High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

An all-in-one, adaptable technology, applied in cutting machinery, earthwork drilling, cutting machinery, etc., can solve problems such as unsynchronized operations, high labor intensity, and limited anchoring speed, so as to improve adaptability and flexibility , high degree of automation, and the effect of reducing the grounding specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

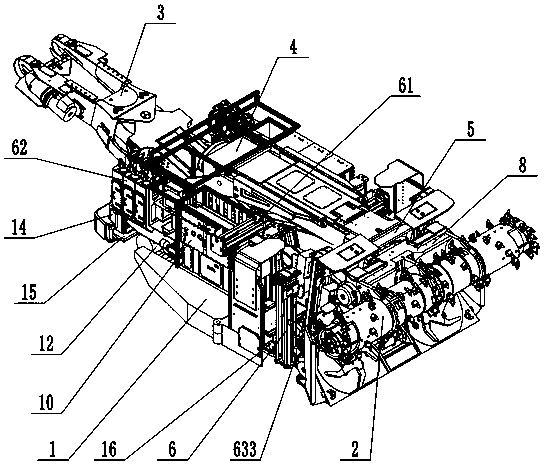

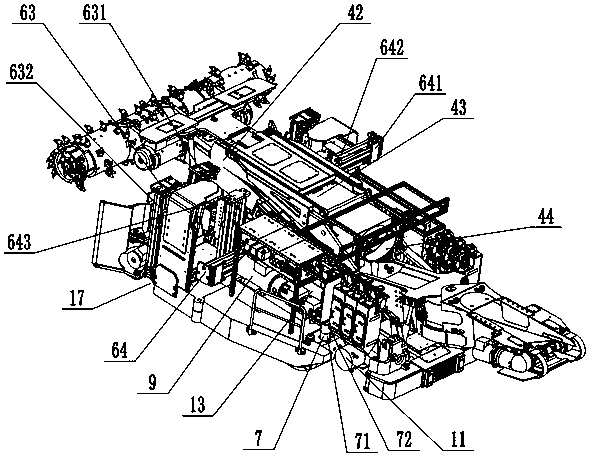

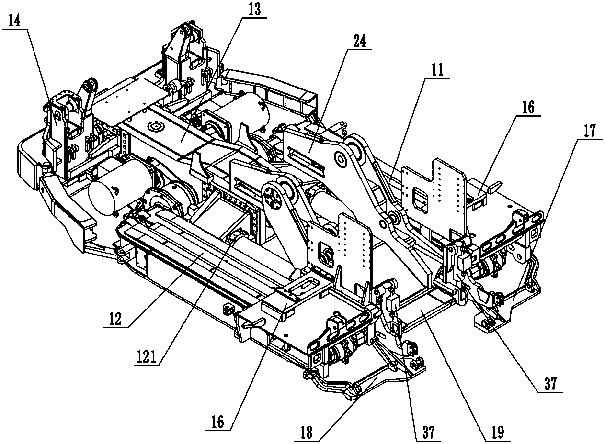

[0044] This embodiment provides a highly adaptable bolt-digging integrated machine with a dual-mode bolt-drilling system, including a frame body 1, a cutting system 2, a multi-functional temporary support system 5, an bolt-drilling system 6, and an anchor-drilling system for controlling The electro-hydraulic control system of the integrated machine; the frame body 1 includes a left running part 11, a right running part 12, a middle frame 13, a tailstock 14, a rear stable support part 15, a left front sliding shoe 17 and a right front sliding shoe 18; left The running part 11 and the right running part 12 are symmetrically fixed on both sides of the intermediate frame 13, the tailstock 14 is fixed at the rear end of the intermediate frame 13, the rear stable support part 15 is connected with the tailstock 14, the left front sliding shoe 17 and the right front sliding The shoes 18 are hinged on the front ends of the left running part 11 and the right running part 12 respectively;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com