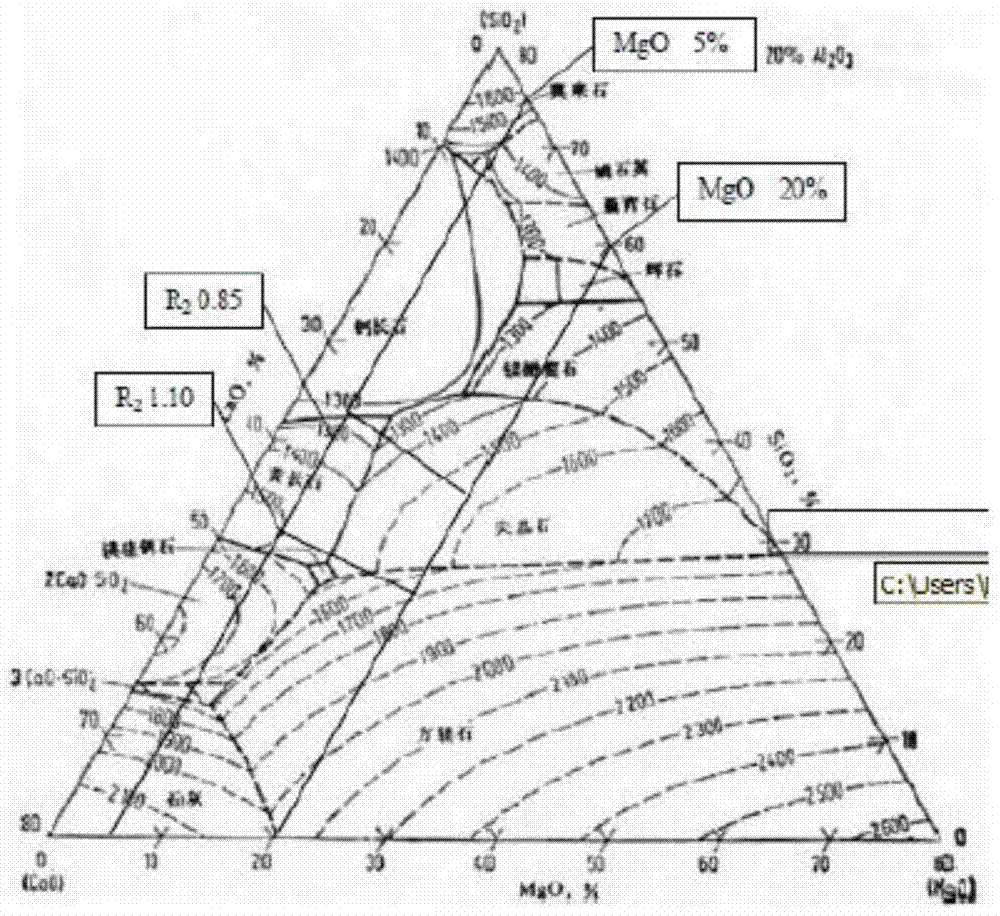

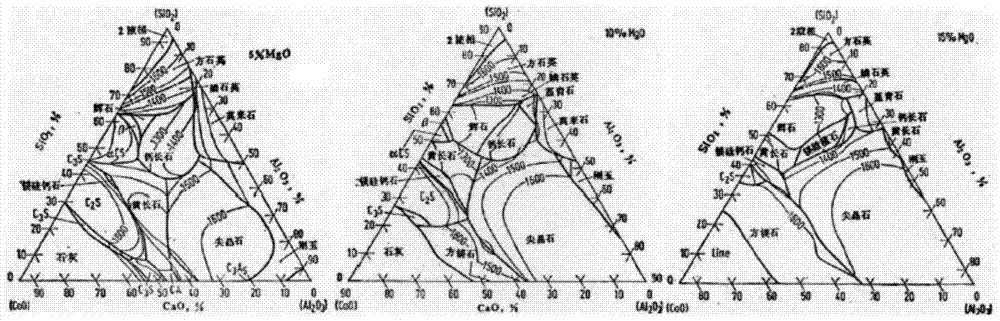

Method for Smelting Laterite Nickel Ore in Blast Furnace for Reducing Magnesium Oxide Content in Slag

A lateritic nickel ore and blast furnace smelting technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as metal loss, unstable furnace conditions, and high production costs, and achieve lower melting point, lower magnesium oxide content, and good slag removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Under the idea described in the specific implementation mode, the applicant gradually improved the production blast furnace smelting process, starting from the raw material process and performing special treatment on low-grade raw ore. During the raw ore screening process, the raw ore with a particle size greater than 25mm and which cannot be further broken is called lump ore. In view of the high content of MgO in the chemical composition of the lump ore and the wide range of particle size fluctuations, in the actual screening process, sieves with apertures of 150mm, 50mm and 25mm were selected to screen out the lump ore. The sieved lumps of different sizes are subjected to coarse crushing, medium crushing, and fine crushing to obtain crushed powder and lumps with a particle size larger than 25mm for sintering, and all laterite nickel ores with a particle size smaller than 25mm are sent to the sintering process. When sintering ingredients, the applicant gave up using li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com