Abrasive paper stacker and abrasive paper stacking method thereof

A palletizer and sandpaper technology, applied in thin material handling, sending objects, transportation and packaging, etc., can solve the problems of error-prone, high labor cost, low sandpaper palletizing efficiency, etc. The effect of fast palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

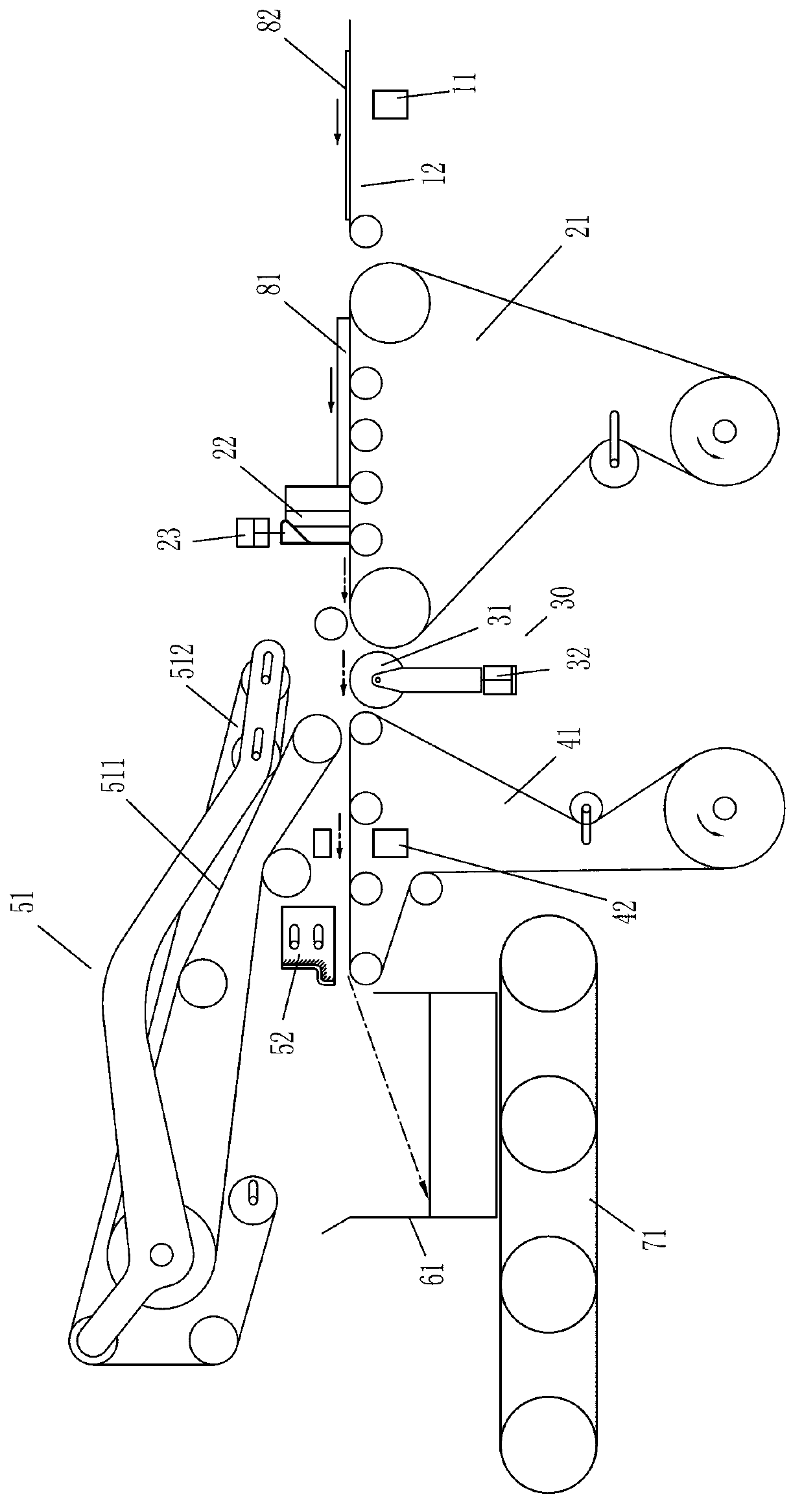

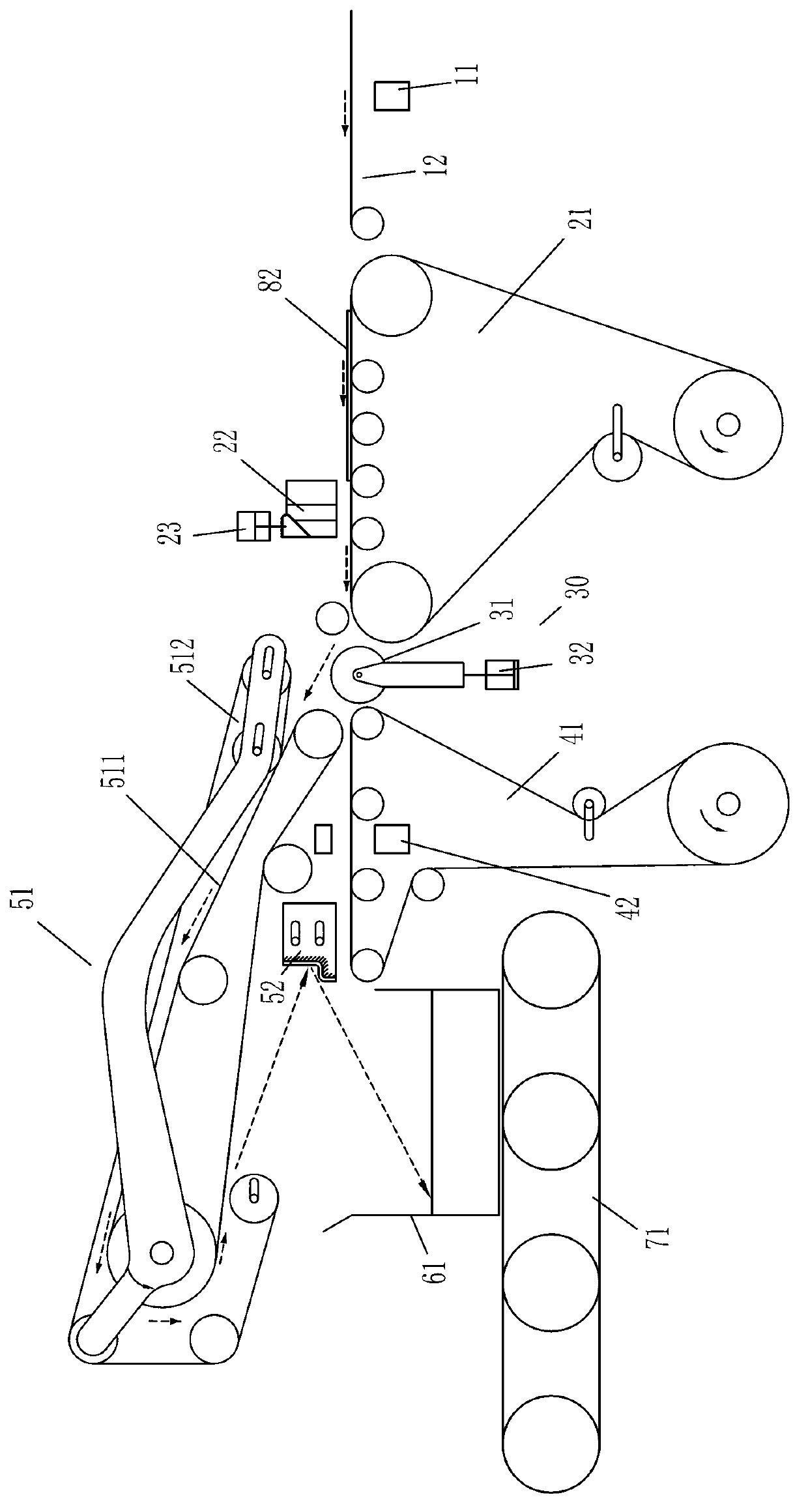

[0018] In the present invention, the sand surface of the sandpaper transported into the sandpaper palletizer of the present invention is directly stacked without turning 180 degrees, which is called forward stacking, and the sandpaper of the set forward stacking quantity is completed at one time. It is called to complete a forward stacking. On the contrary, the sand surface of the sandpaper transported into the sandpaper palletizer of the present invention is turned over by 180 degrees and then stacked is called reverse stacking. Set the number of reverse stacks After the sandpaper is continuously stacked in reverse, it is said to complete a reverse stack.

[0019] Such as figure 1 and figure 2 As shown, the sandpaper palletizer of the present invention includes a sandpaper conveying device 12, an intermittent feeding device 21, a forward conveying device 41, an overturning conveying device 51, a forward and reverse conversion guiding device 30, a bucket platform 52, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com