Spraying device for atomizing and oppositely spraying fine powder and tissue fluid

A technology of spraying device and interstitial fluid, which is applied in the direction of feeding device, chemical instrument and method, chemical/physical process, etc., which can solve the problems of waste of material, feeding cone does not have the function of collecting material, tailing backflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

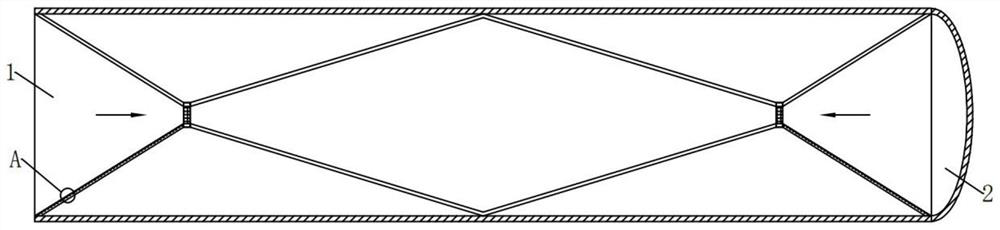

[0037] see Figure 1-4 , in the embodiment of the present invention, a spray device for atomizing and spraying fine powder and tissue fluid, including a feeding cone 1, a feeding cone 2 and an aggregate assembly 3, a feeding cone 1 and a feeding The inner positions of the inner wall of the second cone pipe 2 are all arranged in equal adjacent rows and are embedded with a number of aggregate assemblies 3 that can collect tailings;

[0038] Each set of aggregate assemblies 3 further includes an aggregate shell 301, a guide assembly 302 that can guide the tails into collection, and a pre-collection assembly 303 that can pre-collect the tails;

[0039] Each collecting shell 301 is surrounded and embedded in the inner wall of the feeding cone 1 and the feeding cone 2 in an equal adjacent row;

[0040] A material guide assembly 302 is movably installed at the top position of each collecting shell 301;

[0041] A number of pre-collection assemblies 303 are installed at the right end ...

Embodiment 2

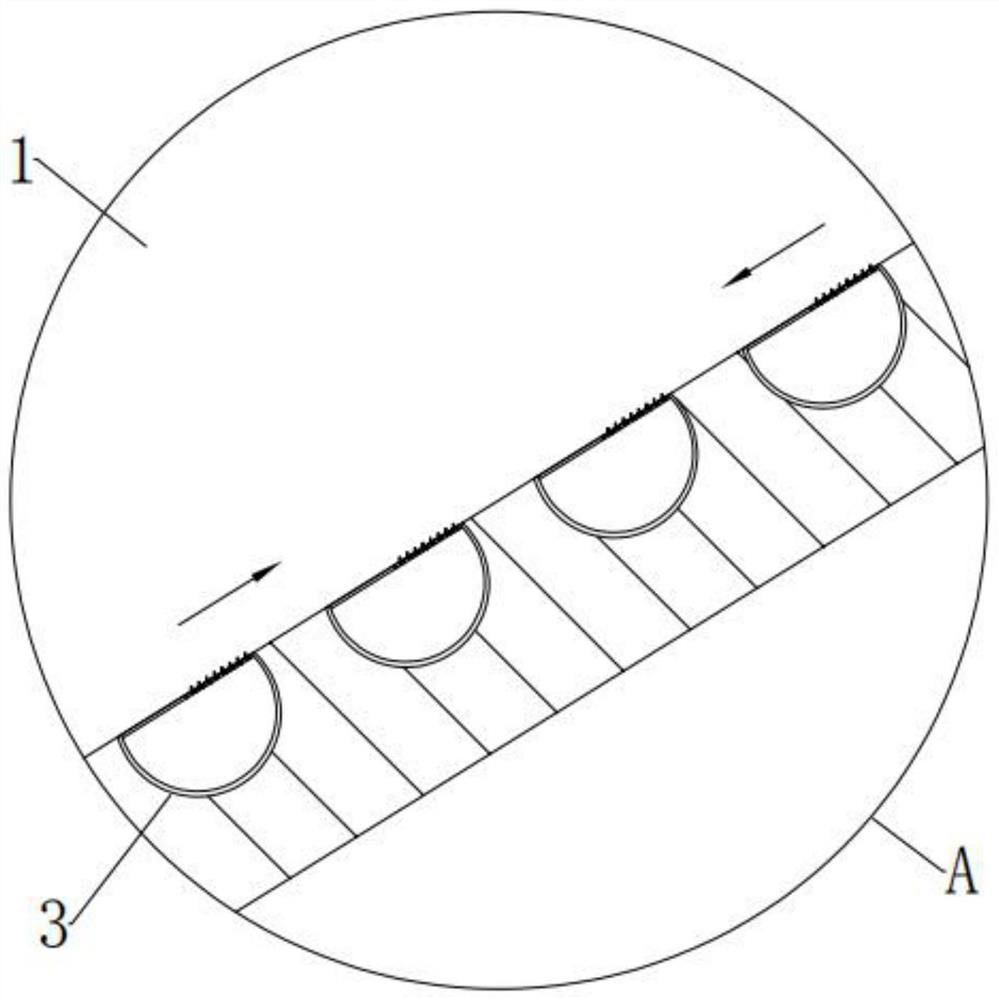

[0046] see Figure 4 The difference between the embodiment of the present invention and the embodiment 1 is that each group of material guide assemblies 302 includes a rotating shaft 302a and a guide plate 302b.

[0047] In the embodiment of the present invention, a rotating shaft 302a is rotatably installed in the middle position of the inner top end of each collecting shell 301 in a front-rear horizontal direction.

[0048] In the embodiment of the present invention, a guide plate 302b is fixed around the outer surface of each rotating shaft 302a, and each guide plate 302b in the feeding cone 1 and the feeding cone 2 is the same as the feeding cone under normal conditions. The inner walls of the first 1 and the feeding cone 2 are on the same plane, and the left and right outer surfaces of each guide plate 302b are tightly magnetically attracted to the top surfaces of the left and right inner walls of each collecting shell 301 under normal conditions. The length of each guid...

Embodiment 3

[0052] see Figure 4-5 The difference between the embodiment of the present invention and the embodiment 1 is that each group of pre-collection components 303 includes a magnetic plate 303a, a rotating rod 303b, an outer plate 303c and an inner plate 303d.

[0053] In the embodiment of the present invention, the position of the right end of each guide plate 302b is equidistantly arranged in a horizontal direction with a plurality of through grooves penetrating up and down, straight left and right arc;

[0054] The through groove that runs through up and down, straight left and right arc here is to facilitate the accumulation of tailings in this through groove and finally fall down into the collecting shell 301 for collection;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com