Autoclaved aerated concrete slab AAC-S finished product discharging continuous stacking device and method

A technology of concrete slabs and autoclaved gas filling, which is applied in the field of palletizing devices, can solve problems such as easy skewing of stacking, achieve the effects of reducing frictional resistance, improving stacking efficiency, and preventing skewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

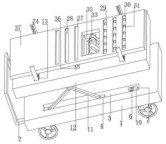

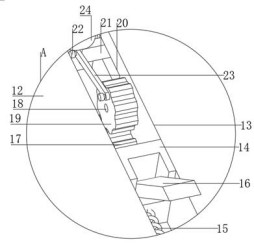

[0030] refer to Figure 1-5 , an autoclaved aerated concrete slab AAC-S finished product discharge continuous stacking device, including a bottom plate 1, a handle 2 fixed at one end of the bottom plate 1 through bolts, a plurality of moving wheels fixed at the bottom of the bottom plate 1 through bolts, and a set on the top of the bottom plate 1 There is a mounting plate 12, a lifting mechanism is arranged between the bottom plate 1 and the mounting plate 12, the top of the mounting plate 12 is provided with a second chute 13 symmetrically distributed on both sides, and a second sliding block 14 is slidably connected in the second chute 13, The same spring 15 is fixed by bolts between the second slide block 14 and the inner wall of the second chute 13, the inside of the second slide block 14 is rotatably connected with a pole 16, and the tops of a plurality of poles 16 are rotatably connected with the same spring 15 through a bearing. A supporting plate 37, the outer side of ...

Embodiment 2

[0040] refer to Figure 1-5 , the present invention also proposes a stacking method of an autoclaved aerated concrete slab AAC-S finished product discharge continuous stacking device, the specific steps are as follows:

[0041] S1. Stacking——When the external conveying mechanism transports the finished concrete slab to the pallet 37, one side of the concrete slab enters the pallet 37 first, and the left side of the pallet 37 is under pressure, so that the left side of the pallet 37 The side moves downward, and then drives the support rod 16 to press down, so that the second slider 14 moves to the outer end, and then drives the tooth plate 17 to move, and then meshes to drive the gear 19 to rotate. Through the transmission and cooperation of the positioning rod 22 and the sleeve rod 23, Make the extruding rod 24 follow the third sliding block 21 and move toward the inner end surface along the third chute 20, thereby forming an extrusion to the middle position of the concrete sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com