Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

A technology for automobile wheel hubs and decorative parts, which is applied to spray devices, liquid spraying equipment, and devices for coating liquid on surfaces, etc., can solve the problems of high spray pressure, low production efficiency, low efficiency, etc., and achieve uniform powder distribution, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

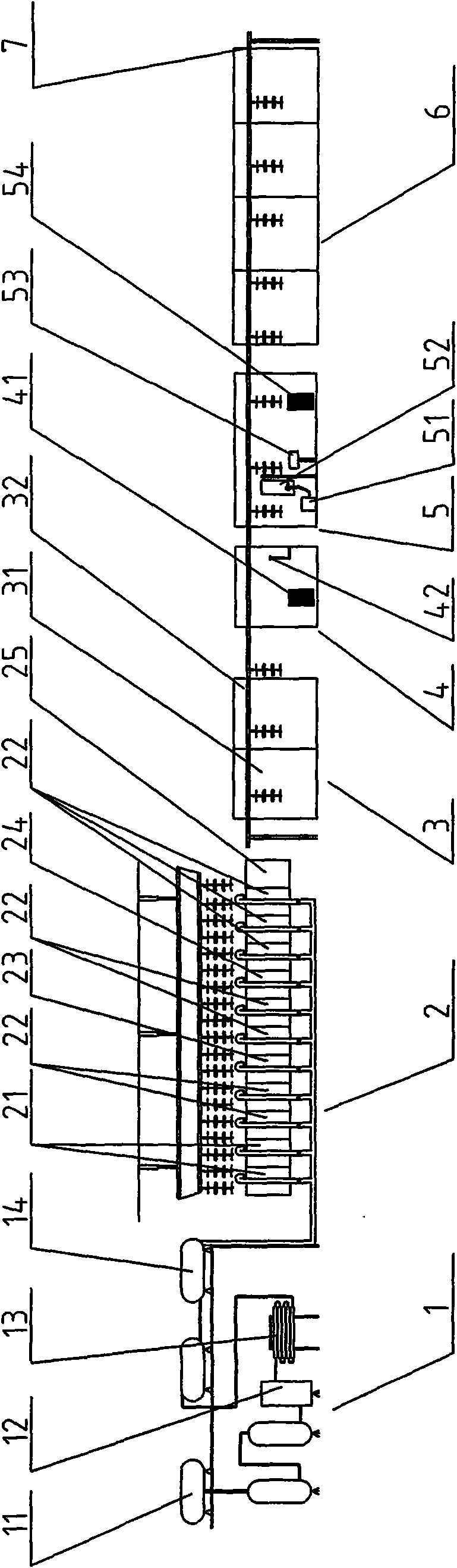

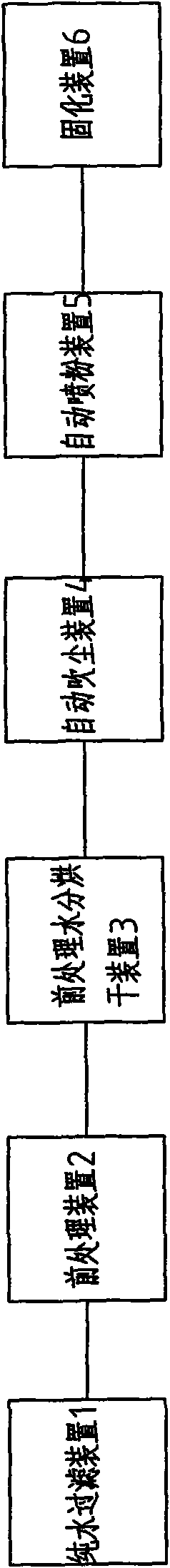

[0033] like figure 1 , 2 As shown, an automatic powder spraying line for automobile wheel hub decorations, including a pure water filter device 1 for providing pure water for the powder spray line, a pretreatment device 2, a pretreatment moisture drying device 3, an automatic dust blowing device 4, Automatic powder spraying device 5, curing device 6, conveying guide rail 7. The pure water filter device 1 includes a tap water tank 11 , a water pump device 12 , a filter device 13 , and a pure water tank 14 in sequence. The tap water tank 11 can store a certain amount of tap water, and the stored tap water is transferred to the filter device 13 through the water pump device 12, and the tap water becomes pure water with an electrical conductivity less than 10 after sand filtration and carbon filtration, and is stored in the pure water tank 14 , this part of pure water will be transported to each washing tank in the pretreatment device 2 through pipelines.

[0034] The pretreatm...

Embodiment 2

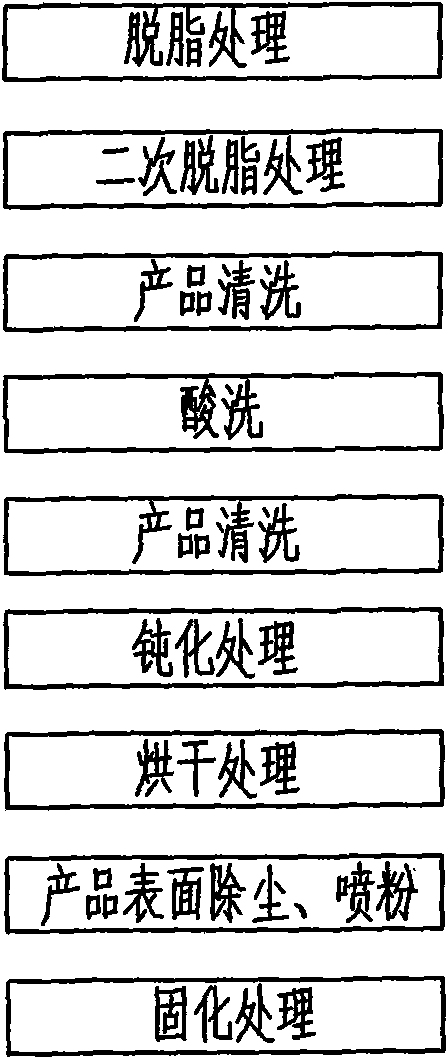

[0040] like image 3 As shown, an automatic powder spraying process for automobile wheel hub decorations, this powder spraying process is mainly suitable for metal automobile wheel hub decorations, especially aluminum or aluminum alloy decorations, and its process steps are as follows:

[0041] (1) Degreasing the product, soaking the product in an alkaline solution with a temperature between 55° and 60° and a pH value between 10 and 12 for 55 to 60 seconds;

[0042] (2) Carry out secondary degreasing treatment on the product, soak the product in an alkaline solution with a temperature between 55°-60° and a pH value between 10-12 for 55-60 seconds;

[0043] (3) Clean the product, and soak the product in a neutral solution with a pH value between 10 and 12 for 55 to 65 seconds at room temperature; this process is repeated three times to initially remove the residual alkaline solution on the product;

[0044] (4) Carry out acidic neutralization treatment to the product. At room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com