Method for improving quality of sintered ore

A technology for sintering and quality, applied in the field of sintering, can solve the problems of unfavorable sintering and blast furnace production, low utilization coefficient of sintering machine, poor sieving index, etc., so as to improve sintering production efficiency, facilitate strengthening and coke ratio, and improve grade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In the embodiment of the present invention, based on the production at that time, the slag basicity and charge structure of the sinter after adjustment are measured and calculated respectively.

[0016] Data analysis and use effect:

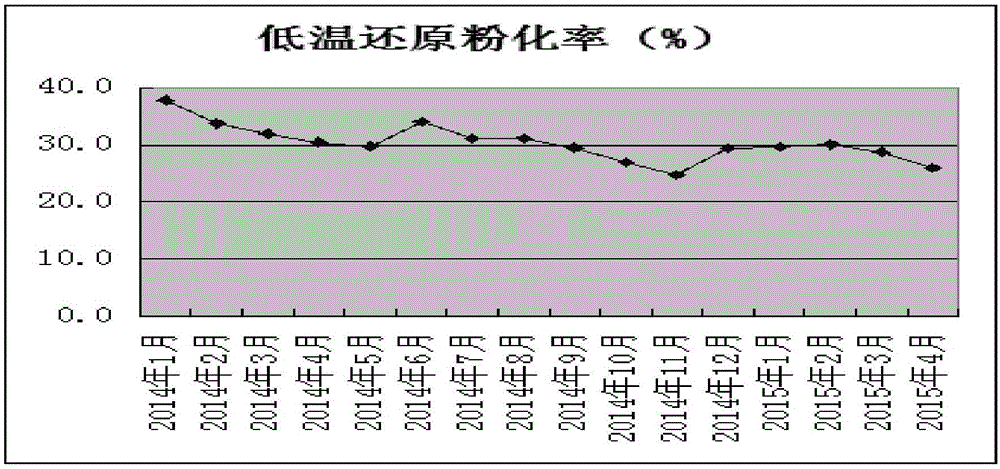

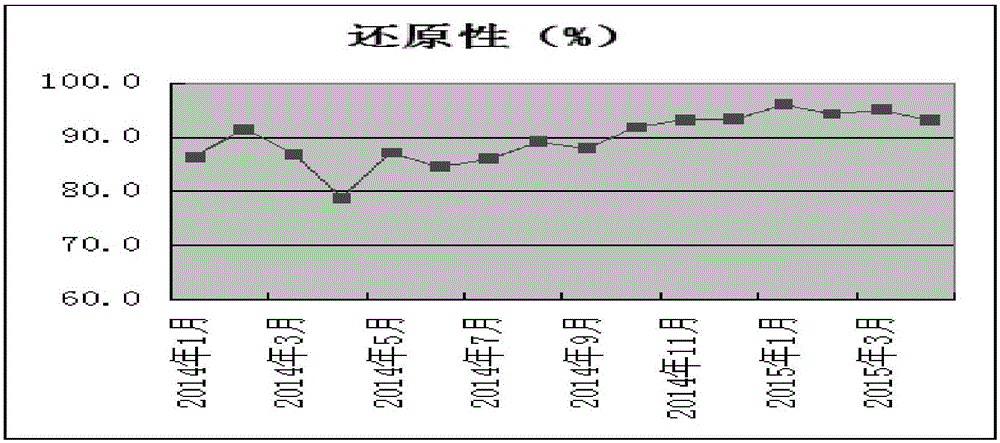

[0017] 1. Low magnesium sintering, data monitoring

[0018] Taking the 3# blast furnace as an example, carry out industrial experiments and gradually spread to other blast furnaces. Use the sintering cup laboratory to track, record, and analyze the changes in sinter performance indicators (low-temperature reduction pulverization rate, reducibility, and droplet performance). The comparison of sinter composition and performance indicators is shown in Table 1. Figure 1-Figure 3 shown. Table 1 is the change table of conventional analysis indicators of sinter. The content of MgO in sinter decreased from 2.3-2.43% to 1.75-2.05%, with an average of about 1.9%. The production capacity of sinter increased, the grade increased slightly, the stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com