MgO optimal distribution method for iron-containing furnace charge of blast furnace

A technology for optimizing distribution and blast furnaces, applied in blast furnaces, blast furnace details, steel manufacturing processes, etc., can solve problems such as poor ironmaking comprehensive indicators and large differences in smelting performance, and achieve the goal of improving smelting performance, improving smelting performance, and increasing strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

[0023] The present invention increases the MgO content of the pellets and reduces the MgO content of the sintered ore, optimally distributes the MgO required for blast furnace smelting to the sintered ore and the pelletized ore, reduces the metallurgical performance difference between the two, and improves the metallurgical performance of the comprehensive charge .

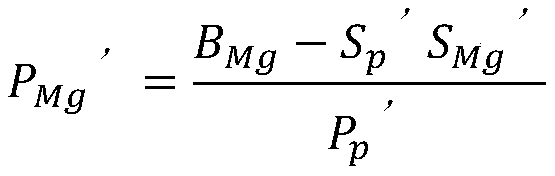

[0024] Calculation steps of MgO optimal distribution method of the present invention

[0025] S1: Determine the optimized sinter MgO content S Mg ’ and binary alkalinity S b Restrictions

[0026] At present, the MgO content of the sintered ore is basically above 2.0%, and the sintered ore has low strength and high energy consumption. A large number of studies have shown that high MgO content in sinter will hinder the formation of calcium ferrite binder phase and reduce the strength of sinter. The conclusion of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com