Production method of high-quality nodulizer

A production method and technology of nodulizers, which are applied in the production process of nodulizers with low oxidation and melting loss, and in the field of production with less segregation of chemical components, can solve the problems of low effective element absorption rate, violent reaction, and low magnesium oxide content. High problems, to achieve the effect of less segregation of chemical composition, stable quality and less melting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

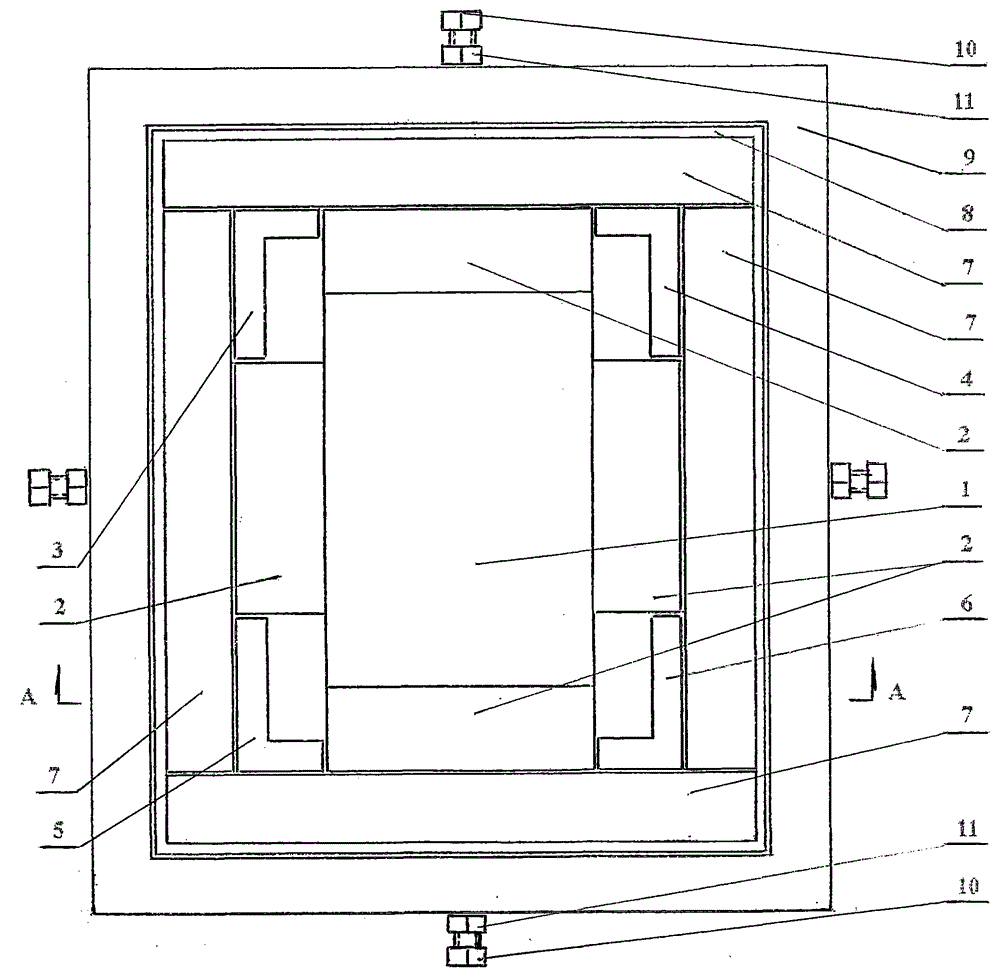

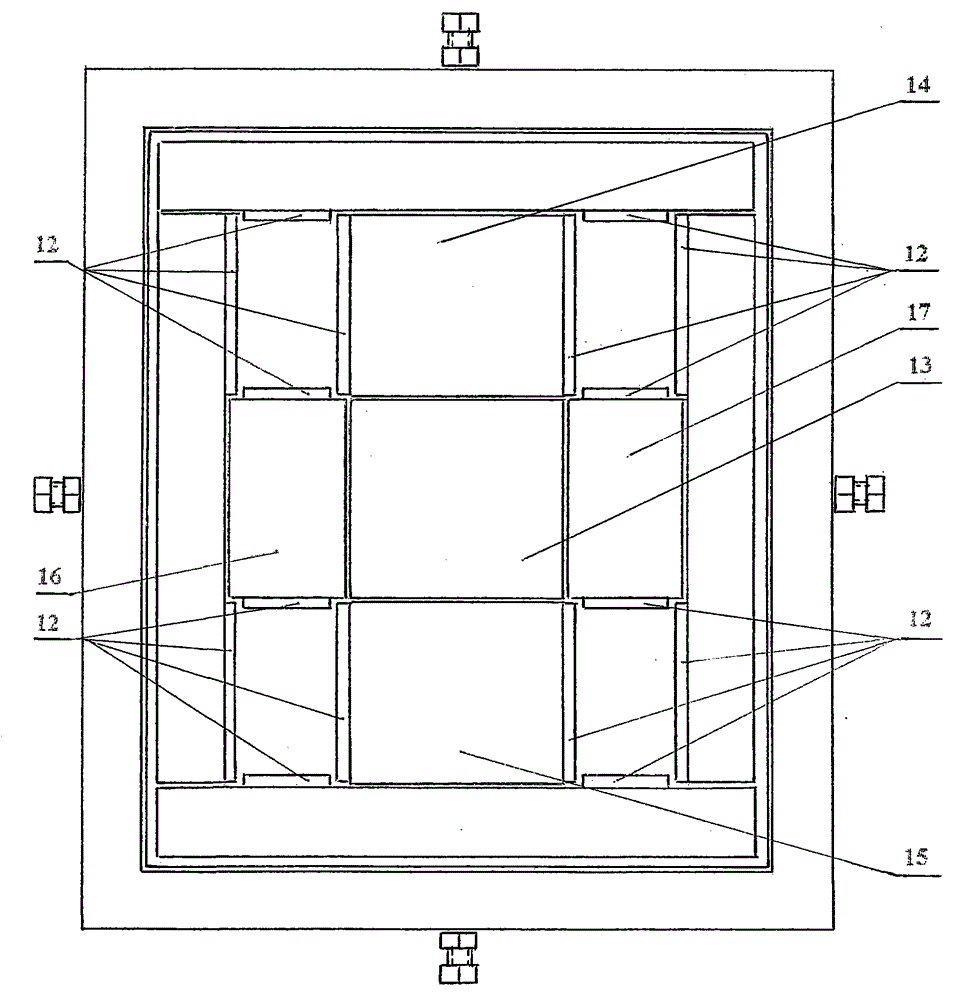

[0017] The implementation of the present invention will be further described in conjunction with the accompanying drawings:

[0018] Since the overall rare earth magnesium silicon ferrosilicon spheroidizer containing Mg10%, Si67%, RE1% has eliminated magnesium light during the smelting and pouring process of the nodulizer, and has reached a stable state, it is completely suitable for the spheroidization treatment temperature ≤ 1600 ℃ Therefore, it is of little significance to reduce the magnesium content; when the magnesium content needs to be reduced, the silicon content should be ensured to achieve a stable state where the nodulizer alloy liquid eliminates magnesium light during the smelting and pouring process.

[0019] The parts of the combined molten pool, except the outer frame 9 of the molten pool, the fastening bolts 10 and the fastening nuts 11, other components can be made of low carbon steel or heat-resistant cast iron.

[0020] Adjusting the spacing of the ribs 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com