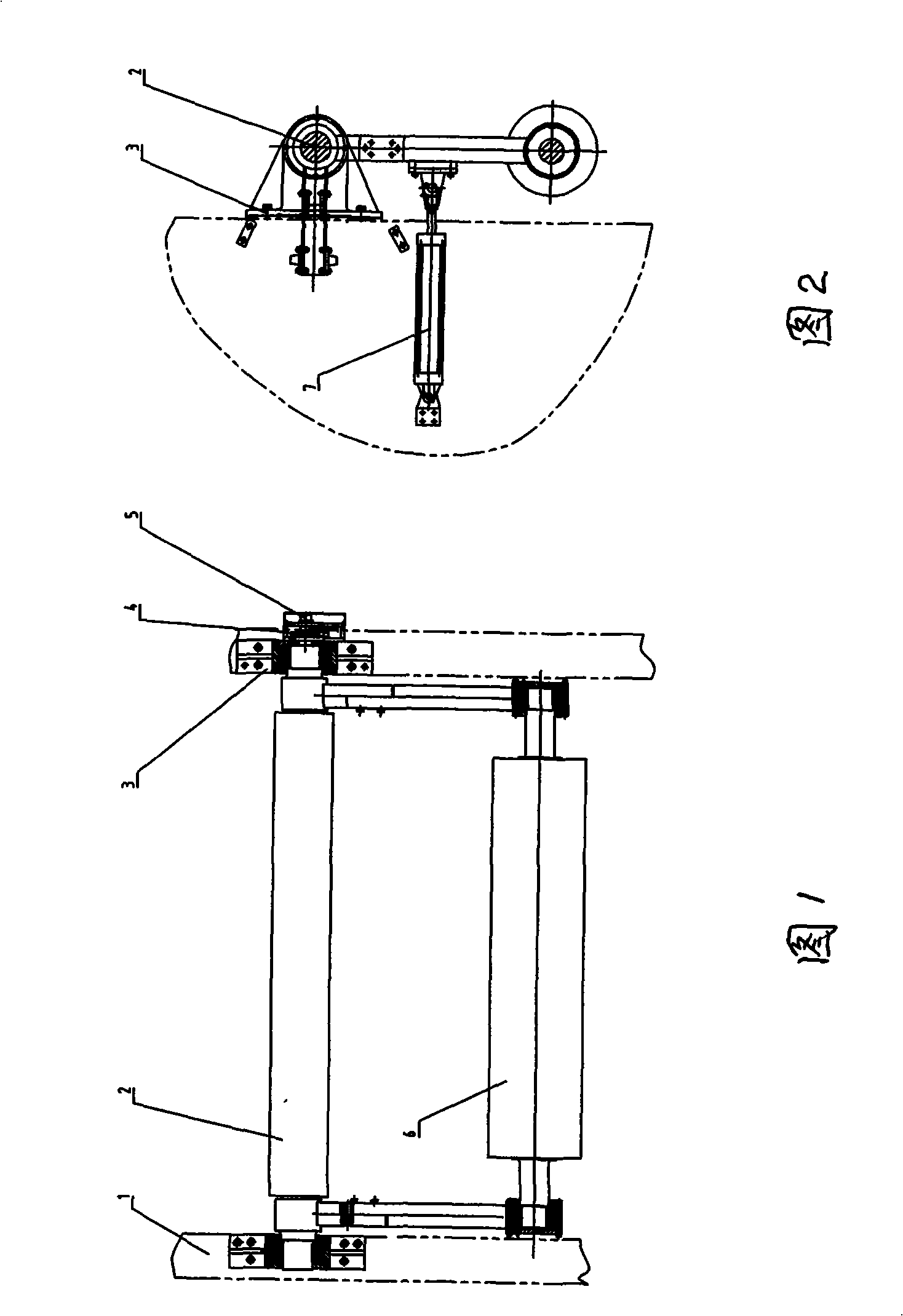

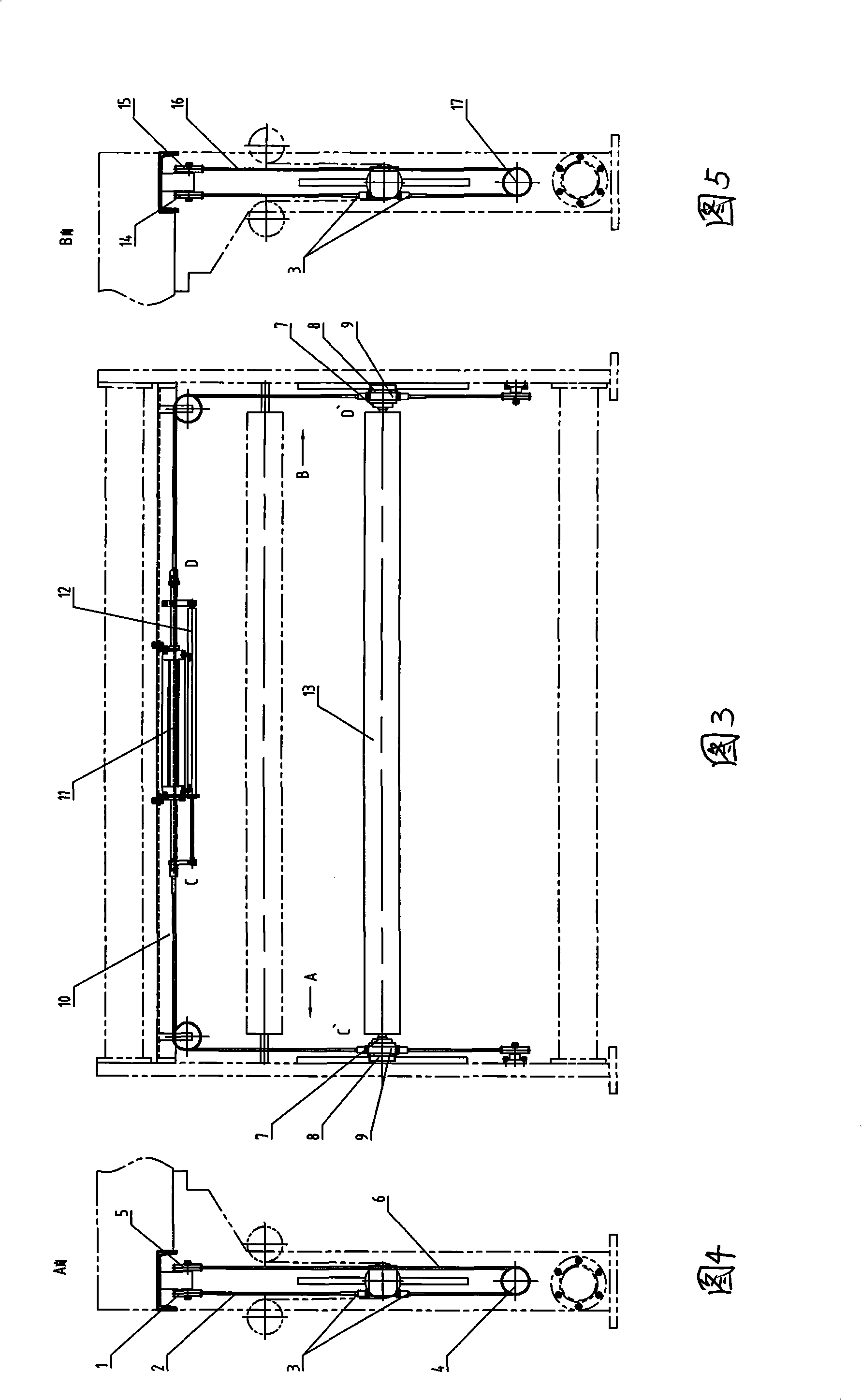

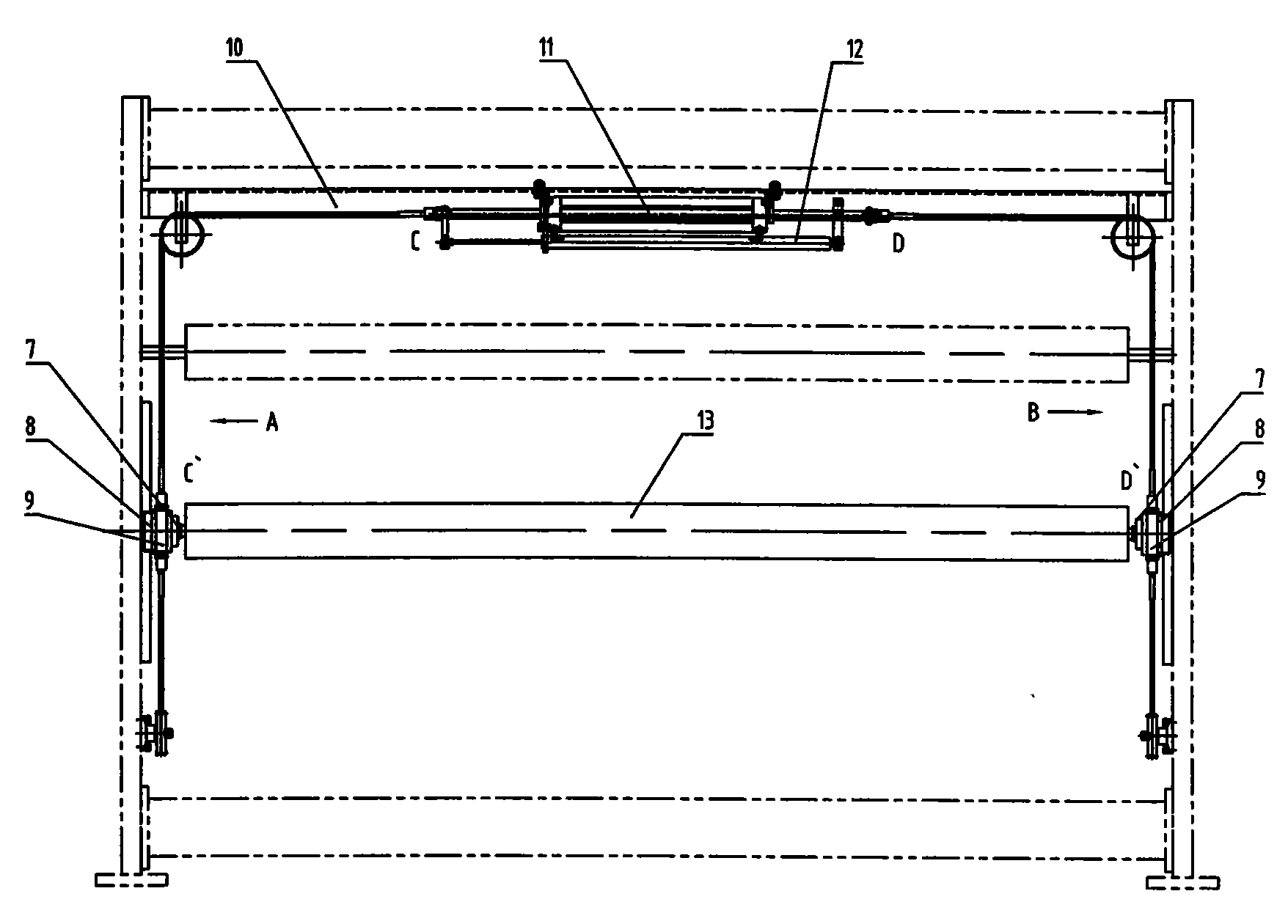

[0013] Such as image 3 , Figure 4 , Figure 5 Shown: the floating roller device for the slitting machine of this embodiment, on the position corresponding to the inside of the two wallboards, a linear guide rail is installed on one side, and the floating roller 13 passes through the circular outer spherical ball bearing 8 with a boss and the mounting plate 9 is installed on the linear guide rail slider, so that the floating roller 13 can move vertically up and down. The beam 10 installed with the double-rod double-acting standard cylinder 11 is also installed in the two wall panels and directly above the floating roller. Once the C end of the piston rod is stretched out, the position of the floating roller 13 is determined by detecting the movement of the piston rod of the cylinder. Stay rope I 2 goes around pulley I 1 and is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com