Process for treating tail gas of rare earth mineral powder and concentrated sulphuric acid roasting process

A roasting process and exhaust gas treatment technology, applied in the field of environmental engineering, to achieve the effect of reducing capacity, volume, avoiding energy consumption and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

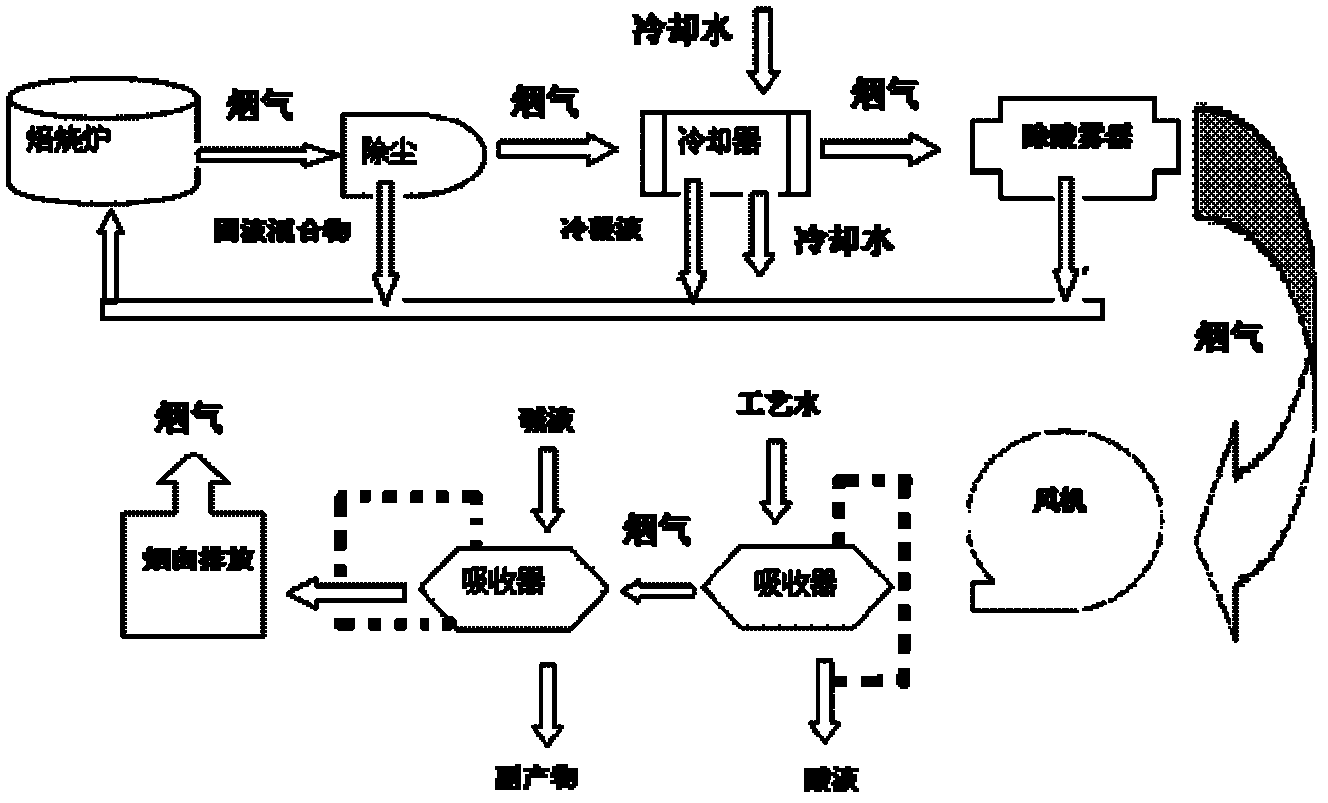

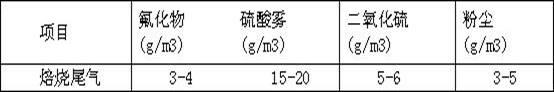

[0058] A roasting project uses concentrated sulfuric acid to roast rare earth concentrates at high temperature. During roasting, sulfuric acid decomposes and sulfuric acid reacts with rare earth minerals to produce sulfur-containing and fluorine-containing tail gas.

[0059]

[0060] 1. Comparison of water saving

[0061] The conventional three-stage spray cooling and acid recovery process cools 15,000m3 / h of flue gas from 300°C to 60-80°C, and the water consumption is about 2t / h. In this way, the water consumption is 48t / h in 24 hours a day, and the water consumption in a year ( Calculated on the basis of 8000 hours), about 16000t / h, ten roasters of the same type in the whole plant, the annual evaporation water consumption is 160000t / h.

[0062] The partition wall is used as a cooler to cool the flue gas from 300°C to 60-80°C. If the inlet temperature of the cooling water is 25°C and the outlet temperature is 30°C, about 120t / h of cooling water is required per hour, but th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com