Profile steel buckling stacking method and stacking equipment

A section steel and stacking technology, which is applied in the field of section steel buckle stacking method and stacking equipment, can solve the problems of time-consuming and laborious, high labor intensity and slow speed of manual turning over section steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

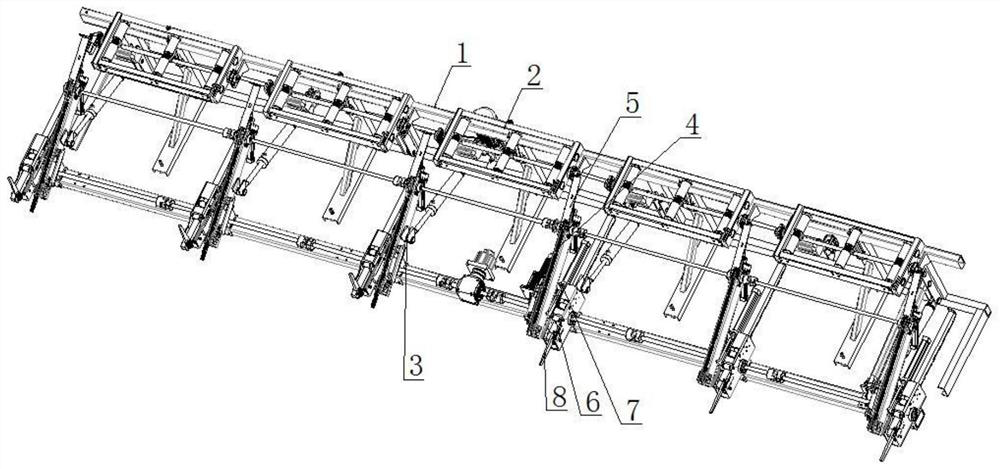

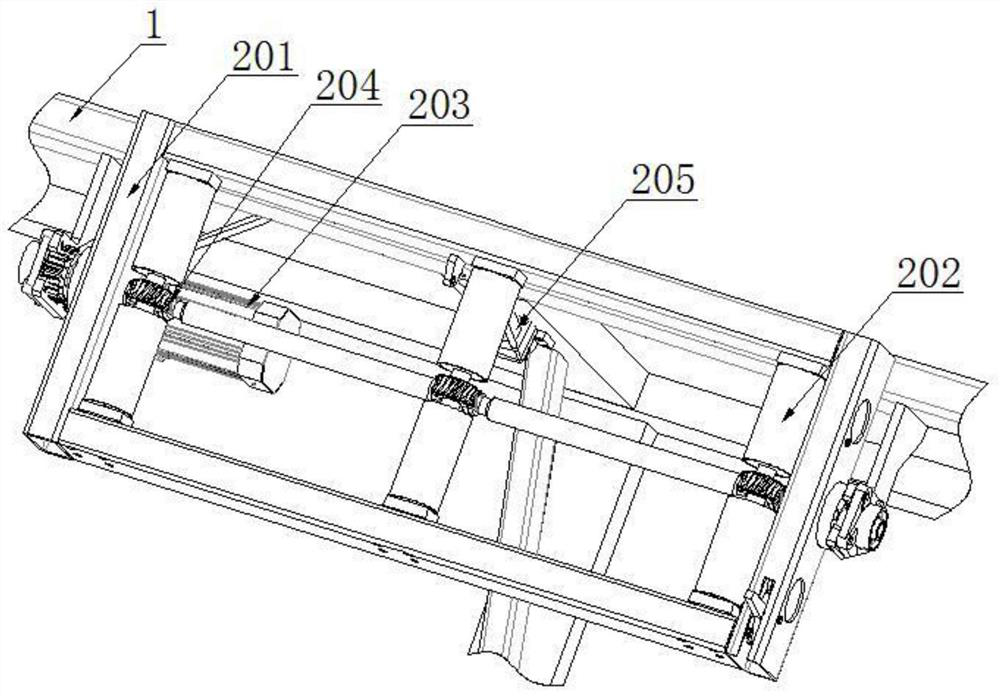

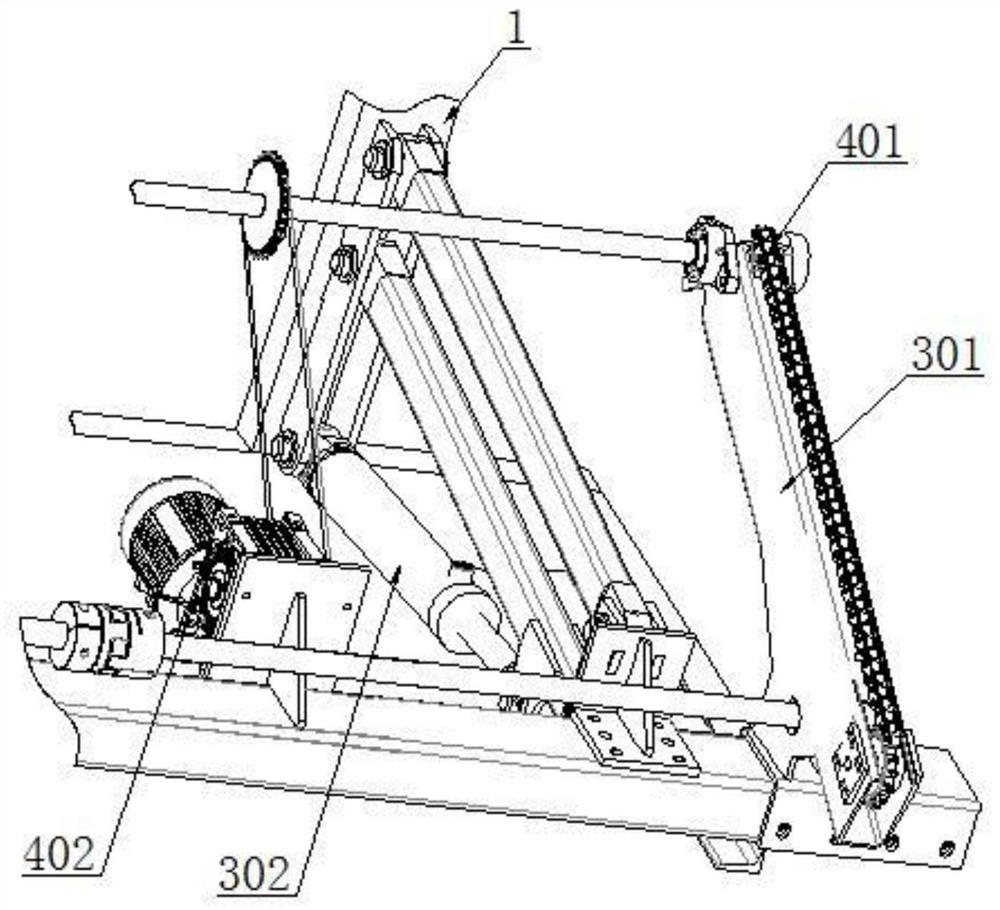

[0032] Such as Figure 1-Figure 7 As shown, the section steel buckle stacking equipment includes a frame 1, and a first conveying mechanism 2 that is transmitted in the left and right direction and rotates up and down is installed on the frame 1. The first conveying mechanism 2 is hinged with the frame 1. Conveying frame 201, the conveying roller 202 that is installed on the conveying frame 201 and rotates along the left-right direction, the first motor 203 that is installed on the conveying frame 201, the worm gear transmission that is connected between the output shaft end of the first motor 203 and the conveying roller 202 The mechanism 204 and the first air cylinder 205 connected between the transport frame 201 and the frame 1 constitute. The lifting mechanism 3 that moves up and down is installed below the first conveying mechanism 2 on the frame 1, and the lifting mechanism 3 is a lifting frame 301 that is hinged with the frame 1 and rotates up and down, and is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com