Medium-five-roller constant speed conveyor

A conveyor and conveying roller technology, applied in the field of middle five-roller constant-speed conveyor, can solve the problems of non-constant speed conveying, spinning machine blockage, broken and crossed lines, etc., to reduce the possibility of broken and crossed lines. , to ensure the effect of synchronous action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

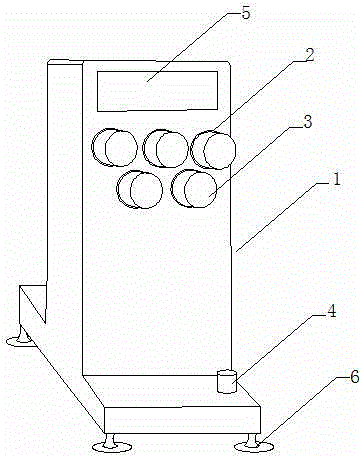

[0013] Such as figure 1 A medium five-roller constant-speed conveyor shown includes a box body 1; a five-ring through hole 2 is provided on one side of the box body; a conveying roller 3 is installed inside the five-ring through hole; the bottom of the box body 1 There is an installation position 4 for the original yarn bobbin; a double closed-loop DC speed control system (not shown) is installed inside the box body 1; the motor and the conveying roller 3 of the double closed-loop DC speed control system are installed through the same belt; The double-closed-loop DC speed control system is installed in cooperation with the PLC controller (not shown); the conveying roller status instrument bit 5 is installed on the upper side of the five-ring through hole 2; the conveying roller status instrument bit 5 is electrically connected to the PLC controller ; Since the dual-loop control of the DC motor by the double-closed-loop DC speed regulation system belongs to the prior art, it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com