Assembled foam stacking and unstacking equipment

An assembled and foam technology, which is applied in the direction of unstacking of objects, stacking of objects, transportation and packaging, etc., can solve problems such as single function, difficult process, insufficient speed of automatic palletizing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

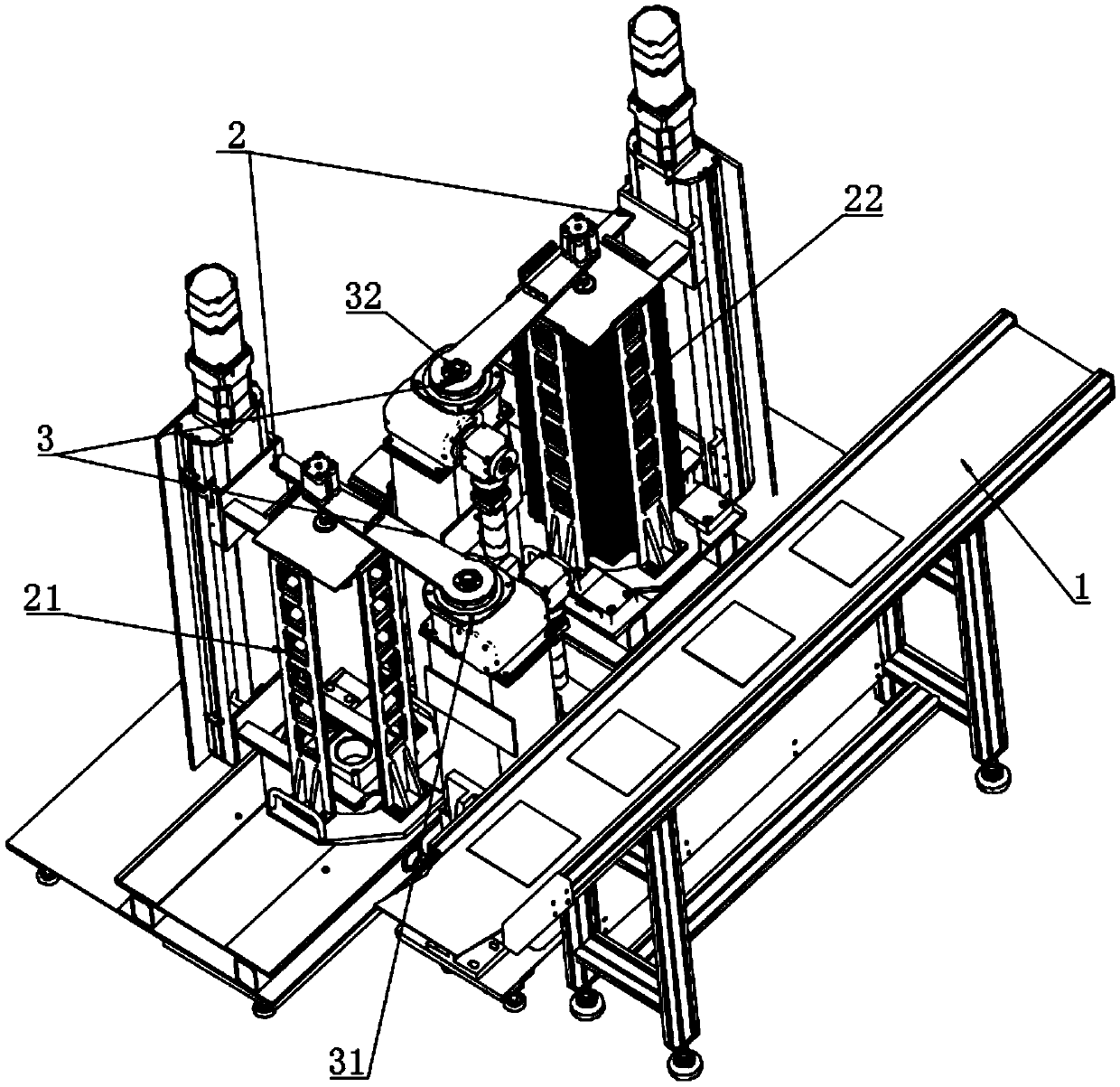

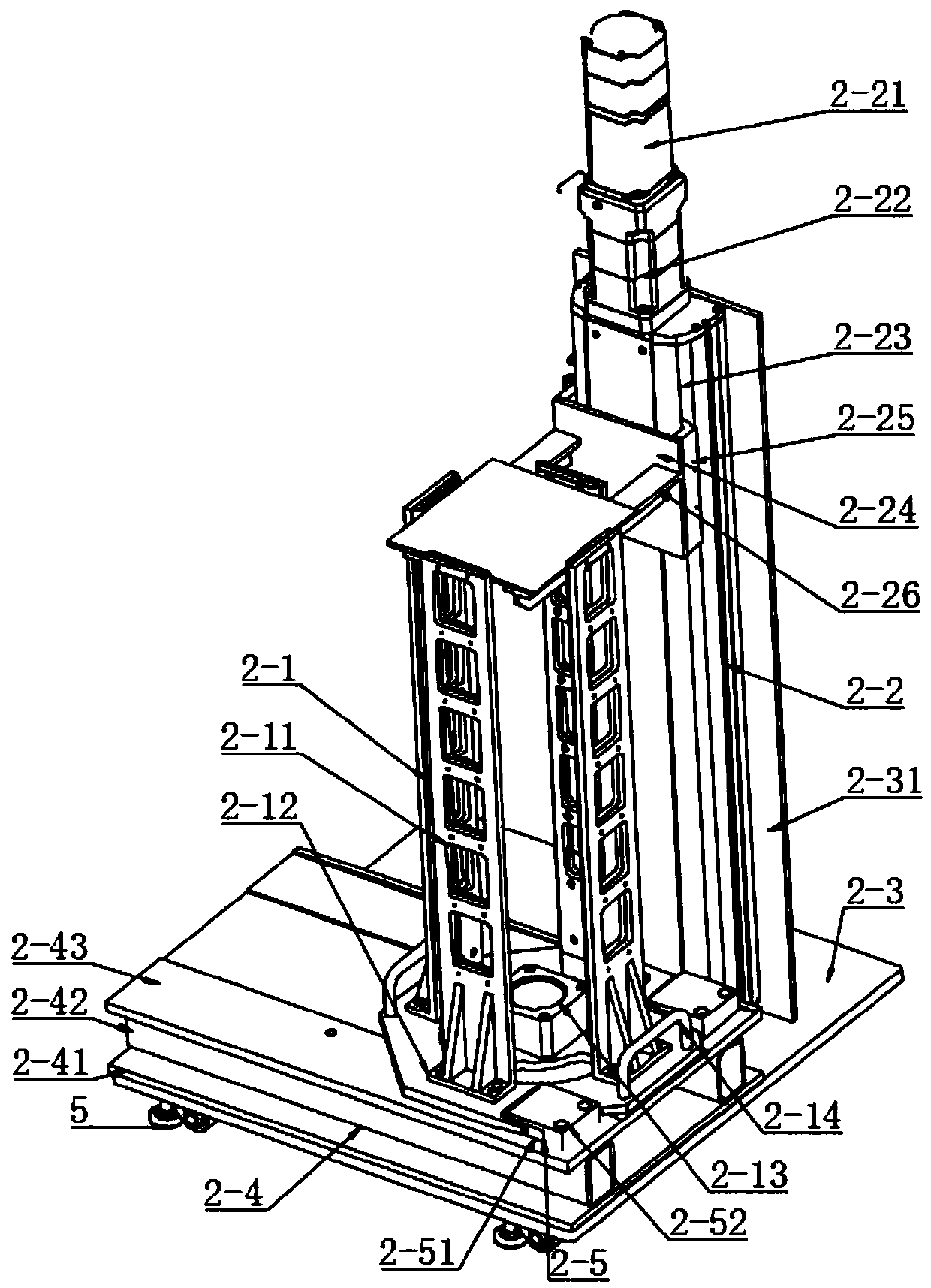

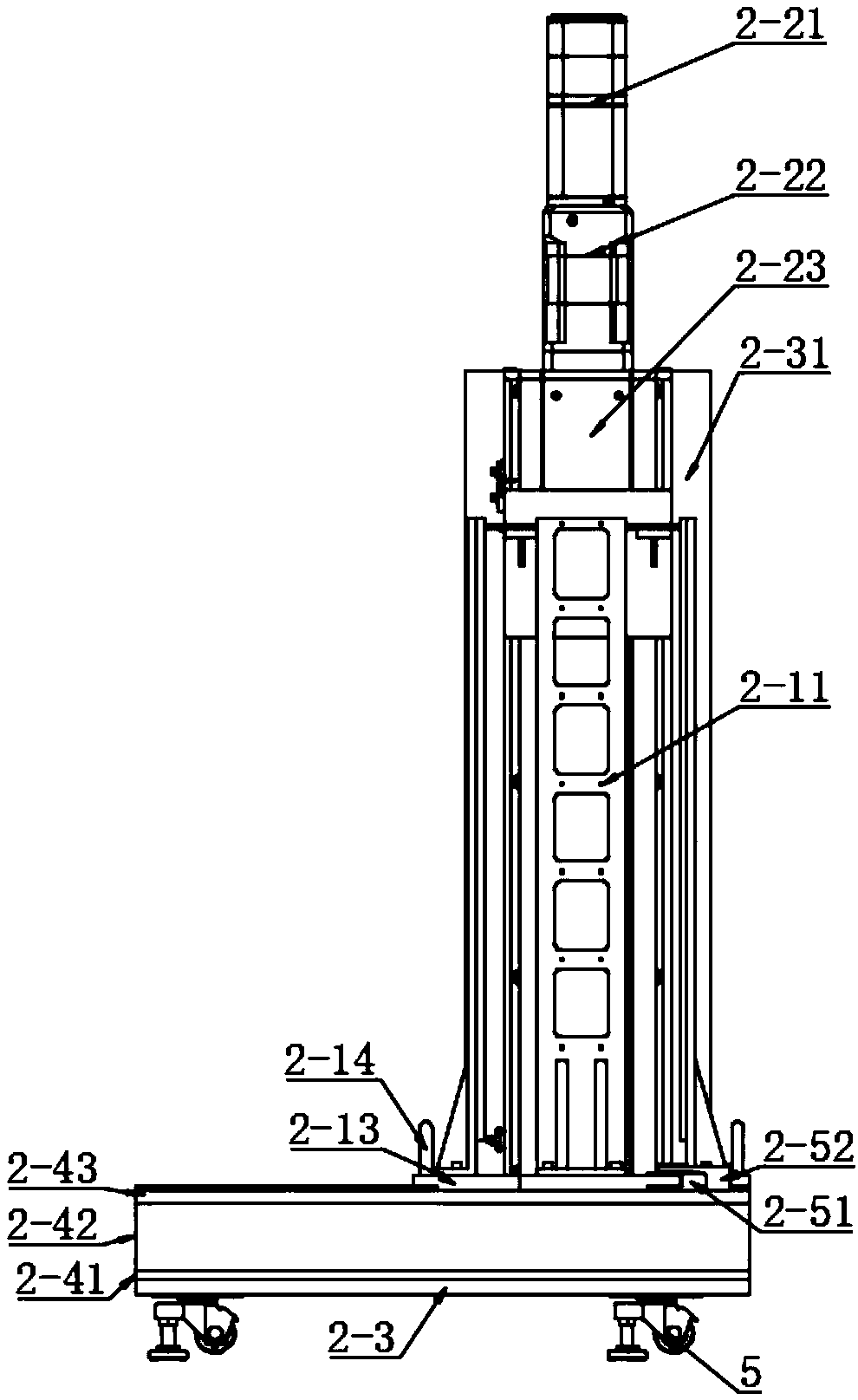

[0059] An assembled foam palletizing and depalletizing equipment, such as figure 1 As shown, it includes: belt line 1 for conveying foam; stacking tool 2 on the side of belt line 1, stacking tool 2 includes mixed stacking tool 21 for cross stacking of foam and hard platen, and separate stacking of hard platen The hard platen stacking tool 22; the manipulator 3 on the side of the belt line 1, the manipulator 3 includes the foam grabbing manipulator 31 for transferring foam between the belt line 1 and the mixed stacking tooling 21, and the hard platen stacking tooling 22 and mixing The rigid platen grasping manipulator 32 for transferring the hard platen between the stacking tooling 21; the detection system, the detection system is used to detect the operating status of the foam palletizing and depalletizing equipment, and sends the detection information to the control system; the control system, the control system It is used to receive the information of the detection system an...

Embodiment 2

[0097] In this embodiment, the equipment in Embodiment 1 is used for the palletizing of foam, such as Figure 12 As shown, in this embodiment, the belt assembly line is arranged at the rear end of the cutting station, and the cut foam is installed in a certain order and the distance interval is sequentially transported from left to right. The upper side of the belt assembly line 1 is provided with a foam Cotton grabbing manipulator 31, the upper side of foam cotton grabbing manipulator 31 is provided with a mixed stacking tool 21, and the right side of mixed stacking tool 21 is provided with a hard platen grasping manipulator 32 and a hard platen stacking tooling 22 in turn, The above-mentioned manipulator and stacking tool are all moved and fixed by casters, and combined and assembled into the foam stacking equipment of the embodiment.

[0098] In order to better understand this embodiment, a complete description of the workflow of this embodiment is given below:

[0099] Fi...

Embodiment 3

[0114] In this embodiment, the equipment in Embodiment 1 is used for the destacking of foam, as Figure 13 As shown, in this embodiment, a foam grabbing manipulator 31 is arranged on the upper side of the belt assembly line 1, and a mixed stacking tool 21 is set on the upper side of the foam grabbing manipulator 31, and the right side of the mixed stacking tooling 21 is arranged in turn. There is a hard platen grasping manipulator 32 and a hard platen stacking tool 22, the above-mentioned manipulator and stacking tooling are all moved and fixed by casters, combined with the foam destacking equipment of the embodiment.

[0115] In order to better understand this embodiment, a complete description of the workflow of this embodiment is given below:

[0116] First of all, the tooling needs to be in place, including the mixed stacking tooling 21 and the hard platen stacking tooling 22 in place.

[0117] The mixed stacking tool 21 is in place: first the fork frame 2-24 connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com