Full-automatic cutting all-in-one machine for pearl wool

A kind of pearl cotton, fully automatic technology, applied in thin material processing, metal processing, transportation and packaging, etc., can solve the problems of reduced production efficiency, waste of labor, no automatic stacking mechanism, etc., to avoid incision damage and reduce material waste. , to avoid the effect of excessive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

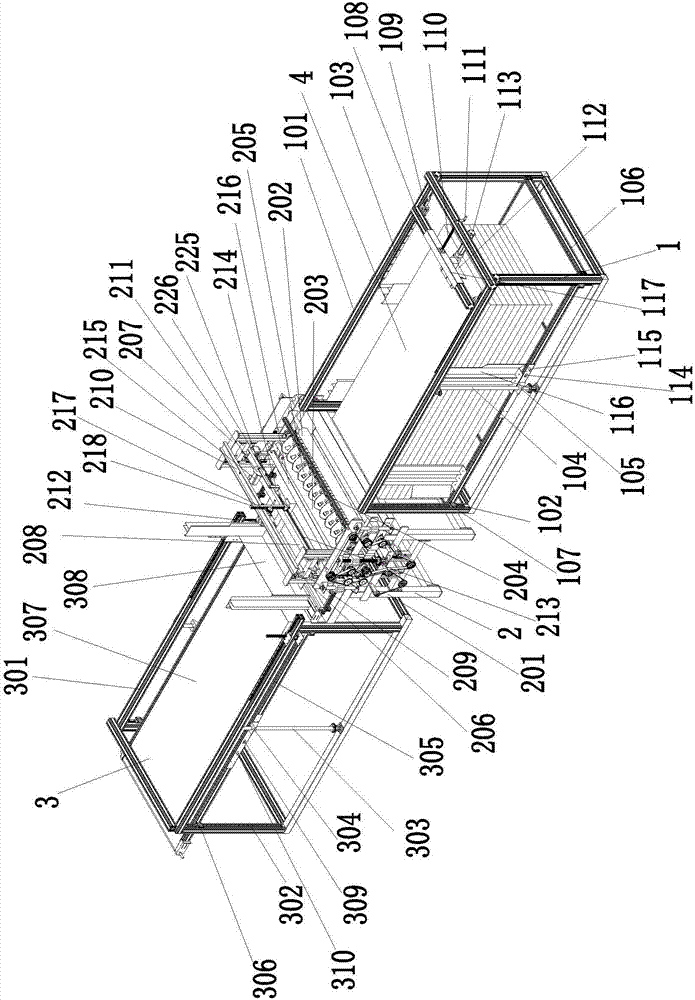

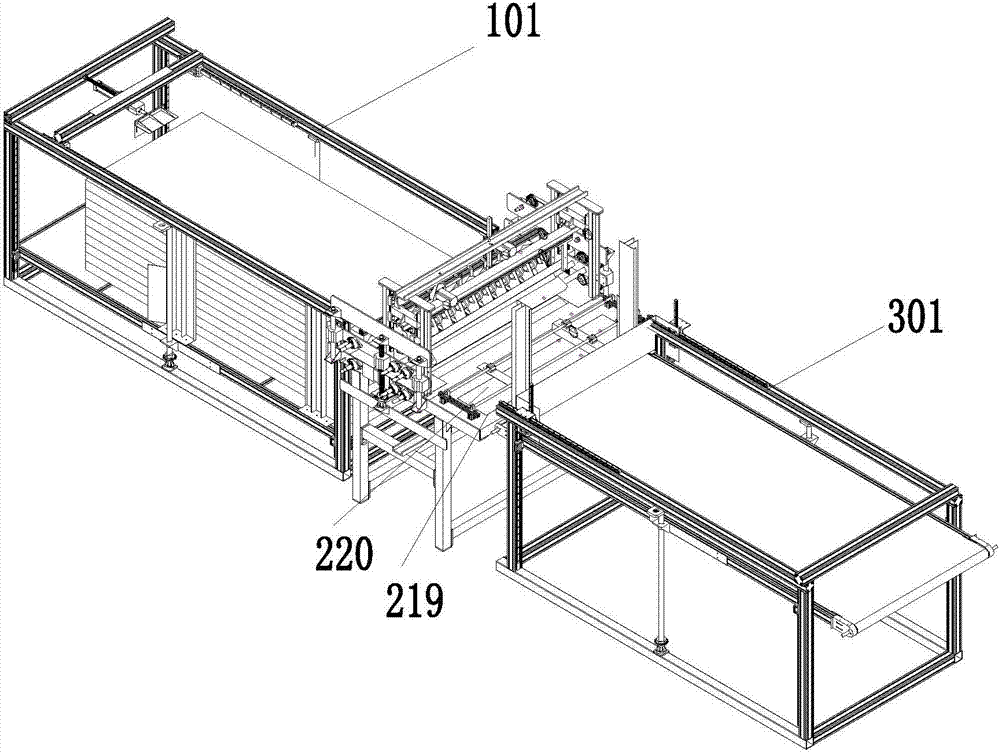

[0032] Example: Fully automatic pearl cotton cutting integrated machine, the composition is as Figure 1 to Figure 5 As shown, it includes an automatic feeding mechanism 1, a horizontal and vertical cutting mechanism 2 and a material discharging mechanism 3 arranged in sequence along the pearl cotton conveying direction;

[0033] The automatic feeding mechanism 1 includes a feeding frame 101, a feeding lifting mechanism is arranged on the feeding frame 101, a feeding lifting frame 106 is arranged above the feeding lifting mechanism, and pearl cotton 4 is stacked on the feeding lifting frame 106. In the upper part of the feed rack 101 is provided with a feeding pusher mechanism, and the end of the feeding pusher mechanism is provided with a push plate 112;

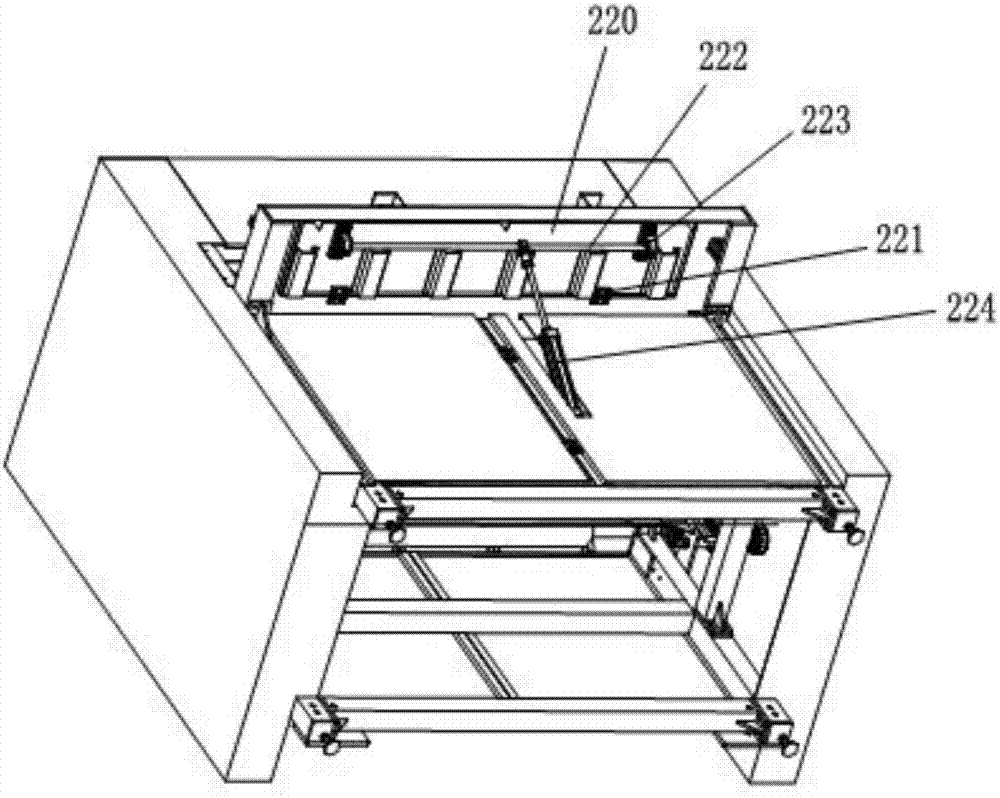

[0034] The horizontal and vertical cutting mechanism 2 includes a cutting frame 201. The cutting frame 201 is provided with a conveying guide roller group, a vertical cutting mechanism and a cross cutting mechanism in sequence a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com