Method for producing extra-coarse tungsten powder

A technology of tungsten powder and sodium tungstate, applied in the field of powder metallurgy, can solve the problems of long reduction time of ultra-coarse tungsten powder, difficult process control, high energy consumption, etc., and achieve the effect of good surface gloss, low cost and broad market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

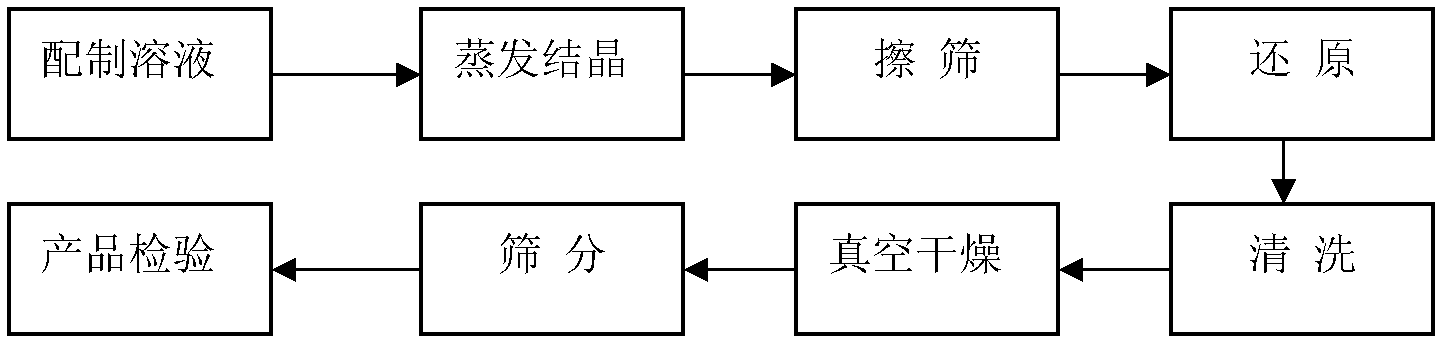

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The preparation of ultra-coarse tungsten powder with an average particle size of 60 μm should be completed according to the following steps (the SEM photo of the prepared tungsten powder is as follows image 3 shown):

[0026] 1. Prepare a mixed solution of sodium tungstate and ammonium tungstate, the molar ratio of sodium tungstate and ammonium tungstate is 1:100.

[0027] 2. Heat the prepared solution to boiling. When 80% to 90% of the volume evaporates, stop heating, send it to a far-infrared oven, and dry it at 120°C for 10 hours. The precursor of ammonium paratungstate and sodium tungstate crystalline mixture is obtained.

[0028] 3. Wipe and sieve the precursor to make -80 mesh powder, add 10% mass fraction of fine tungsten powder return material, and mix for 2 hours with a V-type mixer.

[0029] 4. In the tubular reduction furnace, hydrogen gas is introduced for reduction, the reduction temperature is 800°C, the reduction time is 1h, and the cross-se...

Embodiment 2

[0033] Example 2: The preparation of ultra-coarse tungsten powder with an average particle size of 150 μm should be completed according to the following steps (the SEM photo of the prepared tungsten powder is as follows Figure 4 shown):

[0034] 1. Prepare a mixed solution of sodium tungstate and ammonium tungstate, the molar ratio of sodium tungstate and ammonium tungstate is 1:40.

[0035] 2. Heat the prepared solution to boiling. When 80% to 90% of the volume evaporates, stop heating, send it to a far-infrared oven, and dry it at 150°C for 2 hours. The precursor of ammonium paratungstate and sodium tungstate crystalline mixture is obtained.

[0036] 3. Wipe and sieve the precursor to make -80 mesh powder, add 20% mass fraction of fine tungsten powder return material, and mix for 2 hours with a V-type mixer.

[0037] 4. Put hydrogen into the tube type reduction furnace for reduction, the reduction temperature is 1000°C, the reduction time is 2h, and the cross-sectional fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com