Precision four-post hydraulic cutting machine

A cutting machine and hydraulic technology, applied in metal processing and other directions, can solve the problems of inability to guarantee the synchronous action of four columns, low cutting pressure, low work efficiency, etc., and achieve the effect of good cutting effect, fast blanking speed and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

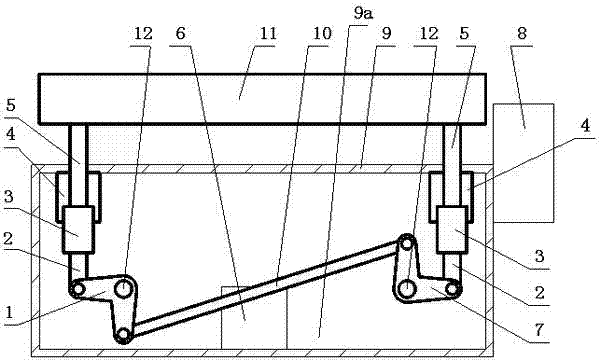

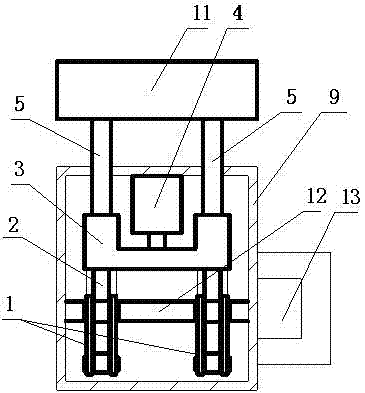

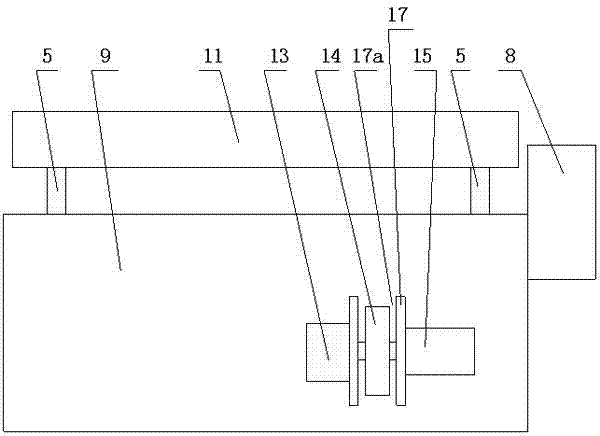

[0015] Embodiment 1: refer to Figure 1~3 . The precision four-column hydraulic cutting machine includes a body 9 containing an oil tank 9a, a pressure back 11, and columns 5 are installed in the four corner holes of the body 9. The lower ends of the two columns 5 on the left and right sides are fixedly connected with hinge seats 3. The upper ends of the columns 5 are respectively connected to the pressure The lower end of the back 11 is fixedly connected, an oil cylinder 4 is arranged between the upper end of the body 9 and the hinge seat 3, the cylinder body of the oil cylinder 4 is fixedly connected with the upper end of the body 9, and the piston rod end is fixedly connected with the hinge seat 3, and the hinge seat in the body 9 3. There is a linkage assembly below. The linkage assembly includes two sets of C-shaped rocker arms 1, C-shaped rocker arms 7, and linkage arms 10. The first C-shaped rocker arm 1 on the left side of the body faces downwards, and the first C-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com