High-speed intelligent mushroom stick packaging production line

A packaging line and fungus stick technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of staff's inability to concentrate, low degree of automation, and poor packaging efficiency, so as to improve the convenience of packaging and improve production Efficiency, ease of palletizing and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

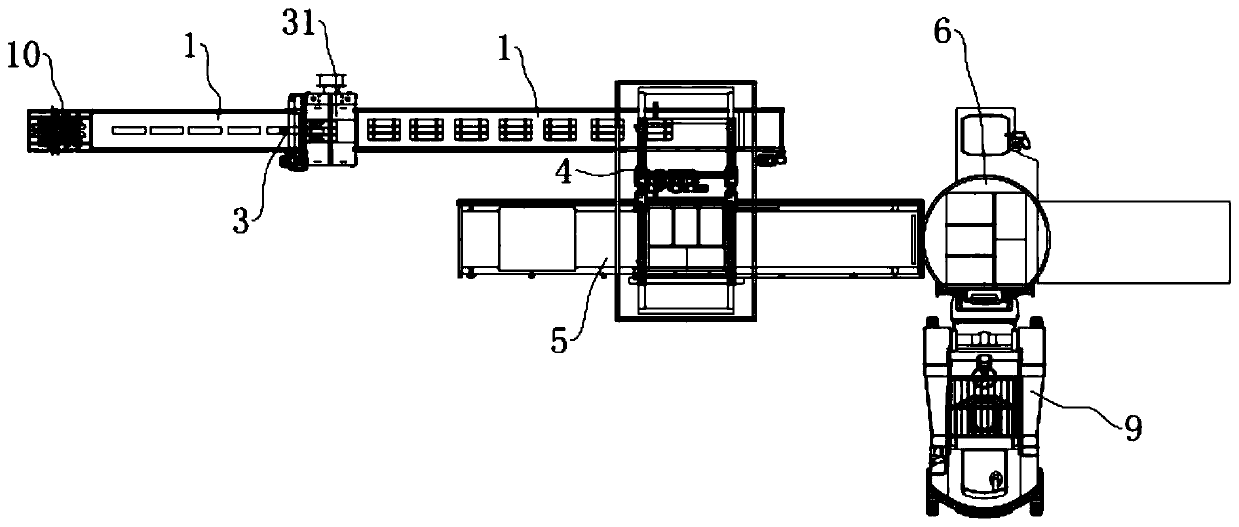

[0030] A high-speed intelligent bacterial stick packaging line, such as figure 1 As shown, it includes the conveying line 1 and the bacteria stick grasping manipulator 2, the bacteria stick sorting mechanism and the palletizer 4 arranged along the conveying line 1 conveying direction in turn, and the feeding end of the conveying line 1 is provided with an automatic feeder for the bacteria sticks. Bacteria stick debag machine 10 for bag removal, the bacteria sticks are sent to the bacteria stick arrangement mechanism after the bacteria sticks are taken off the bag, and the bacteria sticks are put into the bacteria stick arrangement mechanism by the bacteria stick grasping manipulator 2 one by one to be integrated into the bacteria stick bag, and then sent Go to the palletizer 4 for automatic palletizing and automatic packing of mushroom sticks, which has the effect of improving production efficiency.

[0031] Such as figure 1 As shown, the mushroom stick sorting mechanism incl...

Embodiment 2

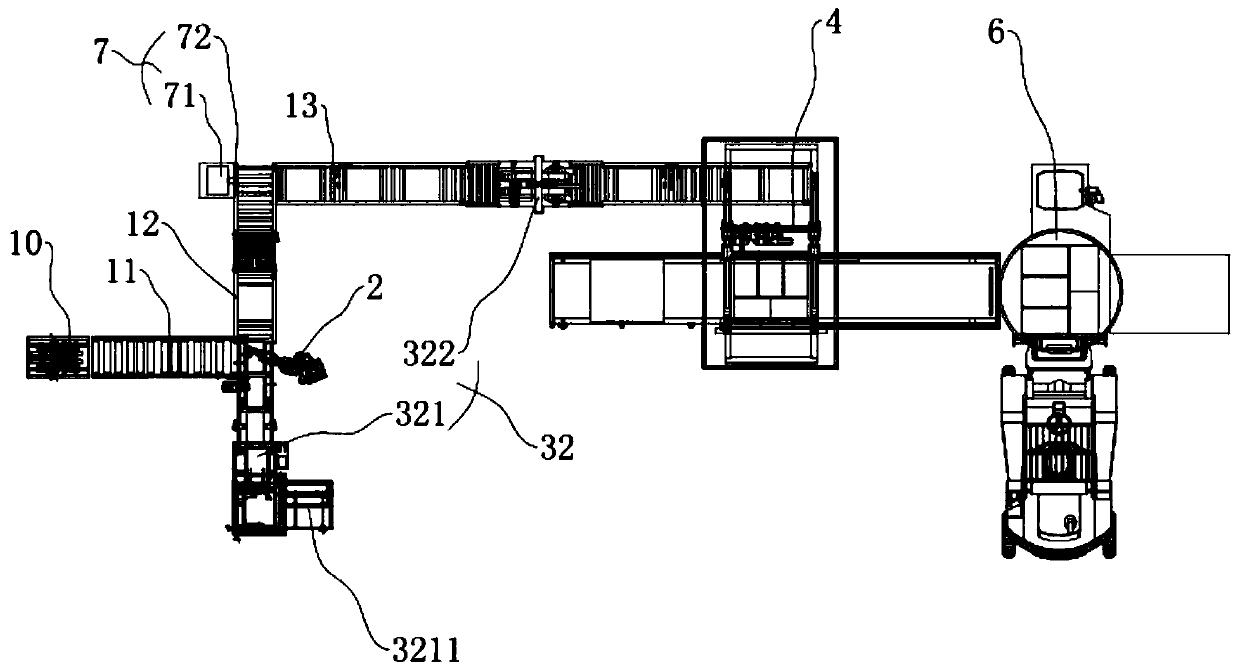

[0037]The difference between this embodiment and Embodiment 1 is that, if image 3 As shown, the bacteria stick finishing mechanism includes a boxing mechanism 32 installed on the conveying line 1, and the boxing mechanism 32 includes a cardboard box folding machine 321 and a box sealing machine 322 installed on the conveying line 1 along the conveying direction in sequence, wherein, in the cardboard One side of the box folding machine 321 is provided with a cardboard placing position 3211, so as to put in cardboard for automatic box folding operation. The case sealing machine 322 adopts an automatic case sealing machine 322 so as to automatically seal the carton opening.

[0038] Further, the conveying line 1 includes a rod conveyor 11, a box conveyor 12 and a stacking conveyor 13 arranged along the conveying direction, wherein the discharge end of the rod conveyor 11 is docked with the rod grabbing manipulator 2; The feeding end of the box conveyor 12 is docked with the car...

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that, if Figure 4 As shown, the bacteria stick arrangement mechanism includes a first branch line 33 and a second branch line 34 whose feed ends are all docked with the conveying line 1, a bacteria stick binding and packing machine 31 arranged on the first branch line 33 and a tying machine 31 arranged on the second line. The packing mechanism 32 on the two-point line 34, wherein the discharge ends of the first branch line 33 and the second branch line 34 are connected to the side of the conveyor line 1 near the stacker 4, and the conveyor line 1 is connected to The position of the first branch line 33 and the second branch line 34 is provided with a reversing mechanism 8 for switching between the first branch line 33 and the second branch line 34; the packing mechanism 32 is consistent with the structure of the second embodiment. Select the branching line that the bacteria sticks are transported by the reversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com