Coagulation type electrostatic dust removing method and its equipment

A technology of electrostatic dust removal and coagulation method, which is applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve the problems of large volume of dust collector and great influence on dust removal efficiency and performance, and achieve small size, high efficiency and economy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

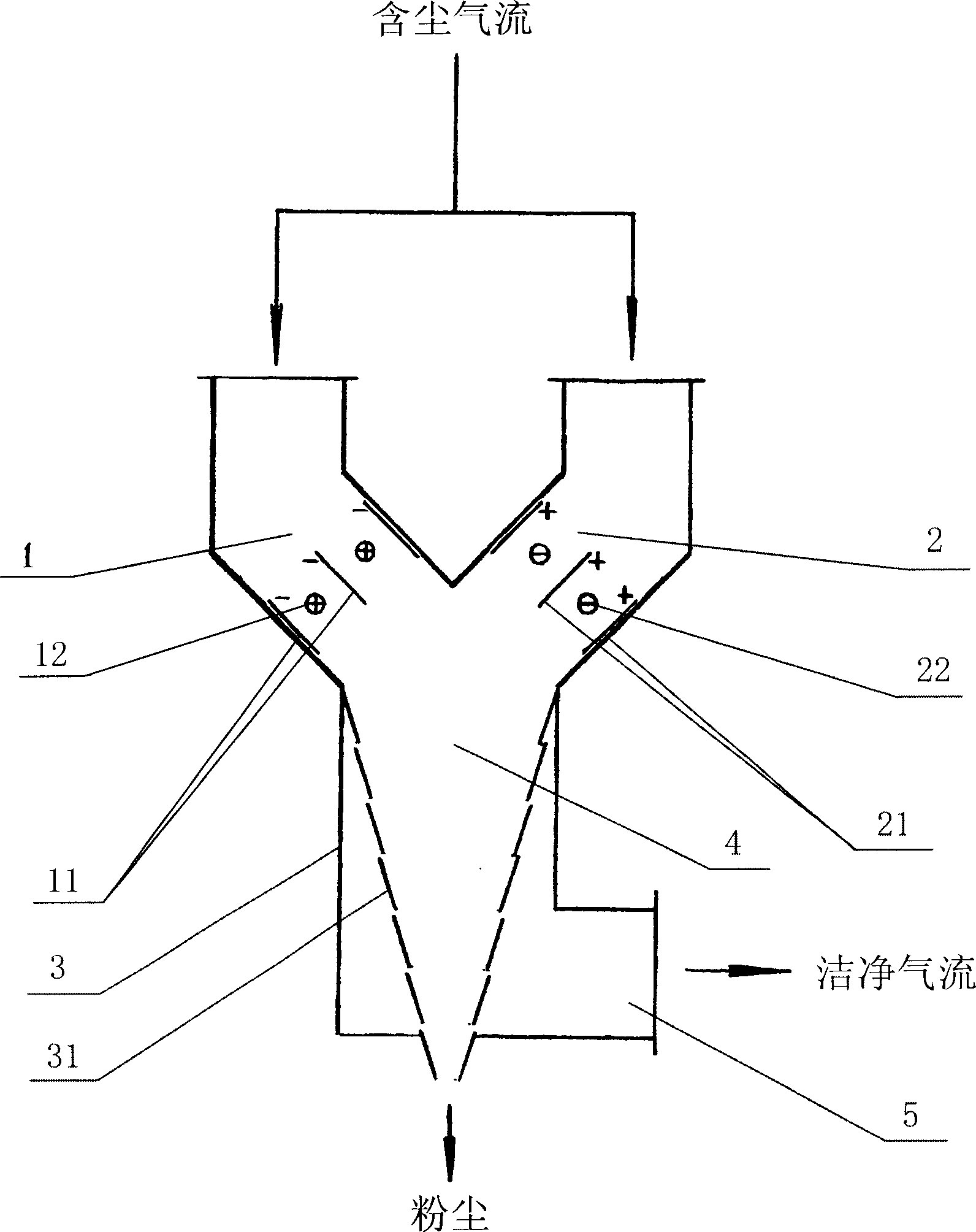

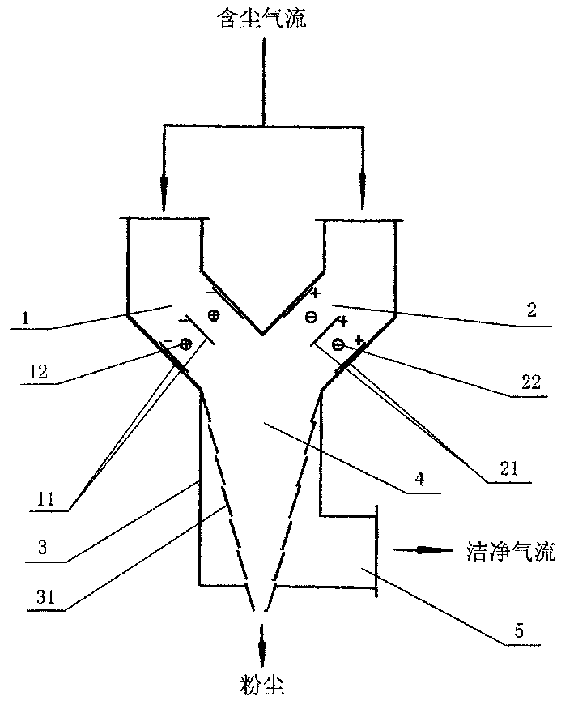

[0013] The structure of the embodiment of the cohesive electrostatic precipitator of the present invention is shown in Fig. 1 . It has a positive charge electric field channel 1, a load electric field channel 2 and a gas-solid separation channel 3, the inlet end of the gas-solid separation channel 3, the positive charge channel 1 and the outlet end of the load electric channel 2 are connected in a three-way manner, Negatively charged electrode plates 11 and positively charged corona wires 12 are provided in the positively charged electric field channel 1, and positively charged electrode plates 21 and negatively charged corona wires are provided in the load electric field channel 2. 22. The gas-solid separation channel 3 is a flue gas channel, and 5 is the exhaust port of the flue gas channel. A gas-solid separation cover 31 with a louvered grille structure is arranged in the flue gas channel as a In the inertial separation zone 4, the gas-solid separation cover is in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com