Production method of oxide pellets

A technology of oxidizing pellets and production methods, which is applied in the field of metallurgical pellet production, can solve the problems of poor pellet strength, uneven distribution of blast furnace airflow, and damaged coke compressive strength and wear resistance, and achieve low roasting temperature , good metallurgical performance, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Use high-alkali metal iron concentrate A1 accounting for 35% of the mass of the mixed concentrate, and low-alkali metal iron concentrate B1 accounting for 65% of the mass of the mixed concentrate; specifically:

[0049] High alkali metal iron concentrate A1 is randomly selected from high alkali metal iron concentrate A. The main chemical components include: measured TFe: 65.76%, FeO: 29.1%, CaO: 1.2%, SiO 2 : 1.8%, MgO: 0.91%, Na 2 O+K 2 O: 0.243%, F: 0.34%;

[0050] Low-alkali metal iron concentrate B1 is randomly selected from low-alkali metal iron concentrate B. The main chemical components include: measured TFe: 65.44%, FeO: 27.18%, CaO: 0.65%, SiO 2 : 7.48%, MgO: 0.41%, Na 2 O+K 2 O: 0.12%, F: 0.06%;

[0051] High-alkali metal iron concentrate A1 is processed by high-pressure roller milling to make its specific surface area reach 1500m 2 More than / g, the two kinds of iron concentrates are mixed to obtain a mixed concentrate, and 2.0% of bentonite is added...

Embodiment 2

[0053] Embodiment 2 (comparative test one of embodiment 1)

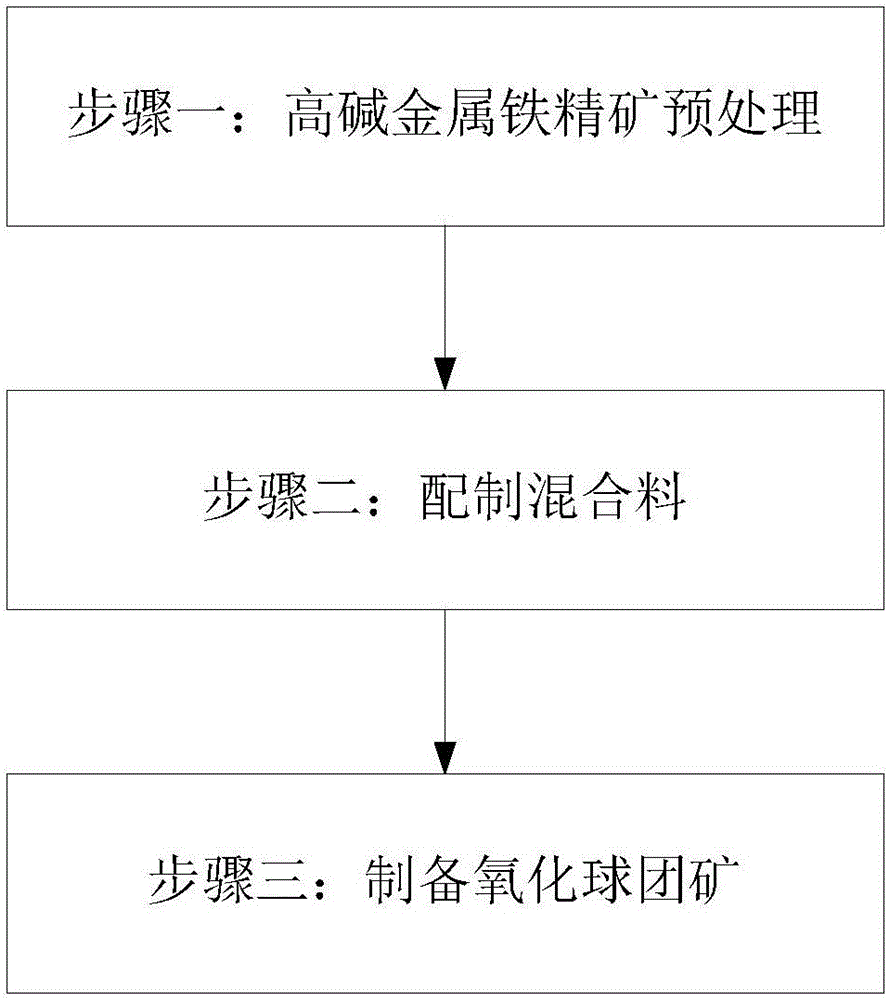

[0054] Method steps such as figure 1 shown. As a comparison with Example 1, the same high-alkali metal iron concentrate A1 and low-alkali metal iron concentrate B1 as in Example 1 were mixed to obtain a mixed concentrate for trial production, wherein the high-alkali metal iron concentrate A1 accounts for 40% of the mass of the mixed concentrate, and low-alkali metal iron concentrate B1 accounts for 60% of the mass of the mixed concentrate to obtain the mixed concentrate, adding 2.0% of bentonite and 2.0% of the first magnesia additive to obtain the mixed material, Bentonite and the first magnesia additive are the same as in Example 1, and then, the pelletizer is used to add water to make pellets; the first magnesia additive includes CaO: 3-5%, SiO 2 : 30-36%, MgO: 30-38%.

[0055] The resulting green ball drop strength is 6.6 times (0.5) -1 , preheating temperature 600, preheating time 9min, calcination temperatu...

Embodiment 3

[0057] Embodiment 3 (comparative test two of embodiment 1)

[0058] As a comparison with Example 1, the high-alkali metal iron concentrate A1, which accounts for 40% of the mixed concentrate mass and is taken at the same time as in Example 1, is used. The measured TFe: 65.76%, FeO: 29.1%, CaO : 1.2%, SiO 2 : 1.8%, MgO: 0.91%, Na 2 O+K 2 O: 0.243%, F: 0.34%; Low-alkali metal iron concentrate B1, which accounts for 65% of the mass of the mixed concentrate, is used. Low-alkali metal iron concentrate B1 is randomly selected from low-alkali metal iron concentrate B. The main chemical composition According to the mass percentage, it includes: measured TFe: 65.44%, FeO: 27.18%, CaO: 0.65%, SiO 2 : 7.48%, MgO: 0.41%, Na 2 O+K 2 O: 0.12%, F: 0.06%; high-alkali metal iron concentrate A1 is treated by high-pressure roller milling to make its specific surface area reach 1500m 2 / g or more, two kinds of iron concentrates are mixed to obtain a mixed concentrate, and 2% bentonite and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com