Magnesium-based pellet ore organic binding agent and preparation and using method thereof

An organic binder and magnesium-based pellet technology, which is applied in the field of binders for metallurgical sintering, can solve problems such as the defects of pellet binders and the influence of sintering ore, so as to improve metallurgical properties, reduce MgO content, and improve sintering. Effect of ore quality and pellet quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

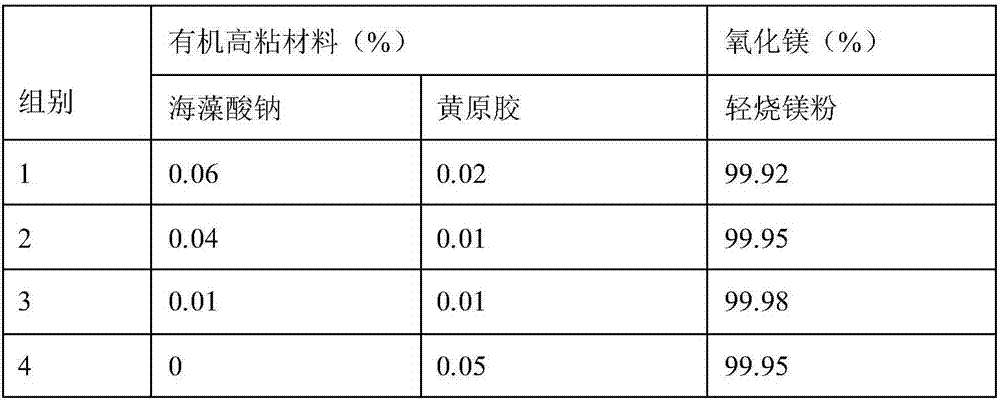

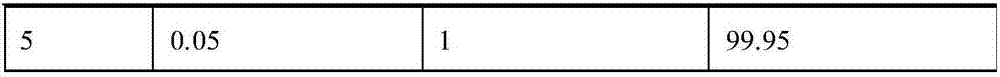

[0016] The magnesium-based pellet organic binder of Examples 1 to 5 has components and weight percentages as shown in Table 1:

[0017] Table 1 Distribution ratio of each group

[0018]

[0019]

[0020] The components are mixed in proportion, and the finished product is obtained after co-grinding, and the particle size of the finished product is less than 0.044mm.

[0021] The finished magnesium-based pellet organic binder products were added to the iron ore concentrate powder to obtain 5 groups of green pellets;

[0022] The performance indexes of the 5 groups of green balls are compared with the performance indexes of the control group made by adding bentonite conventionally, as shown in Table 2:

[0023] Table 2 Comparison Table of Raw Ball Indexes

[0024]

[0025] The above groups of green pellets are roasted to produce finished pellets;

[0026] Roasting technical parameters are shown in Table 3:

[0027] Table 3: Roasting Technical Parameters

[0028] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com