Four-arm anchor rod transshipment unit for coal mine

A technology for bolting rigs and bolts, which is used in the installation of bolts, drill pipes, mining equipment, etc., can solve the problems of tight connection of bolts and unbalanced operation of bolts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

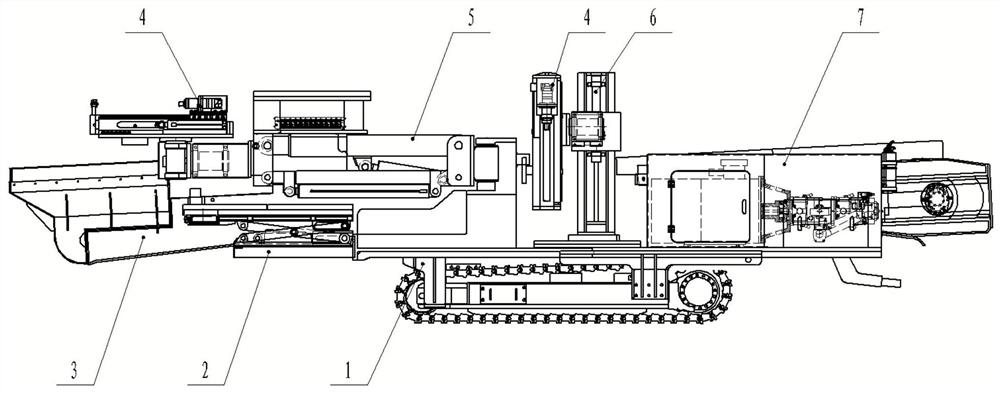

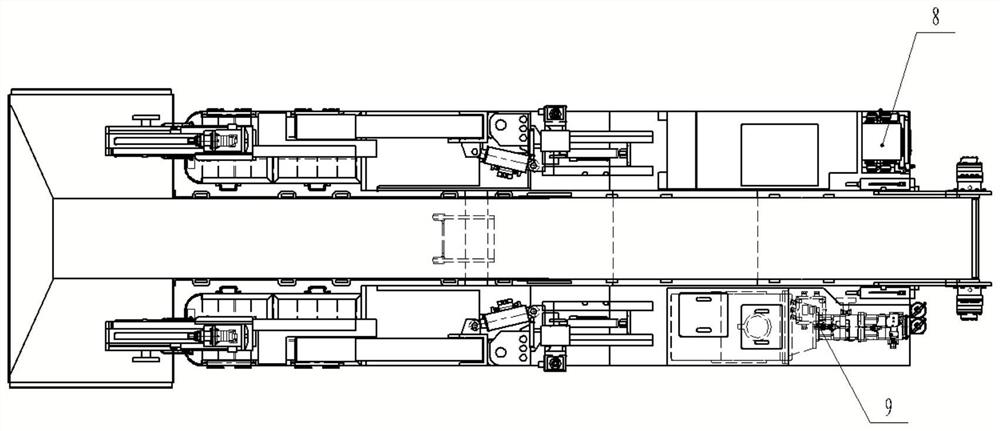

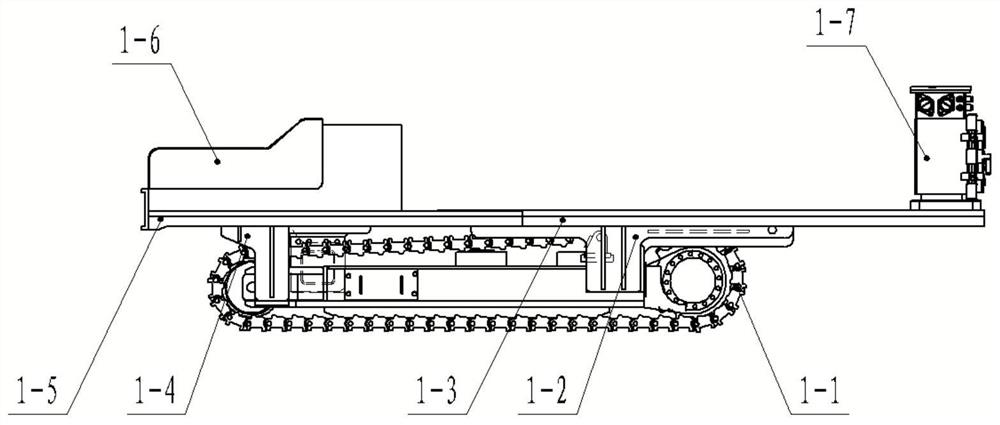

[0035] Such as figure 1 , figure 2 As shown, a four-arm rock bolt reloading unit for coal mines described in this embodiment includes a body part 1, two operating platforms 2, a conveying part 3, four airborne rock bolt rigs 4, two front drilling arms 5, Two angle-adjustable two-way sliding drill boom devices 6, guard plate part 7, electrical system 8 and hydraulic system 9; The two working platforms 2 are symmetrically arranged on both sides of the front end of the body part 1, the conveying part 3 is installed in the middle of the body part 1, and the four airborne bolters 4 are installed on the two front drilling arms 5 and two On an adjustable angle two-way sliding drill arm device 6, two front drill arms 5 are symmetrically arranged on the upper surface of the front end of the body part 1, and are located directly above the work platform 2; the two adjustable angle two-way sliding The movable drilling arm device 6 is symmetrically arranged on the upper surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com