Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Low MgO content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

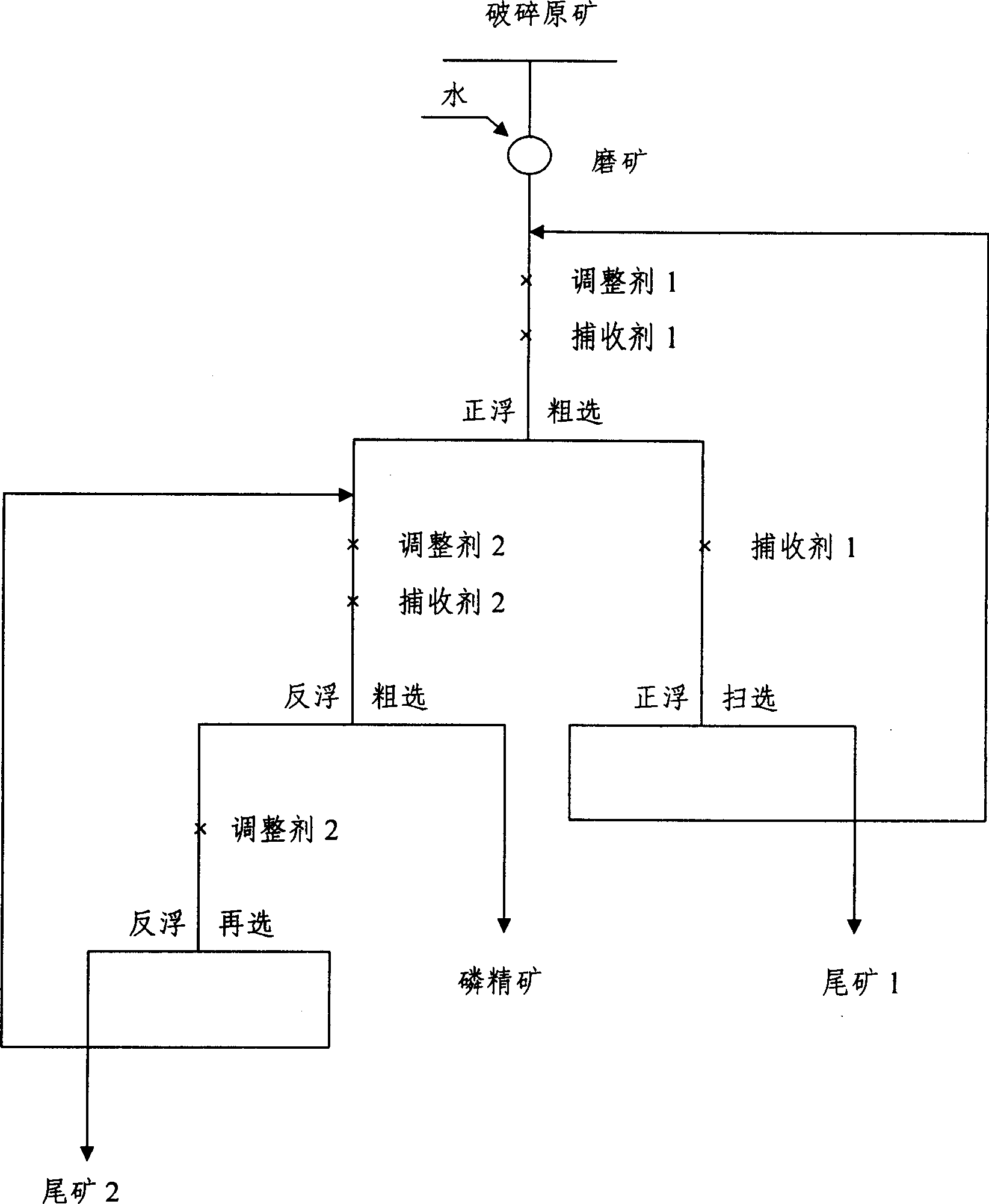

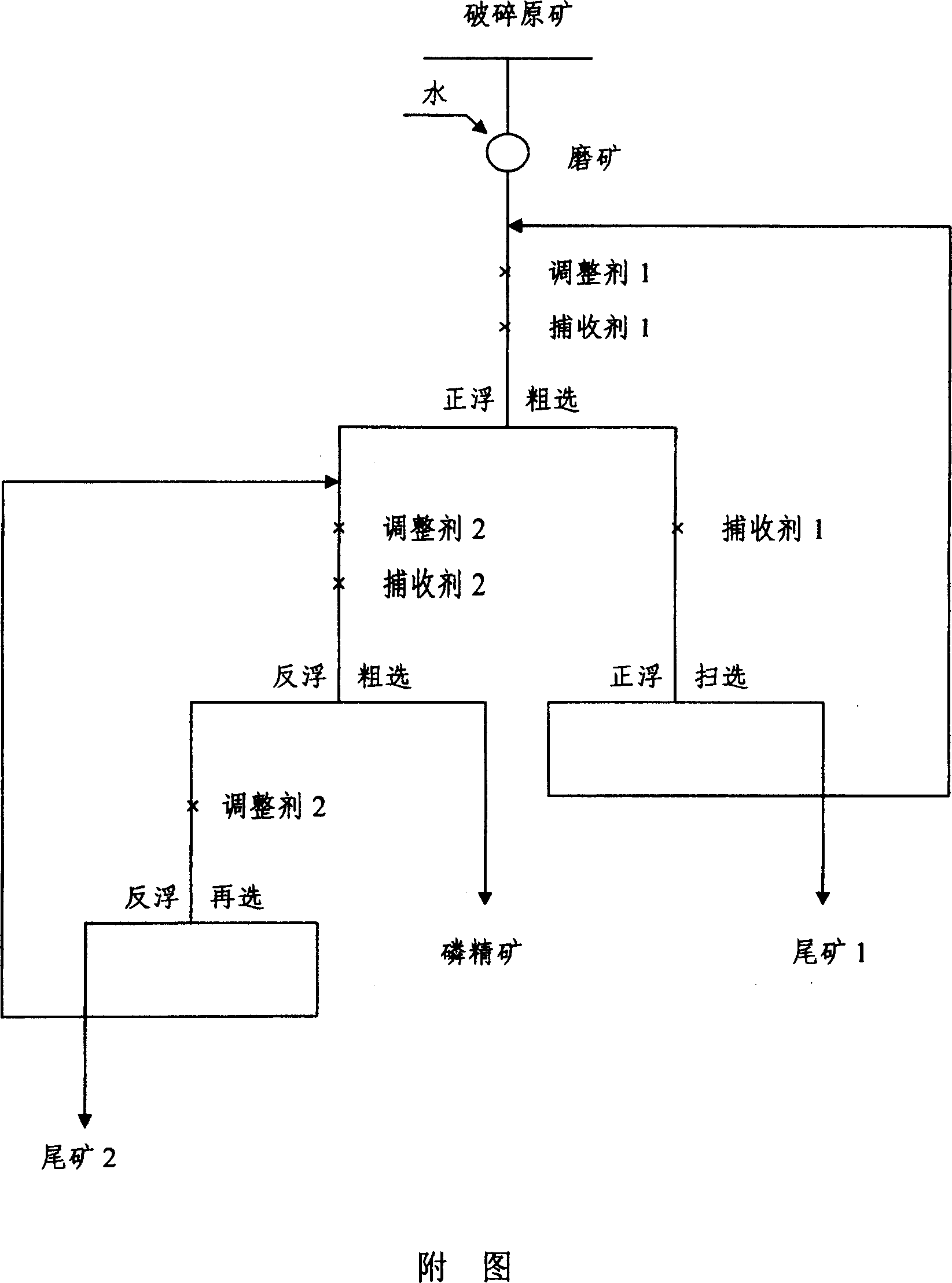

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Branch flotation technology for silicon calcium collophanite

The invention relates to a branch flotation technology for collophanite, which comprises the following steps: crushing and grinding silicon calcium collophanite ores, and then adding water and mixing into slurry, and guiding the slurry to flow into a flotation groove; adding a regulator and a collecting agent for mixing the slurry, and then pouring into a reverse flotation system for performing reverse flotation, wherein products in the groove are reverse flotation concentrates; grading the reverse flotation concentrates into coarse fraction and fine fraction; pouring the coarse fraction partinto a desilicification reverse flotation groove, adding a desilicification regulator and a desilicification collecting agent for mixing the slurry, and then pouring into a desilicification system for performing reverse flotation, wherein products in the groove are desilicification reverse flotation concentrates; pouring the fine fraction part into a normal flotation groove, adding a normal flotation pH (Potential of Hydrogen) regulator, the regulator and the collecting agent for mixing the slurry, and then performing normal flotation, wherein foam products of the normal flotation are normal flotation concentrates; mixing the normal flotation concentrates with the desilicification reverse flotation concentrates, thereby forming the final phosphorus concentrates; and concentrating, filtering and drying, thereby obtaining phosphorus concentrates. The branch flotation technology for collophanite has the advantages that the separation efficiency is high, the technic index is excellent, the content of MgO in the obtained phosphorus concentrates is lower, the quality of the concentrates is high, and the comprehensive cost of the final product of the phosphor concentrates is lower.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Carbonate phosphorite reverse flotation combined collecting agent and preparation method thereof

InactiveCN102513221AStrong harvesting abilityHigh selectivityFlotationFoaming agentPhysical chemistry

The invention discloses a carbonate phophorite reverse flotation combined collecting agent and a preparation method thereof. The collecting agent is a compound anion collecting agent and is formed by mixing basic substance with water, wherein the basic substance mainly comprises the following components in parts by weight: 0.2-0.5 part of higher fatty acid sulfated soap containing unsaturated fatty acid, 0.5-0.8 part of higher fatty acid saponified matter with the fatty acid content of being not more than 50% and 0.01-0.1 part of foaming agent, and the ratio of the basic substance to the water in parts by weight is 1: (20-70). The combined collecting agent has the advantages of strong collecting capability, high selectivity, low dosage, low temperature resistance and the like and is applied to carbonate phophorite reverse flotation with the P2O5 grade of being 25-26%, the P2O5 grade of the obtained concentrate is more than 34%, MgO content is less than 1.2%, and P2O5 recovery rate of the concentrate is more than 90%. The invention has the characteristics of simple preparation process, easy operation, high concentrate P2O5 recovery rate, low MgO content in the concentrate and low flotation cost and is applicable to flotation production of carbonate phophorite and various phosphate ores.

Owner:GUIZHOU UNIV

Iso-floatable separation process of siliceous-calcareous collophanite

ActiveCN102744160ARealize beneficiation and enrichmentReduce dosageFlotationCalcium in biologyPhosphorite

The invention relates to an iso-floatable separation process of siliceous-calcareous collophanite, comprising the following steps of: crushing and grinding siliceous-calcareous-based collophanite ores, adding water, mixing size, and then entering iso-floatable operation for the iso-floatable flotation of the siliceous-calcareous-based collophanite ores; enabling flotation froths to flow into a reverse flotation agitating tank, mixing the size, and then entering a reverse flotation system for the reverse flotation of carbonate gangue minerals, wherein products inside a reverse flotation tank are reverse flotation phosphate concentrates; and enabling the products inside an iso-floatable flotation tank to enter a direct flotation agitating tank and materials obtained after size mixing to enter a direct flotation system for direct flotation, wherein direct flotation froth products are direct flotation phosphate concentrates. The iso-floatable separation process sufficiently utilizes the difference of natural floatability of ores and has the advantages of small using amount of flotation reagent, circulation utilization of beneficiation wastewater, high separation efficiency and excellent process index; the obtained phosphate concentrates contain lower MgO content and high concentrate quality; and final product phosphate concentrates are lower in comprehensive cost.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

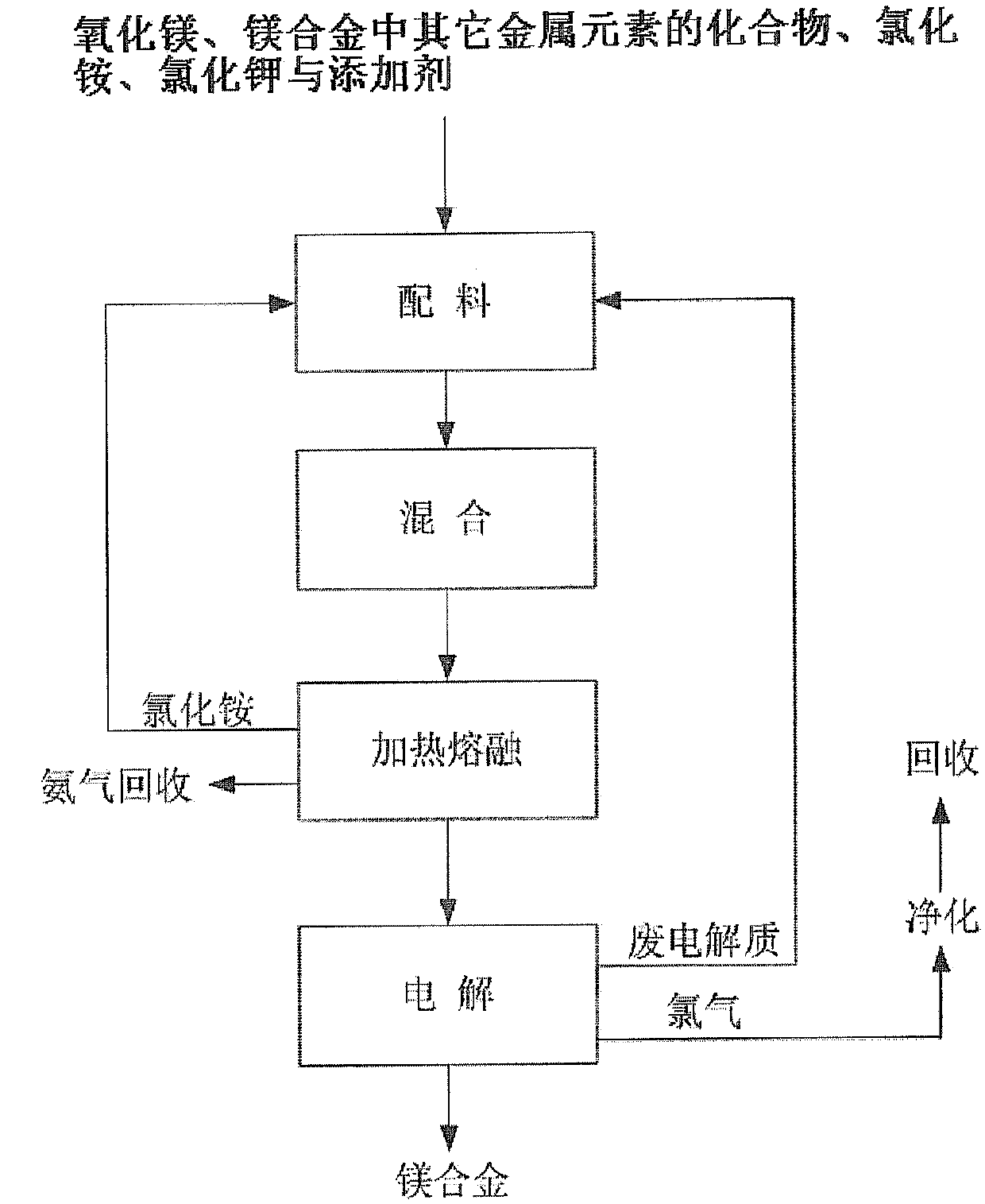

Method using magnesium oxide as raw material for electrolytic preparation of magnesium alloy

Provided is a method for preparing a magnesium alloy by electrolysis using magnesium oxide as a raw material, comprising: (a) evenly mixing magnesium oxide, compounds of the other metal elements in the magnesium alloy, ammonium chloride, potassium chloride and additives to prepare a mixture, wherein the compounds of the other metal elements in the magnesium alloy are selected from one of the group consisting of: chlorides of the other metal elements in the magnesium alloy, oxides of the other metal elements in the magnesium alloy, and chlorides and oxides of the other metal elements in the magnesium alloy; (b) heating the mixture prepared in step (a) to a melting state, so as to prepare an electrolyte melt; and (c) electrolysing the electrolyte melt prepared in step (b), so as to obtain the magnesium alloy. The method of the present invention has a simple process, enables a continuous production, has a high degree of automation, is easy to operate and control and good in terms of environmental protection, and at the same time omits the process of producing metal magnesium and metals for the alloy, thereby shortening the overall manufacturing process of the magnesium alloy and reducing emissions and energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

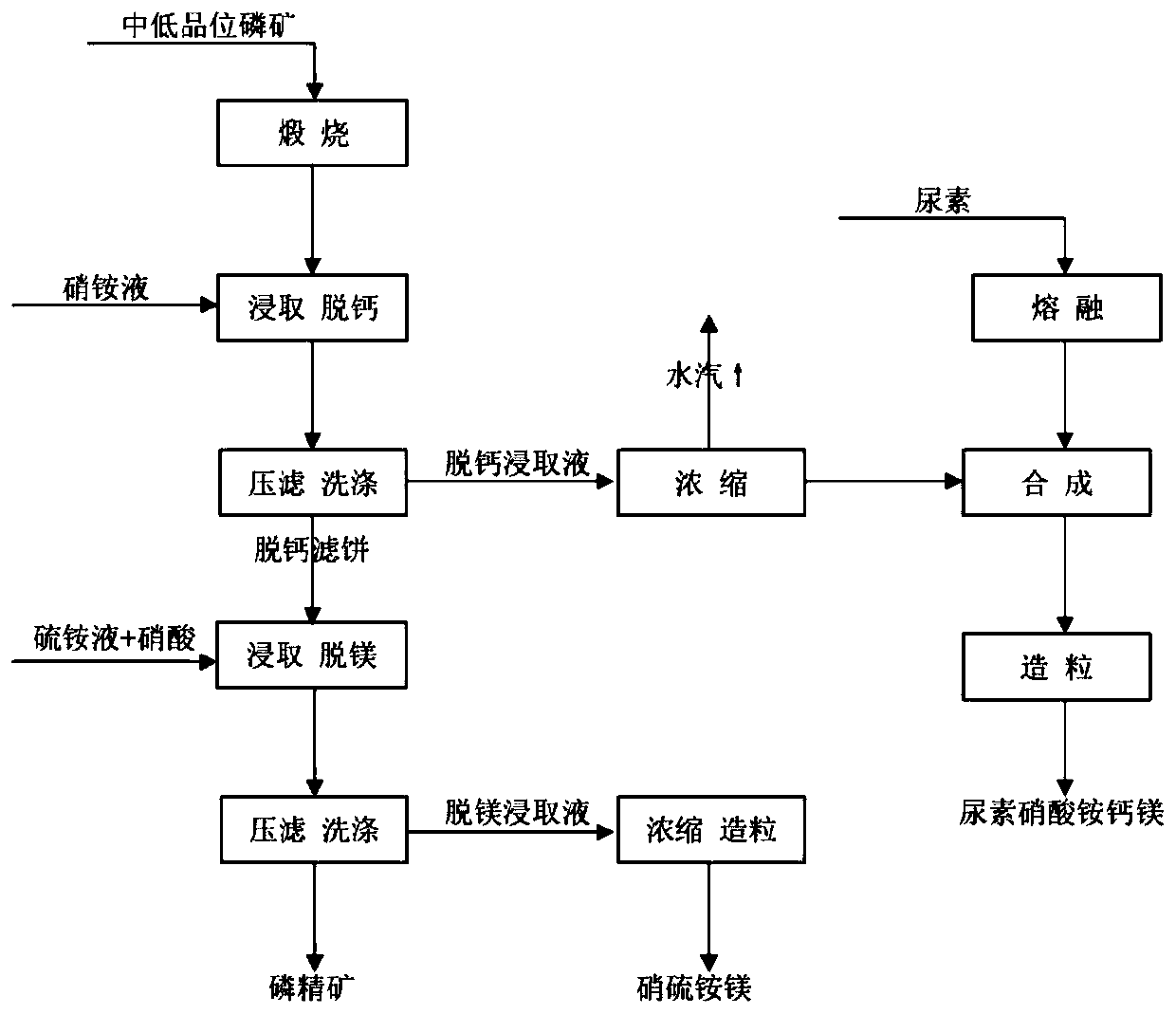

Mineral separation method for separating calcium and magnesium in medium-low-grade phosphorite, urea ammonium nitrate calcium-magnesium fertilizer and ammonium magnesium sulfate nitrate fertilizer

PendingCN111187100APromote growthConvenient supplementCalcareous fertilisersMagnesium fertilisersMagnesium phosphateSoil science

The invention provides a mineral separation method for separating calcium and magnesium in medium-low-grade phosphorite, a urea ammonium nitrate calcium-magnesium fertilizer and an ammonium magnesiumsulfate nitrate fertilizer, and relates to the technical field of mineral separation. The mineral separation method comprises the following steps: sequentially carrying out crushing, calcining, digesting, leaching decalcification and leaching magnesium removing on medium-low-grade phosphorite, wherein the decalcified filtrate obtained by leaching decalcification separation is subjected to concentration and synthesis to prepare a urea ammonium nitrate calcium-magnesium fertilizer, and / or the magnesium-removed filtrate obtained by leaching magnesium removing separation is subjected to concentration and granulation to obtain an ammonium magnesium sulfate nitrate fertilizer. The low-magnesium phosphate concentrate produced through the mineral separation method can meet the requirement for producing a nitrophosphate fertilizer with a low nitrogen-phosphorus ratio while a full-water-soluble urea calcium magnesium ammonium nitrate fertilizer and / or a magnesium ammonium sulfate fertilizer are / is produced as a byproduct, so that phosphorus, calcium and magnesium elements in medium-low-grade phosphorite are recycled.

Owner:GUIZHOU BATIAN ECOTYPIC ENG CO LTD

Collophane anti-floatation collector

Cellophane reverse flotation collector is mixed with base material and water. Wherein, the former comprises with share, saponification material of cotton oil 38~45, dioctyl sodium sulfosuccinate 10~20; the proportion of base material and water is 1:5~20. The collector can make the product grade not less than 37% when the grade of raw material down to 24%, which means important for the usage of low grade phosphorus ore source. It is also characterized in that the recovery rate of concentrate is high, with low content of MgO and low cost. This invention can also be fit to production of all kinds' phosphorus ores.

Owner:黄泽华

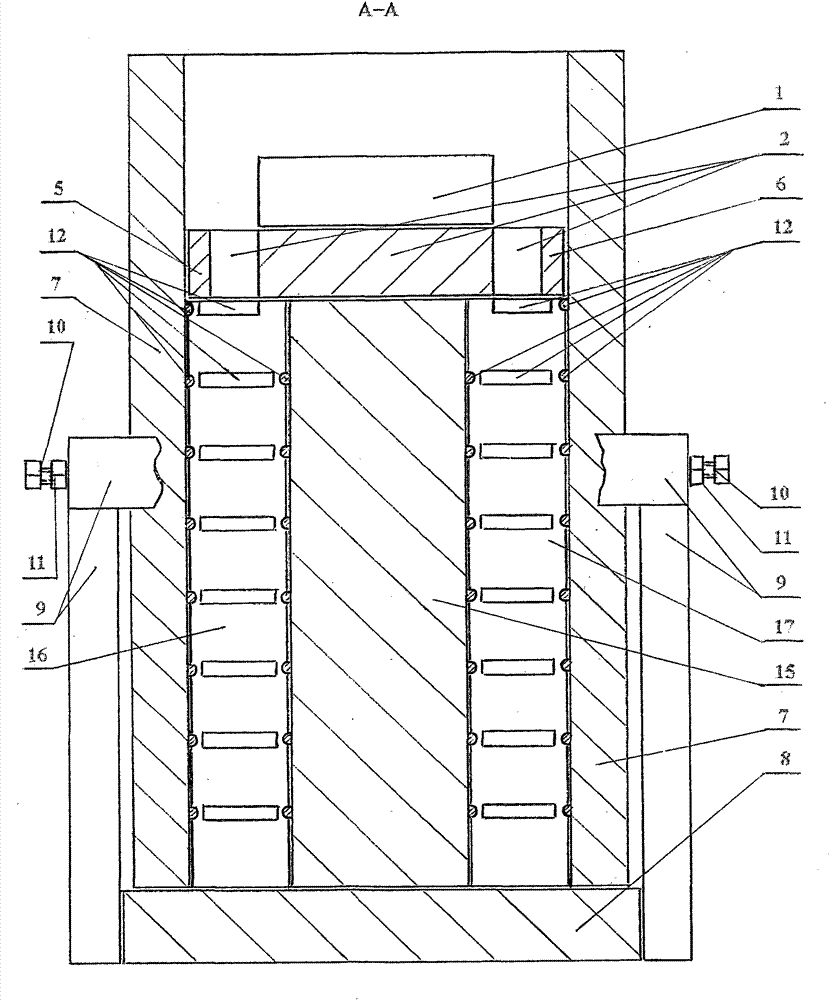

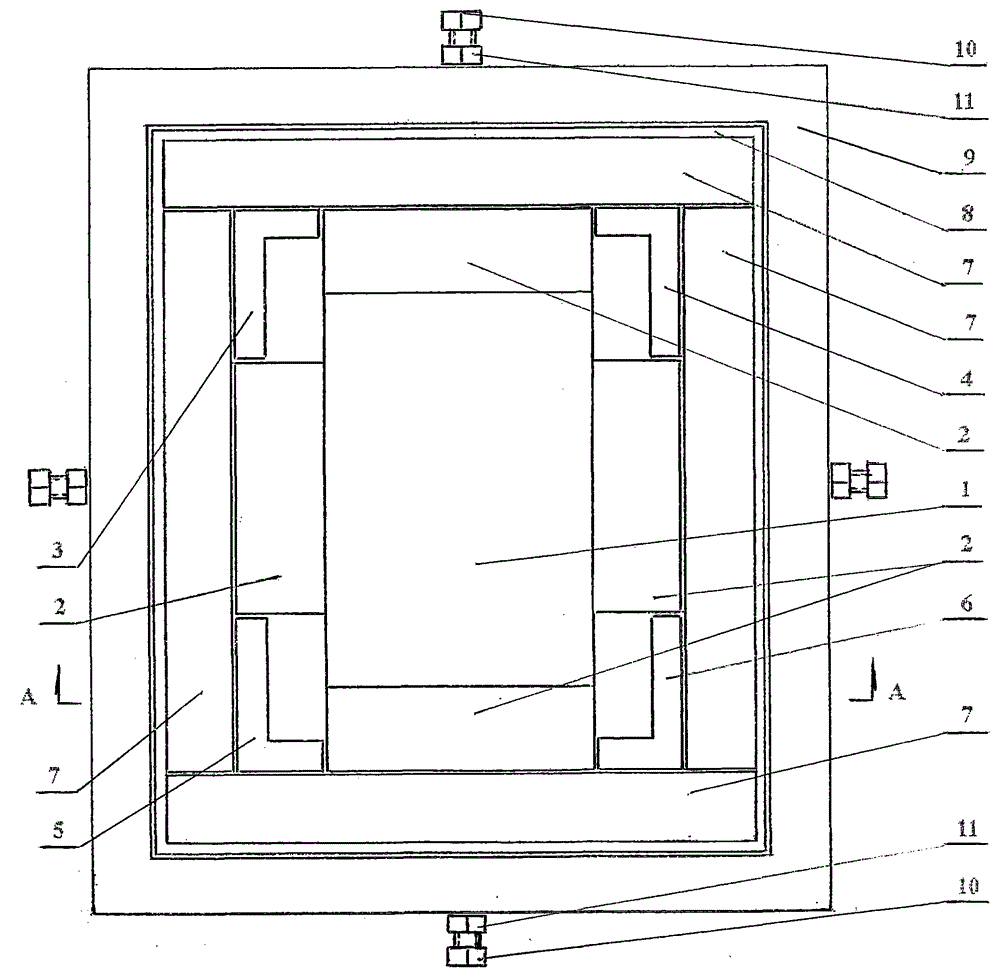

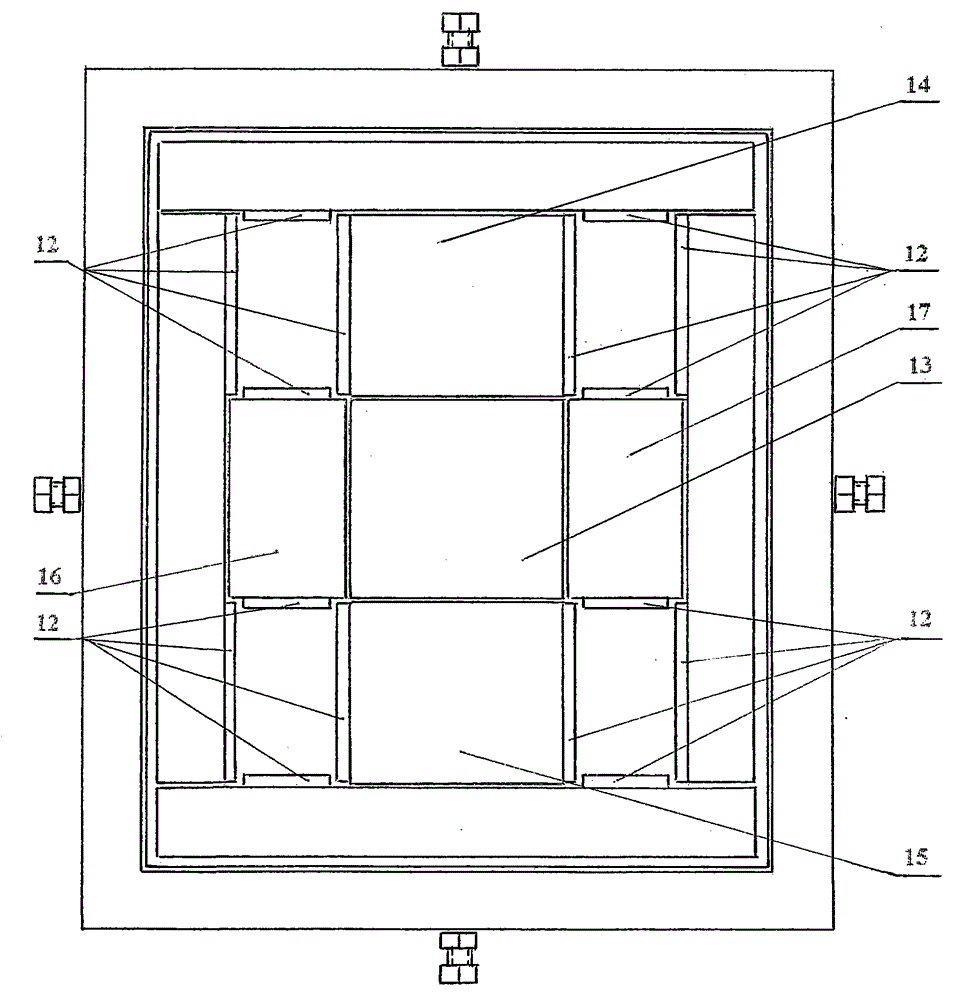

Production method of high-quality spheroidizing agent

ActiveCN103757518AReduce melting lossQuality improvementProcess efficiency improvementHigh magnesiumMelting tank

The invention discloses a production method of a high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent. The production method is characterized in that a first part is a rare-earth magnesium-silicon-iron spheroidizing agent of which the content of Mg is controlled to be not higher than 10%, the content of Si is controlled to be not lower than 65% and the content of RE (Rear Earth) is not higher than 2%, and the rare-earth magnesium-silicon-iron spheroidizing agent containing the ingredient realizes a magnesium light-free status during both melting and pouring, thus generation of magnesium oxide is greatly reduced; a second part is a combined type melting tank for pouring alloy liquid of the ingredient rare-earth magnesium-silicon-iron spheroidizing agent. A new process overcomes the problems of ingredient segregation and high magnesium oxide content of a conventional rare-earth magnesium-silicon-iron spheroidizing agent; the magnesium oxide content of the high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent is smaller than 0.3%; the melting loss of spheroidizing agent alloy is small; the finished product rate of the high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent with required weight and shape is high.

Owner:TIANJIN WANLU OF SCI & TECH

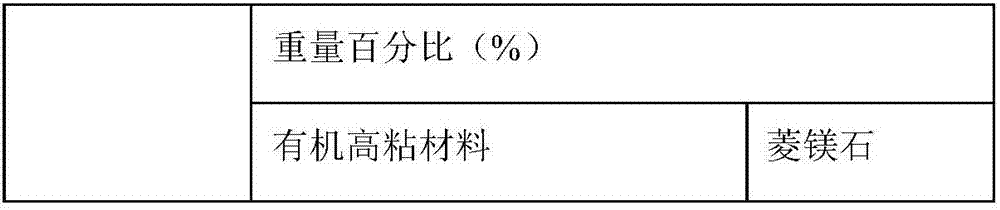

Pellet magnesium composite binding agent and preparation method and application method thereof

The invention relates to a pellet magnesium composite binding agent and a preparation method and an application method thereof. The pellet magnesium composite binding agent consists of the following components in parts by weight: 0.1-0.3 part of organic high molecular materials, 0.1-0.3 part of thickening agent, and 99.5-99.7 parts of magnesium additive. Firstly, the organic high molecular material, the thickening agent and magnesite are uniformly mixed in proportion for cogrinding to obtain a semi-finished product; and then, the semi-finished product is uniformly mixed with caustic burned magnesia in proportion for cogrinding to obtain a finished product. When pellets are produced, the magnesium composite binding agent is added in iron concentrate powder to mix green balls for roasting to prepare finished pellets; and the adding quantity of the magnesium composite binding agent is 1.0-3.5 mass% of the adding quantity of the iron concentrate powder. The magnesium composite binding agent is adopted to replace a bentonite+magnesium additive form, so that the pellet quality is improved, the MgO content in the pellets is increased, the MgO content in sintered ores is reduced, the quality of the sintered ores and the quality of the pellets can be improved, and increment of the yield of a blast furnace and reduction of the energy consumption are finally realized.

Owner:ANSHAN ZHENGDA FURNACE CHARGE +1

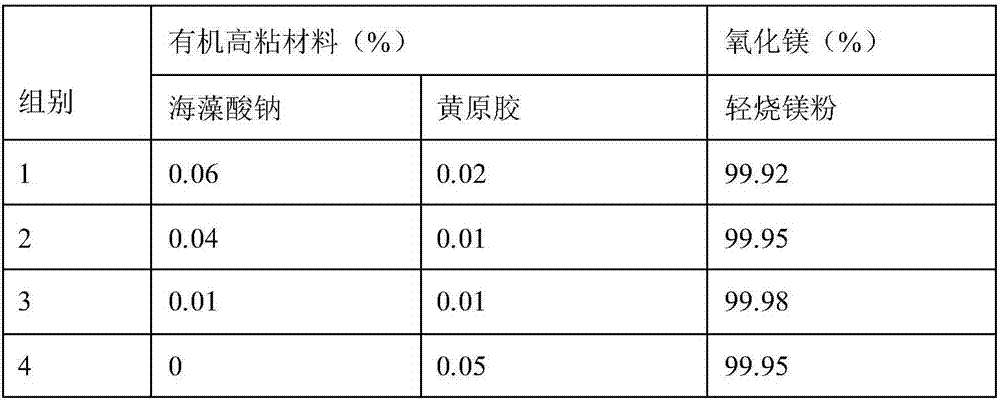

Magnesium-based pellet ore organic binding agent and preparation and using method thereof

The purpose of the present invention is to solve the defects of the pellet binder in the prior art and the problem that the sinter is affected by MgO, and provide a magnesium-based pellet organic binder and its preparation and use methods, which belong to the metallurgical Technical field of binder for sintering. The binder is composed of 0.02%-0.08% of organic high-viscosity material and 99.92-99.98% of magnesium oxide powder. The organic high-viscosity material is one or both of sodium alginate and xanthan gum, and the magnesium oxide powder is lightly burned magnesium Powder, the particle size is less than 0.044mm. The present invention uses magnesium material instead of bentonite, which can improve the quality of pellets, increase the strength and bursting temperature of green pellets, and improve the compressive strength of finished balls and the grade of total iron; at the same time, by adding MgO to pellets, it can not only improve the quality of pellets Excellent metallurgical properties, and can also reduce the MgO content in sinter, so that the quality of sinter and pellets can be improved together.

Owner:ANSTEEL GRP MINING CO LTD

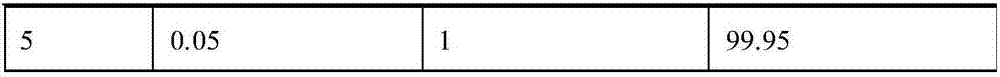

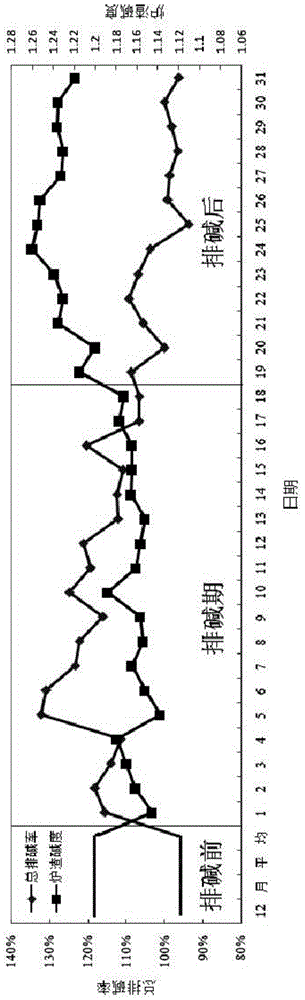

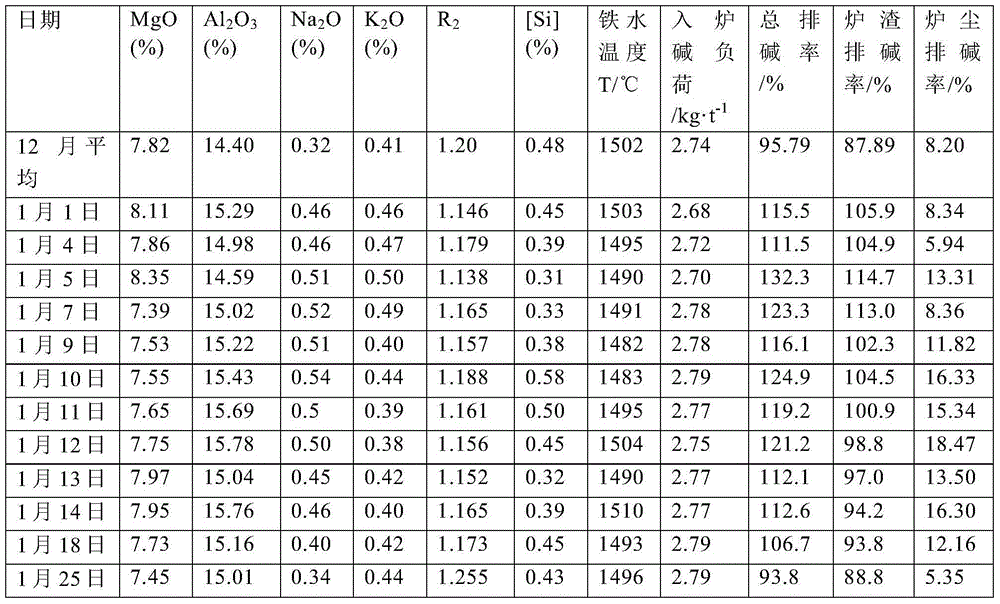

Method for reducing alkali metal enrichment in blast furnace

ActiveCN104152611ALow MgO contentIncrease the content of MgOBlast furnace detailsSlagAlkali metal oxide

The invention relates to a method for reducing alkali metal enrichment in a blast furnace. When loads of in-furnace alkali metal oxides are 2.8 to 3.0 kg / t, the blast furnace carries out alkali removing once in each quarter, and the alkali removing period ranges from 15 days to 20 days; in the alkali removing period, the MgO content in slag of the blast furnace is controlled to be 7% to 8%, and the binary basicity of the slag of the blast furnace is controlled not to be larger than 1.15; in the alkali removing period, the temperature of molten iron in the blast furnace is controlled to be 1490 DEG C to 1500 DEG C; the Si content in the molten iron is controlled to be 0.3 percent to 0.35 percent; the Ti content in the molten iron of the blast furnace is controlled to be 0.1 percent to 0.15 percent. The basicity of the slag of the blast furnace is controlled, components and the temperature of the molten iron of the blast furnace are adjusted cooperatively, the discharge rate of the alkali metal is improved, and the alkali metal enrichment is reduced.

Owner:BEIJING SHOUGANG CO LTD

Pellet ore binding agent containing magnesium oxide and preparation and using method of pellet ore binding agent

InactiveCN107345272AMeet the quality standard requirementsImproved metallurgical propertiesCompressive strengthUltimate tensile strength

The object of the present invention is to provide a pellet binder containing magnesium oxide and its preparation and use method in order to solve the defect of the pellet binder in the prior art and the problem that the sinter is affected by MgO. It is composed of 0.035%-0.075% of organic high-viscosity materials and 99.925%-99.965% of magnesium raw materials. The organic high-viscosity materials are one or two of Tianqing gum and sodium humate, and the magnesium raw materials are those with magnesium oxide content ≥ 45%. Magnesite, the particle size is less than 0.044mm, and the mass percentage of magnesite is more than 95%. In this invention, magnesium raw material is used to replace bentonite, which can improve the quality of pellets, increase the strength and bursting temperature of green pellets, and improve the compressive strength and total iron content of finished pellets. At the same time, adding MgO to the pellets can not only improve the metallurgical properties of the pellets, but also reduce the MgO content in the sinter, so that the quality of the sinter and the pellets can be improved together.

Owner:ANSTEEL GRP MINING CO LTD

Combustion method of fuel in shaft kiln

The invention discloses a combustion method of fuel in a shaft kiln.The method comprises the following steps: (1), gas fuel is sent into the kiln from a calcining zone of the shaft kiln and burns in the kiln to produce fume, and the fume is exhausted from the kiln top after passing by the calcining zone and a preheating zone; (2), solid fuel and gas fuel are added into the kiln from the top of the shaft kiln, pass by the preheating zone, the calcining zone and a cooling zone sequentially and are exhausted out of the kiln from a discharge port in the bottom of the shaft kiln.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

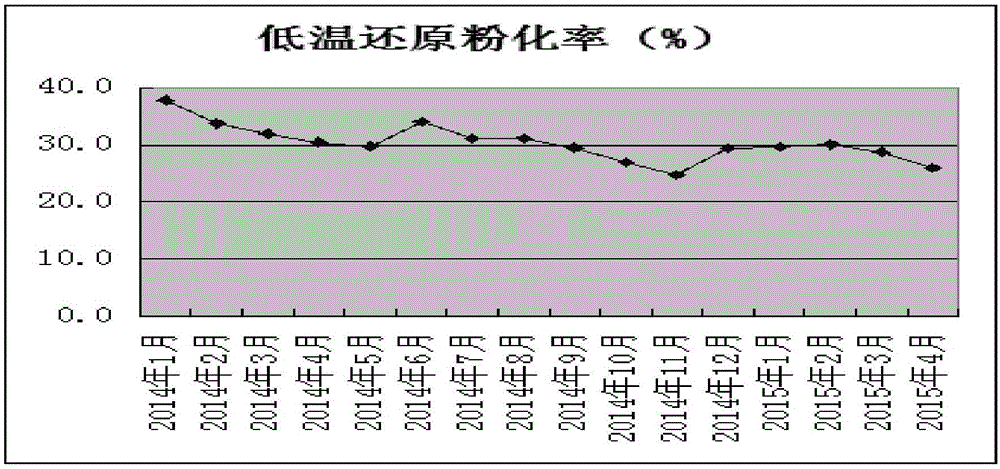

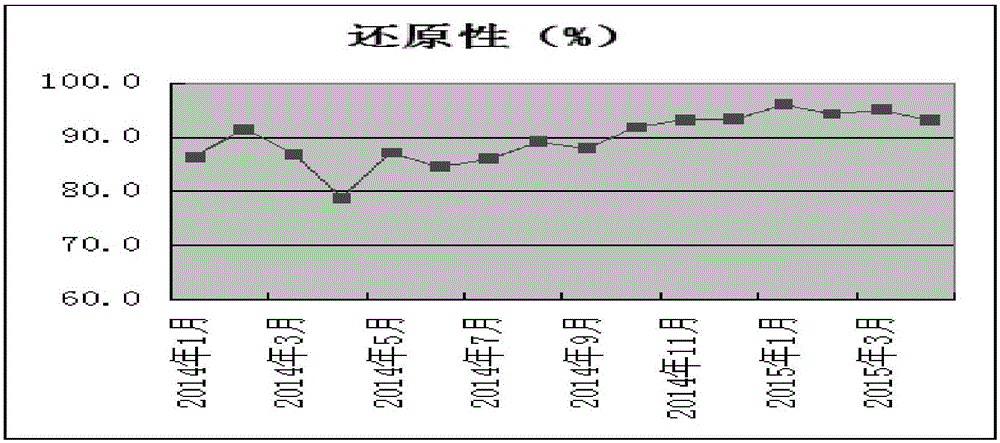

Method for improving quality of sintered ore

The invention discloses a method for improving quality of sintered ore. According to the method, the content of MgO in the sintered ore is reduced, and the content of MgO is enabled to account for 1.75%-2.05% of the total mass of the sintered ore; preferably, the content of MgO in the sintered ore accounts for 1.75%-1.81% of the total mass of the sintered ore. The content of MgO of the sintered ore is properly reduced, sintering and blast furnace production are better, and indexes get better; the sintering production efficiency and the cold strength of the sintered ore are improved, the low-temperature reduction degradation index of the sintered ore is increased, the temperature interval of a soft melting zone of the sintered ore is reduced, and the grade of the sintered ore is improved. Therefore, the permeability of a massive zone and the soft melting zone of a blast furnace is improved, the quantity of slag in the blast furnace is reduced, the smooth operation condition of the blast furnace is improved, and blast furnace smelting strengthening and coke ratio reduction are facilitated.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method of flotation and magnesium reduction for talcum-type copper-nickel sulfide ore

The invention relates to a method of flotation and magnesium reduction for talcum-type copper-nickel sulfide ore. According to the beneficiation method, talcum-type copper nickel polymetallic ore is taken as a raw material, a flotation technology is adopted, and nickel ore concentrate is obtained. The method comprises the steps of ore grinding, size mixing, roughing, scavenging and concentration operation. After ore grinding, sodium hexametaphosphate, butyl xanthate, ammonium dibutyl dithiophosphate, acidified water glass, sodium carboxymethylcellulose and 2#oil are added in sequence, the added sodium carboxymethylcellulose inhibits talcum which easily floats, and the acidified water glass enhances the selectivity of the inhibiting agent. The acidified water glass can form colloidal particles in the ore pulp system, the colloidal particles are selectively adsorbed on the surfaces of gangue mineral particles to make the gangue mineral particles hydrophilic and enhances the selectivity of the inhibiting agent sodium carboxymethylcellulose, and on the basis of not influencing the grade and recovery rate of copper and nickel concentrate, the content of MgO in the copper and nickel concentrate can be significantly reduced by 3% or above. According to the method, the content of MgO in the copper and nickel concentrate can be effectively reduced, and indicators in beneficiation for the talcum-type copper-nickel sulfide ore are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

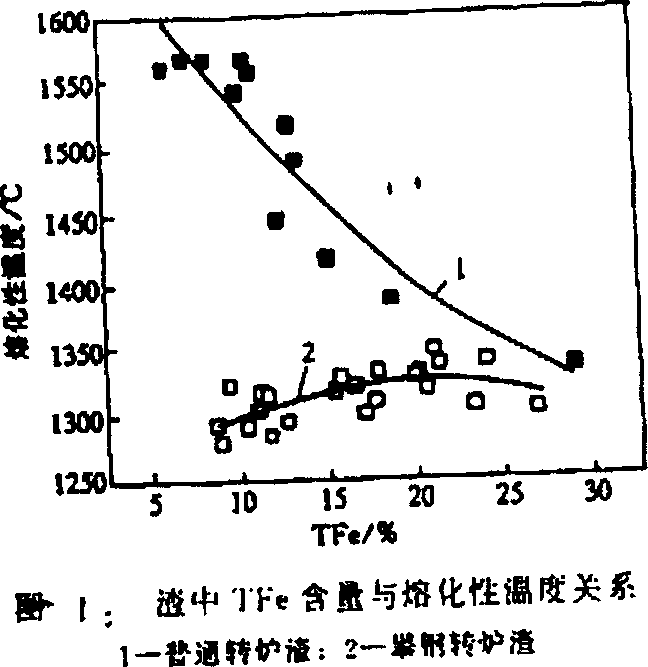

Converter retaining operation method of preventing splash slag and reducing iron loss

The present invention discloses that before and during tapping, carbon containing reductant coal powder, coke powder or graphite powder is added to the surface of slag liquid inside converter so as to reduce FeO in slag liquid, raise slag viscosity and smelting point and protect converter. The method is simple and low in cost, and can reduce steel making cost of converter obviously.

Owner:王虎

Coal gangue power generation and CO2 mineralization collaborative utilization system and working method

ActiveCN114835148AIncrease profitAchieve emission reductionCalcium/strontium/barium carbonatesMagnesium carbonatesCooling towerDust abatement

The invention discloses a coal gangue power generation and CO2 mineralization cooperative utilization system and a working method thereof, and belongs to the technical field of solid waste resource utilization. Comprising a coal bunker, a coal preparation unit, a boiler unit, a power generation unit, a denitration unit, a dust removal unit, a desulfurization unit, a mineralization unit, a fly ash drying unit, a cooling tower, a chimney and a sewage treatment unit. A coal preparation unit and a sewage treatment unit are improved on the basis of an existing coal gangue blending combustion coal-fired power generation system, a mineralization unit and a fly ash drying unit are added, the system can fix part of CO2 in flue gas through the mineralization process of the mineralization unit, and emission reduction of CO2 is achieved; meanwhile, CaO and MgO in the fly ash can be converted into CaCO3 and MgCO3 in the mineralization process, the application field of the solid waste fly ash is widened, and the utilization rate of the fly ash is increased. According to the invention, the utilization of coal gangue solid wastes and the reduction of CO2 emission can be realized; meanwhile, the content of CaO and MgO in the fly ash can be reduced, and the application of the fly ash in the field of building material manufacturing is improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

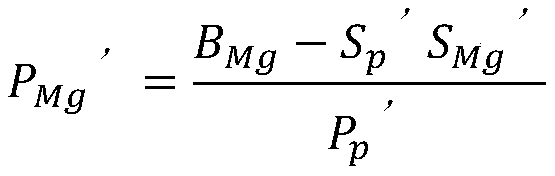

MgO optimal distribution method for iron-containing furnace charge of blast furnace

ActiveCN110982971ALarge span of soft melting zoneImprove smelting performanceSteel manufacturing process aspectsForecastingMaterials scienceBlast furnace

The invention relates to an MgO optimal distribution method for iron-containing furnace charge of a blast furnace. The method comprises the following steps: S1, determining that the MgO content SMg' of optimized sintered ore is less than or equal to 1.8% and the binary alkalinity (CaO / SiO2) Sb' is greater than or equal to 1.8; S2, determining that the MgO content of optimized pellets is 1.5%-2.0%and the binary alkalinity is less than or equal to 0.4, namely, PMg' is greater than or equal to 1.5% and less than or equal to 2.0%, Pb' is less than or equal to 0.4, and the charging proportion Pp'is less than or equal to 30%; S3, according to the binary alkalinity requirement Bb of the blast furnace comprehensive furnace charge and the binary alkalinity constraint condition of each iron-containing furnace charge, determining the charging proportion Pp' of the optimized pellets; S4, determining the MgO content PMg' of optimized pellets and the MgO content SMg' of optimized sintered ore according to the MgO content requirement BMg of blast furnace comprehensive furnace charge, the optimized iron-containing furnace charge proportions and the optimized iron-containing furnace charge MgO constraint conditions. The method has the advantages that the reduction degree of the comprehensive furnace charge is effectively improved, the soft melting temperature is reduced, the interval is narrowed, and the smelting performance is improved.

Owner:ANSTEEL GRP MINING CO LTD

Method for purifying talc associated natural powder quartz and powder quartz

InactiveCN109261344AEfficient separationLow MgO contentFlotationWet separationEnvironmental resistanceProduction line

The invention discloses a method for purifying talc associated natural powder quartz and powder quartz, and relates to the technical field of mineral processing. The method comprises the following steps of: carrying out reverse flotation on natural powder quartz ore pulp to obtain flotation concentrate; wherein the natural powder quartz ore pulp is obtained by pretreating natural powder quartz rawore, the pretreatment comprises scrubbing and dispersing, screening and course eliminating, and centrifuging and desliming. According to the invention, the natural powder quartz ore is subjected to scrubbing and dispersing, screening and course eliminating, and centrifuging and desliming and other pretreatments, the centrifugally separated concentrate is subjected to reverse flotation, and the powder quartz raw ore with the talc content of 2-3% can be separated without using a chemical method to obtain a powder quartz concentrate product with less than 0.01% of MgO and more than 99.7% of SiO2. The method has the advantages of good adaptability to talc-associated powder quartz ore, a short production line flow and a high beneficiation recovery rate, and is an efficient, green and environment-friendly method for purifying high-purity powder quartz ore.

Owner:江西金泰矿业有限公司 +1

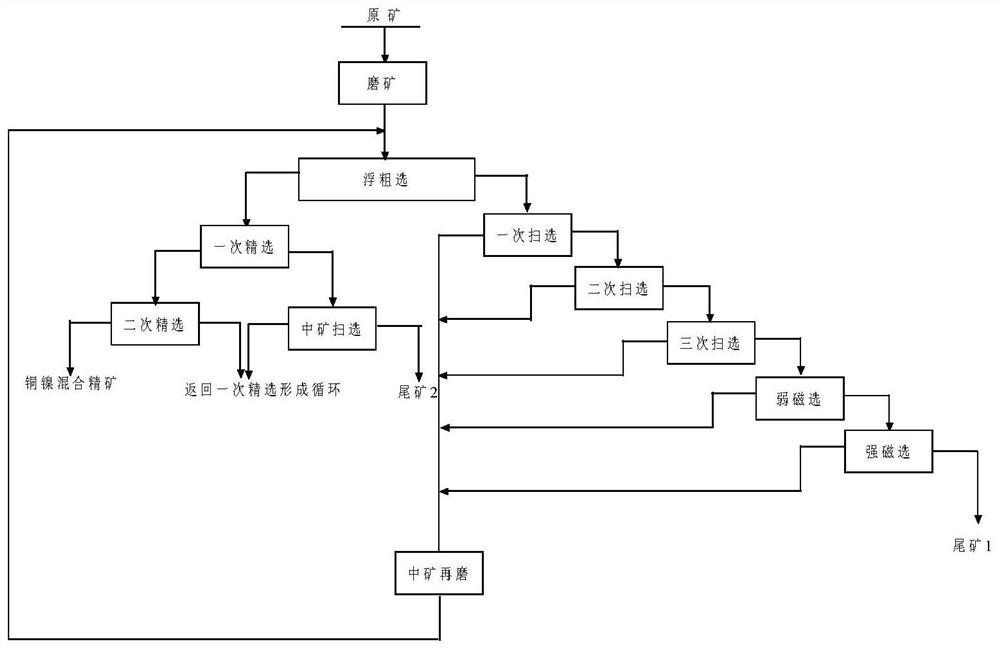

A kind of method for selecting copper and nickel from copper-nickel ore

ActiveCN112619889BHigh recovery rateReduce circulationSolid separationProcess efficiency improvementMagnetic separationGangue

The invention provides a method for beneficiation of copper and nickel from copper-nickel ore. The concentrate obtained by sweeping and the concentrate obtained by magnetic separation are selected. The invention provides a method for separating copper and nickel from copper-nickel ore. The flotation method is used to first select easily floating copper-nickel-bearing minerals, then magnetic separation to select "magnetic" copper-nickel conjoined bodies, and finally regrinding through medium ore. The dissociated conjoined cells are returned to the flotation operation for re-election, which further increases the recovery rate of copper and nickel. At the same time, part of the magnesia-containing gangue can be discarded in advance, reducing the circulation amount of the magnesia-containing gangue in the flotation system, improving the flotation environment, and thereby increasing the copper and nickel content. Nickel recovery rate, reduce MgO content in copper-nickel concentrate. The method has the advantages of simple process, easy control, high separation efficiency, excellent method index, and high quality of the obtained copper-nickel mixed concentrate.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Production method of high-quality nodulizer

ActiveCN103757518BReduce melting lossQuality improvementProcess efficiency improvementHigh magnesiumMelting tank

The invention discloses a production method of a high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent. The production method is characterized in that a first part is a rare-earth magnesium-silicon-iron spheroidizing agent of which the content of Mg is controlled to be not higher than 10%, the content of Si is controlled to be not lower than 65% and the content of RE (Rear Earth) is not higher than 2%, and the rare-earth magnesium-silicon-iron spheroidizing agent containing the ingredient realizes a magnesium light-free status during both melting and pouring, thus generation of magnesium oxide is greatly reduced; a second part is a combined type melting tank for pouring alloy liquid of the ingredient rare-earth magnesium-silicon-iron spheroidizing agent. A new process overcomes the problems of ingredient segregation and high magnesium oxide content of a conventional rare-earth magnesium-silicon-iron spheroidizing agent; the magnesium oxide content of the high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent is smaller than 0.3%; the melting loss of spheroidizing agent alloy is small; the finished product rate of the high-quality overall rare-earth magnesium-silicon-iron spheroidizing agent with required weight and shape is high.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH

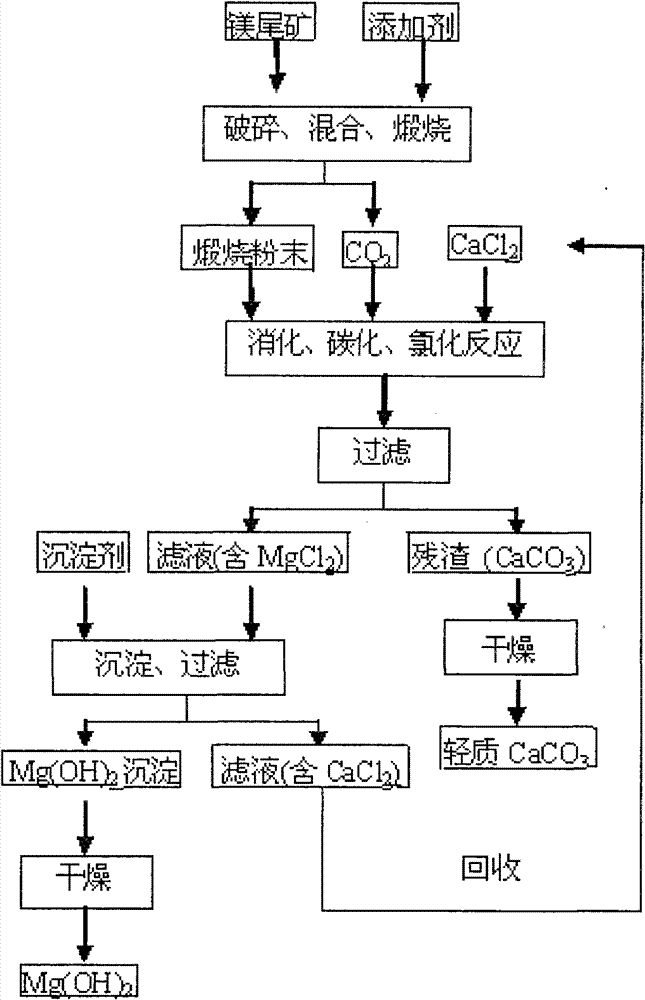

Method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings

InactiveCN101857258BPromote decompositionSolve pollutionCalcium/strontium/barium carbonatesSolid waste disposalCarbonizationMagnesium carbonate hydroxide

The invention discloses a method for preparing light calcium carbonate and magnesium hydroxide from magnesium tailings. A raw material is the magnesium tailings contain 18 to 36 weight percent of calcium oxide. The method comprises the following steps of: crushing and calcining the magnesium tailings to obtain calcined powder and CO2; performing digestion, carbonization and chlorination reaction on the calcined powder and the CO2 in the CO2 atmosphere under the condition of stirring so as to obtain MgCl2-containing solution and light CaCO3 precipitate; and reacting MgCl2 with a precipitator to generate Mg(OH)2 precipitate. In the method, the light calcium carbonate and magnesium hydroxide are prepared from the magnesium tailings discharged in a large quantity and other raw materials so asto solve the problem of environmental pollution and fulfill the aim of fully utilizing calcium and magnesium resources.

Owner:NORTHEASTERN UNIV LIAONING

A kind of forward and reverse flotation method of low-grade siliceous calcareous phosphate rock

The invention relates to a forward and reverse flotation method of low-grade siliceous-calcium collophosphine ore. In the method, phosphate minerals are added to the crushed siliceous-calcium collophosphine ore for flotation adjustment. Collectors and collectors for pulping, add water to dilute and then enter the positive flotation system for positive flotation of phosphate minerals; positive flotation concentrate desliming and desliming, enter the desiliconization reverse flotation stirring tank, the material after pulping Enter the reverse flotation desiliconization system for reverse flotation of siliceous gangue minerals; desiliconization and reverse flotation concentrates remove part of the water, and then grind the ore, add inhibitor sulfuric acid and magnesium collector fatty acid soap for slurry adjustment , carry out magnesium reverse flotation, and the product in the tank is the final phosphorus concentrate, which is concentrated, filtered and dried to obtain the finished phosphorus concentrate. The method of the present invention is more reasonable for the process design of processing low-grade siliceous-calcareous colloidal phosphate rock, and it can effectively improve the P of phosphorus concentrate. 2 o 5 Grade, reduce MgO content, that is to effectively improve the quality of phosphorus concentrate.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Inverse floatation collecting agent for carbonate phosphorus ore

The invention relates to a reverse flotation collector of carbonate phosphate ores and a preparation method thereof. The collector is essentially composed of the following raw materials by weight proportion: 0.5-0.8 part of acidified raw bran oil, 0.5-0.2 part of acidified soy oil, 0.01-0.1 part of foamer which takes semi-finished products after saponification as benchmark. The preparation methodof the collector is that: the mixture of the acidified raw bran oil and the acidified soy oil is taken as raw material, which is heated to 80-100 DEG C, added with soda lye and stirred for saponification, the pH value is controlled between 7 to 8, and then the foamer is added into the mixture to obtain finished products. The collector has the advantages of strong collecting capability, high selectivity, small dosage and low temperature resistance, etc., and is suitable for the ore dressing production of carbonate phosphate ores and various phosphorus ores; even when the grade of carbonate phosphate ores is reduced to 17%, the quality of the produced phosphate concentrate still can meet qualification requirements; in addition, the invention has simple preparation technique, easy operation,high recover rate of ore concentrate, low content of MgO in ore concentrate and low ore dressing cost.

Owner:HUBEI FORBON TECH

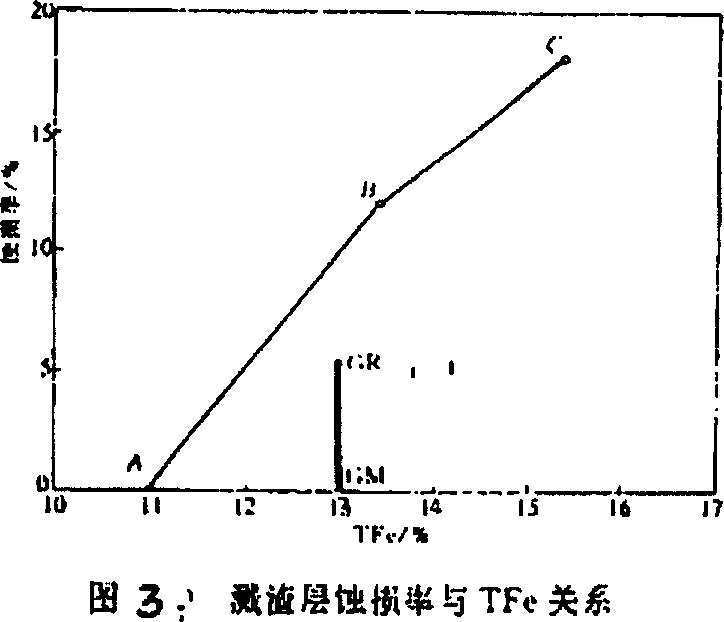

Method for Smelting Laterite Nickel Ore in Blast Furnace for Reducing Magnesium Oxide Content in Slag

The invention discloses a method for smelting laterite nickel ore in a blast furnace which can reduce the content of magnesia in slag. The method is to sieve the raw laterite nickel ore with a 25mm sieve first, and then crush and sieve the oversize material with a 25mm sieve. The sintered ore is sent to the blast furnace for smelting; in the blast furnace slag removal process, the steelmaking converter refining reduced slag is sprayed into the blast furnace slag for secondary slagging, and the injection amount of the steelmaking converter refining reducing slag is less than 1% of the mass of the blast furnace slag / 12. The invention effectively reduces the MgO content of the blast furnace slag from the original 16-20% to below 10%, can reduce the content of Cr2O3 and FeO, improves the desulfurization effect of the blast furnace, saves lime for steelmaking production, and reduces the production cost of the metallurgical process , to ensure the quality of molten steel, and at the same time, the blast furnace slag can be used in a large amount in the cement industry, with remarkable economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

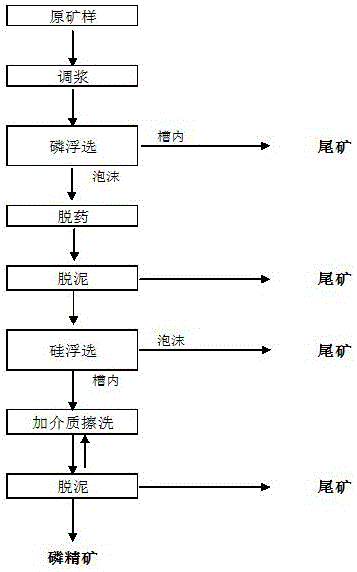

A kind of beneficiation method of mechanically demagnesizing collophosite with external medium

ActiveCN104475270BRaise the gradeQuality assuranceFlotationMagnesium phosphateMagnesium orthophosphate

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Production method of ultralow-magnesium and low-silicon active refined lime

The invention discloses a production method of ultralow-magnesium and low-silicon active refined lime. The ultralow-magnesium and low-silicon active refined lime is prepared by reducing the content of Mg and Si impurities in limestone raw materials and lime step by step through the procedures of preparing a surfactant, pretreating the limestone raw materials, calcining the lime and the like. The process is reasonable in design, the obtained ultralow-magnesium and low-silicon active refined lime is stable in quality, low in impurity element content and high in activity, and specifically, calcium oxide is larger than or equal to 92%, the activity degree is larger than or equal to 400 ml, the sulfur content is smaller than or equal to 0.01%, the carbon content is smaller than or equal to 0.02%, MgO is smaller than or equal to 0.5%, and SiO2 is smaller than or equal to 0.8%.

Owner:HUNAN HENGSHAN BICHENG CALCIUM IND CO LTD

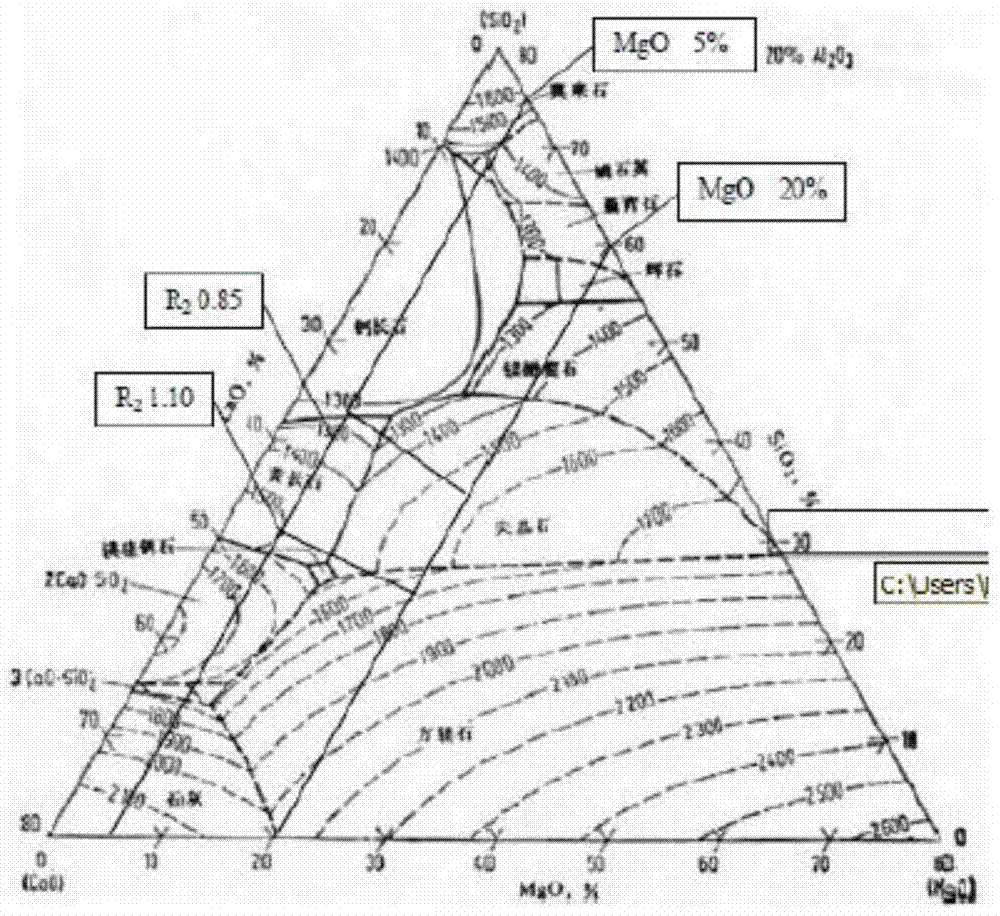

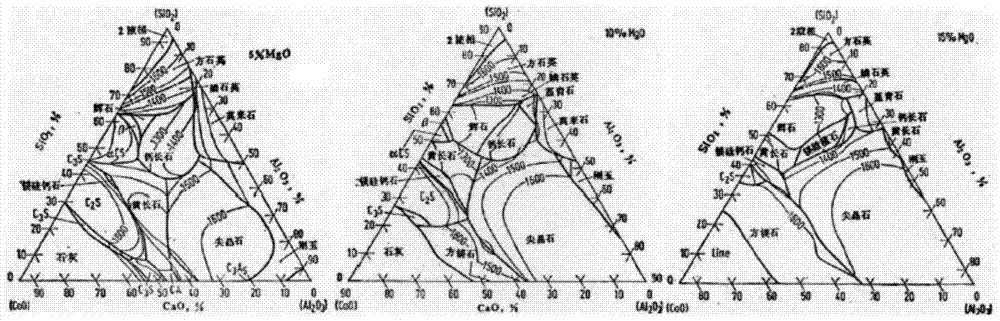

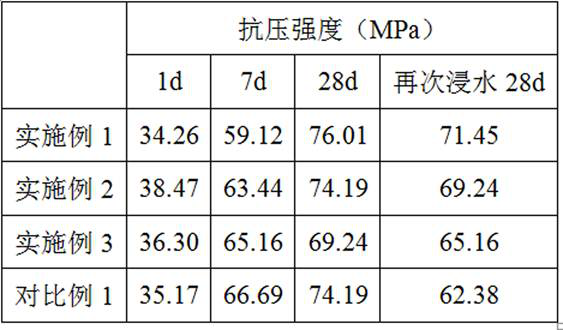

Magnesium phosphate cement containing C7A5M minerals and preparation method thereof

The invention discloses magnesium phosphate cement containing C7A5M minerals and a preparation method. The magnesium phosphate cement is prepared from the following raw materials in parts by weight: 15 to 40 parts of C7A5M, 30 to 50 parts of MgO, 15 to 20 parts of phosphate and 2 to 10 parts of boron-containing substances. According to the invention, the composition range of the final mineral phase of the magnesium phosphate cement is provided, and the C7A5M mineral phase can be separately fired at high temperature and compounded with commercially available magnesium oxide; or the mixed ore phase of C7A5M and MgO can be firstly fired at high temperature, and then is compounded with corresponding phosphate and boron-containing substances to prepare the magnesium phosphate cement containing C7A5M minerals. The composition mode of an original hydration product is changed according to the component range provided by the invention, a novel hydration product is formed, the magnesium phosphate cement is endowed with excellent hydration hardening performance, and the water resistance is greatly improved.

Owner:FUZHOU UNIV

Method for preparing magnesium alloy by electrolysis using magnesium oxide as raw material

Provided is a method for preparing a magnesium alloy by electrolysis using magnesium oxide as a raw material, comprising: (a) evenly mixing magnesium oxide, compounds of the other metal elements in the magnesium alloy, ammonium chloride, potassium chloride and additives to prepare a mixture, wherein the compounds of the other metal elements in the magnesium alloy are selected from one of the group consisting of: chlorides of the other metal elements in the magnesium alloy, oxides of the other metal elements in the magnesium alloy, and chlorides and oxides of the other metal elements in the magnesium alloy; (b) heating the mixture prepared in step (a) to a melting state, so as to prepare an electrolyte melt; and (c) electrolysing the electrolyte melt prepared in step (b), so as to obtain the magnesium alloy. The method of the present invention has a simple process, enables a continuous production, has a high degree of automation, is easy to operate and control and good in terms of environmental protection, and at the same time omits the process of producing metal magnesium and metals for the alloy, thereby shortening the overall manufacturing process of the magnesium alloy and reducing emissions and energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com