Treatment system for separating manganese-iron alloy slag iron and separating method

A ferromanganese alloy slag and processing system technology, applied in the field of metallurgy, can solve the problems of difficult separation of slag and iron, high slag inclusion rate of products, low metal recovery rate, etc., to reduce labor intensity, high degree of automation, and high quality of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

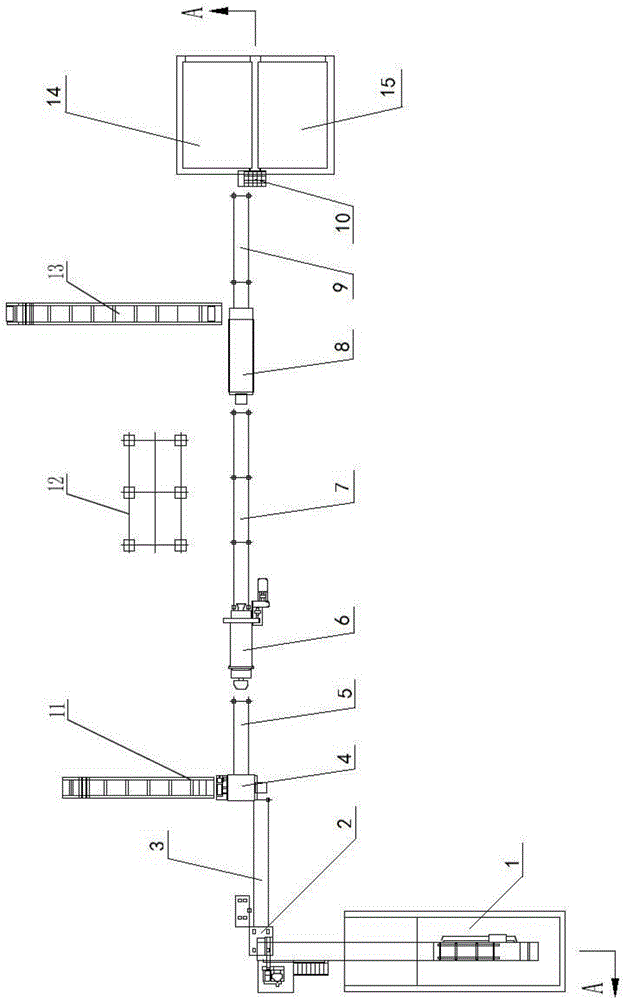

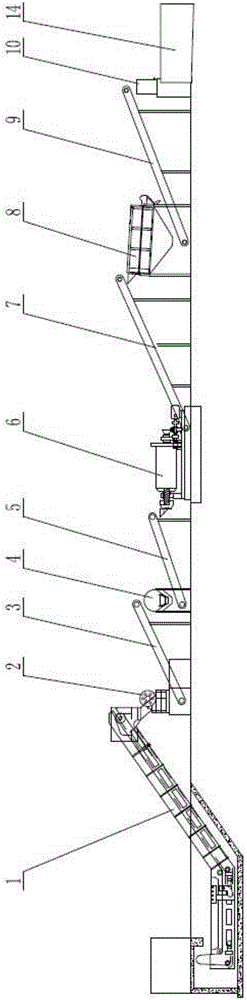

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a treatment system for separating ferromanganese alloy slag and iron, including a slag remover 1, a crusher 2, a first cylindrical screen 4, a ball mill 6, a second cylindrical screen 8 and a jig that are arranged in sequence 10. A first belt conveyor 3 is provided between the crusher 2 and the first cylindrical screen 4; a second belt conveyor 5 is provided between one of the outlets of the first cylindrical screen 4 and the ball mill 6; the ball mill 6 A third belt conveyor 7 is arranged between the second cylindrical screen 8; a fourth belt conveyor 9 is arranged between one side of the second cylindrical screen 8 and one side of the jig 10; The other side of the machine 10 is provided with a fine powder pool 14 and a tailings pool 15 . In addition, a fifth belt conveyor 11 is provided at the other discharge port of the first cylindrical screen 4 ; a sixth belt conveyor 13 is provided at the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com