Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2772 results about "Dust abatement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust abatement refers to the process of inhibiting the creation of excess soil dust, a pollutant that contributes to excess levels of particulate matter. Frequently employed by local governments of arid climates such as those in the Southwest United States, dust abatement procedures may also be required in private construction as a condition of obtaining a building permit. Dust control is most commonly used in vineyards, orchards and logging roads.

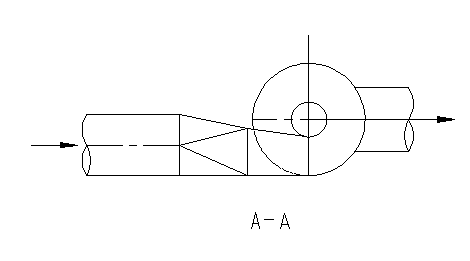

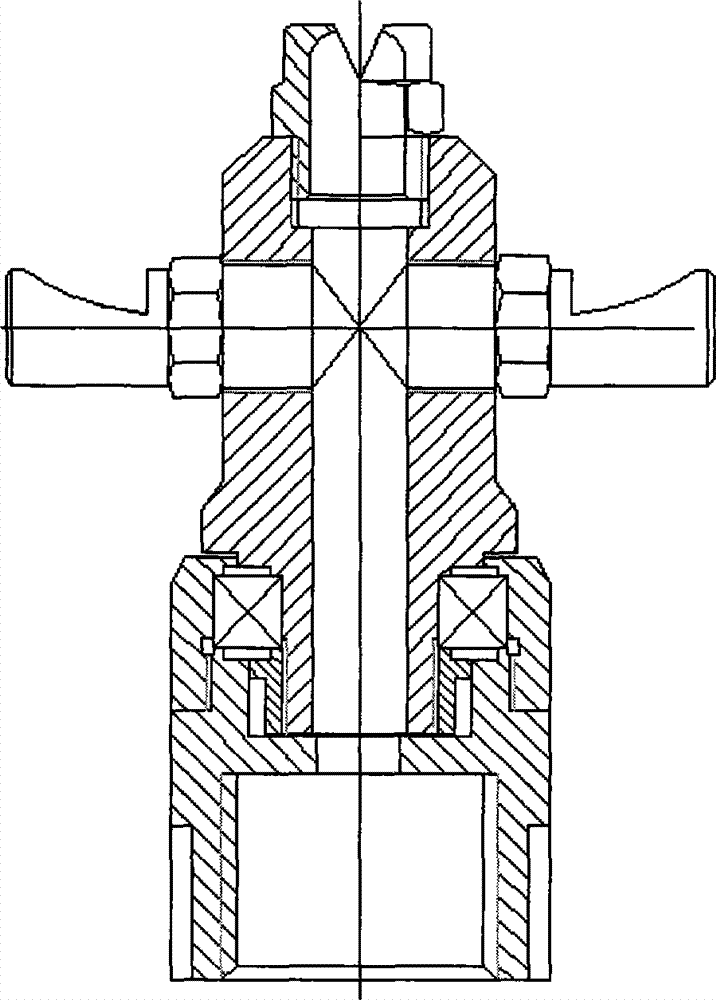

Decelerated centrifugal dust removing apparatus for dust cleaner

InactiveUS20030200736A1Avoid secondary pollutionSmooth rotationCombination devicesAuxillary pretreatmentLow noiseFilter system

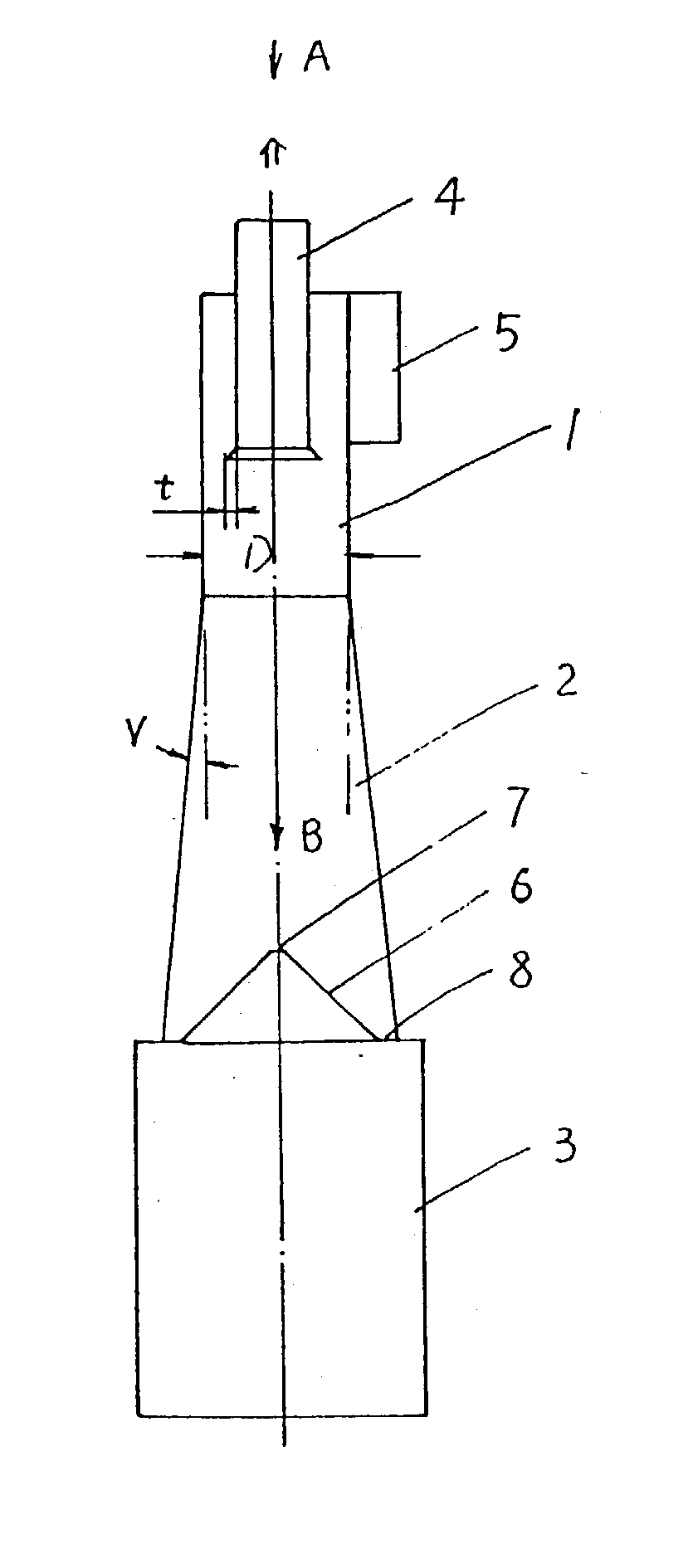

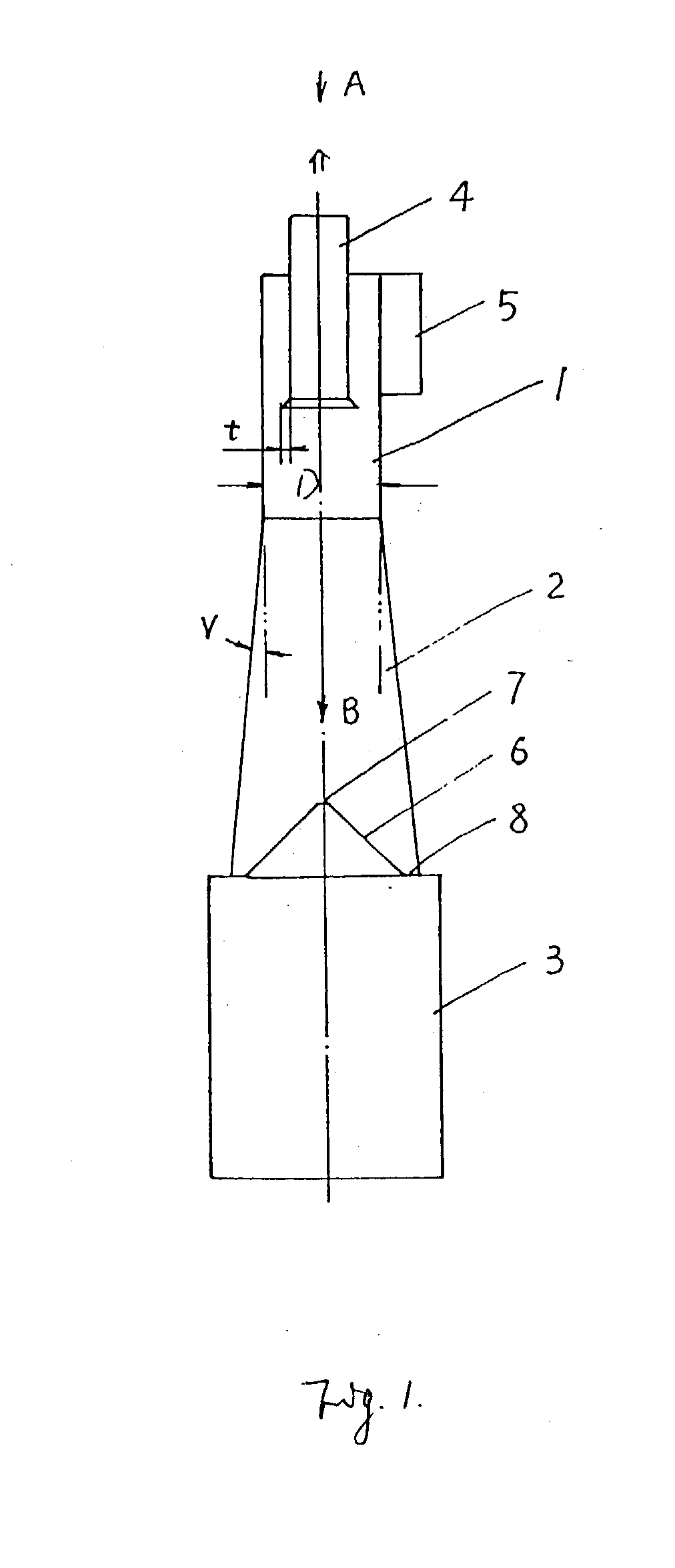

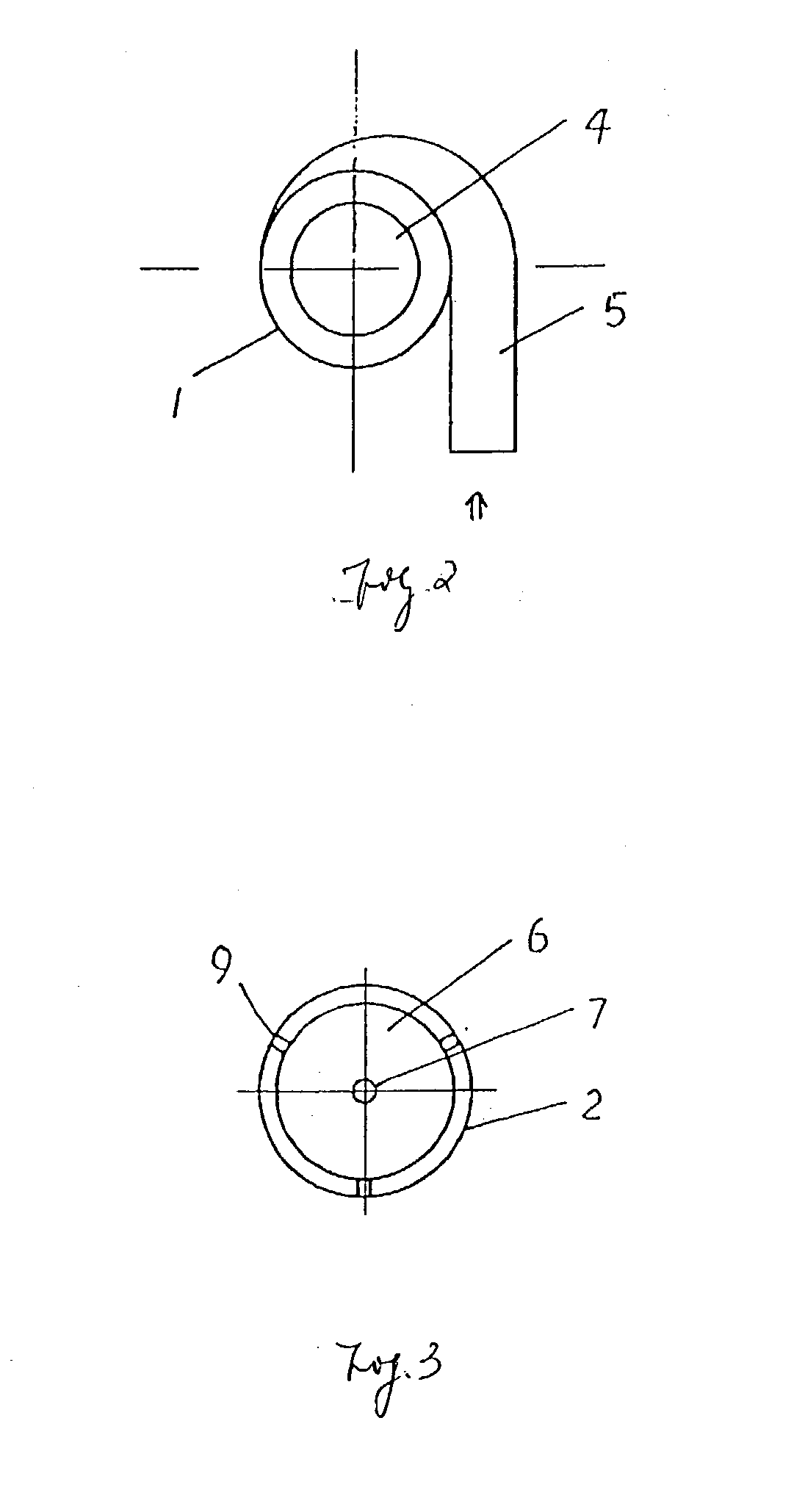

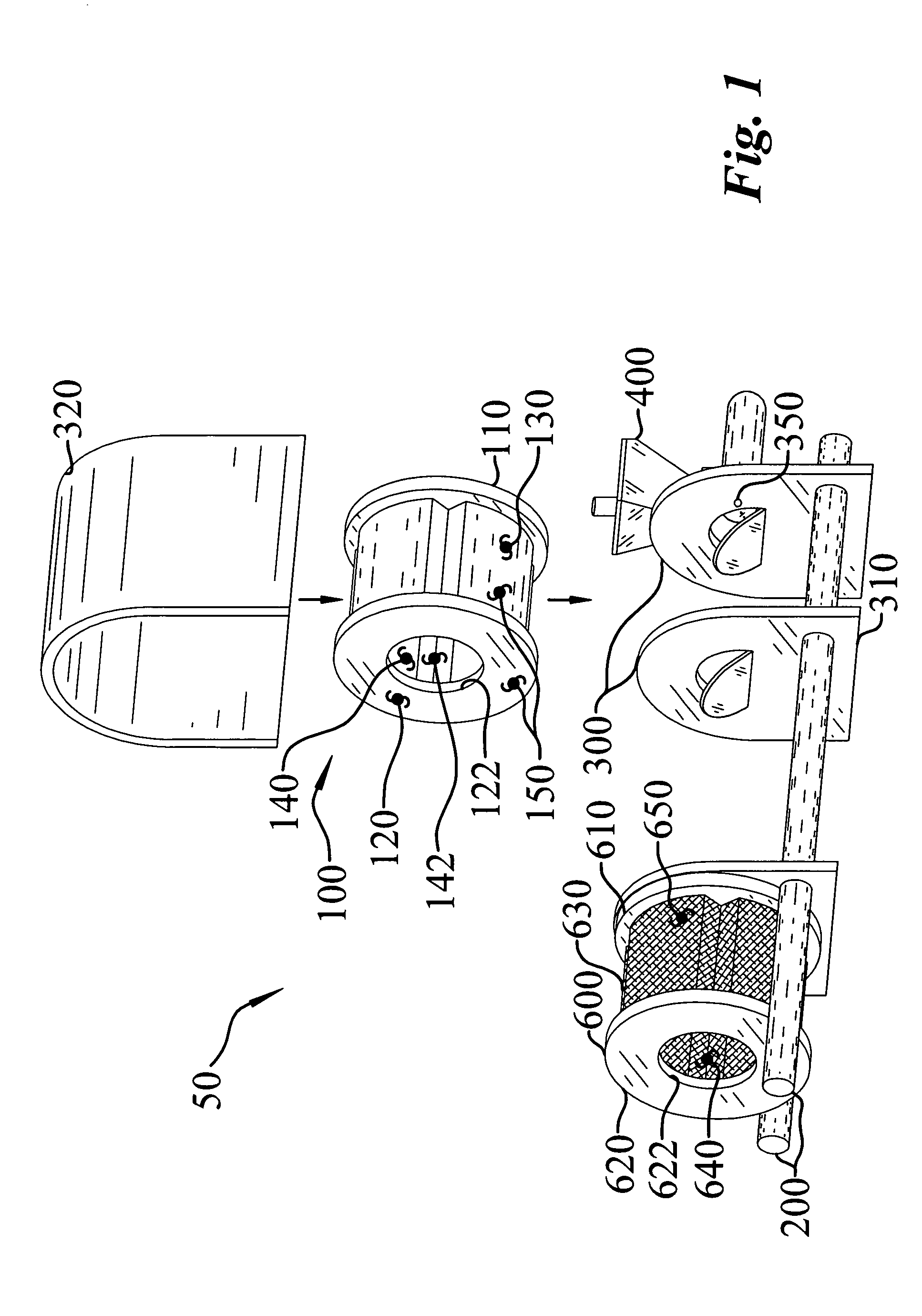

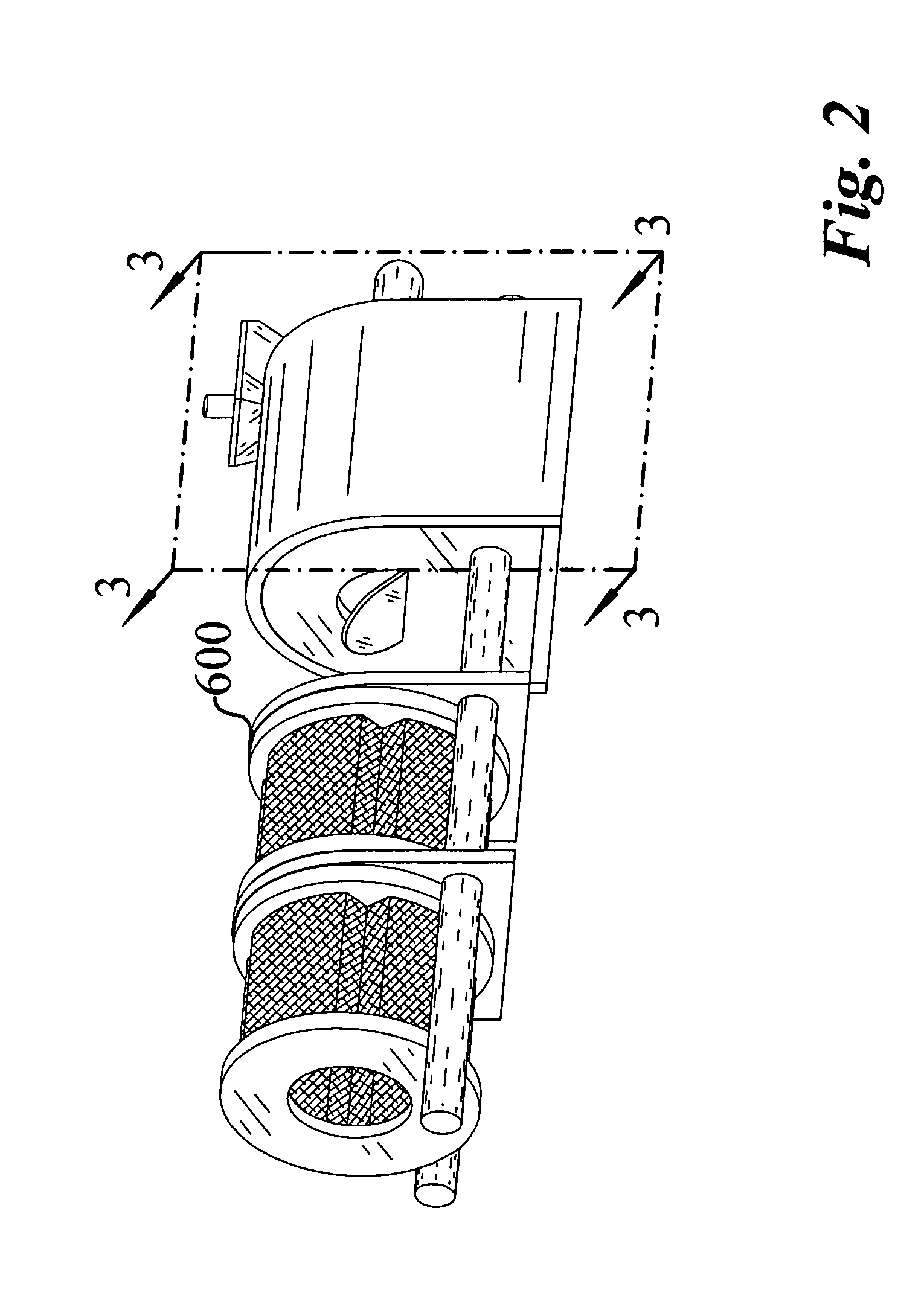

The present invention discloses a decelerated centrifugal dust removing apparatus for a dust cleaner. It comprises a cylinder, a conical cylinder and a dust collector box connected in the given order from the upper part to the lower part, as well as an air outlet pipe and an air inlet pipe on the cylinder body. The conical cylinder has a small upper end and a large lower end. In the conical cylinder, on the lower part of the air outlet pipe (under the air outlet pipe) there is an umbrella-shaped reflector in the center of which is provided a hole for air returning. Between the periphery of the umbrella reflector and the side wall is provided an annular gap for the falling down of dust. The apparatus features small loss of air flow pressure, good effectiveness of air suction, high quality of dust filtering, and low noise. With the apparatus, the secondary pollution of the cleaned air can be effectively prevented, and it is especially suitable for use in a secondary stage filtering system of the dust cleaner and for separating small and fine dust particles.

Owner:SUZHOU KINGCLEAN FLOORCARE

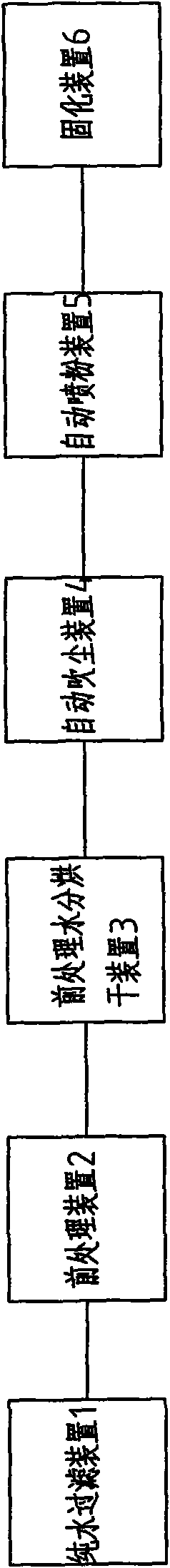

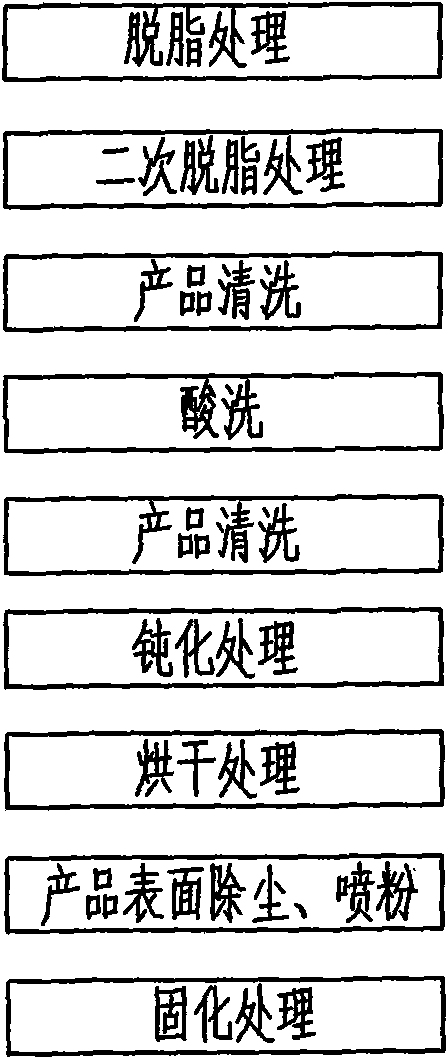

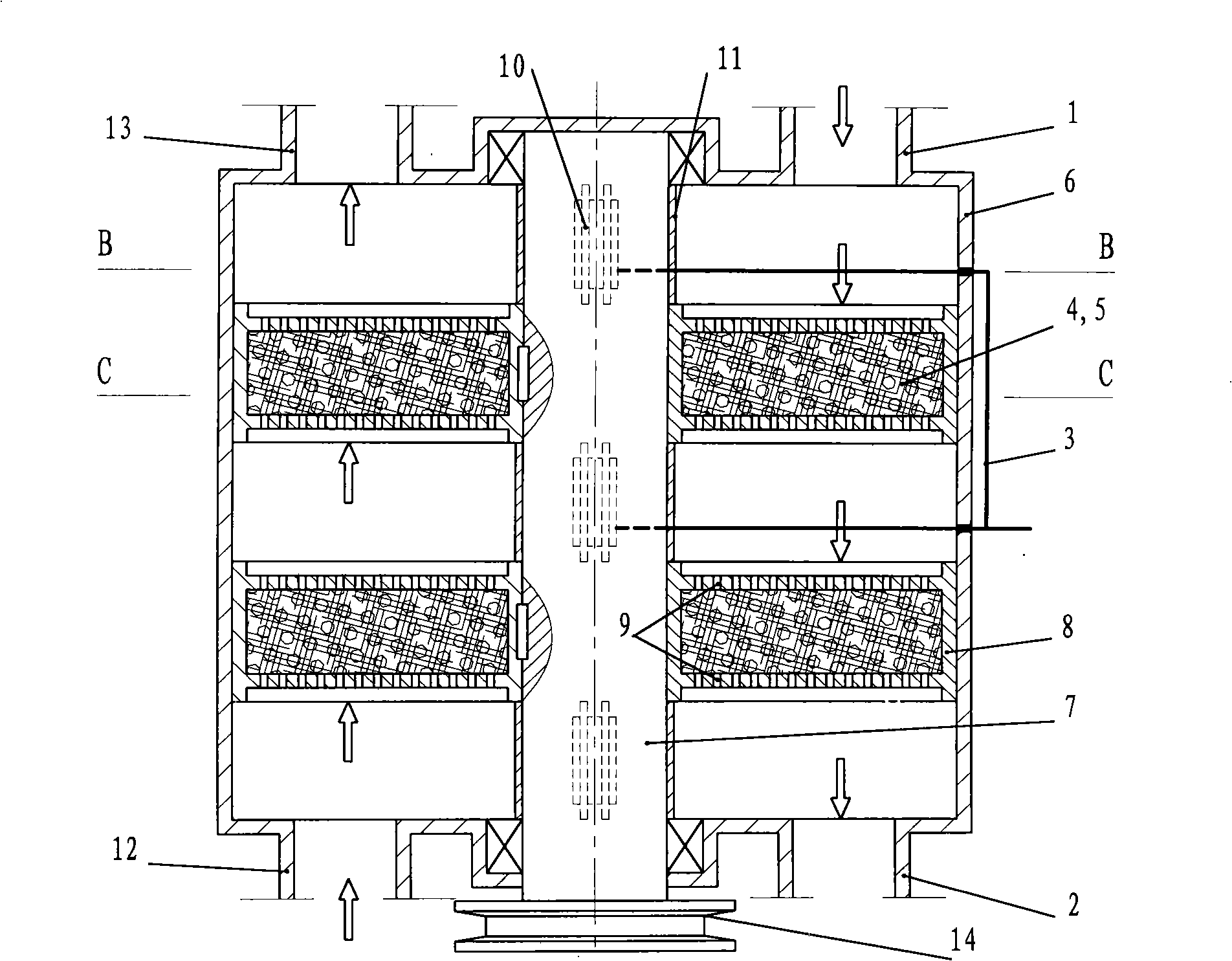

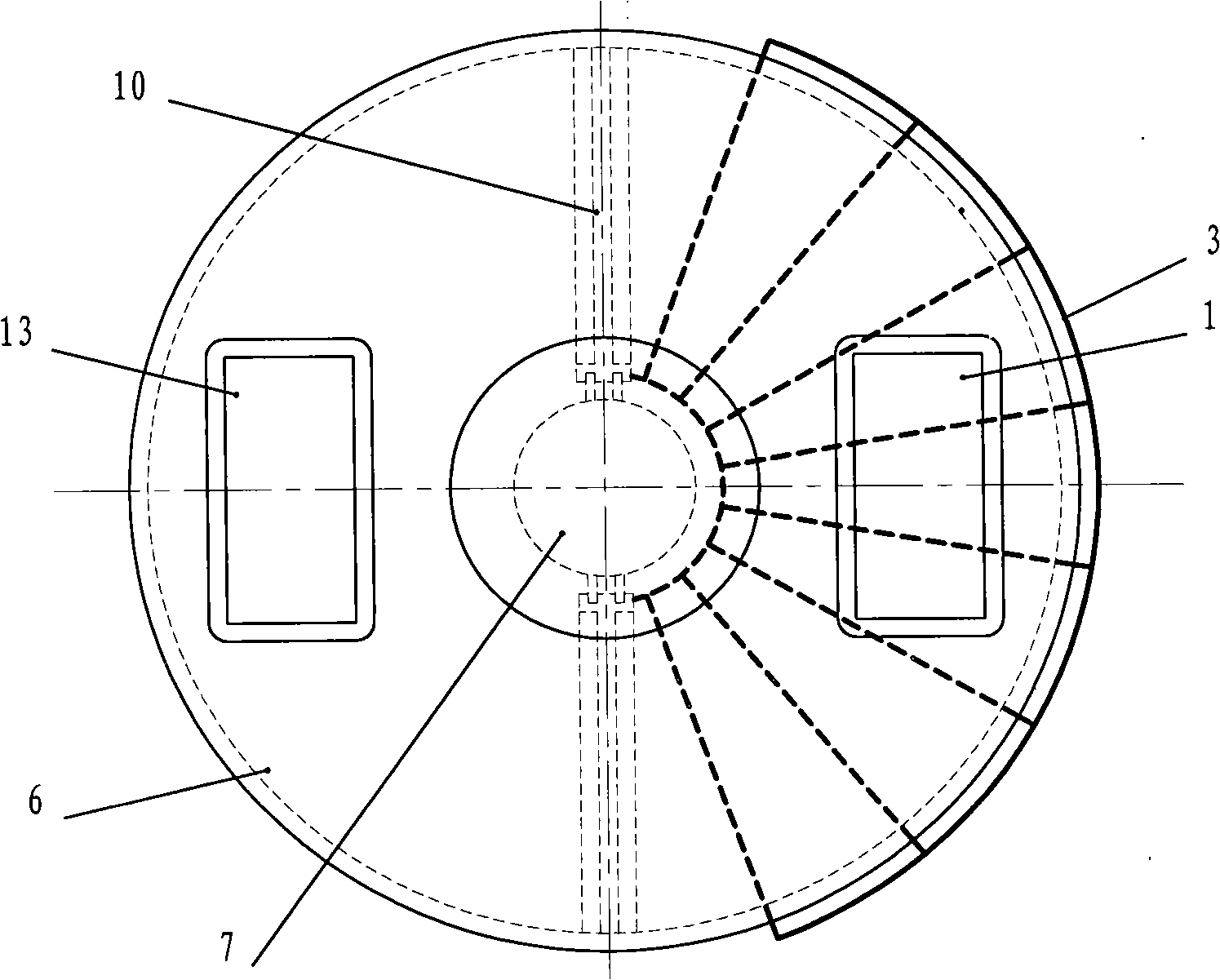

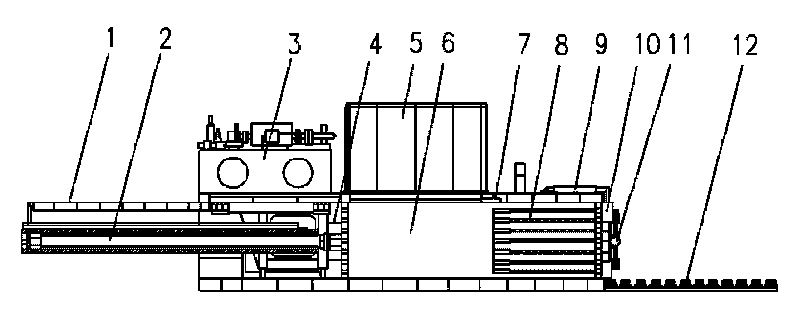

Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

ActiveCN101602042AEvenly distributedSave resourcesLiquid spraying plantsPretreated surfacesSurface cleaningFiltration

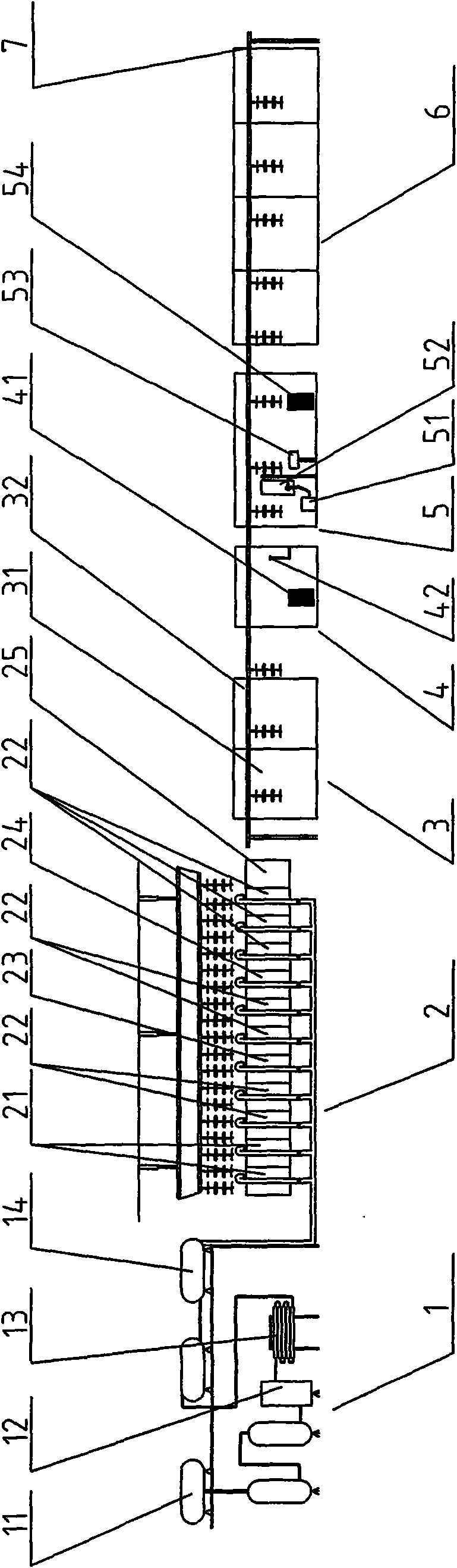

The invention relates to an automatic powder spraying line for automobile wheel hub finishing components and a technique thereof; the production line comprises a pure water filtration system for providing pure water for the power spraying line, a pretreatment device, a pretreatment water content drying device, an automatic dust blowing device, an automatic powder spraying device, a solidifying device and a conveying lead rail; wherein, the pretreatment device sequentially comprises a pickling tank, alkaline wash tank and a passivation tank; the automatic powder spraying device comprises a tank body, a powder spraying gun, a powder storage tank, a powder sucking device, a constant temperature and humidity device. The production technique has the following steps: 1) alkali degreasing, 2) product surface cleaning, 3) drying, 4) dust abatement, 5) power spraying, 6) solidification. The production line of the invention features high degree of automation, suitability for mass production, high output benefits and low cost; in addition, the production technique equipped with the production line is more reasonable, components produced by the coating method of powder spraying has more uniform surface color and thickness.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

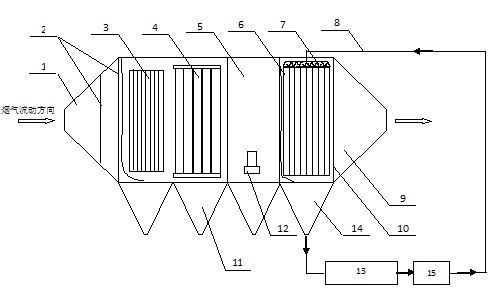

Electrostatic precipitator with high-efficiency dust collecting pole

The invention relates to an electrostatic precipitator of an efficient dust collecting electrode, comprising a shell which is provided with an airflow inlet and an airflow outlet. A discharge electrode and a dust collecting electrode are arranged in the shell. Wherein, the dust collecting electrode comprises a hollowed-out metal shell, and a dust collecting plate or a dust collecting sphere or an alveolar porous plate which is filled in the shell and manufactured by porous metallic foams or porous foam plastics processed via conductive treatment, and the dust collecting plate or the dust collecting sphere moves between an integration chamber and a dust cleaning chamber. The electrostatic precipitator of the efficient dust collecting electrode of the invention selects the porous metallic foams or the porous foam plastics processed conductive treatment, to manufacture a flat type, a granular type or an alveolar porous type to fill in the shell of a metal framework or a reticular formation to manufacture the dust collecting electrode with different structures such as rotary type, flat brattice type, circular flow type and so on, and at the same time separates a dust collecting area and a dust cleaning area to make dust collection efficiency of the electrostatic precipitator reach to more than 99.99%. The dust collecting electrode of the invention is particularly applicable to the last stage of the electrostatic precipitator, wherein, after dust abatement, dust content of the gas per cubic meter is less than or equal to 10mg.

Owner:孟金来

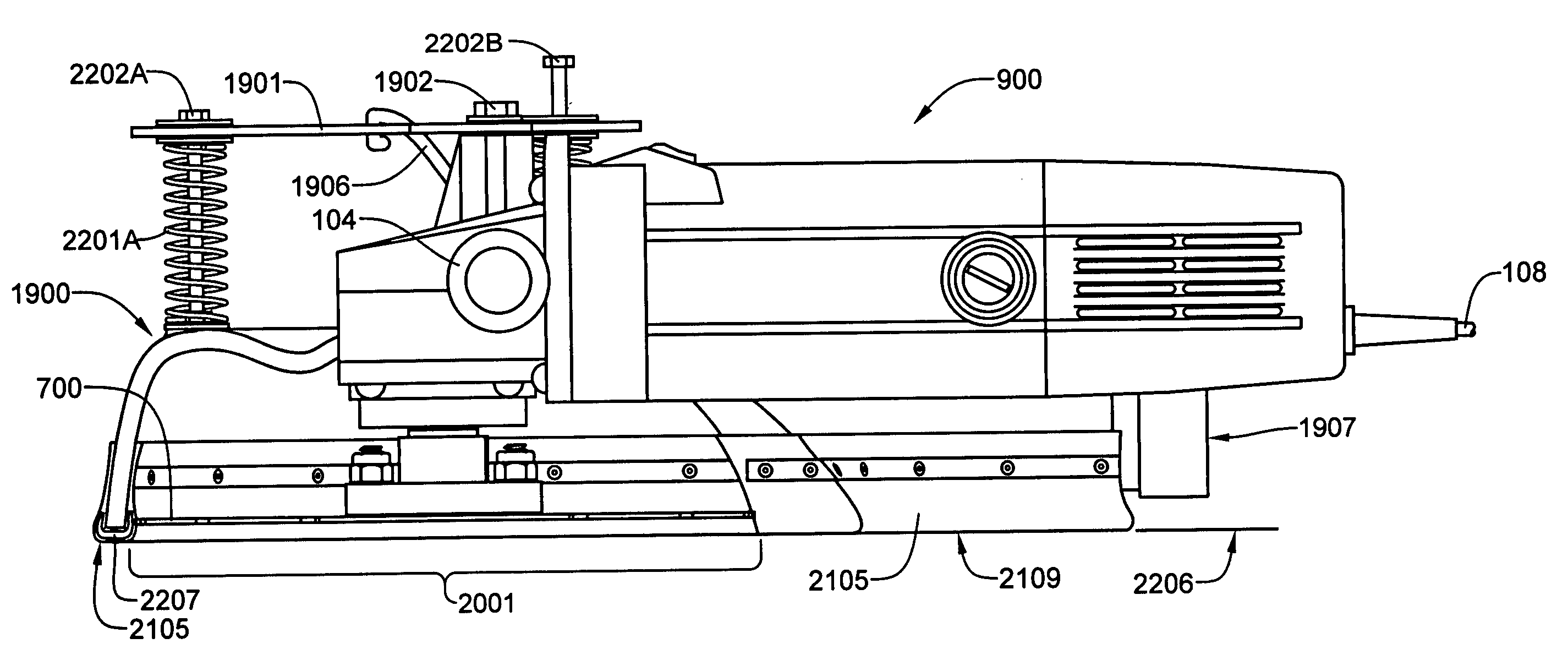

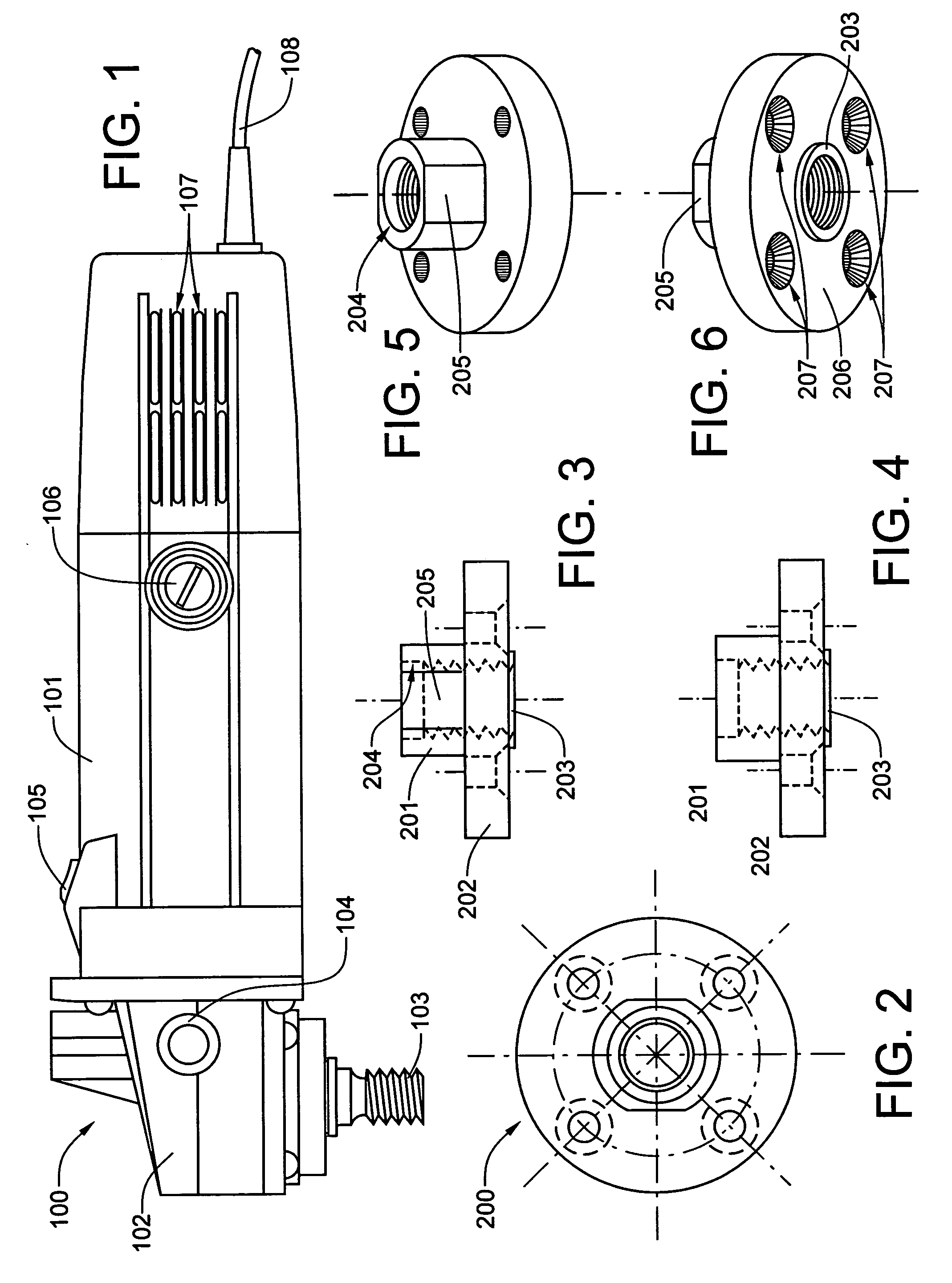

Handheld flush-cutting concrete saw having a dust abatement vacuum hood

A dust abatement vacuum hood, provided for a flush-cutting concrete saw, includes a rigid shell that is preferably either vacuum formed or injection molded from a tough polymeric material that may be reinforced with structural fibers. Alternatively, the vacuum hood may be stamped or cast from a durable metal. The vacuum hood is equipped with a vacuum port to which one end of a vacuum hose may be attached. The opposite end of the vacuum hose is attached to a vacuum cleaner system. The vacuum hood has a spring-mounted attachment bracket that can be bolted directly to the concrete saw. As the blade of the concrete saw rotates, pulverized concrete is discharged into a chamber opening of the vacuum hood. Internally, the vacuum hood is shaped so that the pulverized concrete is directed toward the vacuum port, from where it is directed to the vacuum cleaner system.

Owner:PRECISION CONCRETE CUTTING

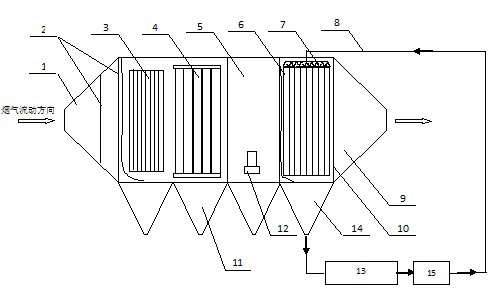

Wet-dry mixing electric dust remover

InactiveCN101816975AEfficient dust removalImprove dust removal efficiencyExternal electric electrostatic seperatorElectrodes cleaningEmission standardEngineering

The invention relates to a wet-dry mixing electric dust remover. The electric dust remover mainly consists of an inlet smoke box, an air flow uniformly-distributing plate, a shell, a cathode line, an anode plate, an outlet smoke box, an outlet trough-shape plate, a rapping device, an ash bucket, a water distribution device and a water tank. The electric dust remover is characterized in that the upstream in the inflow direction of the smoke gas or the exhaust gas is provided with a dry-type ash removal electric field which adopts mechanical rapping, electromagnetic rapping or acoustic wave to remove the ash, the last electric field is a wet-type ash removal electric field which adopts a water film to remove the ash, the dry-type ash removal electric field and the wet-type ash removal electric field are arranged in the same shell, and the wet-type ash removal electric field is connected with an ash removal water treatment recycling system. The invention integrates the advantages of the dry-type electric dust removal and the wet-type electric dust removal, efficiently removes dust, ensures emission standards and minimizes the corrosion protection investment caused by the wet-type ash removal, the water treatment equipment investment and the running cost.

Owner:SHANDONG ELECTRIC POWER RES INST

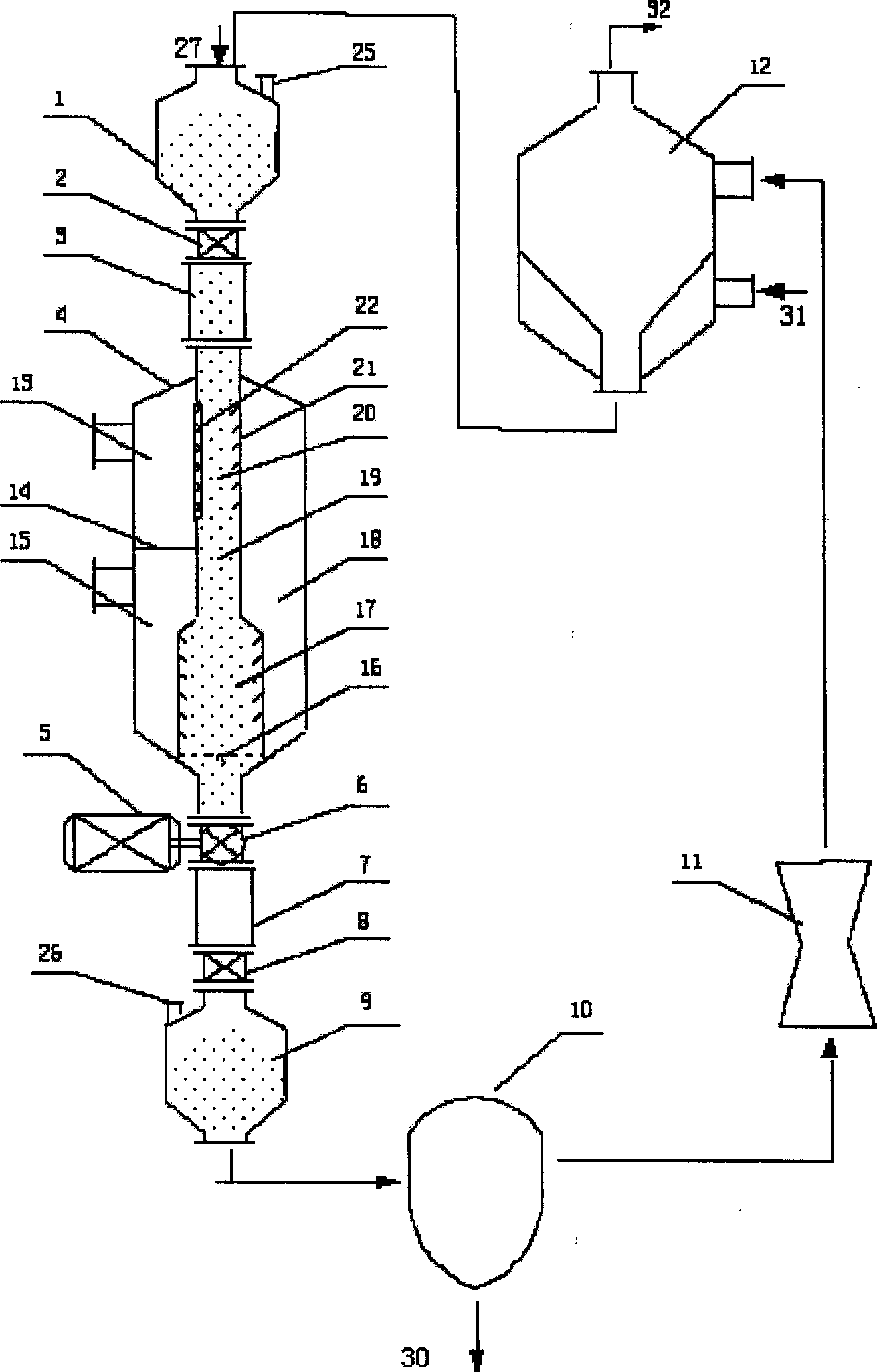

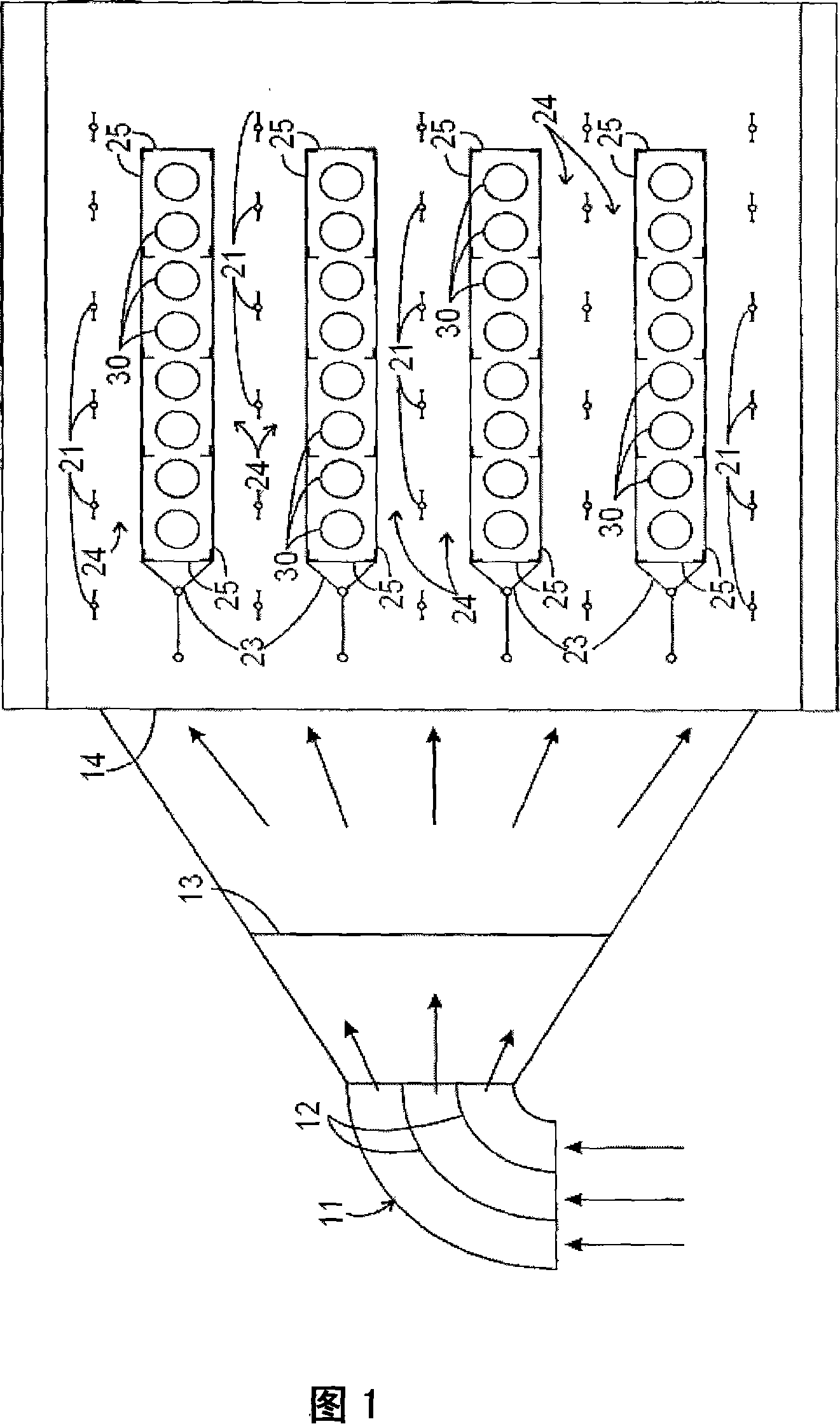

Integrated method and device of high temperature coal gas desulfur and dust removing

InactiveCN1478872ATake advantage ofOvercoming the disadvantage of low utilizationGas purification by treating with solidsFilter mediaSmall footprint

A process for desulfurizing and dusting high-temp gas features that the metallic oxide as desulfurizing agen is used as filter medium, the composite moving particles bed is used as filter, and the particles move downward and gas passes transversely through the particle layer to remove gas-state sulfide and dust. Said composite particles-moving bed has upper and lower layers and the gas passes through the particle layer upward.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

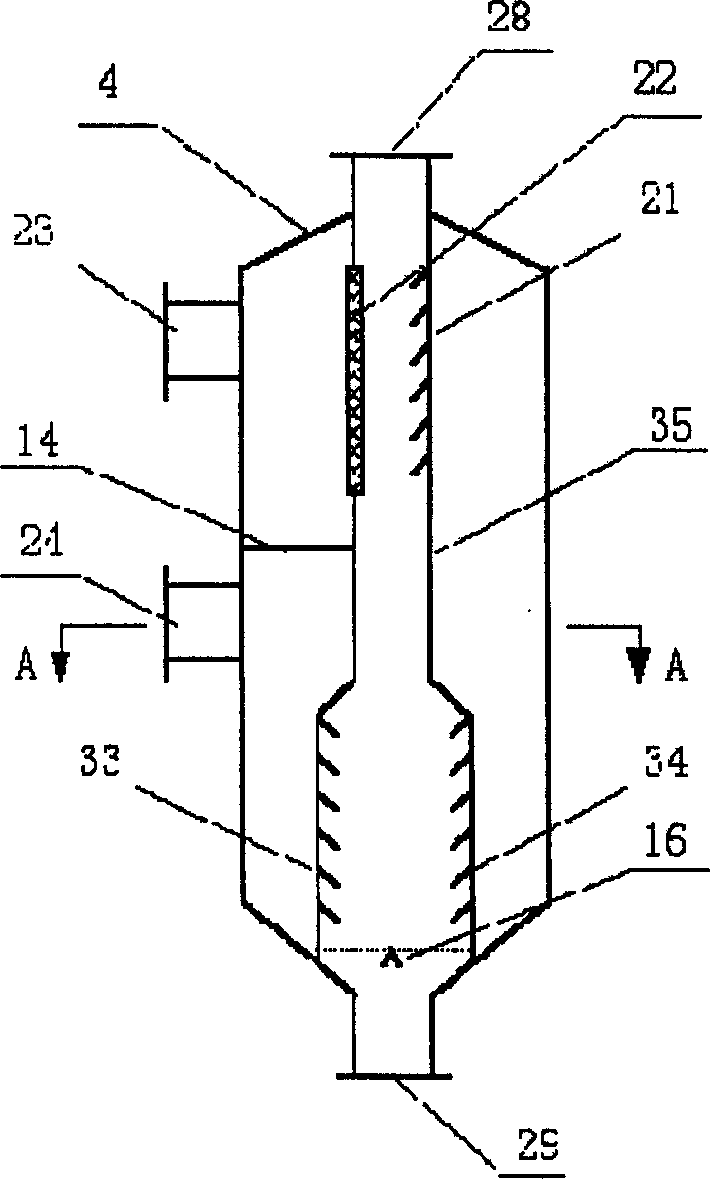

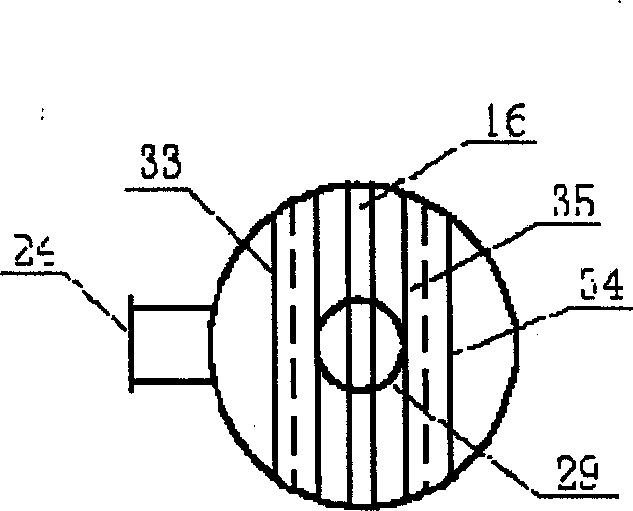

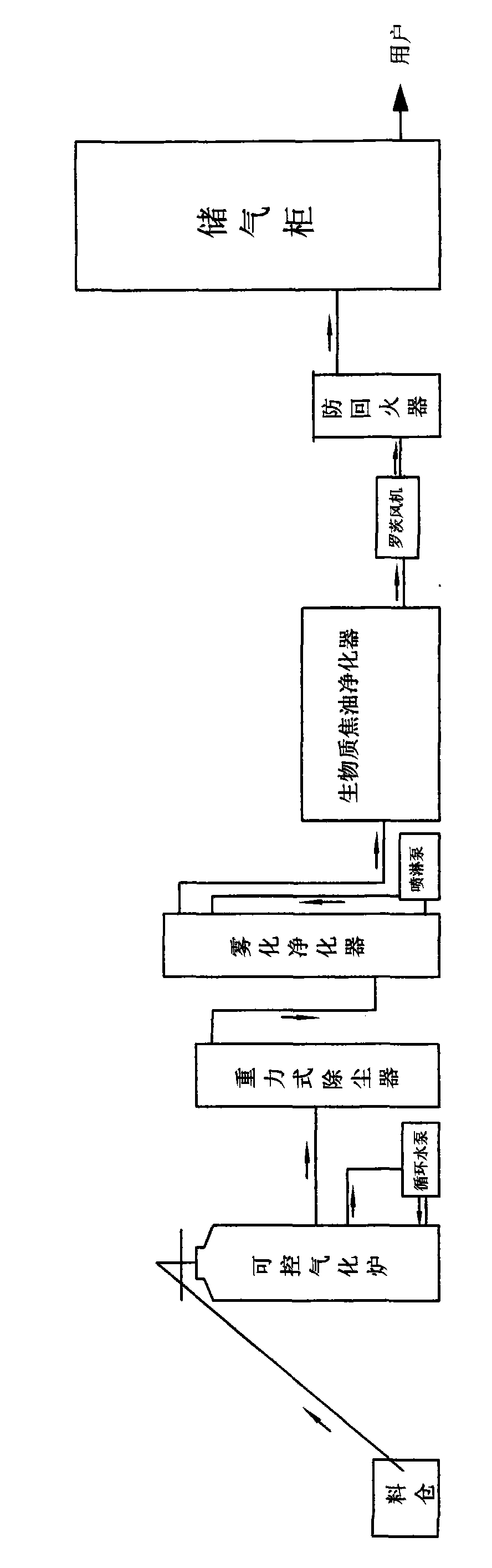

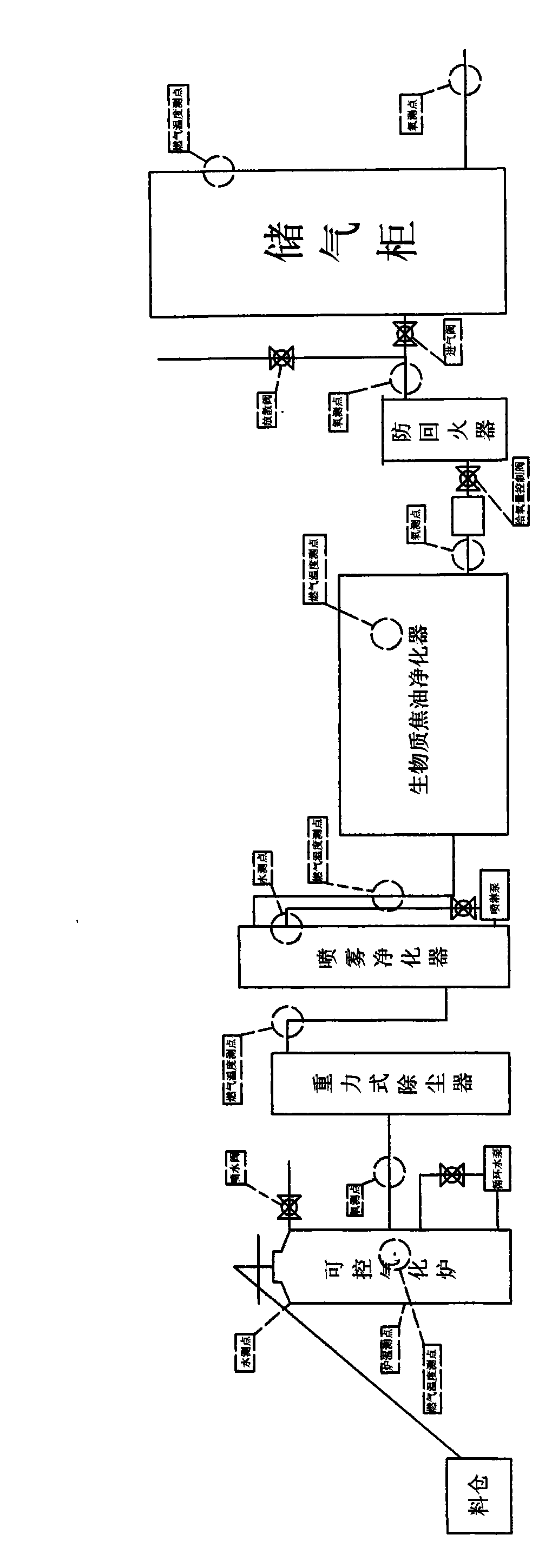

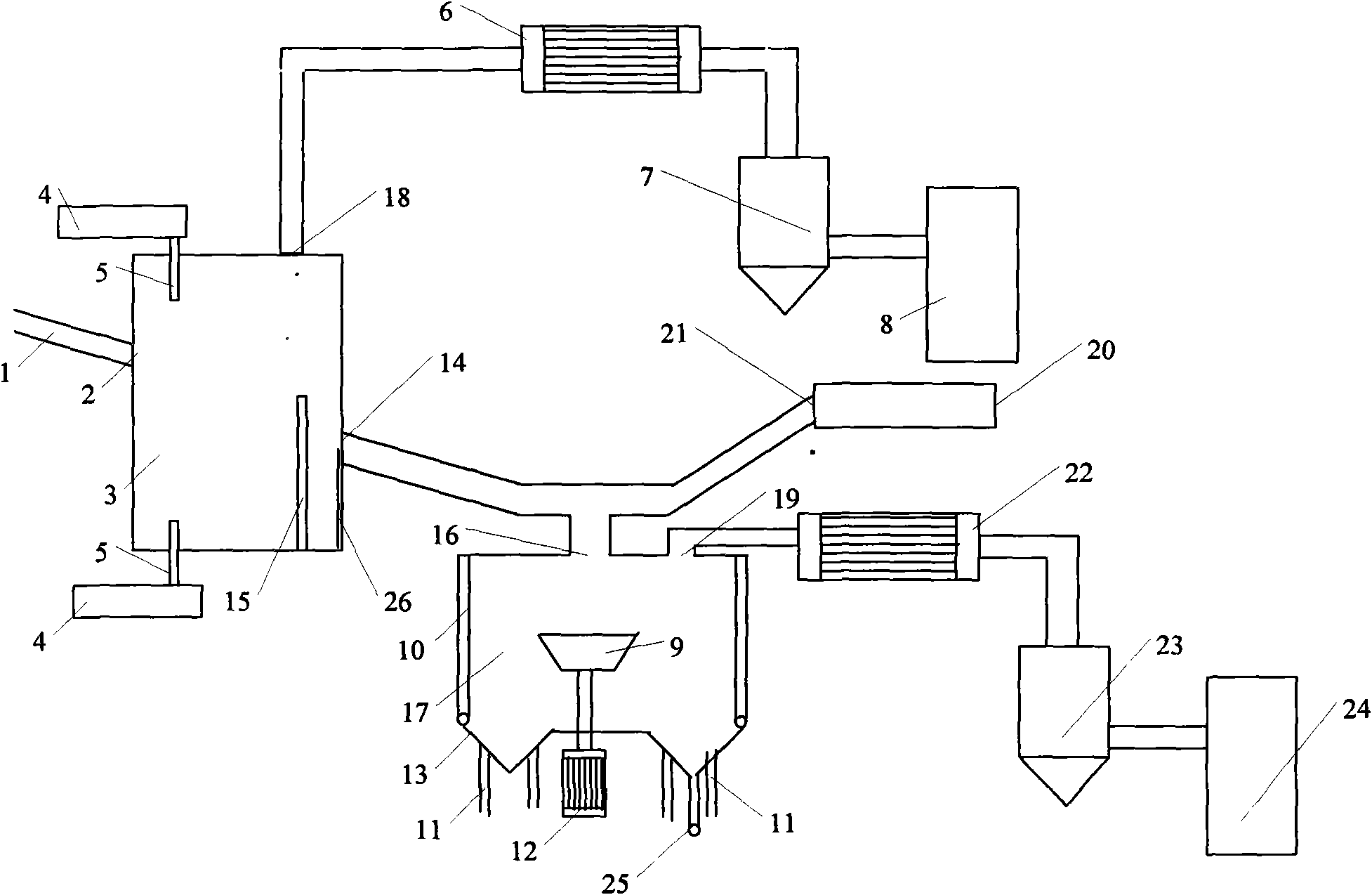

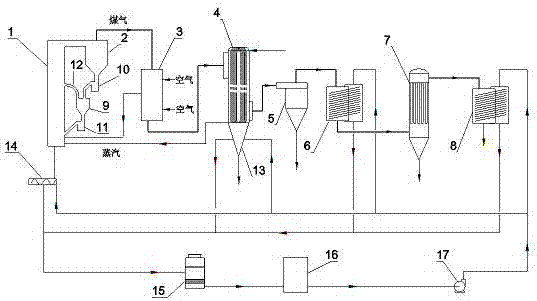

Method for preparing fuel gas by gasifying biomass materials and device thereof

InactiveCN101649226AReduce cloggingSolve the blockageCombined combustion mitigationCombustible gas productionTarProcess engineering

The invention relates to a method for preparing fuel gas by gasifying biomass materials and a device thereof, belonging to the technical fields of methods for preparing fuel gas by solid biomass materials in a gasifying process and the devices thereof. The method comprises the following steps: feeding, gasifying, dedusting, spraying and purifying, detarring, pumping front-end gases and conveying rear-end fuel gas by a Roots blower, and conveying the fuel gas to a fuel gas storage cabinet through a tempering preventing device. The device realizing the method comprises a feeding mechanism, a controllable gasifying furnace and a circulation water pump, a gravity deduster, a spraying purifier and a spraying pump, a biomass tar purifier, the Roots blower, the tempering preventing device and thefuel gas storage cabinet. The device is used for transforming the solid biomass materials of straws and the like into the fuel gas with less impurities and high heat value and supplying the fuel gasfor users centrally.

Owner:ZHENYU COMPLETE SET ELECTRIC EQUIP GROUP BEIJING

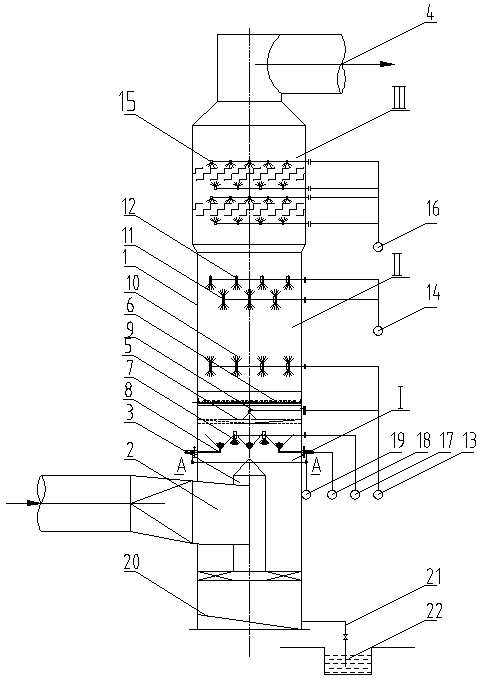

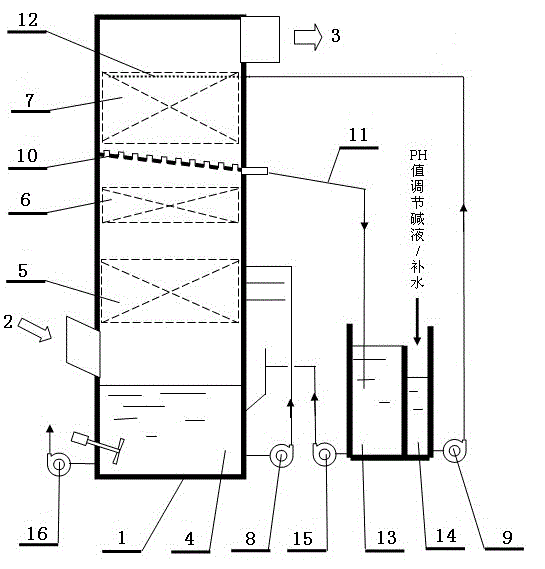

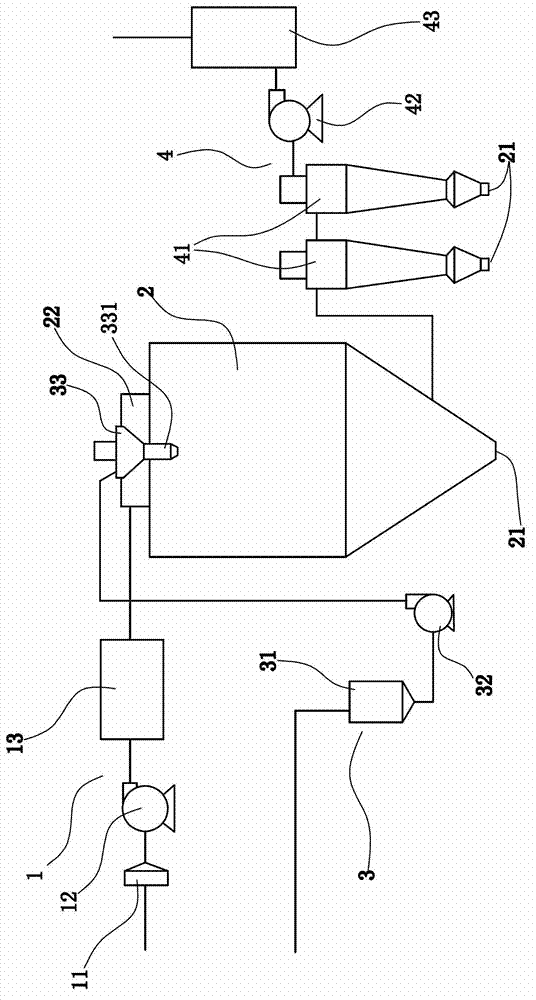

Efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device

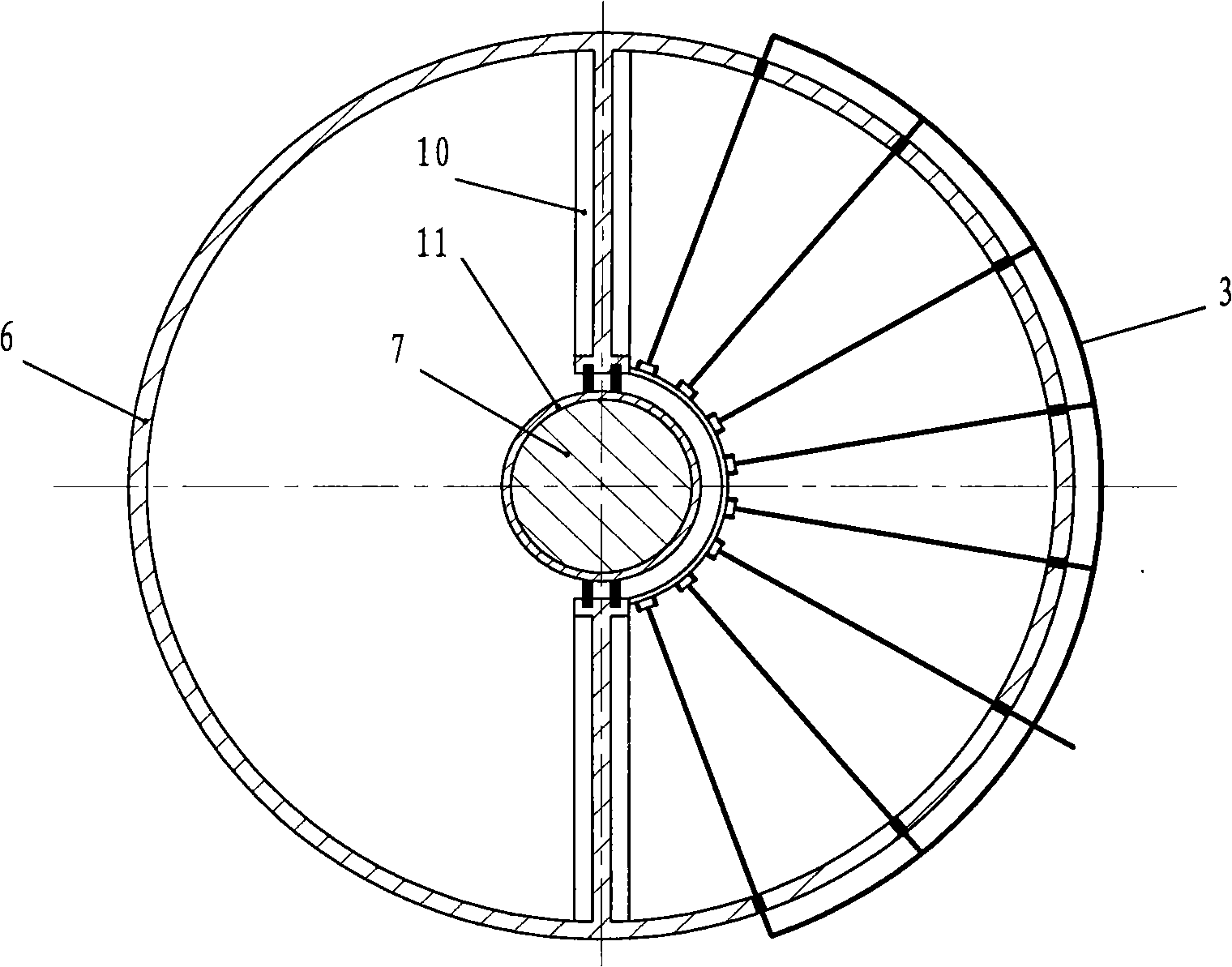

ActiveCN103316553AUniform rotary contactMake full use of the mass transfer efficiency of block purificationUsing liquid separation agentSuspended particlesParticulates

The invention relates to an efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device comprising a washing tower, wherein the lower end of the washing tower is provided with a smoke inlet tangent with the washing tower; a center steady flow column is arranged in the middle of the lower end of the washing tower to form an annular channel with the washing tower; a fog condensation trapping area, a sprinkling washing area and a dehydration demisting area are arranged above the steady flow column from bottom to top; a variable flow jet intercepting layer is arranged between the fog condensation trapping area and the sprinkling washing area; a smoke outlet is formed in the upper end of the washing tower. According to the efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device, the variable flow jet intercepting layer is additionally arranged in the washing tower so that rotary flow direction jet flow and plug flow transformation are implemented in the smoke flow direction sequentially, fogdrop groups of different fine particle sizes or the fogdrop groups of an absorbent are poured into the fog condensation trapping area to form a high-density fog group fog field taking suspended particles as a core, and the fog group fog field can be efficiently condensed and intercepted by the variable flow jet intercepting layer to improve the classification purification efficiency of particulate matters with the particle size being less than 40 microns so as to improve the total dust-removing purification efficiency of sprinkling the washing tower under the condition of low energy consumption.

Owner:JIANGSU BOJI SPRAYING SYST HLDG CO LTD

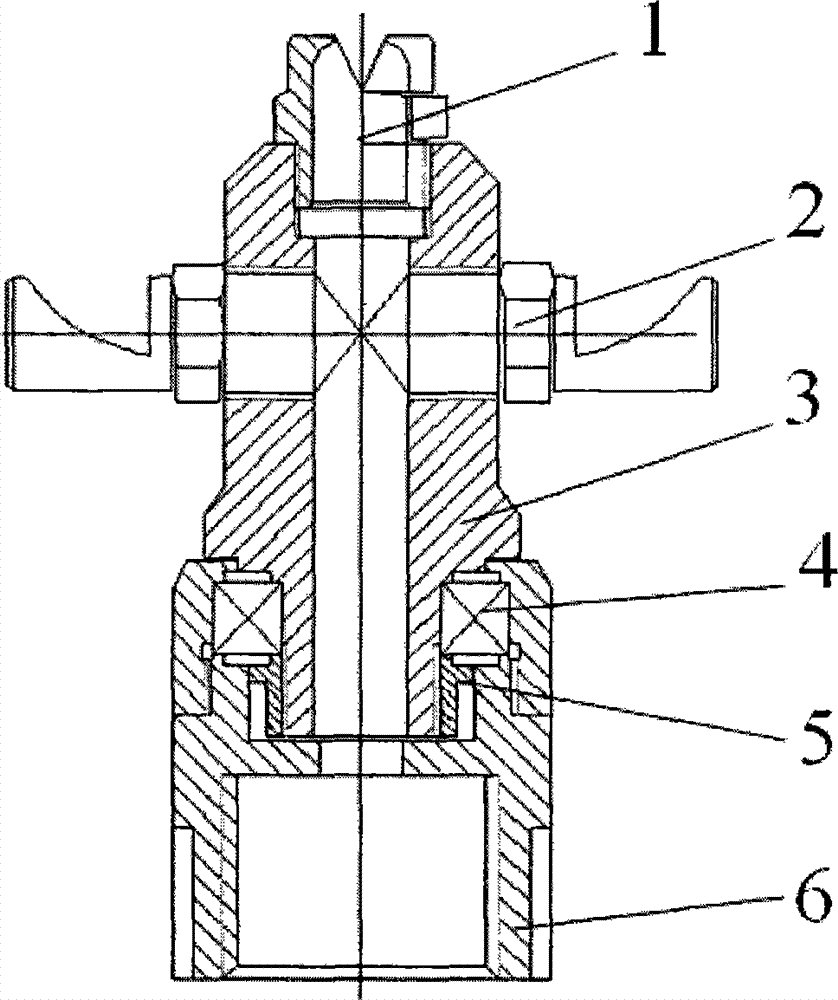

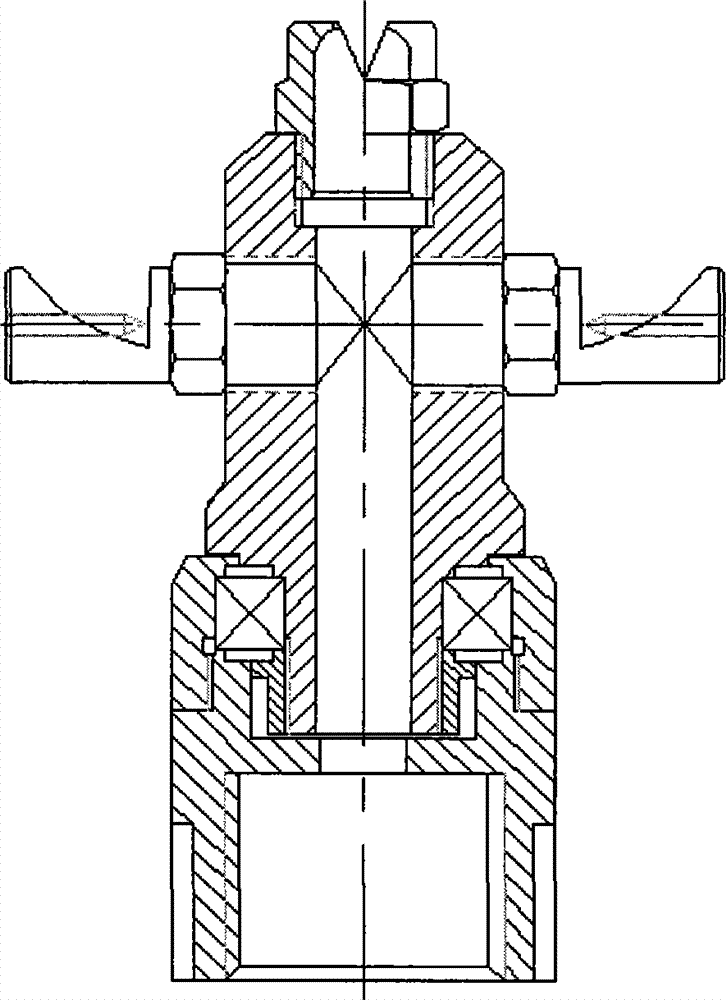

Novel rotational flow atomization apparatus and application technology

InactiveCN104741258APromote aggregationLow costUsing liquid separation agentMovable spraying apparatusSprayerEngineering

The invention relates to a novel rotational flow atomization apparatus and an application technology. The structure characteristics of a core unit, namely a novel rotary sprayer is that the upper part, connected with fluid, of the rotary sprayer is fixed, the lower part of the rotary sprayer is connected with the upper part through one or a plurality of nozzles by virtue of bearings, the lower part of the sprayer is pushed to rotate at high speed by reactive force formed when a part of kinetic energy of the fluid under pressure is ejected from the nozzles, and meanwhile, most of kinetic energy can be effectively converted into surface energy which can facilitate water flow atomization when impacting the bevel or oblique seam of the sprayer or passing through a hole. The novel sprayer has the advantages that the use pressure is low, the rotating speed is rapid, fogdrops are small and uniform, and the fog spraying coverage area is large. The novel rotational flow atomization apparatus can be applied to extinguishment, black smoke can be instantaneously eliminated, fire head is suppressed in seconds, and big fire can be extinguished within ten seconds; when the novel rotational flow atomization apparatus is applied to flue gas purification, rotational flow like tornado can be produced in a tower, and high-efficient desulfurization dust removal is realized; the novel rotational flow atomization apparatus can be widely applied to city purification, park green space watering, landscape decoration, and crop watering, fertilization, pesticide application and industrial mixing, separating, mass transfer and heat transfer processes, and the circumjacent PM 2.5 and other gaseous pollutant can be effectively removed.

Owner:BEIJING CHINA SCI PURIFICATION ECO TECH

High-efficiency wet-type electric dust removal and desulfuration system and process

ActiveCN102716639AGuaranteed desulfurization efficiencyImprove dust removal system efficiencyCombination devicesGypsumWater balance

The invention discloses a high-efficiency wet-type electric dust removal and desulfuration system and a process. A wet-type electric dust remover is arranged above a demister in a desulfuration tower. First of all, the demister is used for pre-removing mist drops and dust from clean smoke; the wet-type electric dust remover is used for performing fine treatment on the clean smoke; therefore, an extremely high environment-friendly discharging requirement is met; and the desulfuration efficiency is guaranteed, the efficiency of a dust removal system of the desulfuration tower is improved, and the dust discharge concentration at the outlet of the desulfuration tower is reduced, so that the latest discharge standard required in China is met. According to the wet-type electric dust remover, the problem of gypsum rain can be solved; various pollutants can be removed at the same time; furthermore, a water accumulation plate is arranged between the demister and the wet-type electric dust remover and used for collecting and recycling washing water of the wet-type electric dust remover, so that the washing water of the wet-type electric dust remover cannot directly enter into a neutralization oxidation pond of the desulfuration tower; and therefore, the water balance of the whole system is guaranteed.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Static electric cloth bag compact mixed type dust remover and its running method

InactiveCN101121152AGuaranteed efficiencyGuaranteed removalCombination devicesElectrode constructionsFlue gasEngineering

An electrostatic bag closely hybrid dust remover and the operation method are mainly used for the flue gas disposal in a power plant etc. A grounding collecting plate is placed between a high voltage discharge electrode and the bag inside a dust removing room. An electrostatic dust removing area is formed by two sides of the high voltage discharge electrode and the grounding collecting plate; a filtering and dust removing area is formed by two sides of the bag and the grounding collecting plate. When the bag filters, the grounding collecting plate is closed, and the flue gas enters into the dust removing room and goes through the electrostatic dust removing area to arrive at the end of the grounding collecting plate and then enters into the filtering and dust removing area. When the bag reversely blows and cleans ash, the grounding collecting plate opens, the gas and dust for reverse blowing and ash cleaning pass through the grounding collecting plate directly and reach the electrostatic dust removing area, and the dust for reverse blowing and ash cleaning is collected by static electricity. Compared with the prior invention, the dust removal is separated into two steps: when the bag filters, an electrostatic dust remover is completely used to greatly reduce a dust-containing concentration of the flue gas which enters into the bag; when the bag reversely blows and cleans ash, the electrostatic dust remover is used to effectively remove the dust for ash cleaning.

Owner:TSINGHUA UNIV +1

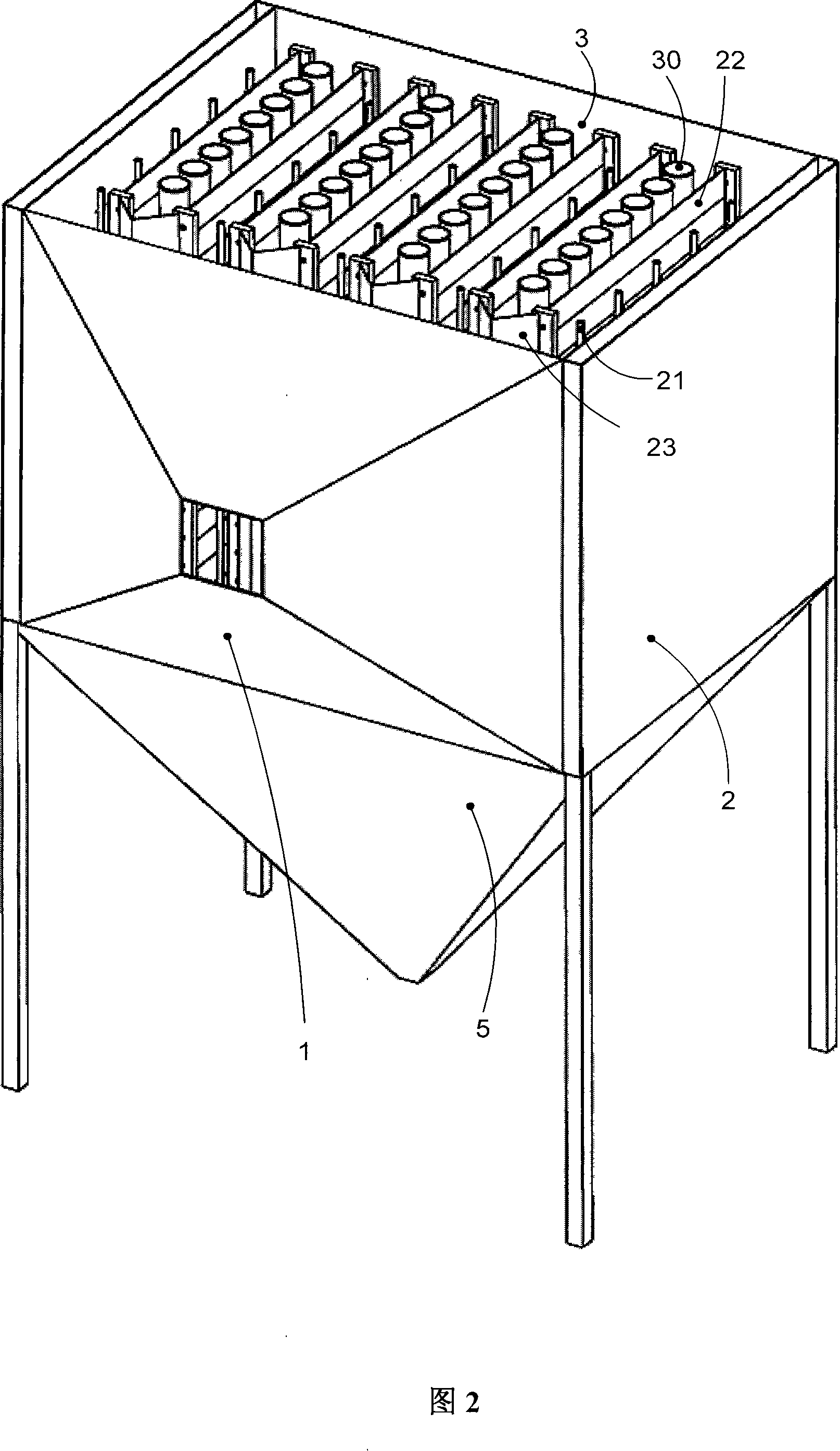

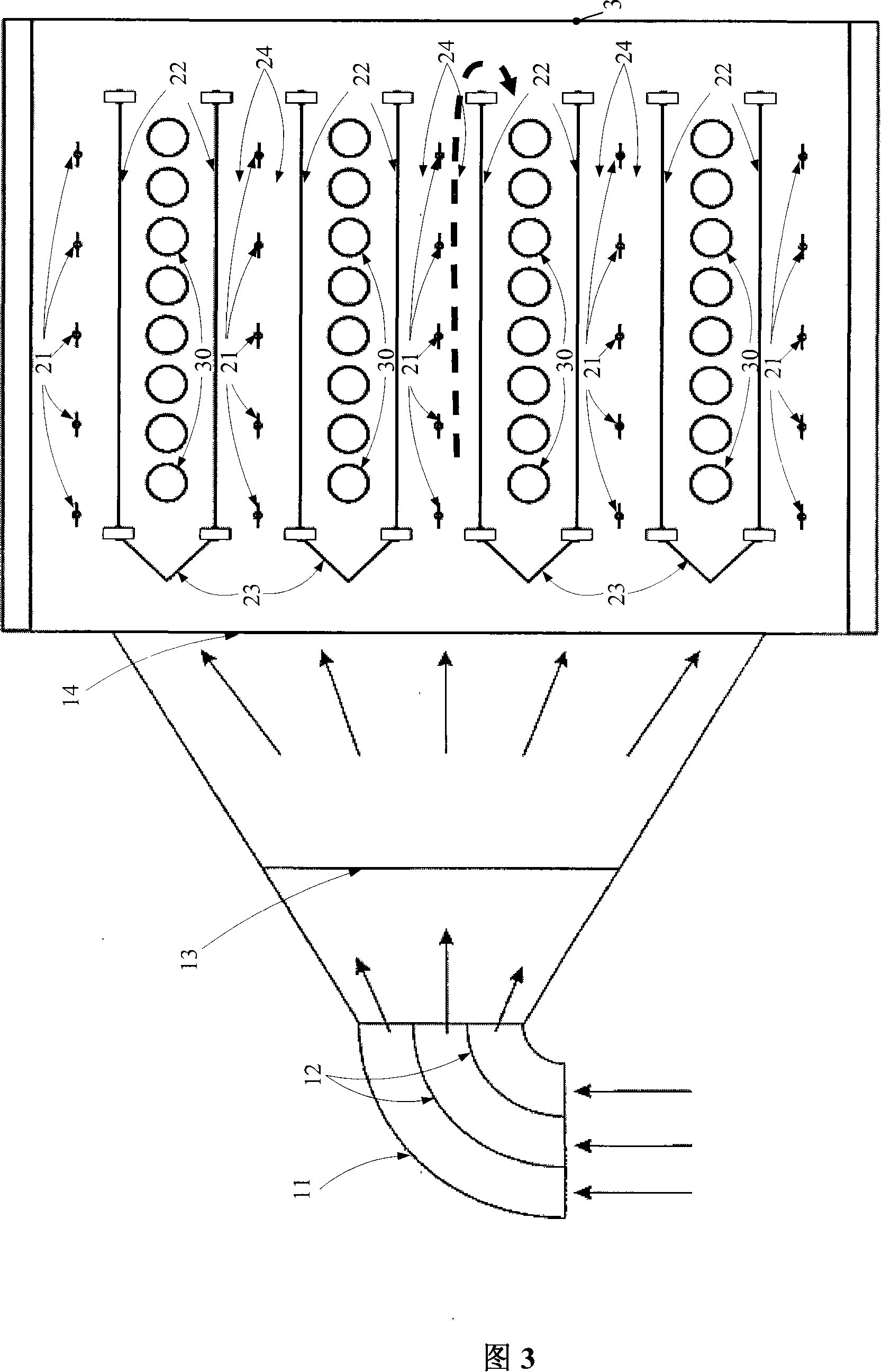

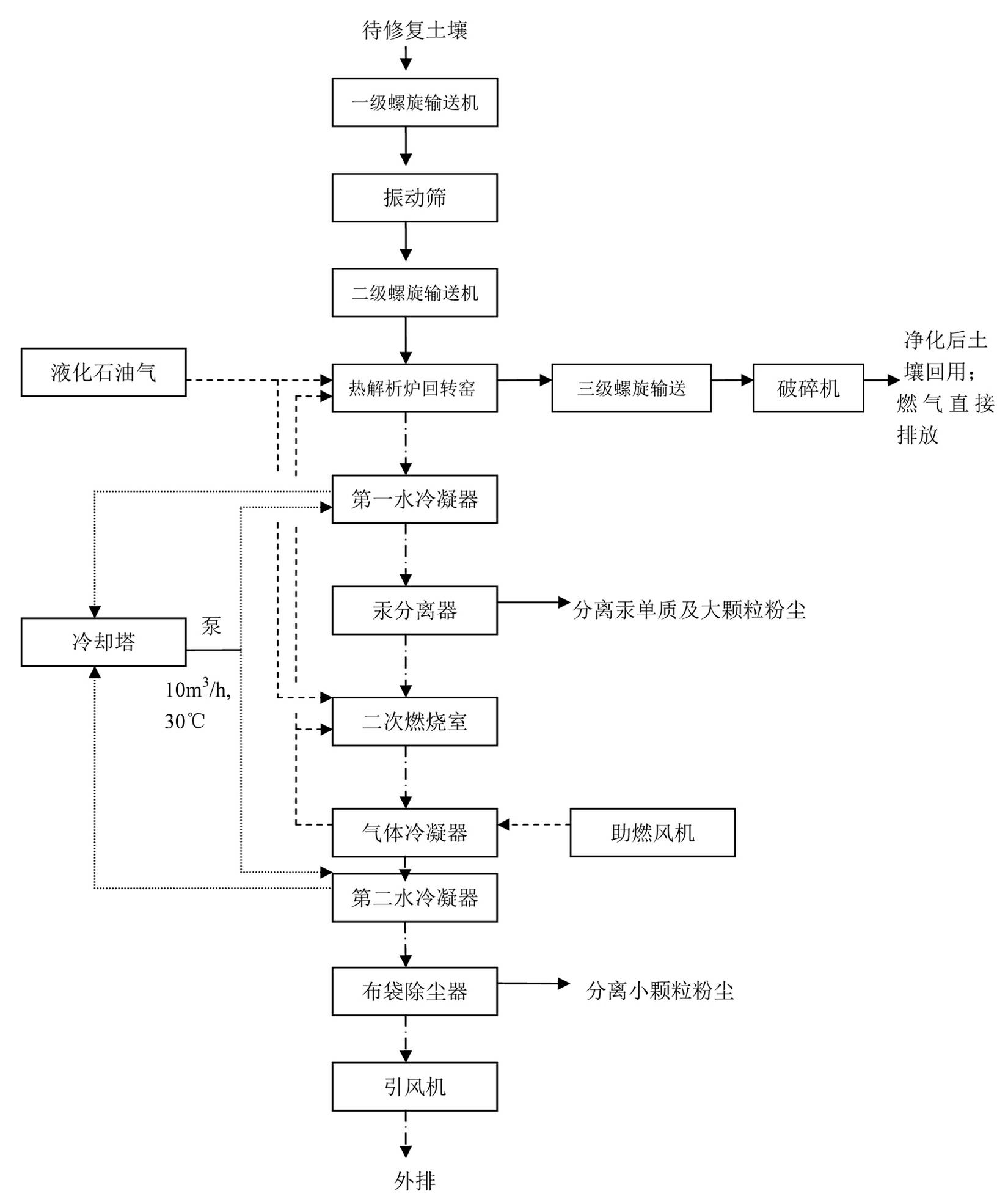

Soil remediation method

ActiveCN102527705ASolve pollutionSimple repair processContaminated soil reclamationSoil remediationExhaust fumes

The invention discloses a soil remediation method, comprising the following steps: (1) conveying to-be-remedied soil to a vibrating screen via a first-level spiral conveyer, conveying the screened soil to a rotary kiln of a thermal desorption furnace via a second-level spiral conveyer to heat and desorb the soil; (2) conveying the roasted soil to a crusher via a third-level spiral conveyer to crush; (3) decreasing the temperature of waste gas from the rotary kiln of the thermal desorption furnace to 280-320 DEG C through a first water condenser; (4) separating dust particles and liquid mercury from the waste gas passing through the first water condenser in a mercury separator; and (5) burning the waste gas from the mercury separator in a secondary combustor, decreasing the temperature of the waste gas to 150-200 DEG C via a gas condenser and a second water condenser, dedusting the gas via a bag-type dust remover and discharging the dedusted gas through a draught fan. The soil remediation method disclosed by the invention has the advantages that: the soil pollution problem can be well solved; the remedied soil can be directly used; in addition, the remediation process is simple andpracticable, and the cost is low.

Owner:广州市金龙峰环保设备工程股份有限公司 +1

Method for innocent treatment of enteromorpha and equipment using same

ActiveCN101758060ANo pollution in the processEasy to transportConveyorsSolid waste disposalLow noiseBound water

The invention provides to a method for innocent treatment of enteromorpha and equipment using the same, which is characterized by comprising the following steps: (1) with pressing dehydrogenation packing equipment, pressing and dehydrating fresh enteromorpha which is just salvaged, packing the fresh enteromorpha to form enteromorpha enclosed mass, and then transporting the mass to a disposal field; (2) sending the mass into a shearer for shearing and shattering, releasing free water in an enteromorpha tubular structure and conducting pressing and dehydrating for the second time; (3) after the second time of pressing and dehydrating, sending the enteromorpha into air dehydration equipment for drying and dehydrating through hot blast, and dehydrating most of the free water and bound water contained in the enteromorpha; (4) conducting bed cleaning and edulcoration through a cyclone dust removal system; and (5) smashing with a pulverizer. The method aims to transportation cost and pollution, and has high treatment efficiency and low energy consumption, thus the edulcoration after treatment can be put into good use. The pressing dehydrogenation packing equipment is driven by hydraulic pressure and the working force is adjustable. The equipment has low noise, is simple to operate, and convenient to feed. The equipment can feed much one time, and feeding compression can be conducted for more than one time.

Owner:青岛海大生物集团股份有限公司

Method of producing forsterite refractory

A method for producing forsterite refractory is characterized by comprising: a. mixing the raw magnesite flotation tailing or magnesite shaft kiln dust removing powder, light burning magnesite powder and cabosil, wherein the weight ratio Mgo / SiO[2] is 1.342-1.476; b. according to the weight ratio, uniformly mixing 80-100 portions of mixed materials obtained in step a and 0-20 portions of burnable lost property, additionally with 30-70 portions of water, producing briquette; drying the briquette obtained in step b at 15-50 DEG C for 3-24 hours, drying at 110 DEG C for 12 hours, burning at the oxidative atmosphere; keeping warm at 500-650 DEG C for 2-3 hours, 1500 DEG C for 3-5 hours. The invention uses the industrial waste to produce the forsterite refractory, greatly reduces the production cost of the forsterite refractory, decreases the dust pollution and improves the ecologic environment.

Owner:海城华宇耐火材料有限公司

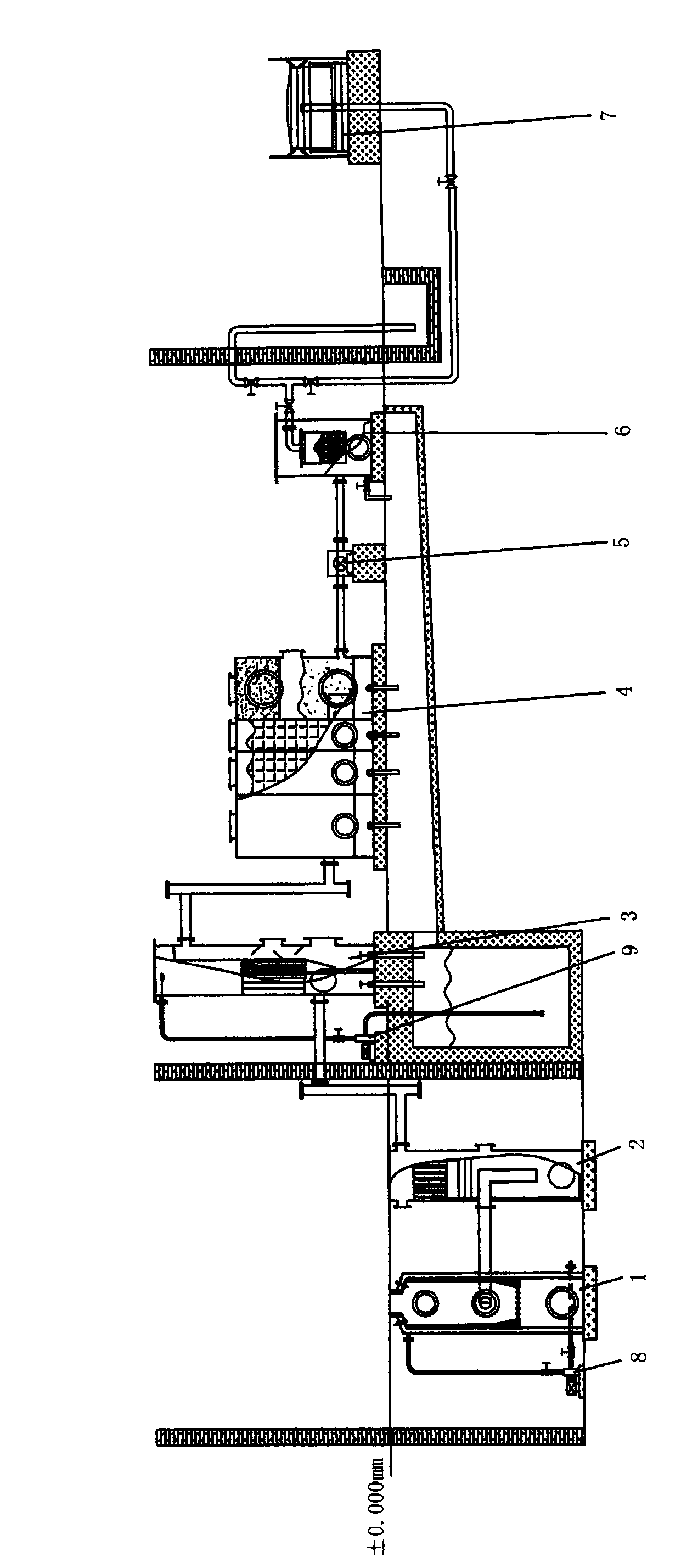

Compound coal gasification system and method of blast furnace slags

ActiveCN101597657AWide adaptabilityImprove gasification efficiencyRecycling and recovery technologiesCombined combustion mitigationSlagEnergy conservation

A compound coal gasification system and a method of blast furnace slags relate to the blast furnace slag utilization technology. The system comprises a slag gasifier, a heat exchanger, a gas deduster, a gas storage tank, a coal feeding device, a spray gun, a secondary coal feeding device and a particle gasifier. The method comprises the following steps: the blast furnace slags are placed into the slag gasifier from a slag inlet through a slag runner; pulverized coal and gasifying agents are injected into the slag gasifier, the generated gas enters the heat exchanger, undergoes cooling and dedusting and then enters the gas storage tank; when flowing out of the slag outlet, the slags are mixed with the pulverized coal in a pipeline and react with the gasifying agents to generate gas which enters the heat exchanger, undergoes cooling and dedusting and then enters the gas storage tank. The method of the invention has enormous environmental benefits and is of significance to realize the national goal of energy conservation and emission reduction.

Owner:NORTHEASTERN UNIV

Method and system for purifying flue gas generated by incinerating waste materials

InactiveCN101869800AAvoid pollutionReduce contentCombination devicesLighting and heating apparatusAtmospheric airCyclonic spray scrubber

The invention discloses a method and a system for purifying flue gas generated by incinerating waste materials and aims at providing a method for purifying flue gas, which can reduce the content of dioxin in the flue gas generated by incinerating waste materials, avoid the pollution of heavy metals in the waste material to the environment, and is beneficial to protecting the environment and guaranteeing the health of a human body and a purifying system for realizing the method. The method comprises the following steps of: incinerating waste materials at high temperature of 1,000-1,200 DEG C for 1.7-3s; dust-collecting and temperature-reducing treatment: treating flue gas generated by a high-temperature incineration furnace and passing through a cyclone dust collector and an electrostatic precipitator in sequence by using two-stage wet dust collectors; spraying a limestone solution into a first-stage wet dust collector to remove acid gases; spraying an NaOH solution into a second-stage wet dust collector to damage the content of the dioxin in the flue gas; carrying out active carbon power spraying treatment and active carbon adsorption treatment on the flue gas of which the temperature is reduced; and raising the temperature of the flue gas to 210 DEG C for denitrification treatment, washing and heating the denitrified flue gas, and then exhausting the heated flue gas to the atmosphere.

Owner:于金玲

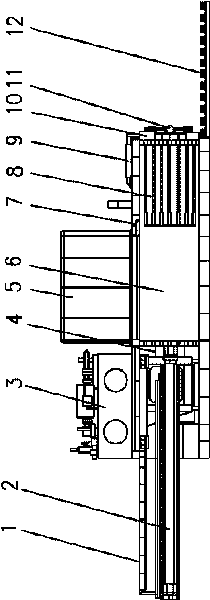

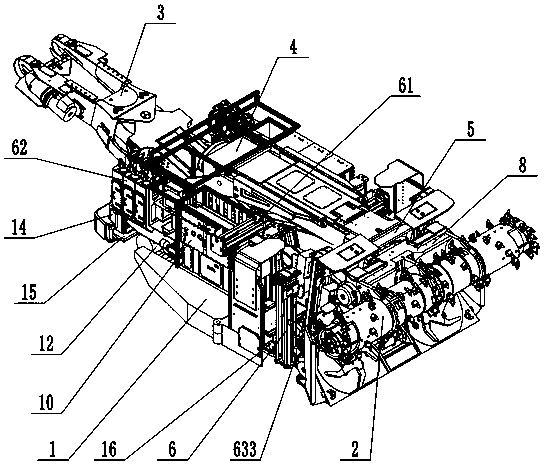

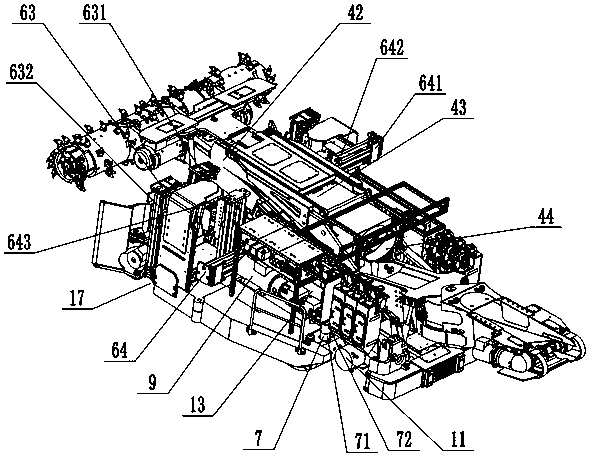

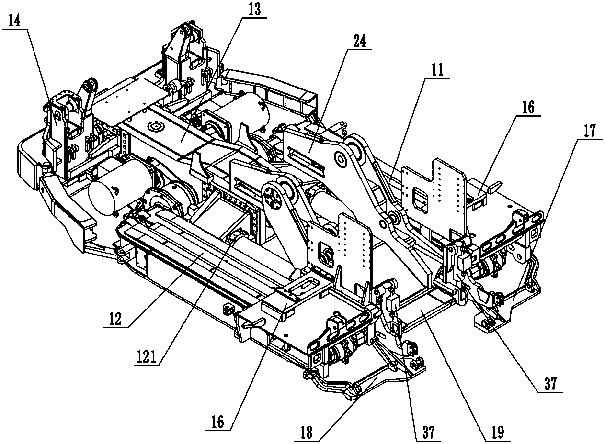

High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

PendingCN111075444AAchieving parallel operation of anchor diggingFully automatedPropulsionAnchoring boltsSupporting systemElectric control

The invention provides a high-adaptability digging and anchoring integrated machine with a dual-mode anchor drilling system, and belongs to the technical field of underground coal mining equipment. The high-adaptability digging and anchoring integrated machine comprises a frame main body, a cutting system, a conveying system, a dust removing system, a multifunctional temporary supporting system, the dry-wet dual-mode anchor drilling system, an automatic lubricating system, a water-cooling spraying system, a hydraulic system and an electric control system, wherein a traveling mechanism adopts awide crawler design, so that the adaptability of the digging and anchoring integrated machine to a muddy bottom plate is improved; and the dry-wet dual-mode anchor drilling system has two functions of dry dust removal and wet dust removal, and real-time switching selection is carried out according to the geological conditions of the roadway bottom plate without replacing a drill box. By means ofthe high-adaptability digging and anchoring integrated machine, the problems of muddy of the bottom plate, poor stability of a top side wall and low tunneling efficiency in the rapid coal roadway tunneling under the complex geological conditions are solved; the integrated parallel operation of tunneling, anchor protection, transportation, dust removal and the like of a roadway tunneling working surface is realized; and the efficiency and safety of coal mining and transportation are improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

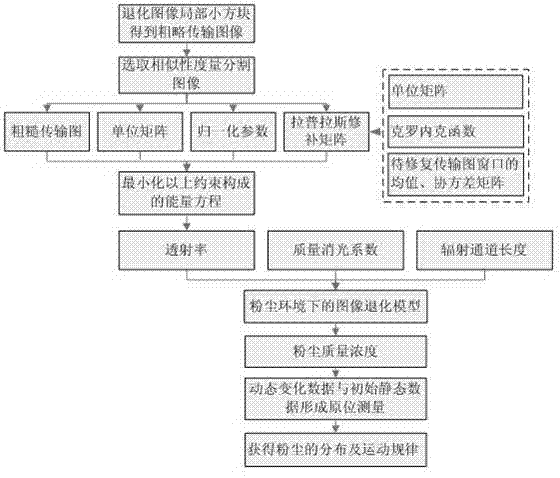

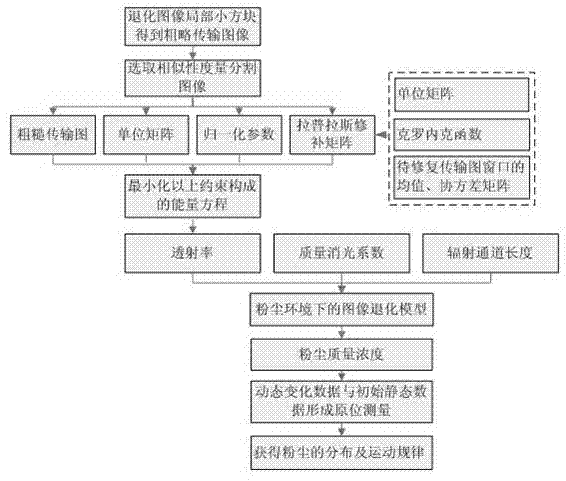

Monitoring and measuring method for dust concentration in working faces in underground coal mine

ActiveCN102353622AOvercoming airspace sampling flawsQuick measurementParticle suspension analysisMining engineeringRadiation length

The invention provides a monitoring and measuring method for dust concentration in working faces in an underground coal mine, and the method overcomes the problems of a slow speed in sampling dust, complicated sampling and incapability of satisfying requirements of safe production on-line monitoring in the prior art. The monitoring and measuring method comprises the following steps: (1) acquiringa rough transmission diagram having a blocking effect based on a degraded image in a working face dust environment; (2) carrying out refined processing on the rough transmission diagram so as to obtain transmissivity corresponding to each pixel point in the diagram; (3) calculating an absorption factor and a scattering factors, calculating an absorption coefficient and a scattering coefficient, and calculating an extinction coefficient; (4) measuring the length of a radiation channel; (5) calculating mass concentration of dust and a changing process of dust concentration based on the transmissivity, the extinction coefficient and radiation length. The beneficial effects of the invention are as follows: rapid measuring is realized; the requirement for real time dynamic measurement is met; the method is of important significance for implementation of corresponding dustproof measures in the underground coal mine. Appropriate dedusting methods can be employed according to different environments when distribution and motion rules of dust in coal mining working faces are mastered.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

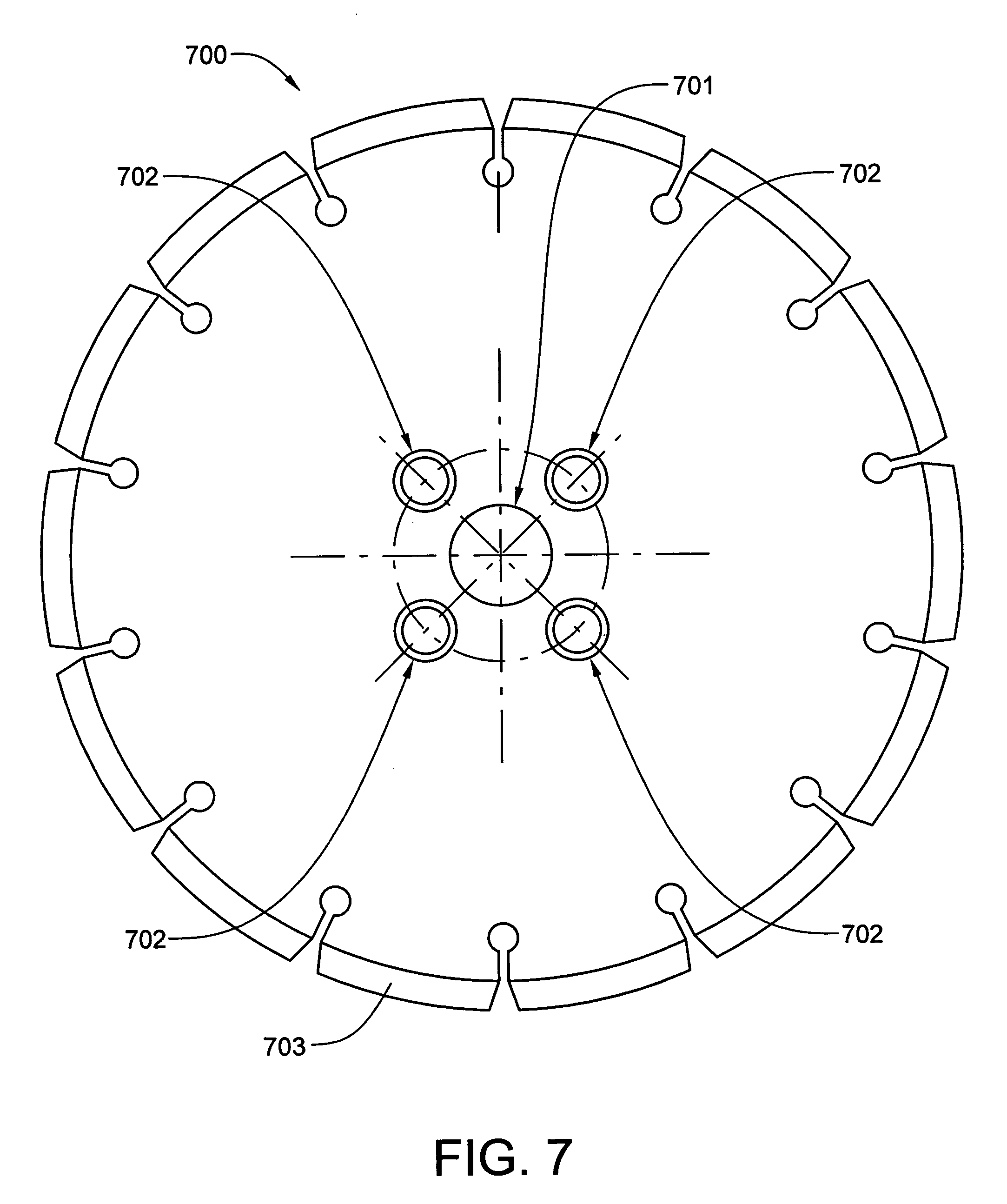

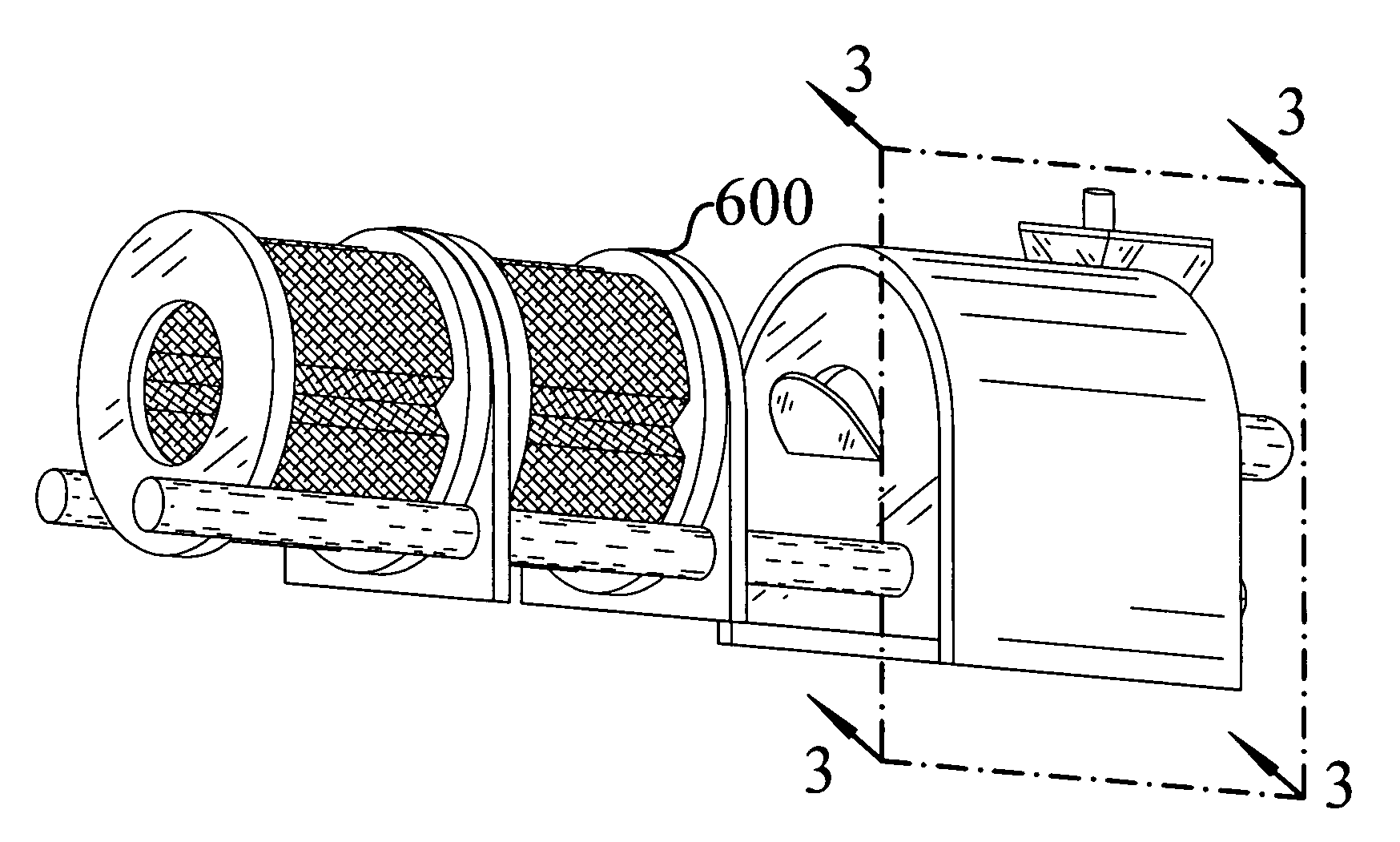

System and method for dusting soft capsules

InactiveUS20080166477A1Prevent surfaceConfectioneryVacuum evaporation coatingParticulatesSystems design

A capsule dusting system is designed to expose capsules to a dusting agent in a controlled manner. The system incorporates a tumbling basket positioned within an enclosure. The tumbling basket is loaded with capsules and is rotatably connected to a drive shaft. A dust injection system meters the dusting agent into the dust injection system. The dust injection system may include a dusting injector that translates between two positions. At one position, the dusting injector is loaded with dusting agent by a powder supply system. At the other position, the dusting injector is positioned to inject the dusting agent into the tumbling basket. A gas is fluidly connected to the dusting injector to cause the dusting agent to disperse into the tumbling basket. The enclosure contains the dusting agent within the system to reduce the environmental, health, and safety hazards associated with airborne particulates.

Owner:R P SCHERER TECH INC

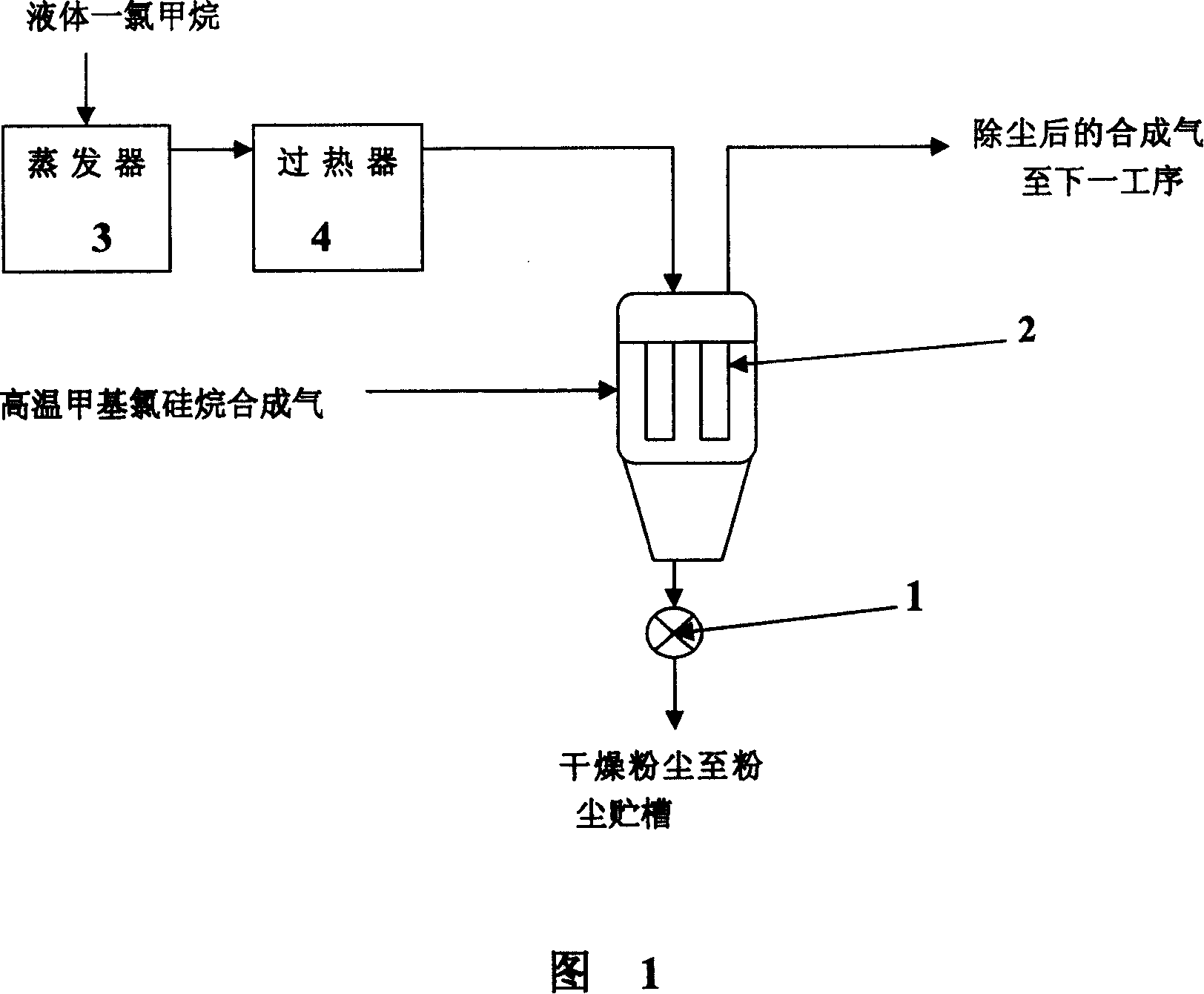

Dry dust removing method by using inorganic chlorosilane gas and device thereof

The present invention relates to dry dedusting process and apparatus for organic chlorosilane gas. The dry dedusting process includes the following steps: 1. filtering dusty high temperature organic chlorosilane gas to dedust; 2. pressurizing and evaporating liquid organic chlorosilane gas for generating back blowing gas, heating organic chlorosilane vapor and regulating flow rate; and 3. feeding the heated organic chlorosilane gas to the filter to eliminate dust in the filter through back blowing. The dry dedusting apparatus includes one evaporator, one heater and one ceramic filter connected successively. The present invention has high dedusting efficiency, low power consumption, high product recovering rate and simple process.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

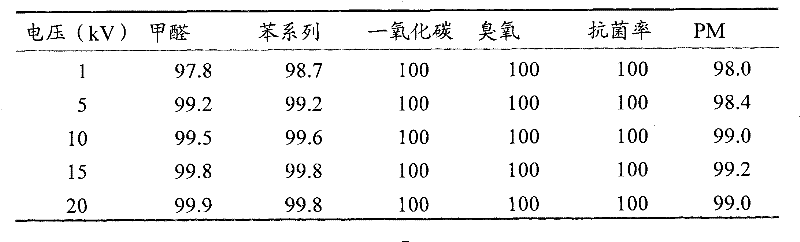

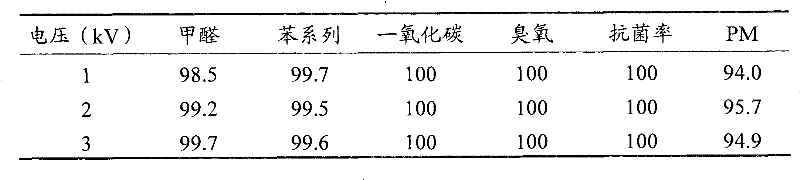

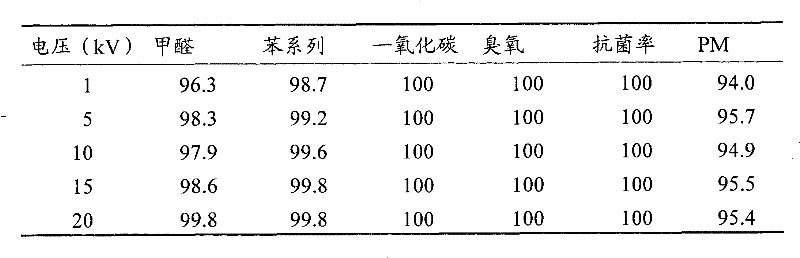

Multifunctional high-efficiency air purifier for indoor (vehicle) environment

InactiveCN102284077AImprove the bactericidal effectImprove processing efficiencyManganese oxides/hydroxidesDeodrantsChemistryBenzene

The present invention is a single-atom nano-composite catalyst air purifier that simultaneously removes formaldehyde, benzene series organic matter, carbon monoxide, ozone and high-efficiency antibacterial in a room (vehicle) by atmospheric pressure plasma and room temperature catalysis, and involves plasma, electrostatic dust removal, and environment Catalysis, environmental protection and air purification fields. It is characterized in that pollutants such as formaldehyde, benzene series organic matter, carbon monoxide, ozone, bacteria and germs in the air are effectively removed through low-temperature plasma, electrostatic dust removal and integrated catalyst integration technology, as shown in the figure. The present invention successfully utilizes plasma, electrostatic precipitator and room temperature catalyst technologies, successfully and efficiently removes multiple pollutants at the same time without secondary pollution, and overcomes the existing single technology in closed or semi-closed spaces such as rooms (vehicles) The application bottleneck in the field of air purification in China has an absolute leading position in the world.

Owner:SHANGHAI NIUYI NEW ENERGY TECH

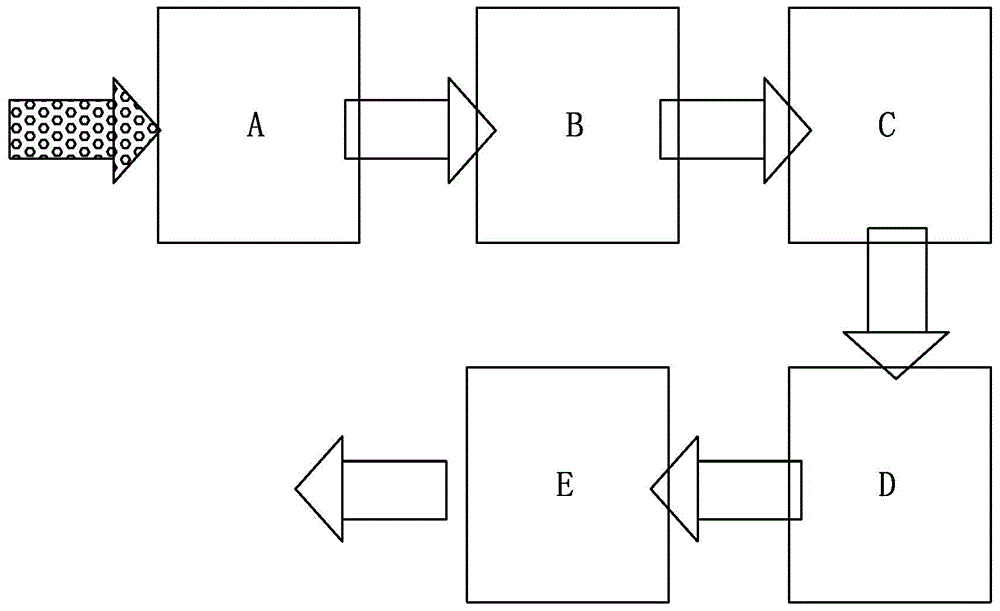

Air purification unit applicable to remove fine particles in the air in the home environment

ActiveCN104566650AImprove charging capacityStable ionizationMechanical apparatusLighting and heating apparatusHome environmentUltraviolet lights

The invention relates to an air purification unit applicable to remove fine particles in the air in the home environment and belongs to the field of electrostatic dust removal. The device comprises an air inducing unit, an air purification unit and an air channel. The air purification unit comprises a positive high-voltage pulse charge region, a negative high-voltage pulse charge region, a static coagulation region under an alternating electric field, a dust particle collection region, a plasma disinfection region and a negative ion region which are arranged successively. A narrow-pulse discharging mode and a negative direct-current high-pressure discharging mode are used, a working voltage below 30KV and a working current below 10mA are used, and the collection efficiency of more than 90% of particles with diameters below 10 microns is achieved in the home environment; the problems of over-large 'wind resistance' and 'secondary pollution' of prior home air conditioners are solved, fine particles in the air can be removed in the home space size range, the air can be disinfected, and the problem of ultraviolet light leakage harms is solved.

Owner:上海安平静电科技有限公司

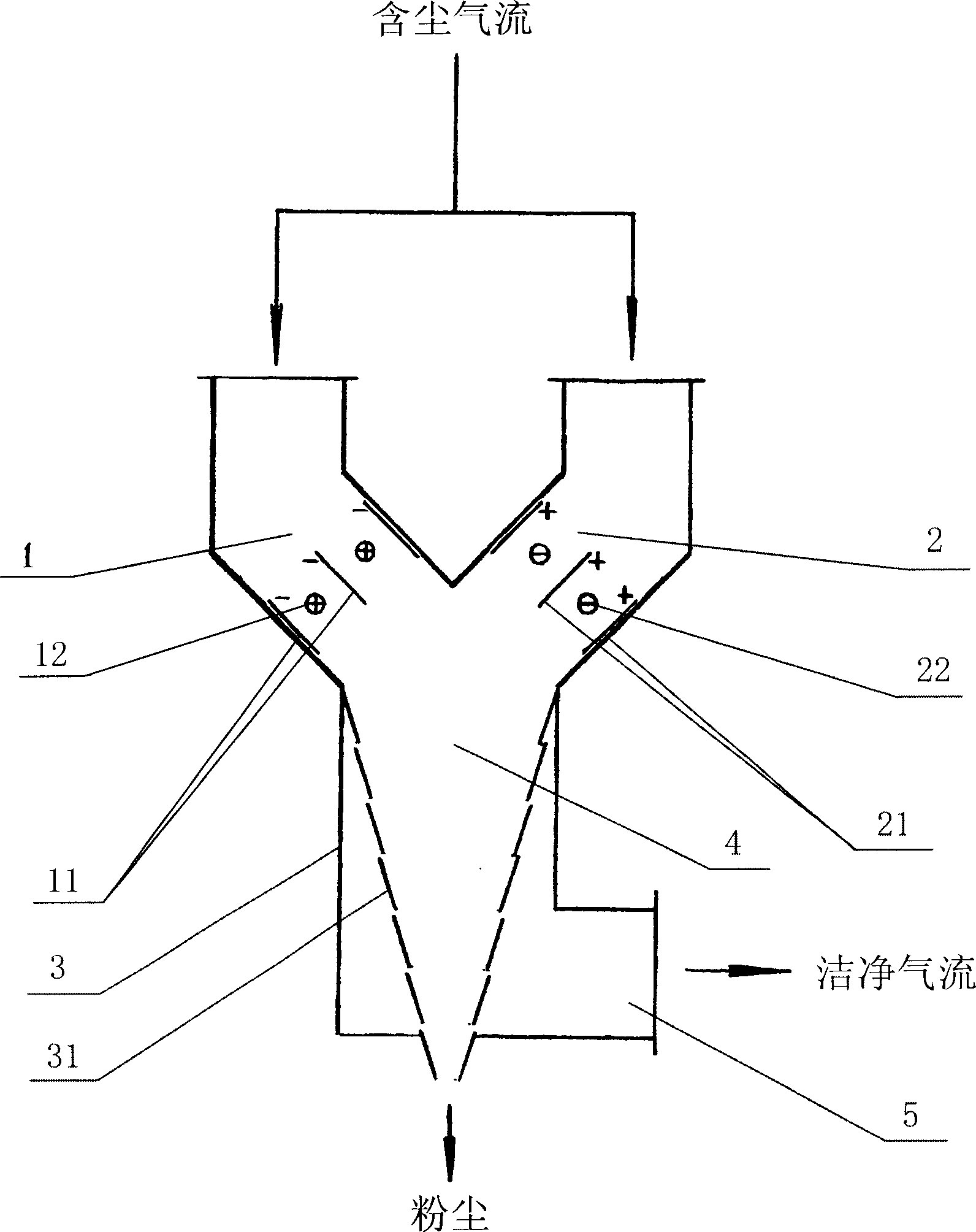

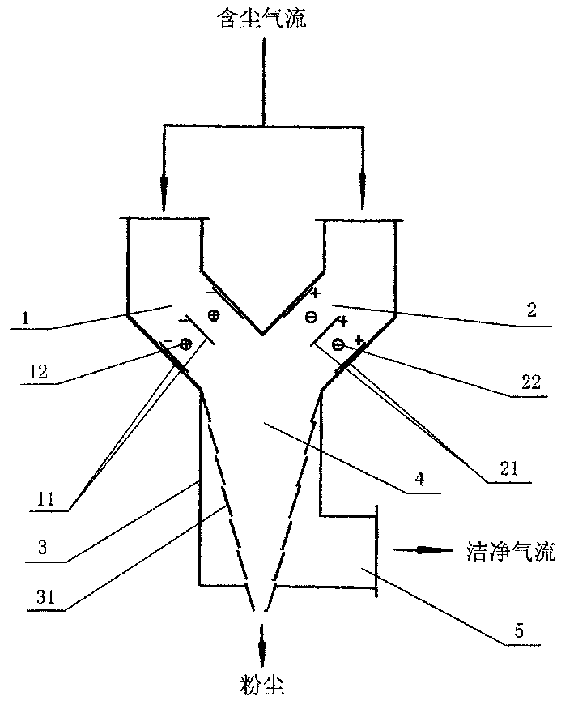

Coagulation type electrostatic dust removing method and its equipment

InactiveCN1426841AEasy to separateSmall flow cross sectionElectrostatic separationEngineeringMechanical engineering

A coagulation-type electrostatic precipitation method and its apparatus features that the small charged dust particles are coagulated to become big ones for easily removing them. The dust-contained airflow is divided into two streams. One is electrified by positive charges and another by negative charges. After they are conveyed together, the particles with different polarities are coagulated and then they are separated out by the inertial separation method. Its advantages are small size device and high efficiency.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Circulating fluidized bed coal gasification multi-stage cooling and dedusting process and device

ActiveCN107418634AHigh calorific valueIncrease consumptionEnergy inputGasification processes detailsFluidized bed gasifierShell and tube heat exchanger

The invention provides a circulating fluidized bed coal gasification multi-stage cooling and dedusting process and device. In the process, a mixture of semicoke and high-temperature coal gas generated by a circulating fluidized bed gasifier is subjected to gas-solid separation through a cyclone separator, then the semicoke is returned to the gasifier through a return device at the bottom of the cyclone separator to continue participation in reaction while the high-temperature coal gas enters a tube side of a shell-and-tube heat exchanger, and low-temperature air enters a shell side of the shell-and-tube heat exchanger and absorbs heat energy transferred by the coal gas in heat exchange tubes; heated high-temperature air enters the bottom of the gasifier to be used for gasification; cooled low-temperature coal gas is subjected to multi-stage cooling and dedusting through a waste heat boiler, cyclone dust removal, heat pipe heat exchange, bag dust removal and heat pipe cooling prior to being used in subsequent procedures. In the process, the high-temperature coal gas discharged from the gasifier is subjected to cyclone separation and then exchanges heat with air without flowing through the waste heat boiler, the temperature of air serving as a gasifying agent is raised while a heat value of the coal gas is increased, high safety in technical operation is achieved, and great cooling and dedusting effects can be achieved by combination with multi-stage subsequent heat exchange and dedusting procedures.

Owner:中科清能燃气技术(北京)有限公司

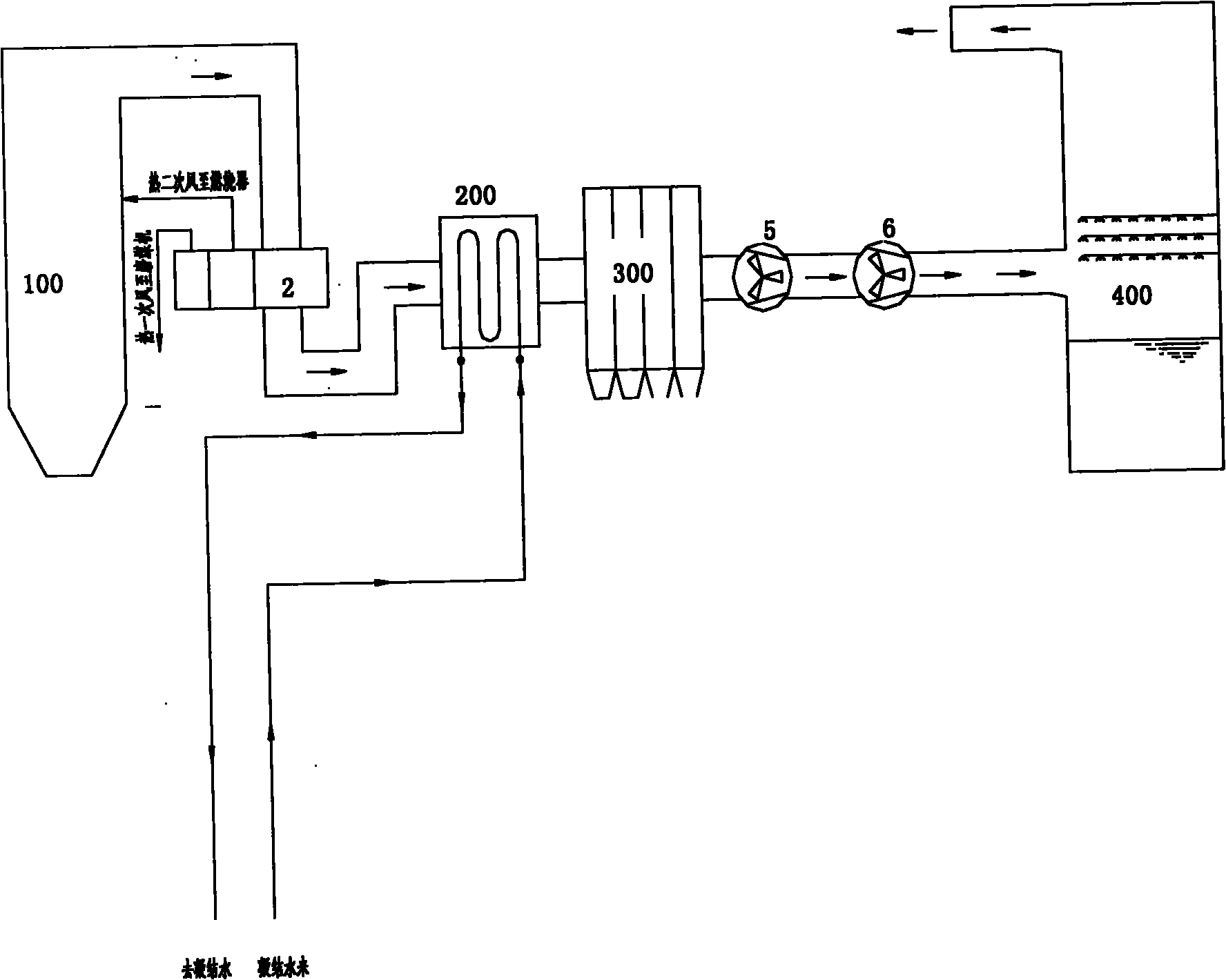

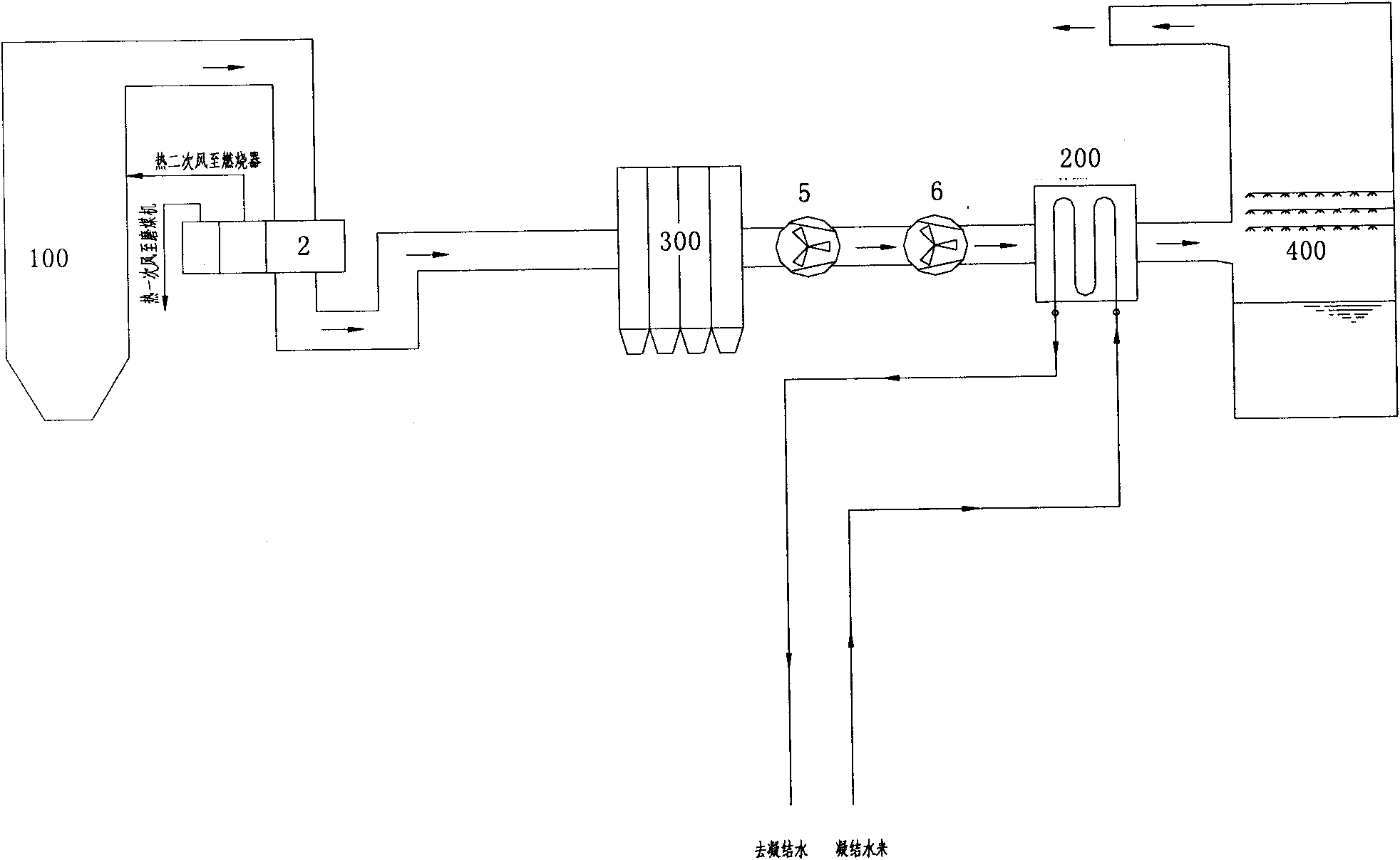

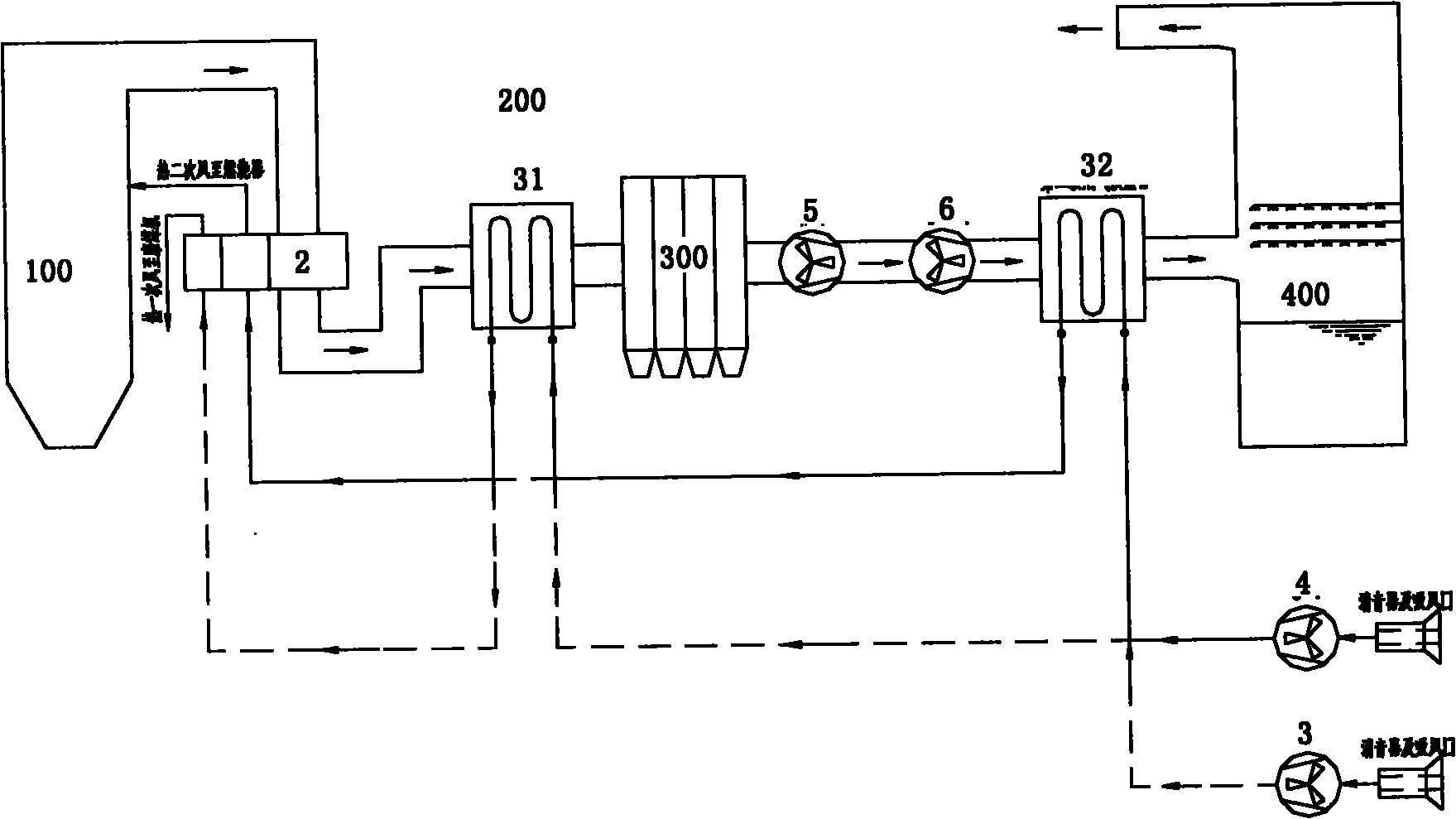

Two-stage smoke-gas-air heat-exchanger system applied to thermal power plant

The invention provides a two-stage smoke-gas-air heat-exchanger system applied to a thermal power plant, which comprises a boiler unit, a smoke-gas residual-heat utilizing unit, a smoke-gas dust-removing unit and a smoke-gas desulfurizing unit, wherein the boiler unit is used for discharging smoke gas, and the smoke-gas residual-heat utilizing unit comprises a preheater, a first-stage smoke-gas heat exchanger and a second smoke-gas heat exchanger; the first-stage smoke-gas heat exchanger is arranged between the preheater and the smoke-gas dust-removing unit, and the second smoke-gas heat exchanger is arranged at an inlet of the smoke-gas desulfurizing unit; both the first-stage smoke-gas heat exchanger and the second smoke-gas heat exchanger are smoke-gas-air heat exchangers; or, the first-stage smoke-gas heat exchanger is a smoke-gas-water heat exchanger, a water source at a condensed-water side is condensed water in a steam-turbine condensed-water system, and the second smoke-gas heat exchanger is the smoke-gas-air heat exchanger; or, the first-stage smoke-gas heat exchanger is the smoke-gas-air heat exchanger, the second smoke-gas heat exchanger is the smoke-gas-water heat exchanger, and the water source at the condensed-water side is the condensed water in the steam-turbine condensed-water system.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

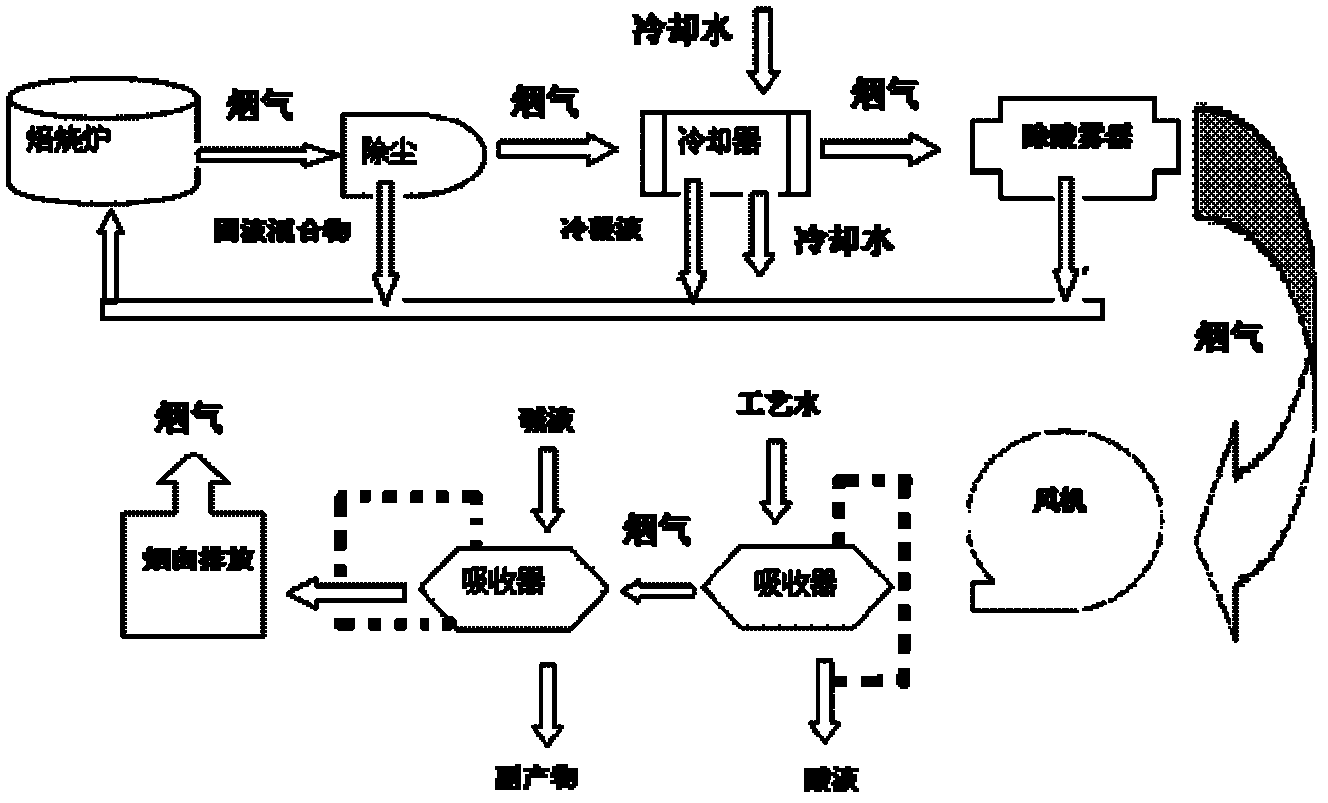

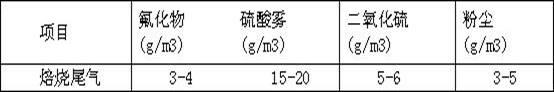

Process for treating tail gas of rare earth mineral powder and concentrated sulphuric acid roasting process

ActiveCN102247708AAvoid energy consumptionAvoid investmentDispersed particle separationVapor condensationHydrogen SulfateHexafluorosilicic acid

The invention relates to a process for treating tail gas of a rare earth mineral powder and concentrated sulphuric acid roasting process. The process comprises the following steps of: introducing the tail gas of 300 DEG C of the process into a dust remover for dust removal with a machine; then introducing the tail gas into a condenser for cooling, condensing massive sulphuric acid fog and water vapour in the smoke and recycling acid liquor; introducing the cooled smoke into an acid fog collector, collecting acid fog and water fog in the smoke for recycling; boosting the treated smoke by a fan, introducing the treated smoke into a first absorber, washing by diluted acid liquor or process water to remove residual sulphuric acid fog, hydrofluoric acid and fluosilicic acid from the smoke; andthen introducing the smoke into a second absorber, washing the smoke by an alkali washing tower to remove residual sulphuric acid fog, hydrofluoric acid and SO2 gas from the smoke, and discharging the smoke out after defogging. The process provided by the invention can save massive smoke cooling water, produce less waste water, reduce waste water treatment cost, and recycle the side product fluoric acid produced by solid mineral substances, sulphuric acid, hydrofluoric acid and the like in the tail gas as a raw material for recycling fluorine.

Owner:北京鸿源龙嘉环保科技有限公司

Mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck

ActiveCN103786628AImprove spray distanceIncrease speedSpraying vehiclesLiquid spraying apparatusWater storage tankGear wheel

The invention relates to a mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck, mainly solving technical problems of high investment caused by individual use of spray dust-settling devices and poor effect caused by common use of the spray dust-settling devices due to far distance on conditions of multiple and dispersed dust source points, variable dust source locations and complicated conditions of dust sources. The technical scheme includes that a water storage tank is connected with a high-pressure water pump through a water pipe and high-pressure water is pumped to a spraying assembly; a hydraulic station is connected to a hydraulic motor of a mist spraying device through a high-pressure oil pipe to drive an impeller of axle-flow fans to generate high-pressure air flows, the high-pressure air flows send mist to a dust working face, and high-pressure oil of a hydraulic station is connected to a hydraulic cylinder; the mist spraying device is lifted and then is driven to oscillate around a rotating bearing by a motor and a reduction gearbox via a rotational driving gear; a carriage engine drives a power generator through a double-output transmission in a gear shifting manner so that power required for system running is obtained. The mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck is mainly used for far-distance large-range dust settling and removing and firefighting in fugitive emission fields such as tunnel heading, blast mining, loading, crushing and unloading.

Owner:PINGAN ELECTRICAL

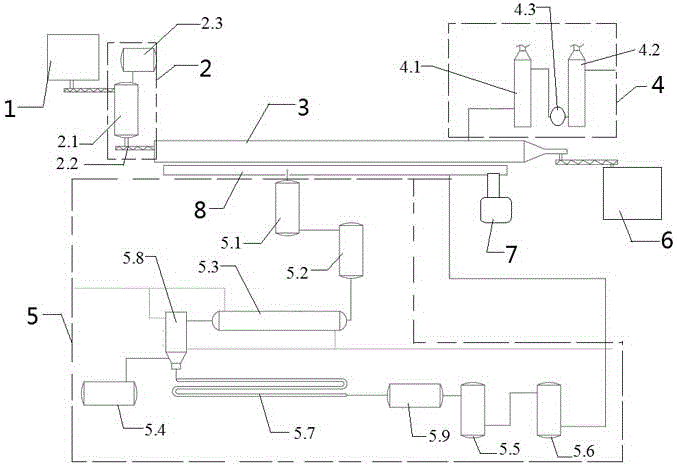

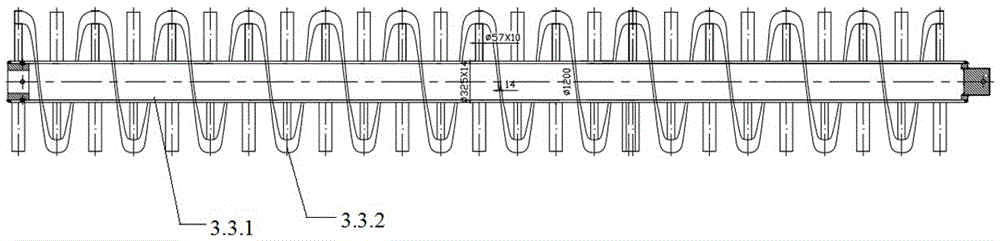

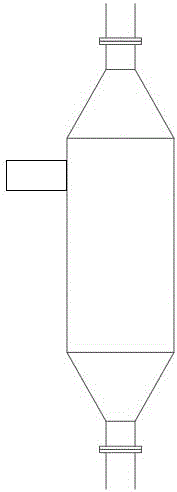

Waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology

The invention relates to a waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology. According to the technical scheme, the device comprises a preprocessing unit, a conveying and feeding unit, a thermal cracking unit, a desulfuration and atomization unit, an oil gas purifying and condensing unit, a carbon black deep processing unit, an oxygen supply air blower and a fuel gas spray gun, wherein the preprocessing unit, the conveying and feeding unit and the thermal cracking unit are connected in sequence, the desulfuration and atomization unit, the oil gas purifying and condensing unit, the carbon black deep processing unit, the oxygen supply air blower and the fuel gas spray gun are connected with the thermal cracking unit, a tail end outlet of the preprocessing unit is connected with the conveying and feeding unit, the thermal cracking unit mainly comprises a furnace body, the furnace body is connected with the oxygen supply air blower and the fuel gas spray gun, and the fuel gas spray gun comprises a natural gas spray gun and a waste gas spray gun. The waste tire low-temperature and normal-pressure continuous thermal cracking production device has the advantages that a full-sealed structure is adopted in the production process, and a strong atomization tower is adopted for performing cooling, dust removal and purification, so that environment pollution is lowered to the minimum; due to the fact that recycled combustible gas and cooling water is recycled, purified and secondarily utilized, energy is saved, the production cost is lowered, and the principle of energy conservation and emission reduction is met.

Owner:高义强

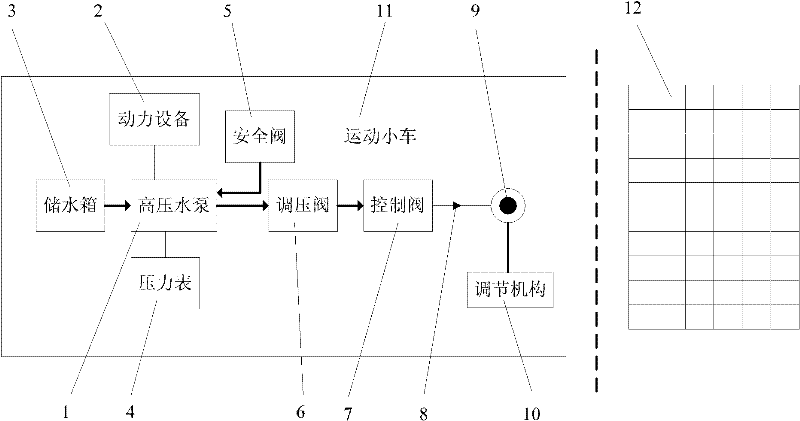

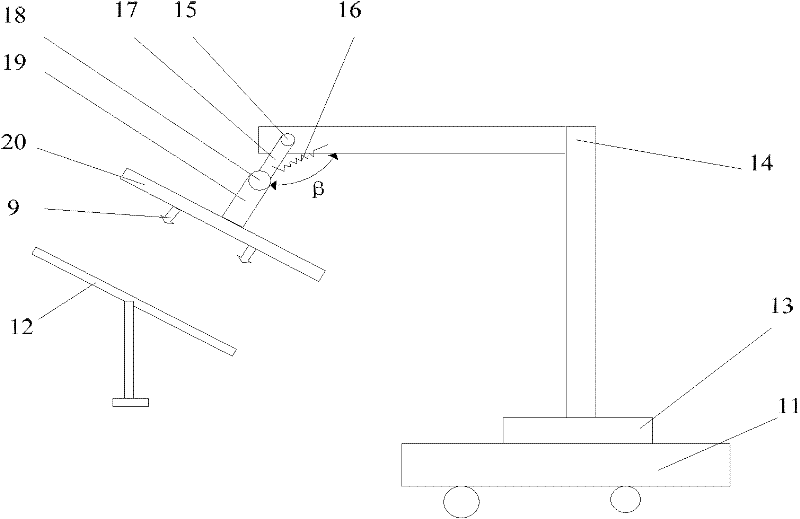

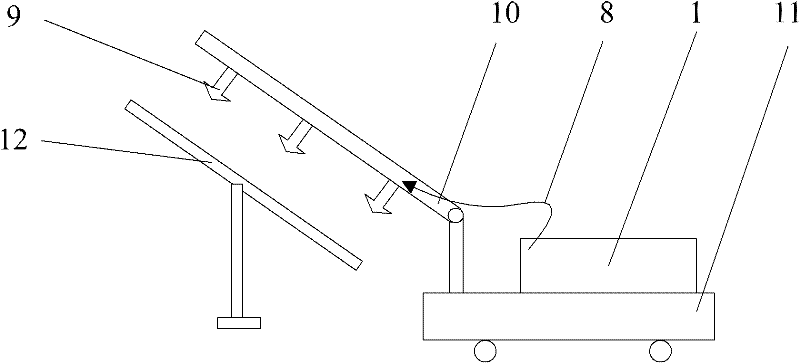

Solar panel array surface dust removal system and method

ActiveCN102441541ANo pollutionImprove protectionCleaning using liquidsWater savingHigh pressure water

A solar panel array surface dust removal system and a method belong to the technical field of solar photovoltaic power generation. The solar panel array surface dust removal system comprises a high-pressure water generating device, a delivery pipe, an adjusting mechanism, at least one jetting device and a moving trolley, high-pressure water generated by the high-pressure water generating device forms a high-pressure water flow jetting plane via the jetting devices, two comprehensive actions of impacting and shearing are produced for dust covered on surfaces of solar panel arrays, and accordingly the dust of the surfaces of the solar panel arrays is removed. The main steps of the method comprise that basic dust removal parameters are determined, parameters of the jetting devices are selected, overall arrangement of the jetting devices is determined according to the sizes of the solar panel arrays, and a cleaning operation path is planned. The solar panel array surface dust removal system and the method are simple to be realized, are applicable to installation of most of solar panel arrays, save water, do not damage surfaces of solar panels, do not pollute environments, not only can realize a large-range high-efficient dust removal, but also have an auxiliary summer cooling function and a winter snow removal function.

Owner:北京动力协合科技有限公司

High-speed centrifugal drying method and drying system for implementing method

InactiveCN102788488AFast dryingIncrease surface areaDrying gas arrangementsDrying solid materialsProcess engineeringTower

The invention discloses a high-speed centrifugal drying method, which comprises the following steps of: installing a hot-air drying device, a to-be-dried material conveying device and a tail gas filtering device; when the hot-air drying device works, filtering air to form high-speed airflow; heating the airflow and then jetting the airflow into a drying tower through a pipeline to form high-speed rotary hot airflow; when the to-be-dried material conveying device works, filtering a to-be-dried material and then conveying to a centrifugal atomizer at the top part of a dryer to form atomized liquid drops jetted into a drying room; enabling the atomized liquid drops to be contacted with the high-speed rotary hot airflow, and then, drying to form finished products; delivering the finished product from an outlet at the bottom part of the drying tower; separating tail gas entering the tail gas filtering device through a plurality of cyclone separators in sequence; delivering the finished products mixed in the tail gas from outlets at the bottom parts of the cyclone separators; further filtering the tail gas to remove dust; and then, discharging to the air to finish a high-speed centrifugal drying process. The invention also discloses a drying system.

Owner:梁首强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com