Settling material collecting device

A collection device and collection box technology, applied in the direction of zinc oxide/hydroxide, etc., can solve the problems of heavy secondary zinc oxide that cannot be recovered in time, product quality impact, environmental pollution, etc., to facilitate repeated processing and utilization, improve Resource utilization, effects of avoiding proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

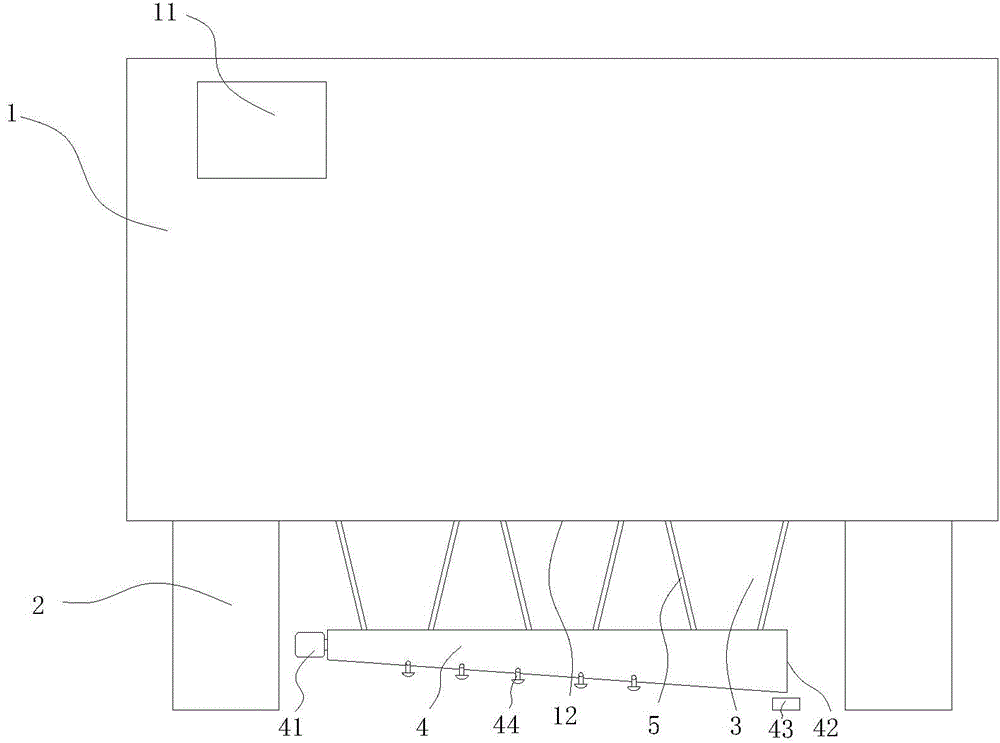

[0012] The present invention as figure 1 As shown, it includes a collection box 1, the collection box 1 is arranged on the column 2, the top of the collection box 1 is provided with a feed port 11, and the bottom is provided with a number of discharge ports 12; it also includes a collection device , the collection device is located below the discharge port 12, the collection device includes several collection hoppers 3, delivery pipe 4, hot air blower 41, collection box 43 and some vibrating hammers 44, the collection hopper 3 corresponds to the discharge port 12 of the collection box one by one, and is evenly distributed to avoid jamming. The upper part of the collection hopper 3 is connected to the discharge port 12, and the lower part is connected to the delivery pipe 4;

[0013] The conveying pipe 4 is inclined, the lower end of the conveying pipe 4 is provided with an outlet 42, the hot air blower 41 is arranged at the upper end of the conveying pipe 4, and the receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com