Full-automatic shaping and stacking device and method

A palletizing device and automatic technology, applied in the field of palletizing, can solve the problem that the development space of automatic palletizing equipment cannot be underestimated, and achieve the effect of compact structure and small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

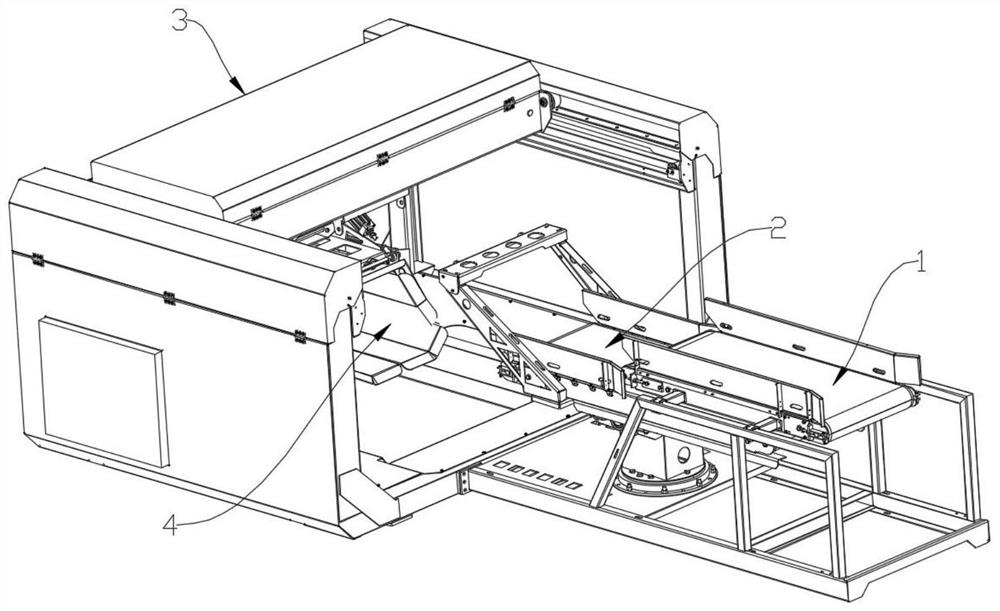

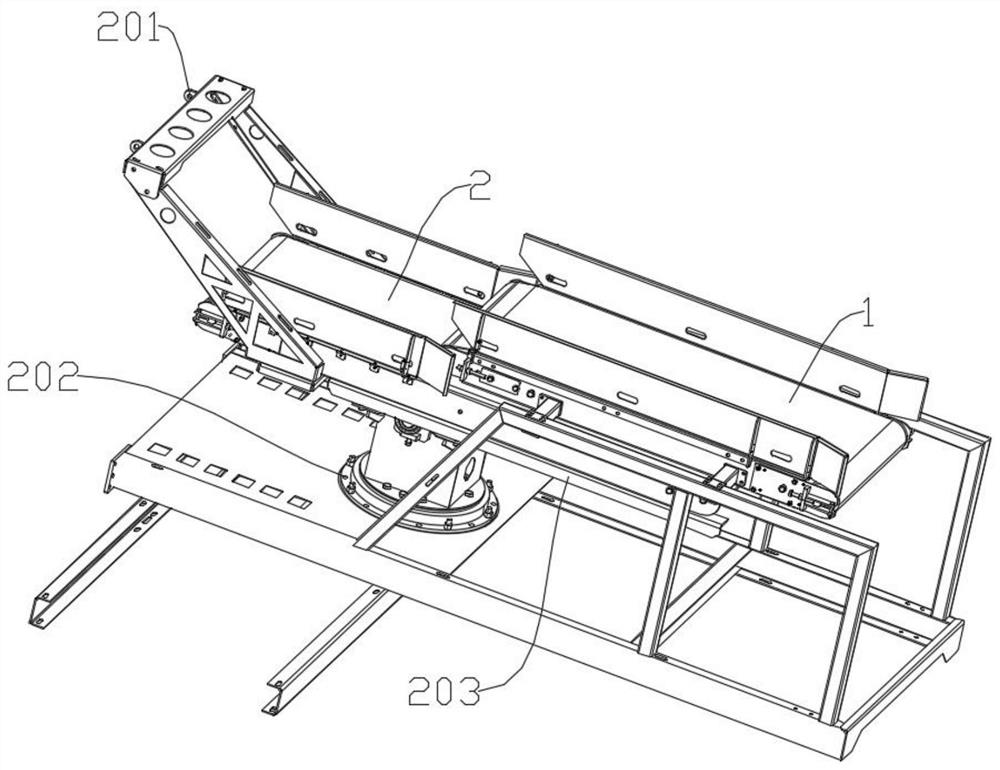

[0064] Such as figure 1 As shown, a fully automatic plastic palletizing device includes a feeding belt 1, a conveying mechanism 2, a manipulator 4, a manipulator driving mechanism 3, a palletizing mechanism 5, a tray loading mechanism 6, and an output mechanism 7.

[0065] Among them, the conveying mechanism 2 can transport the material to the manipulator 4; the manipulator 4 can receive the material from the conveying mechanism 2, and can shape the left and right sides of the material, and can place the material in the opening and closing mechanism after shaping Preliminary stacking is carried out on the opening and closing door 903 of 9; the palletizing mechanism 5 includes a lifting platform 508, and the lifting platform 508 receives the materials dropped by the opening and closing door 903, and the lifting platform 508 moves upward so that the upper surface of the material touches the opening and closing The lower surface of the door 903 forms the shaping of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com