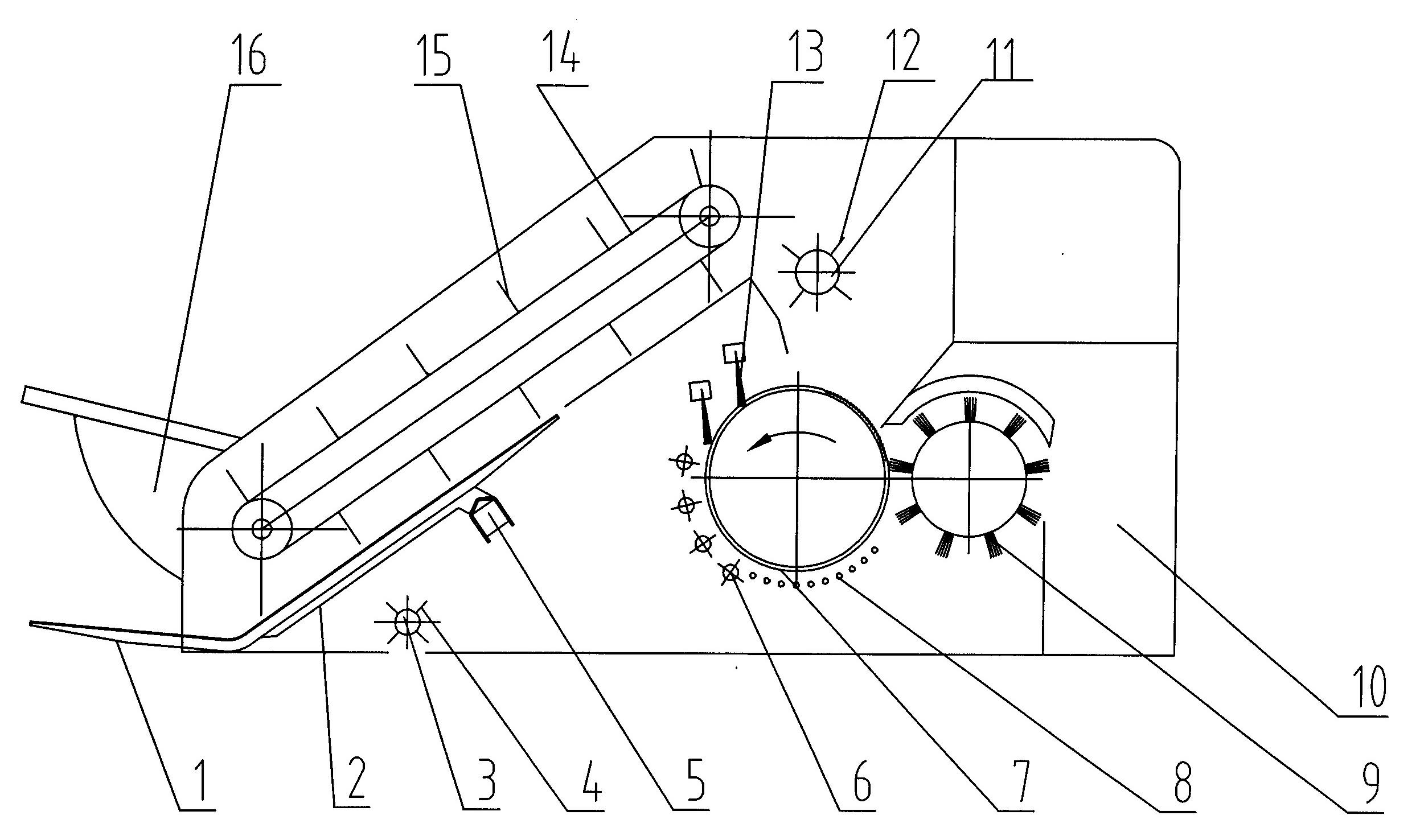

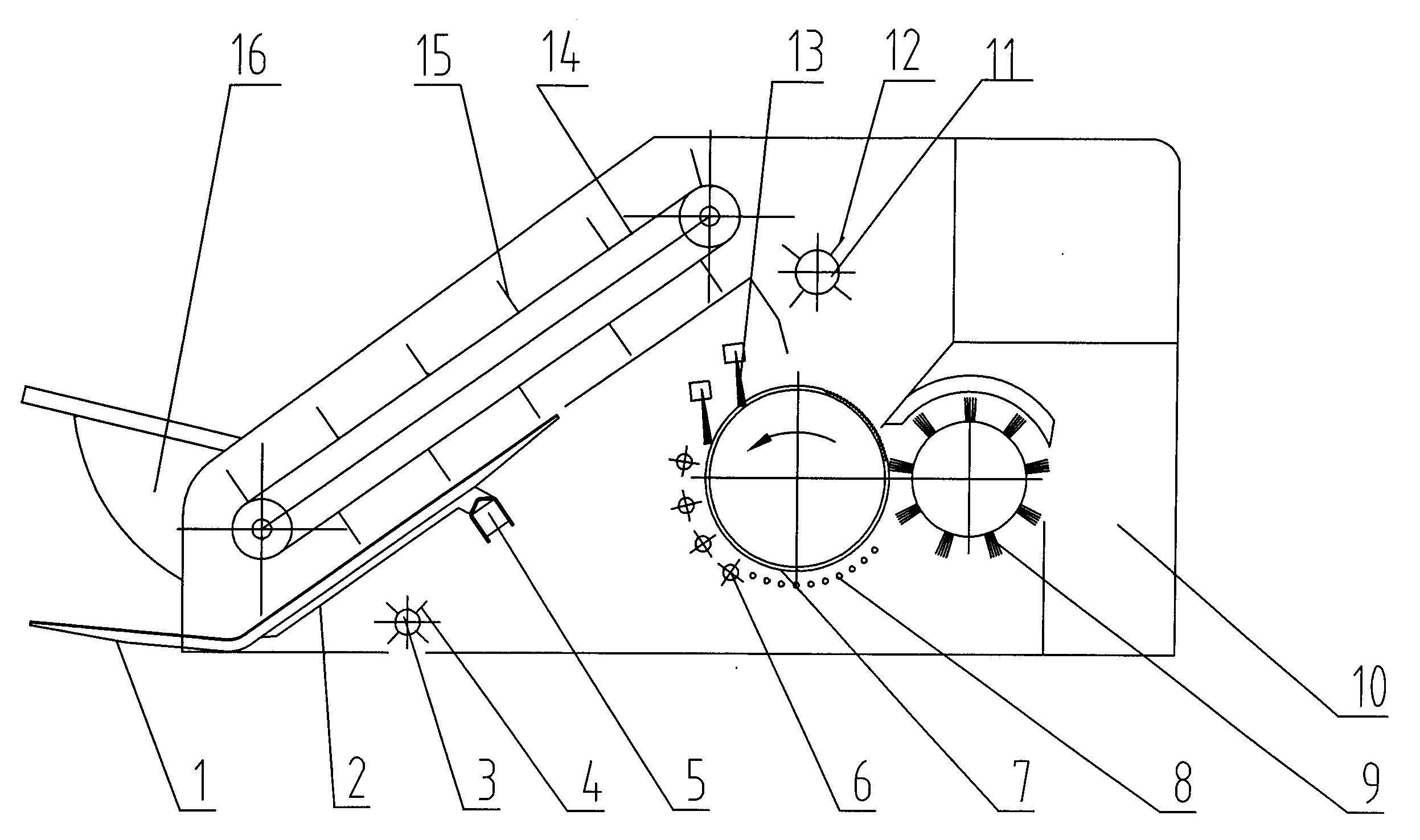

Combined comb-tooth-type cotton picker with self-cleaning function

A self-cleaning and combined technology, applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of increasing the cost of cotton processing, complex structure of the whole machine, impact on cotton quality, etc. Convenience and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A combined comb-tooth cotton picking device with self-cleaning function, as shown in the accompanying drawings, includes a power-driven chain rake conveying device 14 installed on the front end of the frame and a U-shaped sawtooth cylinder 7 and a wire brush. The cleaning device composed of cotton roller 9 is equipped with a cotton stem pressure guiding device 16 on the frame at the front of the picking table, and the comb teeth 1 parallel to each other are evenly distributed on the beam 5, and the front ends of the comb teeth 1 are inclined upwards. A power-driven anti-pushing roller 3 is arranged at the rear and lower part of the comb teeth 1, and a chain rake conveying device 14 matched with the comb teeth 1 is arranged above the comb teeth 1. At the outlet of the chain rake conveying device 14, A flower feeding roller 11 is arranged at the place, and a flower cleaning device composed of a U-shaped sawtooth cylinder 7 and a steel wire brushing roller 9 is arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com