Soil remediation method

A soil remediation and soil technology, applied in the field of soil remediation, can solve problems such as low efficiency, achieve the effects of low cost, simple and easy remediation process, and solve the problem of soil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

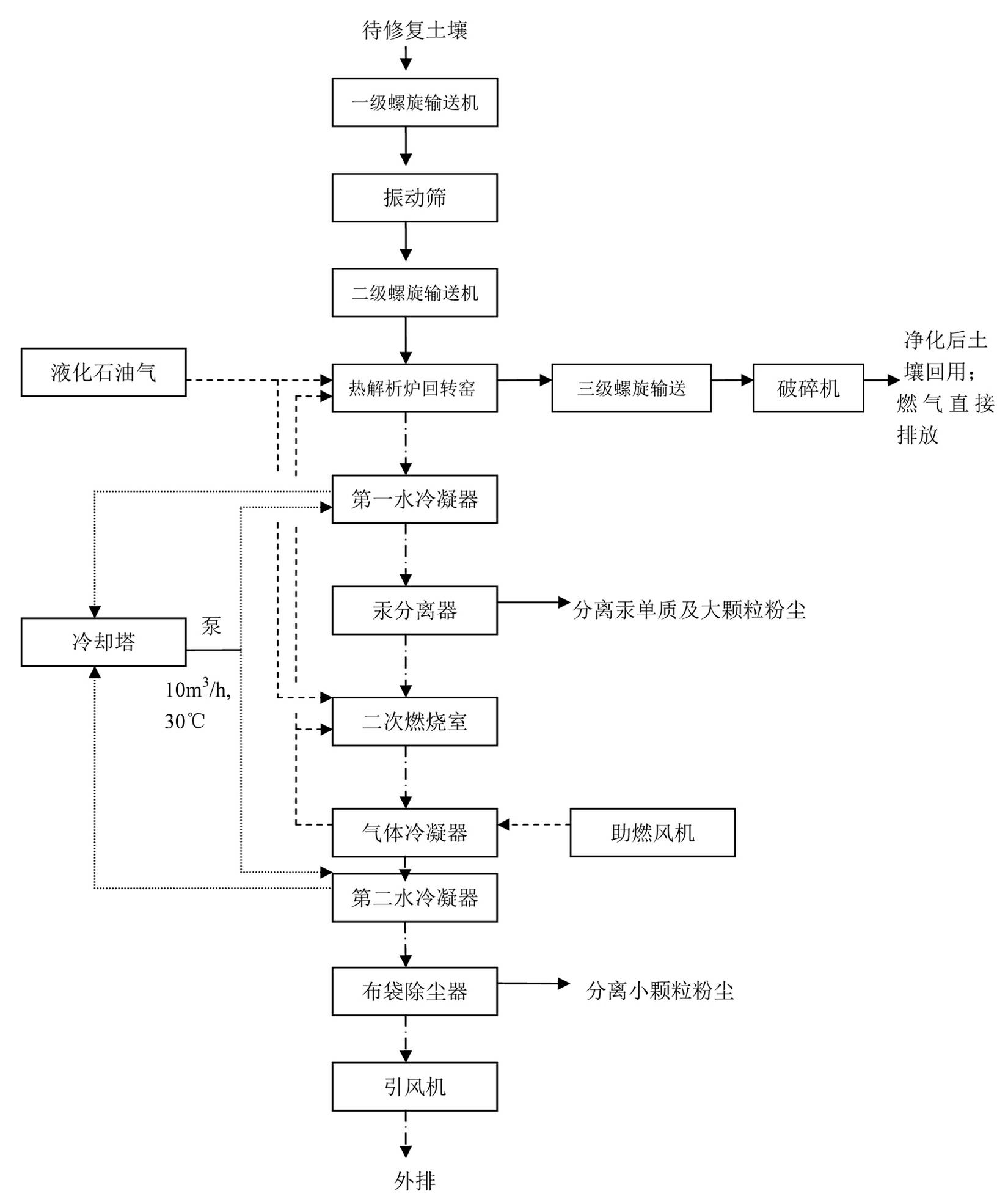

[0029] Such as figure 1 Shown, a kind of soil remediation method, comprises the following steps:

[0030] 1) The primary screw conveyor transports the soil to be repaired (humidity <25%) to the vibrating screen for screening, and the secondary screw conveyor transports the screened soil (particle size <14mm) to the rotary kiln of the thermal desorption furnace (Yixing Hua Produced by Rui Incinerator Technology Development Co., Ltd., model: HR-X), the temperature of the material in the rotary kiln of the thermal desorption furnace is kept in the range of 450°C -800°C, and the pressure in the rotary kiln of the thermal desorption furnace is -50Pa to -60Pa ;

[0031] 2) The three-stage screw conveyor transports the thermally decomposed soil to the crusher for crushing at a conveying speed of 100kg / h, and the crushed soil can be used as commercial land soil;

[0032] 3) The exhaust gas from the rotary kiln of thermal desorption furnace is 620m 3 The flow rate of / h passes throu...

Embodiment 2

[0038] Such as figure 1 Shown, a kind of soil remediation method, comprises the following steps:

[0039] 1) The primary screw conveyor transports the soil to be repaired (humidity <25%) to the vibrating screen for screening, and the secondary screw conveyor transports the screened soil (particle size <14mm) to the rotary kiln of the thermal desorption furnace (Yixing Hua Produced by Rui Incinerator Technology Development Co., Ltd., model: HR-X), the temperature of the material in the rotary kiln of the thermal desorption furnace is kept in the range of 450°C to 800°C, and the pressure in the rotary kiln of the thermal desorption furnace is -80Pa to -100Pa ;

[0040] 2) The three-stage screw conveyor transports the roasted soil to the crusher for crushing at a conveying speed of 80kg / h, and the crushed soil can be used as commercial land soil;

[0041] 3) The waste gas from the rotary kiln of thermal desorption furnace is 640m 3 The flow rate of / h passes through the first ...

Embodiment 3

[0046] Such as figure 1 Shown, a kind of soil remediation method, comprises the following steps:

[0047] 1) The primary screw conveyor transports the soil to be repaired (humidity <25%) to the vibrating screen for screening, and the secondary screw conveyor transports the screened soil (particle size <14mm) to the rotary kiln of the thermal desorption furnace (Yixing Hua Produced by Rui Incinerator Technology Development Co., Ltd., model: HR-X), the temperature of the material in the rotary kiln of the thermal desorption furnace is kept in the range of 450 ° C -800 ° C, and the pressure in the rotary kiln of the thermal desorption furnace is -50Pa to -60Pa ;

[0048] 2) The three-stage screw conveyor transports the roasted soil to the crusher for crushing at a conveying speed of 120kg / h, and the crushed soil can be used as commercial land soil;

[0049] 3) The waste gas from the rotary kiln is 660m 3 The flow rate of / h passes through the first water condenser to cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com